Device and process method for extracting plant aromatic oil

A plant aromatic oil and oil outlet technology, which is applied in the field of devices for extracting plant aromatic oil, can solve the problems of high energy consumption, large amount of cooling water, low oil yield, etc. The effect of reducing the amount of steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

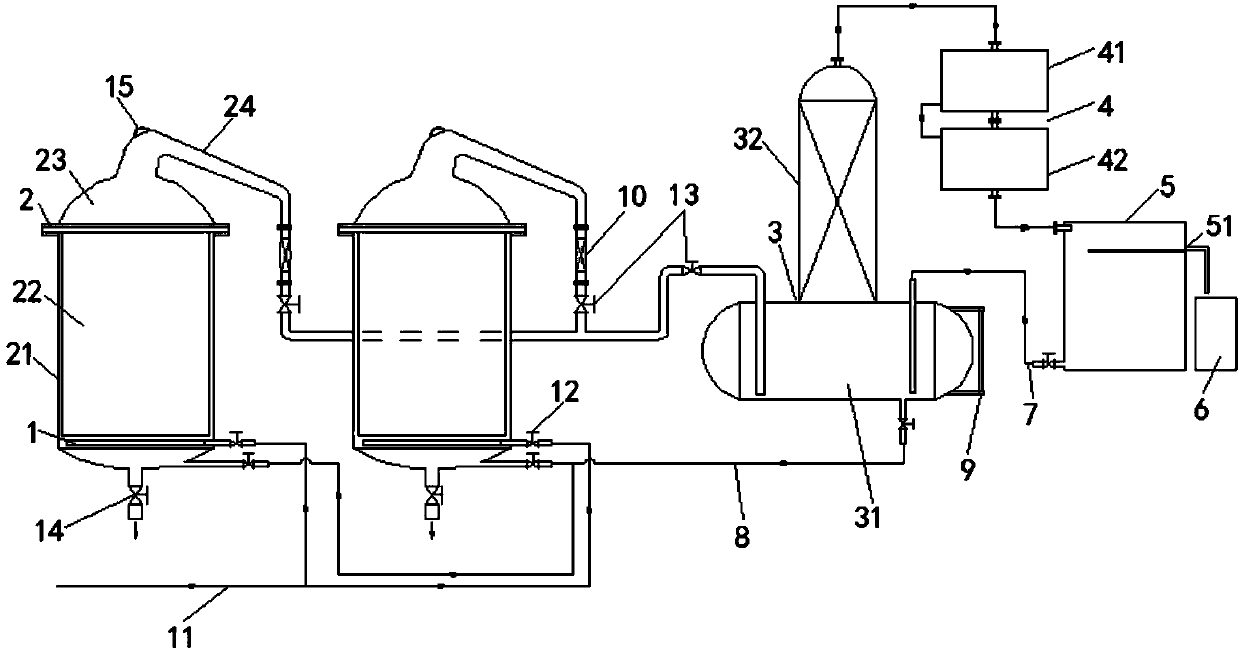

[0048] Embodiment 1: distilled melaleuca oil

[0049] Include the following steps:

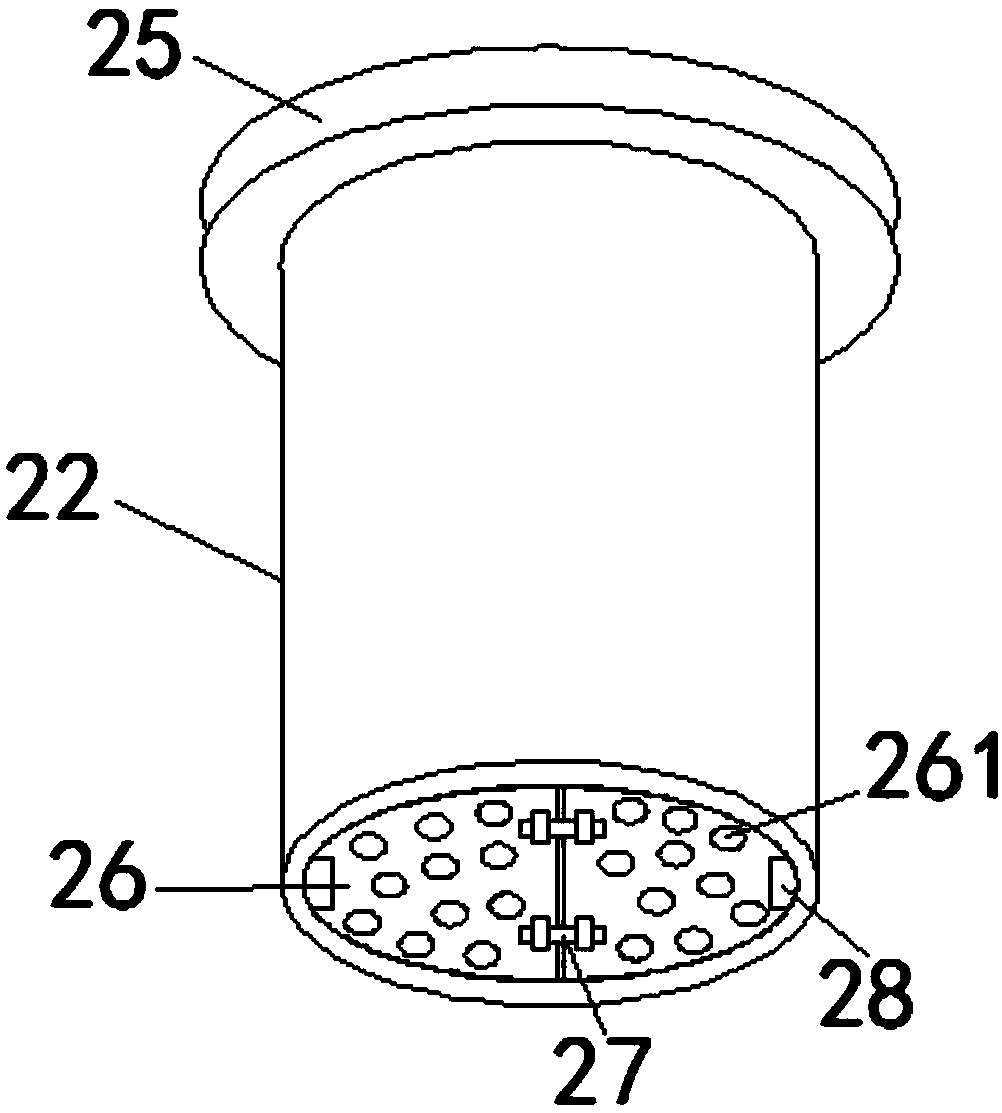

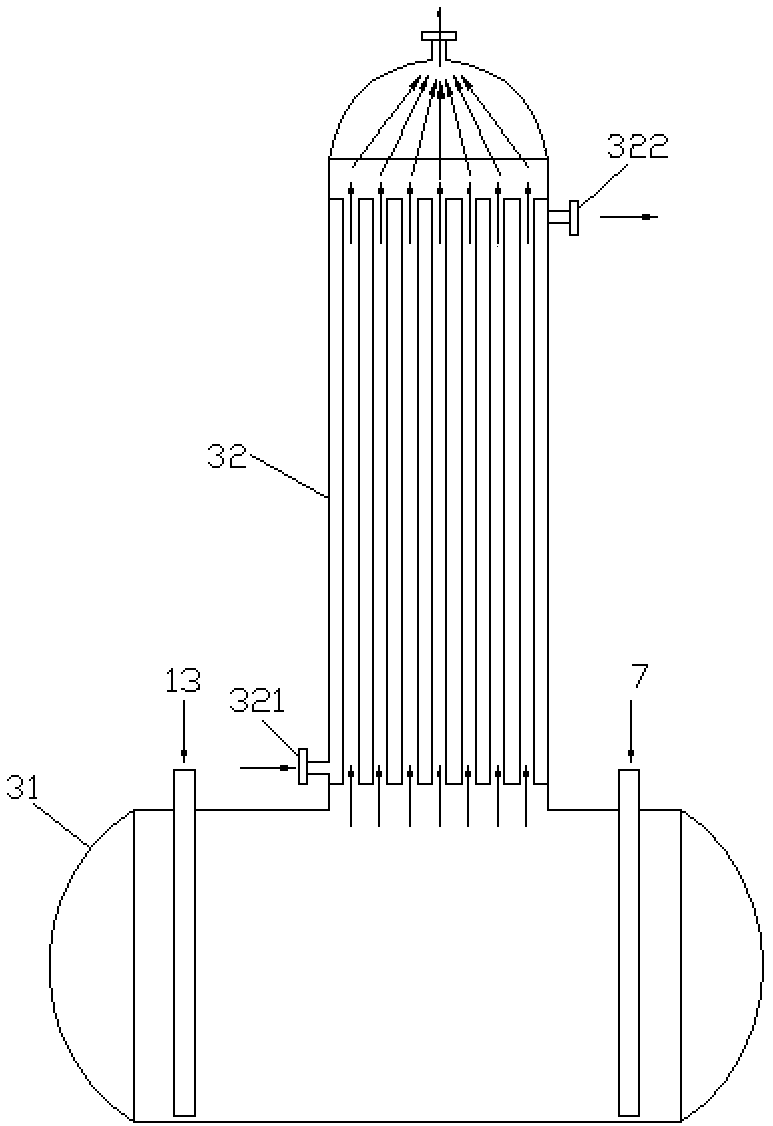

[0050] A. Equipment selection and equipment parameters: use a boiler with an evaporation capacity of 1t, the boiler provides steam for the steamer 2 through the steam delivery pipe 11, and the volume of the steamer 22 is 2m 3 , After the pot body 21 and the cover 23 are assembled, the water pressure reaches 2kg / cm 3 above; reboiler tower kettle 31 is 1.5m 3 , tower diameter Φ=30cm, tower height 2m, packing height 1.7m; condenser 41 adopts heat exchange area of 24m 2 1Cr18Ni9Ti plate condenser, cooler 42 with a heat exchange area of 8m 2 1Cr18Ni9Ti cooler;

[0051] B, raw material processing: adopt the Melaleuca branch and leaf that Guangxi Dongmen Forest Farm produces, cut the branch and leaf into the specification that the length is below 10cm with the electric vine cutting machine;

[0052] C. Loading and equipment installation: put the raw materials processed in step B into the ste...

Embodiment 2

[0059] Example 2: Distillation of oil of lemon eucalyptus

[0060] The specifications and parameters of the equipment used in this example are the same as those in Example 1, and the steps of the distillation process are the same as those in Example 1, with the difference that: the raw material of step B is the branches and leaves of Eucalyptus lemon produced in Wuming District, Nanning City, Guangxi.

[0061] Compared with the distillation process with re-evaporation system and two-stage water return system in this embodiment, the oil yield is increased from 0.9% to 1.2%, the distillation time is shortened from 2h to 1h, and the energy consumption is saved by 50%.

Embodiment 3

[0062] Example 3: Distillation of star anise oil

[0063] The equipment specifications and parameters selected in this embodiment are the same as those in Example 1, and the distillation process steps are the same as those in Example 1, with the difference that: the raw material in Step B is the star anise branches and leaves produced in Debao County, Baise City, Guangxi.

[0064] Compared with the distillation process without re-evaporation system and two-stage return water system in this embodiment, the oil yield is increased from 0.9% to 1.5%, the distillation time is shortened from 2h to 1.5h, and the energy consumption is saved by 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com