Dry oil deodorizing process and equipment

A deodorization and oil technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of affecting oil quality, unfavorable for oil storage and packaging, etc., to achieve the effect of small space occupation, simple and convenient equipment assembly, and increased output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

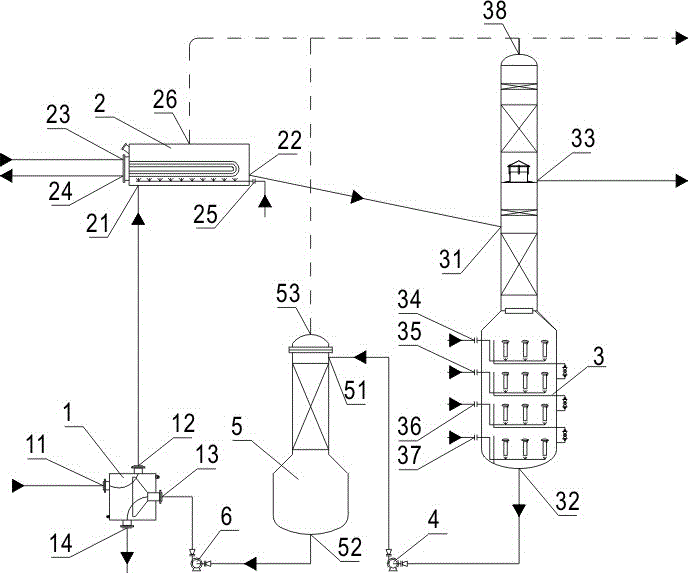

[0015] Such as figure 1 As shown, the oil to be deodorized enters the low-temperature oil inlet of the spiral plate heat exchanger 1 and conducts oil-oil heat exchange with the deodorized oil to heat up to 170°C, and then enters the low-temperature oil outlet of the spiral plate heat exchanger 1 and enters the vacuum heater 2 shell side through high temperature The heat source is heated to the deodorization temperature of 235°C; under the action of gravity, the oil flows into the packing combination deodorization tower 3 by itself for 45 minutes to complete the stripping and deodorization; the deodorized oil is pumped into the dry steam tower 5 through the deodorized oil pump 4 for dry steaming to further remove low-carbon After chaining small molecules, the pump 6 is pumped into the high-temperature oil inlet of the spiral plate heat exchanger 1 through the dry steam tower to exchange heat with the oil to be deodorized for 10 minutes to cool it down to 140°C, and then flow...

Embodiment 2

[0022] Such as figure 1 As shown, the oil to be deodorized enters the low-temperature oil inlet of the spiral plate heat exchanger 1 and conducts oil-oil heat exchange with the deodorized oil to heat up to 185°C, and then enters the low-temperature oil outlet of the spiral plate heat exchanger 1 and enters the vacuum heater 2 shell side through high temperature The heat source is heated to the deodorization temperature of 250°C; under the action of gravity, the oil flows into the packing combination deodorization tower 3 by itself for 70 minutes to complete the stripping and deodorization; the deodorized oil is pumped into the dry steam tower 5 through the deodorized oil pump 4 for dry steaming to further remove low-carbon After chaining small molecules, the pump 6 is pumped into the high-temperature oil inlet of the spiral plate heat exchanger 1 through the dry steam tower to exchange heat with the oil to be deodorized for 13 minutes to cool it down to 160°C, and the high-t...

Embodiment 3

[0029] Such as figure 1 As shown, the oil to be deodorized enters the low-temperature oil inlet of the spiral plate heat exchanger 1 and conducts oil-oil heat exchange with the deodorized oil to heat up to 200°C, and then enters the low-temperature oil outlet of the spiral plate heat exchanger 1 and enters the vacuum heater 2 shell side through high temperature Heat the heat source to the deodorization temperature of 260°C; under the action of gravity, the oil flows into the packing combination deodorization tower 3 for 90 minutes to complete the stripping and deodorization; the deodorized oil is pumped into the dry steam tower 5 through the deodorized oil extraction pump 4 for dry steaming to further remove low-carbon After chaining small molecules, the pump 6 is pumped into the high-temperature oil inlet of the spiral plate heat exchanger 1 through the dry steam tower to exchange heat with the oil to be deodorized for 15 minutes to cool it down to 180°C, and the high-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com