Method for strengthening iron removal by oxygen oxidation in solution by using microbubble generating device

A microbubble generating device and oxygen oxidation technology are applied in the direction of improving process efficiency, etc., which can solve the problems of high equipment cost and operating cost, slow oxidation rate of ferrous ions, long time for oxidation and iron removal, etc., and achieve simple structure and shortened time. Running time, effect of shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

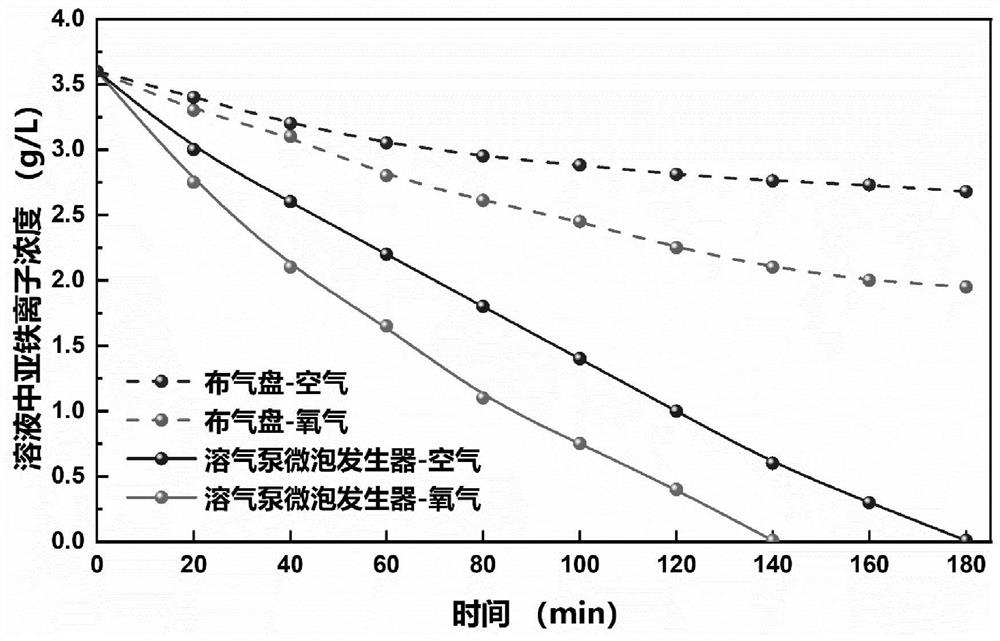

[0029]The method for strengthening oxygen oxidation and iron removal by applying a microbubble generating device of the present invention is applied to the filtrate after the compounding of rhodochrosite from Geely Baikuang Manganese Industry, using a micro-nano bubble generating device based on the action of a dissolved air pump to oxidize and remove iron, and the volume of the treatment solution is 20L, The iron content in the solution is 3.6g / L, the solution temperature is 50℃, the mechanical stirring is 100rpm, and the amount of bubbles generated is 0.7-1m 3 / h, using ammonia (NH 3 mass fraction 15%) is the neutralizer to adjust the endpoint pH of the solution to 6-6.5. Air and pure oxygen were used as oxidants for oxidative iron removal, and a gas distribution plate with a diameter of 30 cm was used for comparative experiments. The concentration of ferrous ions in the solution was analyzed in real time by chemical titration. The results of the change of ferrous ion concen...

Embodiment 2

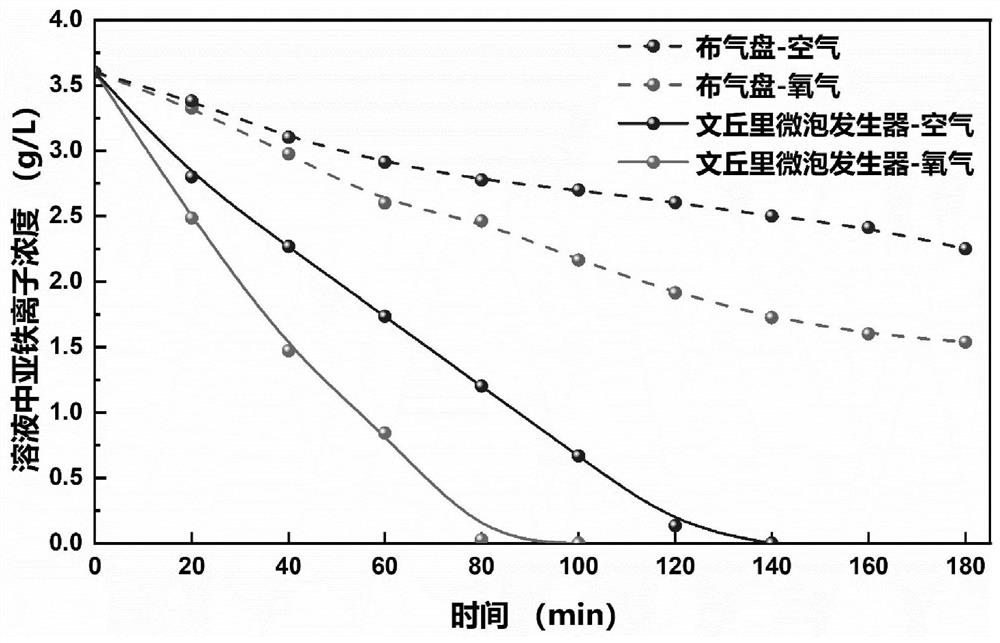

[0031] The method for strengthening oxygen oxidation and iron removal by applying a microbubble generating device of the present invention is applied to the rhodochrosite compound suspension of Geely Baikuang Manganese Industry. The bubble generating device oxidizes and removes iron, the volume of the treated suspension is 20L, the iron content in the solution is 3.6g / L, the solution temperature is 50℃, the mechanical stirring is 100rpm, and the amount of bubbles generated is about 3-4m 3 / h, using ammonia (NH 3 15 wt. %) as a neutralizer to adjust the pH of the end point of the solution to 6-6.5. Air and pure oxygen were used as oxidants for oxidative iron removal, and a gas distribution plate with a diameter of 30 cm was used for comparative experiments. The concentration of ferrous ions in the solution was analyzed in real time by chemical titration. The results of the change of ferrous ion concentration with time are as follows: figure 2 shown.

Embodiment 3

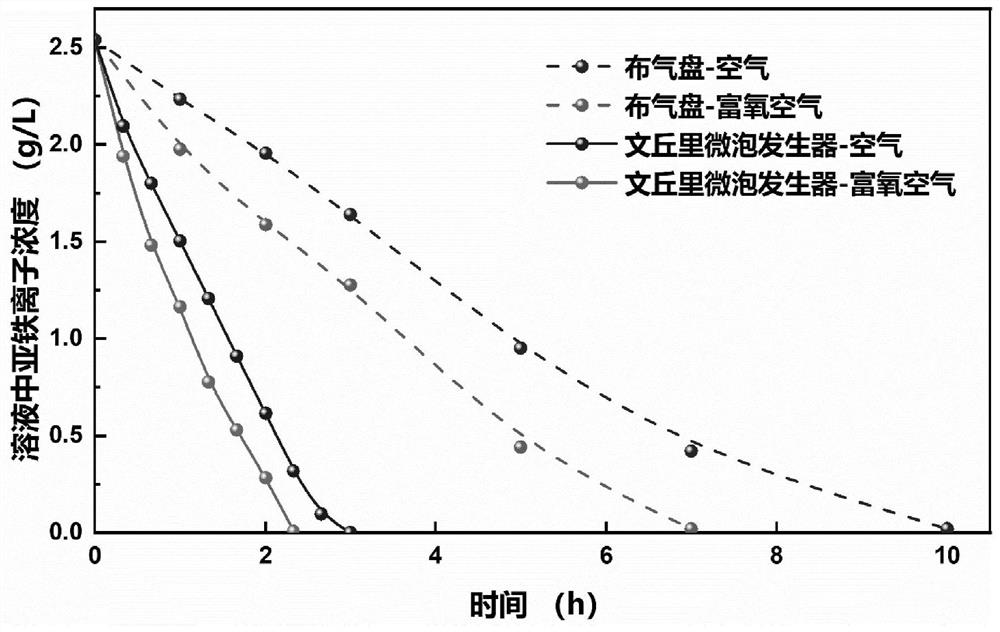

[0033] The method for strengthening oxygen oxidation and iron removal by applying a microbubble generating device of the present invention is applied to the process of wet smelting zinc oxidation and iron removal in Chihong Zinc and Germanium Huize Smelting Branch. The concentration of ferrous ions in the pre-iron solution was 2.54g / L, and the goethite method consistent with the industry was used to remove iron. The volume of the test solution is 20L, the temperature of the solution is 80-85°C, and the slurry calcium hydroxide is used as a neutralizing agent to adjust the pH of the solution to 4.5-5.2. Air and oxygen-enriched air (O 2 50vol%) for iron removal by oxidation, and the amount of bubbles generated is about 1m 3 / h, in addition, compared with the air distribution pipe aeration used in the field, the ferrous ion concentration in the solution was analyzed in real time by chemical titration, and the change of ferrous ion concentration with time was as follows: image ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com