Device and method for reducing temperature of poor-absorption liquid feed material of Ethylene Oxide absorption tower

A technology of ethylene oxide and feed temperature, applied in the direction of organic chemistry, etc., to achieve the effect of low operating cost, reduction of steam volume, and steam saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

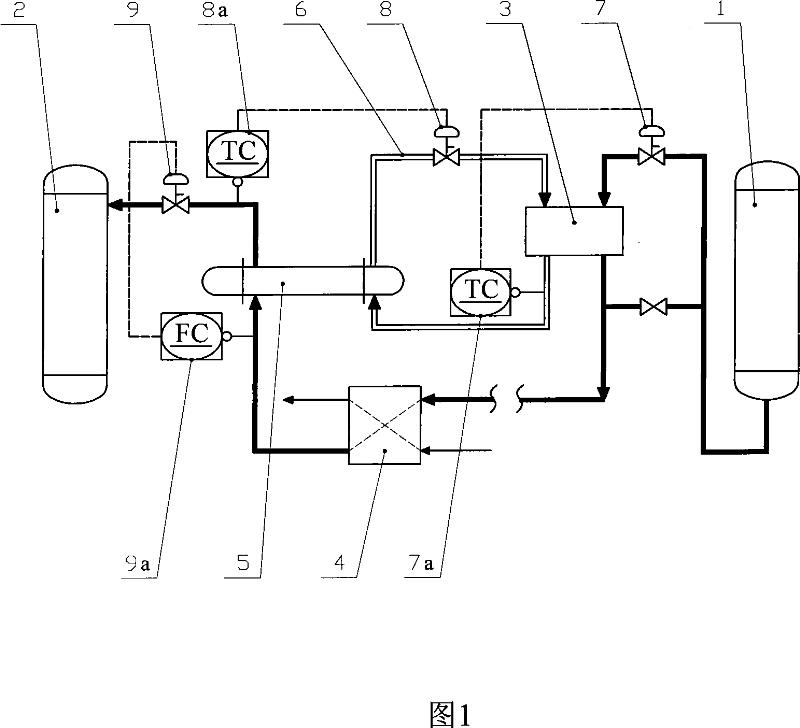

[0022] Figure 1 shows an embodiment of the present invention, including an ethylene oxide desorption tower 1, an ethylene oxide absorption tower 2, a refrigerator 3, a lean absorption liquid cooler 4, a lean absorption liquid aftercooler 5 and a low-temperature water circuit 6. Among them, the refrigerator 3, the lean absorption liquid cooler 4 and the lean absorption liquid aftercooler 5 are arranged in sequence between the ethylene oxide desorption tower 1 and the ethylene oxide absorption tower 2; the refrigerator 3 and the lean absorption liquid aftercooler 5 is located on the low-temperature water circuit 6, and the low-temperature water is produced by the refrigerator 3 by using the waste heat of the lean absorption liquid from the bottom of the ethylene oxide desorption tower 1 as the heat source.

[0023] In order to obtain a better cooling effect and make better use of the waste heat of the lean absorption liquid, the refrigerator 3 adopts a lithium bromide absorption ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com