Patents

Literature

76results about How to "Has width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Face-painting product having function of dispelling stria gravidarum and method for preparing the same

ActiveCN101152138APromote absorptionPenetrate more fasterCosmetic preparationsToilet preparationsCentella asiatica extractCollagen i

The present invention relates to a cosmetic product with dispelling striae gravidarum effectiveness and a manufacturing method. Nutrient components synergy and can repair the elastic fiber effectively. Sweet almond oil and olive oil in the formula are rich in unsaturated fatty acid, which is totally identical with fats secretory of human; so essential fatty acid is added; the skin is repaired. Vitamin E has anti-aging and antioxidant effectiveness; small molecule faba bean peptide and nanometer parcel epidermal growth factor biomimetic peptide have strong physiological excitation signal which is easily absorbed by the skin; so the skin is stimulated to compose collagen which markedly amends the striae gravidarum. Centella asiatica extract can promote the composition of collagen I and III and can promote the composition of polysaccharide, which effective prevents and repairs the striae gravidarum.

Owner:天津盛世永业科技发展有限公司

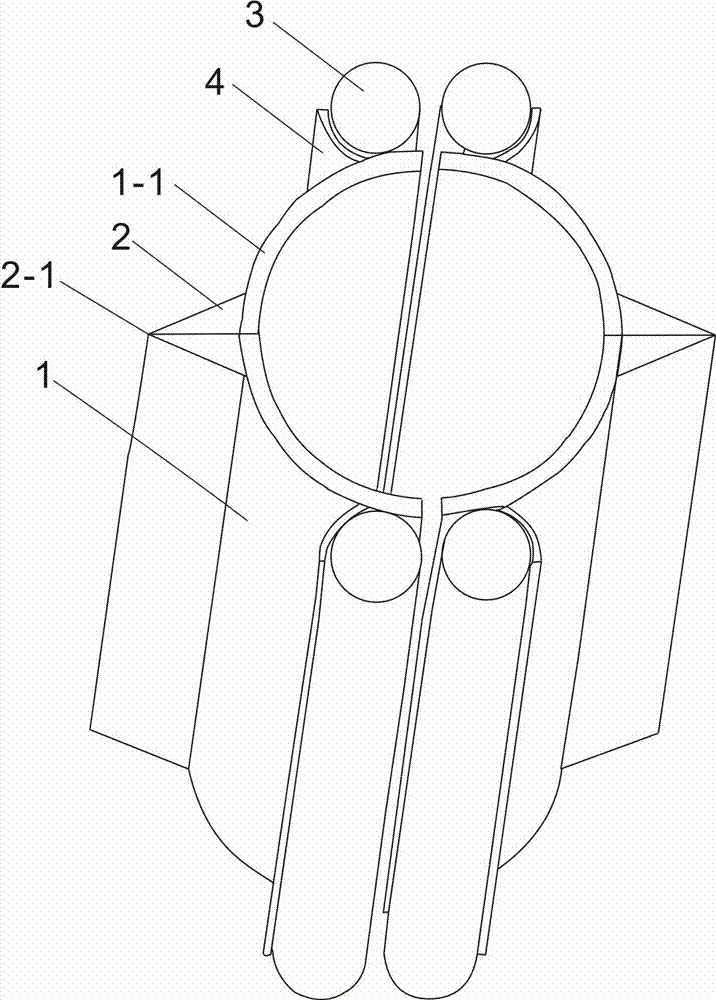

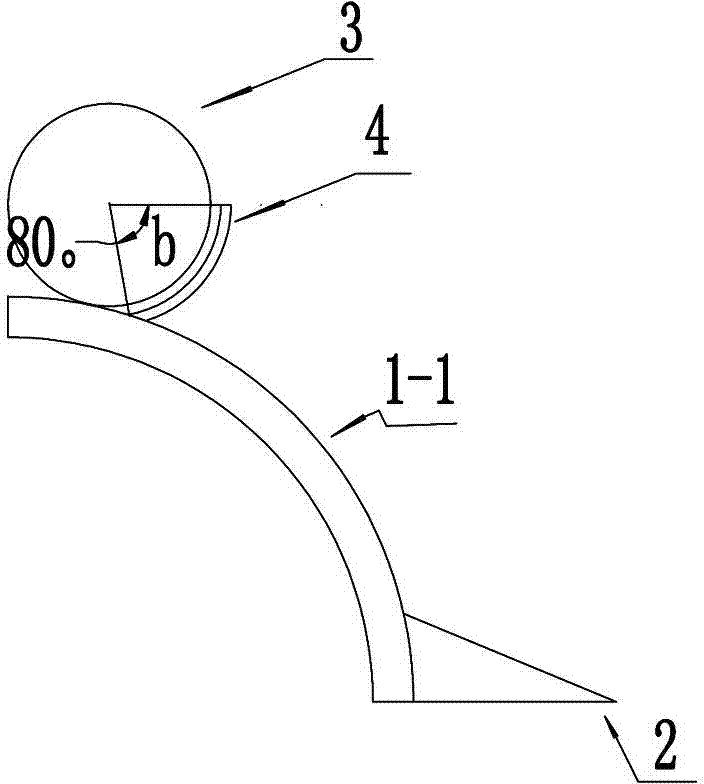

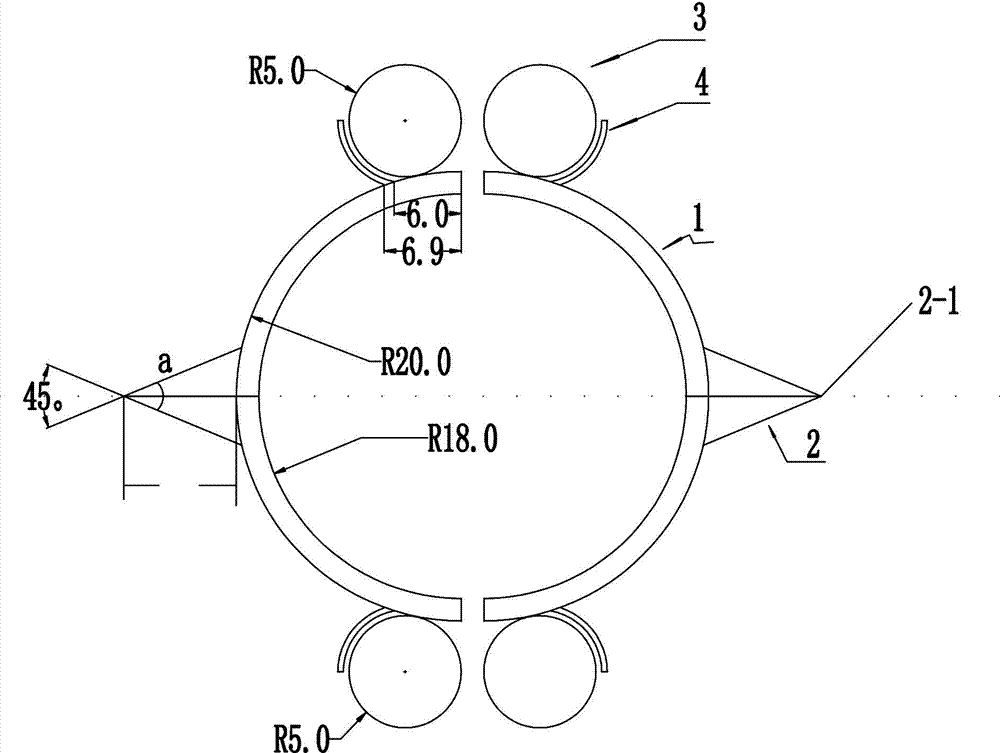

Static blasting and energy-gathering device and blasting method thereof

The invention discloses a static blasting and energy-gathering device. The static blasting and energy-gathering device comprises a main body protective barrel which is formed by splicing two circular-arc-shaped steel templates which are not connected, wherein a connecting line of middle points of the two circular-arc-shaped steel templates is perpendicular to a pre-splitting line; a splitting angle is arranged on the outer part of each circular-arc-shaped steel template, and the tip end of the splitting angle and the pre-splitting line are positioned on the same straight line. A method for blasting by applying the static blasting and energy-gathering device comprises the following steps: 1) drilling; 2) placing a static stone-breaking and energy-gathering device; 3) pouring stone breaker slurry for breaking stones; 4) recycling. According to the static blasting and energy-gathering device and the blasting method provided by the invention, the problems of long crushing time, high dosage for crushing and the like can be solved, the static crushing and blasting time is shortened, the dosage per crushing volume is reduced, and the crushing efficiency of a static crushing agent is improved.

Owner:泰州市海通资产管理有限公司

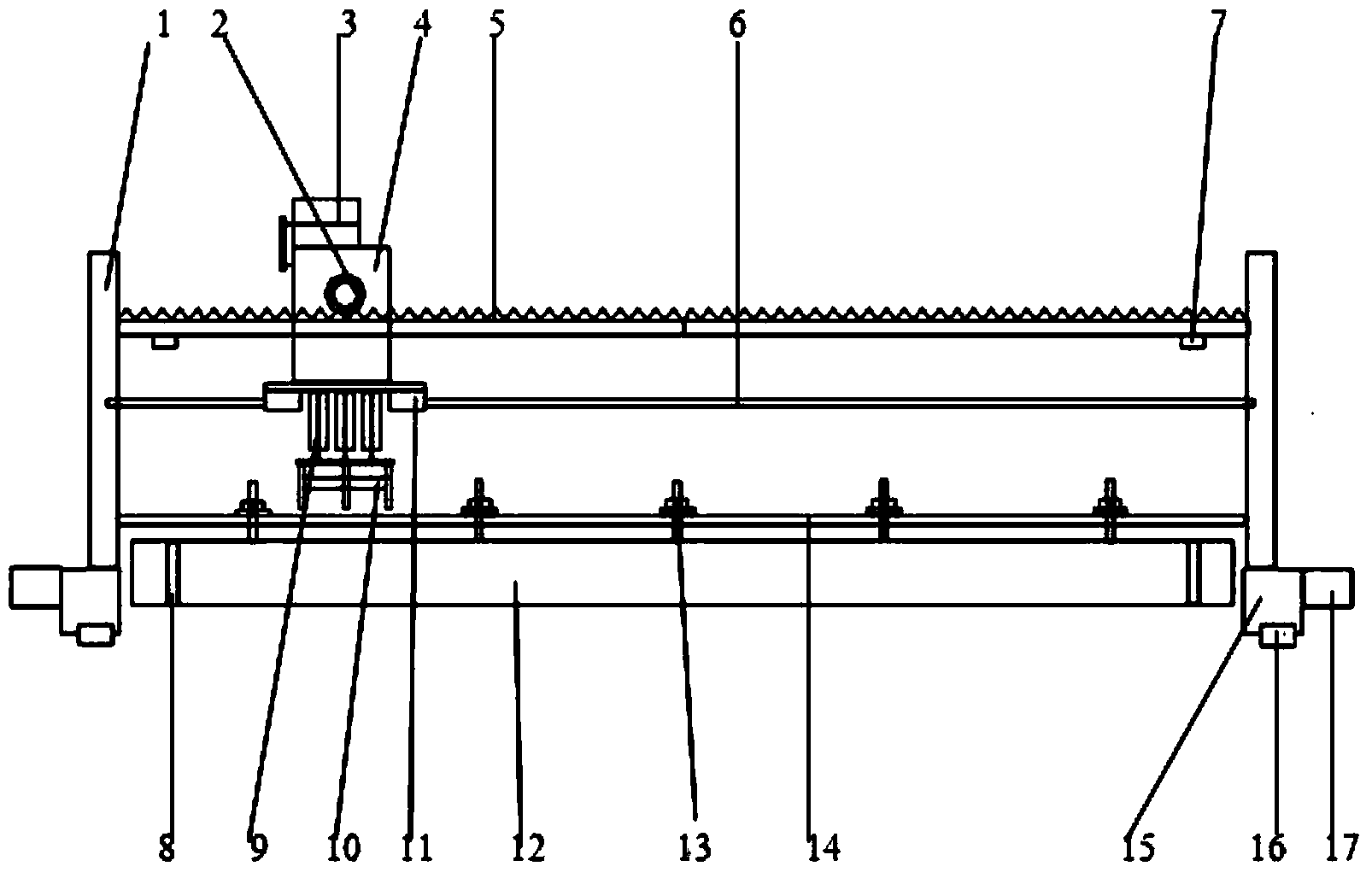

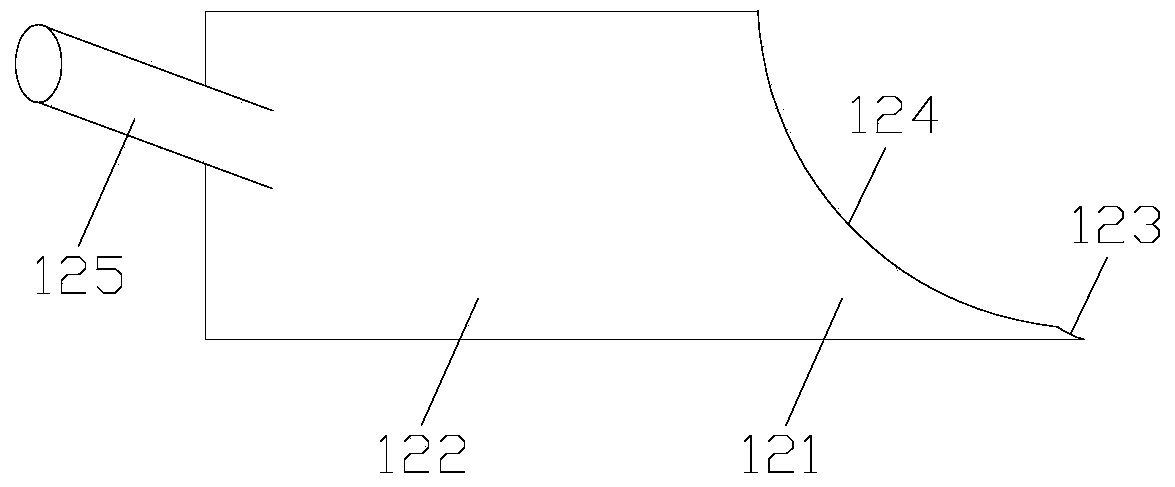

Simple casting type asphalt concrete paver

The invention discloses a simple casting type asphalt concrete paver which comprises a rack, a scraper distributor, a screed plate, a lifting device and a translating device, wherein a traveling device is arranged on the rack; the scraper distributor is arranged on the lifting device; the lifting device is arranged on the translating device; the translating device is arranged on the rack; the creed plate is connected with the rack and is positioned at the output end of the scraper distributor. The simple casting type asphalt concrete paver disclosed by the invention has the advantages of low production cost, convenience for operation, fewer faults, reliable performance and high temperature resistance; the construction requirements of the paving width, the paving thickness and the like can be met; besides, the compactness of the paved asphalt concrete is consistent, and the paving surface is smooth.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

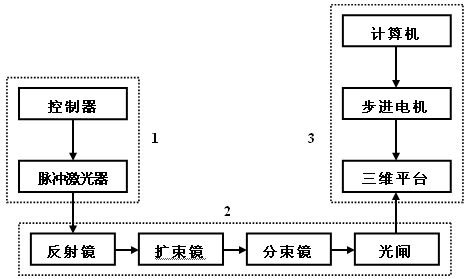

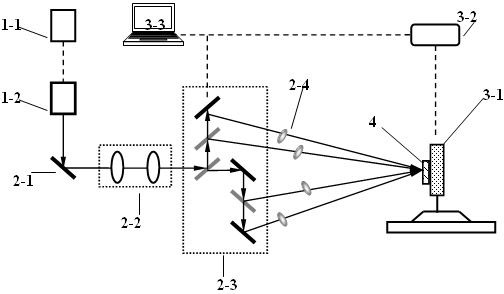

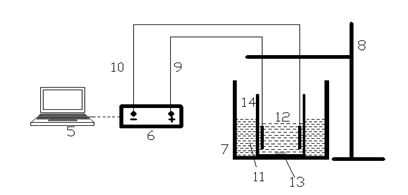

Method and device for preparing microtexture through laser photoetching assisted electrochemical deposition

The invention discloses a method and a device for preparing a microtexture through laser photoetching assisted electrochemical deposition, and belongs to a method and a device for preparing a surface structured coating. The method comprises the following steps of: photoetching the surface of a metallic material, on which photoresist is previously spin-coated, by using a pulse laser photoetching technique; soaking in developing solution to remove the exposed photoresist; then performing controllable electrodeposition of a composite coating on the surface of the material by using an electrochemical deposition technology; and finally removing unexposed photoresist to obtain a surface composite coating with a regular microtexture on the surface of the metallic material to realize maximization of tribological performance of the surface. The device comprises a pulse laser photoetching system device and an electrochemical deposition device, wherein a laser photoetching system consists of a pulse laser module, an optical path transmission module and a three-dimensional moving module which are connected in sequence. The device has the advantage of controllable structure. The structure and the composition of the composite coating are controllable. The application range is wide. By combining the laser photolithographic machining technology and the electrochemical deposition technology, the maximization of the anti-friction and anti-wear property of the material surface is realized.

Owner:CHINA UNIV OF MINING & TECH

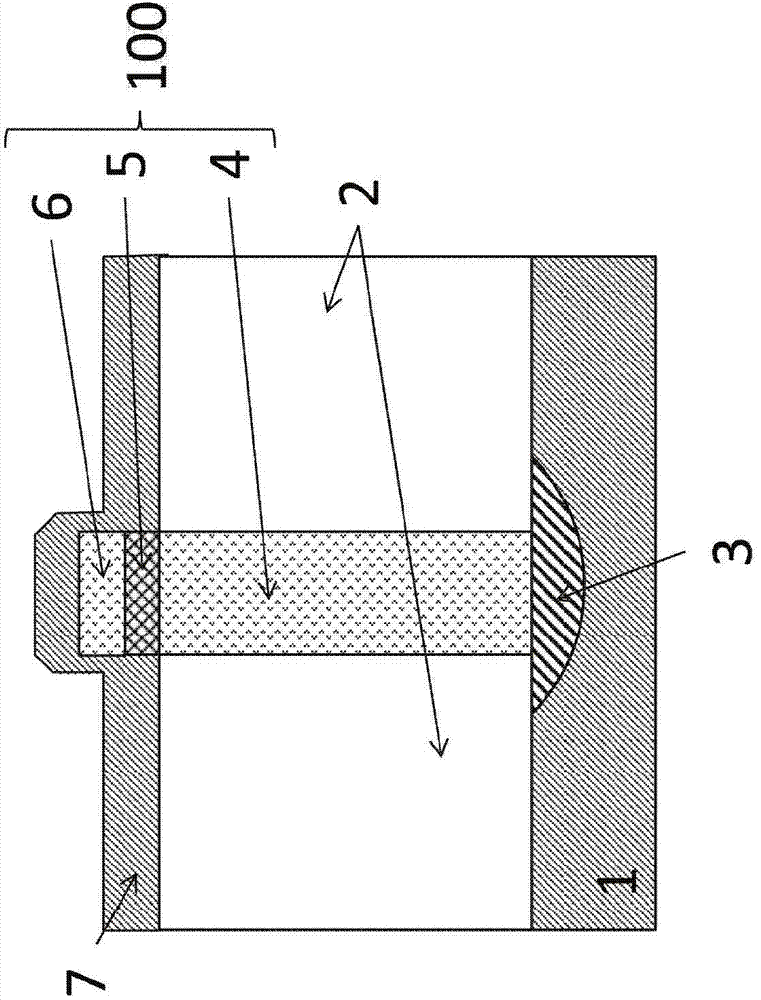

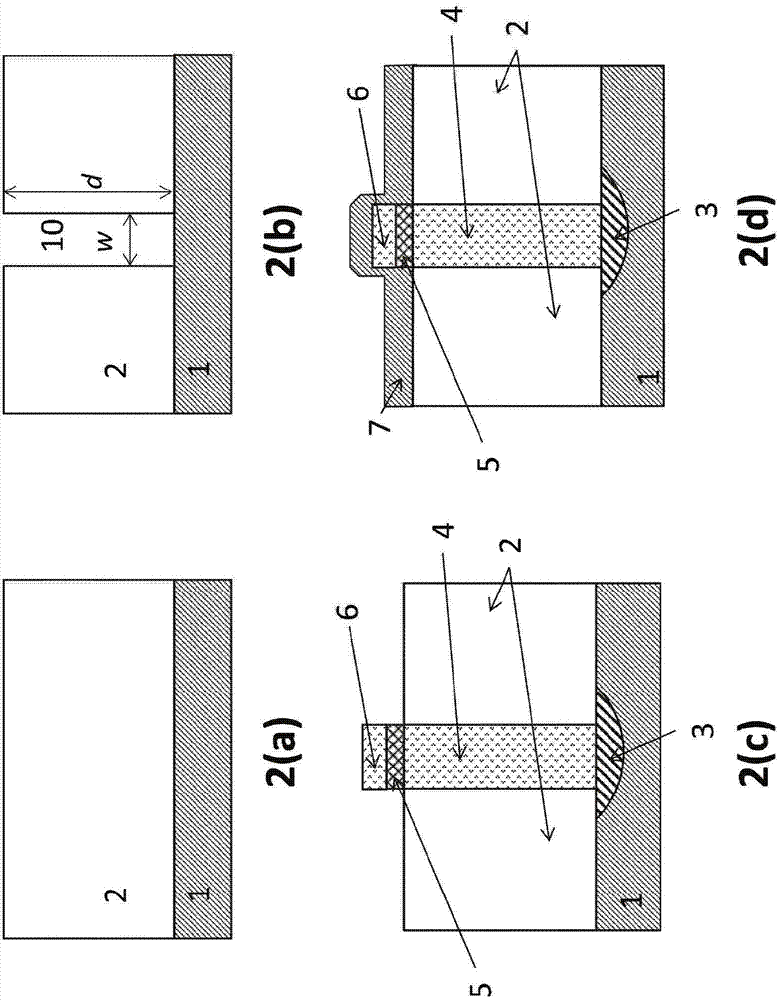

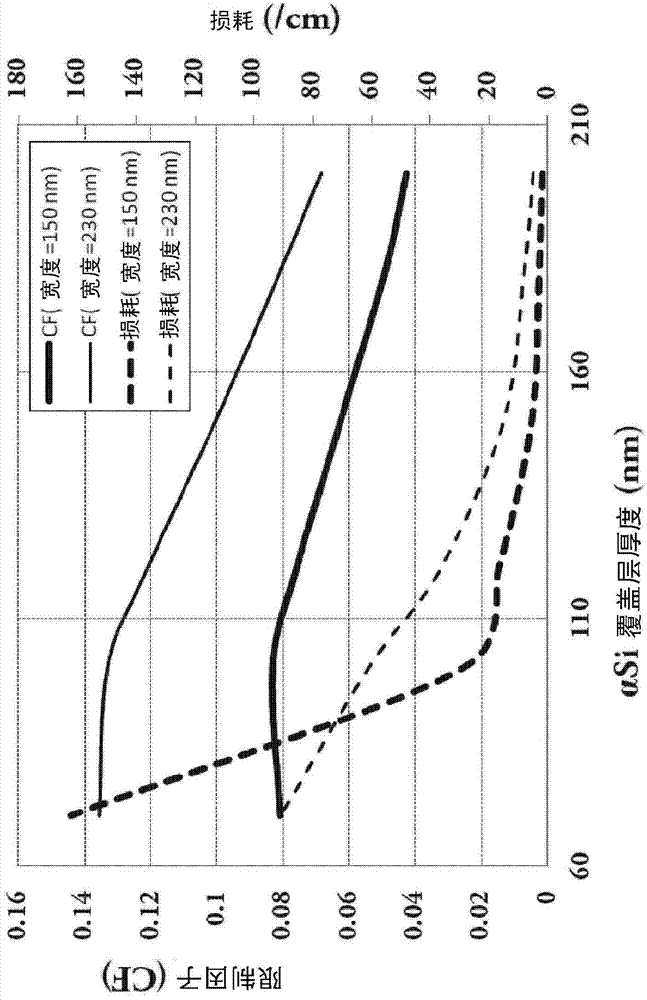

Hybrid waveguide laser and method for manufacturing hybrid waveguide laser

ActiveCN104283093ALower the thresholdReduce power consumptionLaser detailsSemiconductor lasersElectricityWaveguide lasers

The invention relates to a hybrid waveguide laser and a method for manufacturing the hybrid waveguide laser. The hybrid waveguide laser is sub-micron III-V in level and comprises a channel waveguide, a lateral cladding layer adjacent to the waveguide in the transverse direction, and a light limiting element. The channel waveguide is 50 nm to 800 nm in width and 500 nm to 1200 nm in height. The light limiting element is used for limiting the light within the waveguide. The waveguide may comprise an III-V lamination comprising a lower cladding layer, an active region and an upper cladding layer. The laser may be optically coupled to an output waveguide which may be electrically pumped. The invention also provides a method for integrating the sub-micron III-V level waveguide laser onto a silicon photon platform. The method comprises the steps of providing an electricity insulating layer on a silicon substrate, etching a channel of 50 nm to 800 nm in width in the electricity insulating layer, forming a channel waveguide in the channel through providing an III-V lamination during the local epitaxial growth process, and providing a light limiting element to limit the light within the waveguide.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

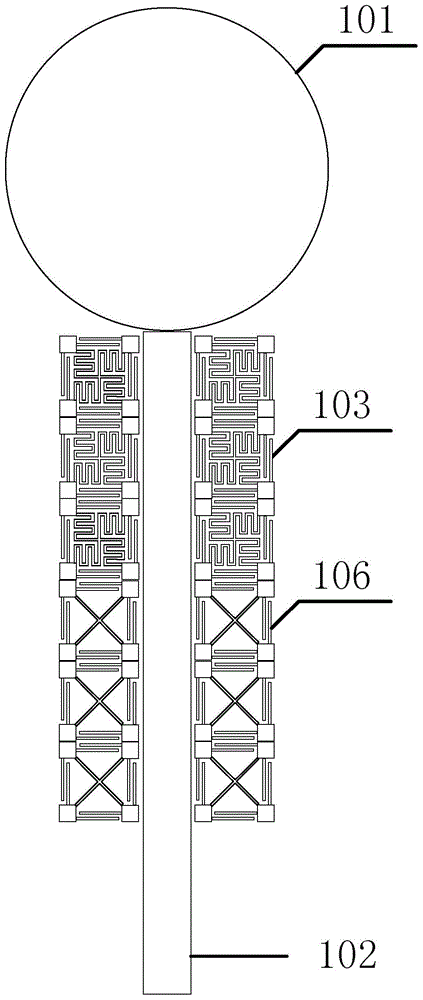

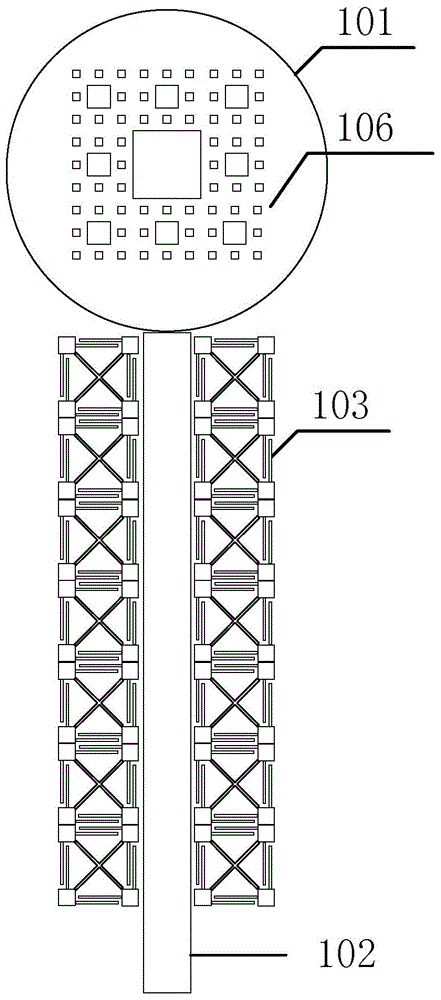

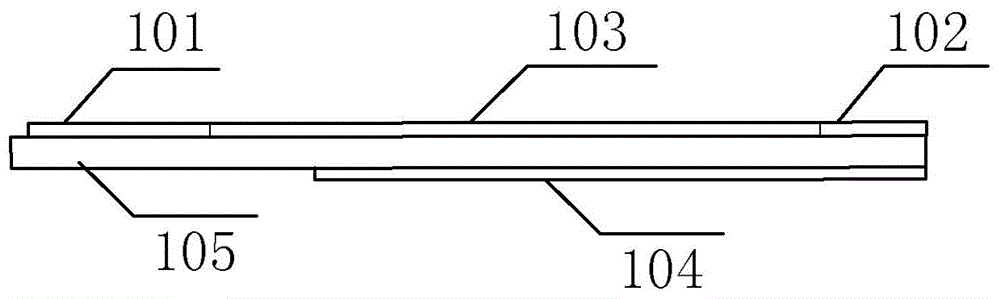

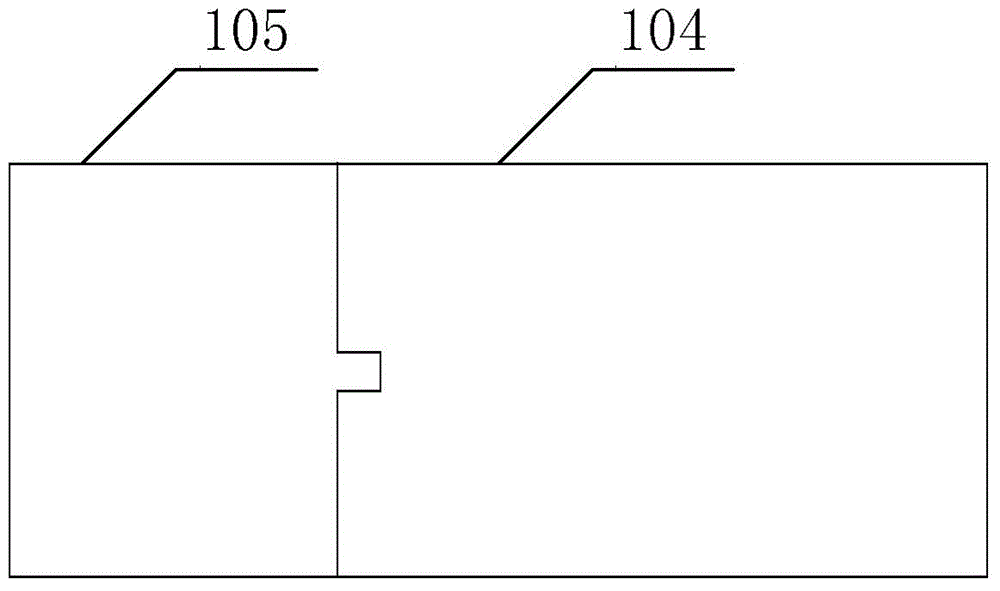

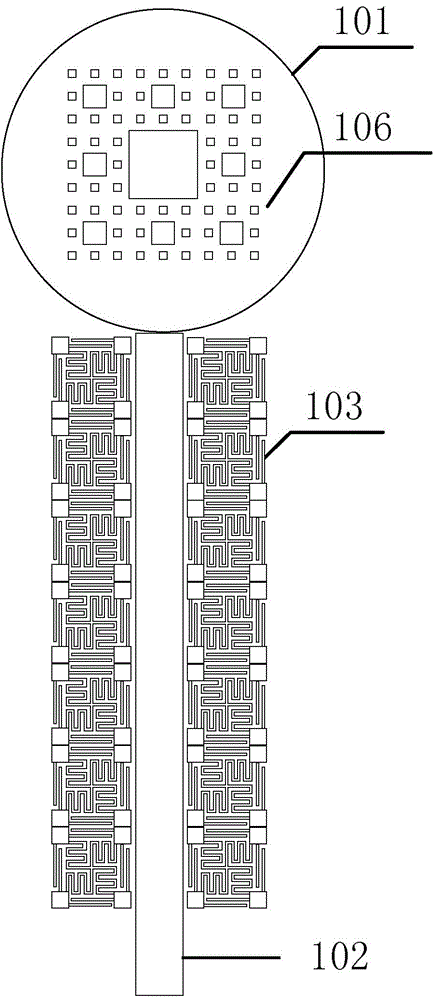

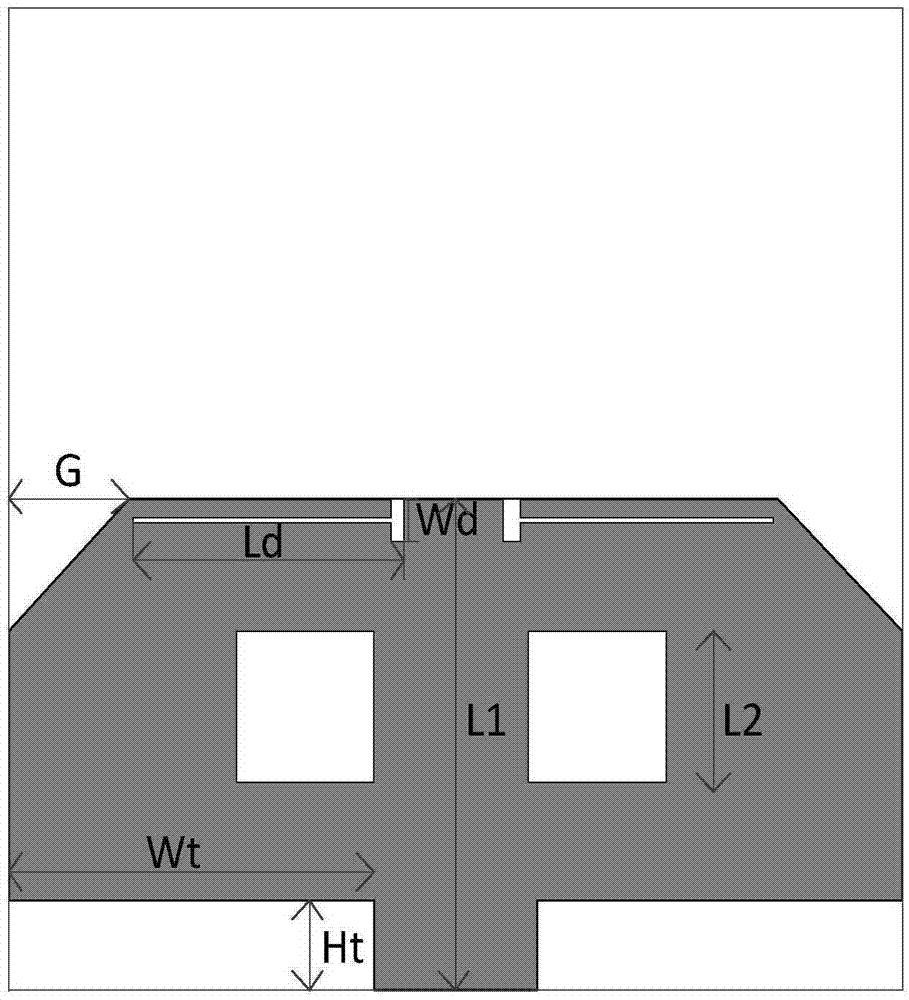

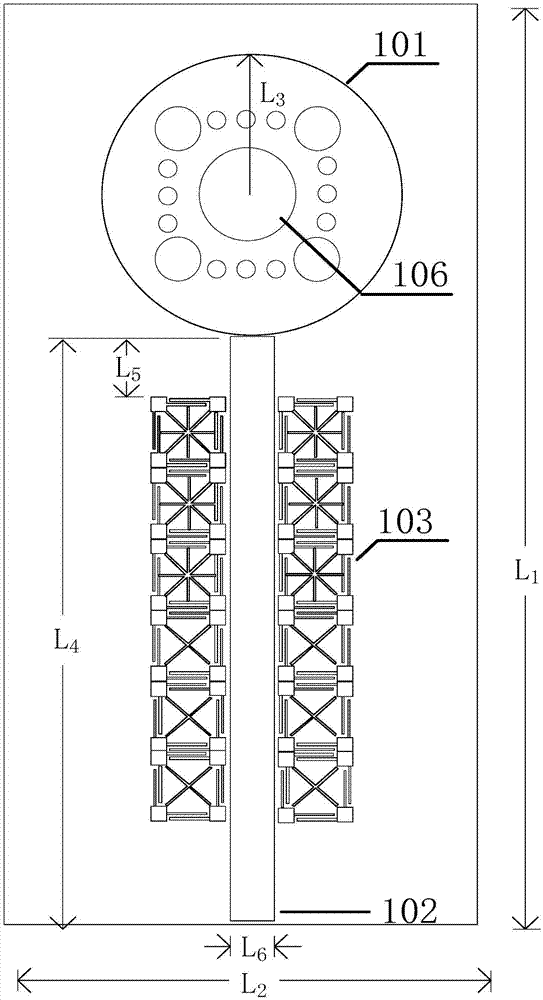

UWB (ultra wide band) antenna with dual resistance band function

InactiveCN104681955ASimple designCompact structureRadiating elements structural formsAntenna couplingsImpedance matchingWide band

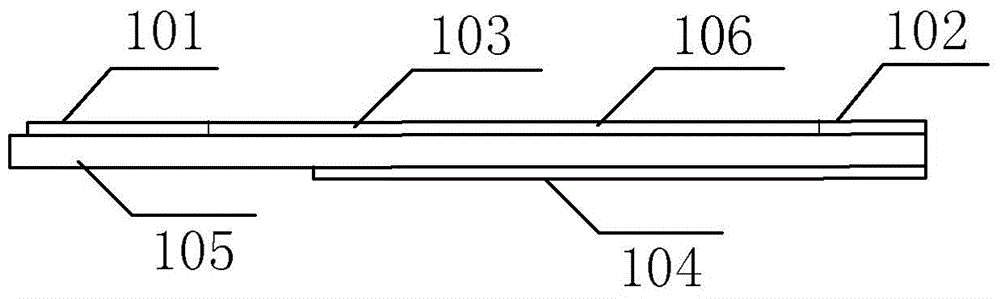

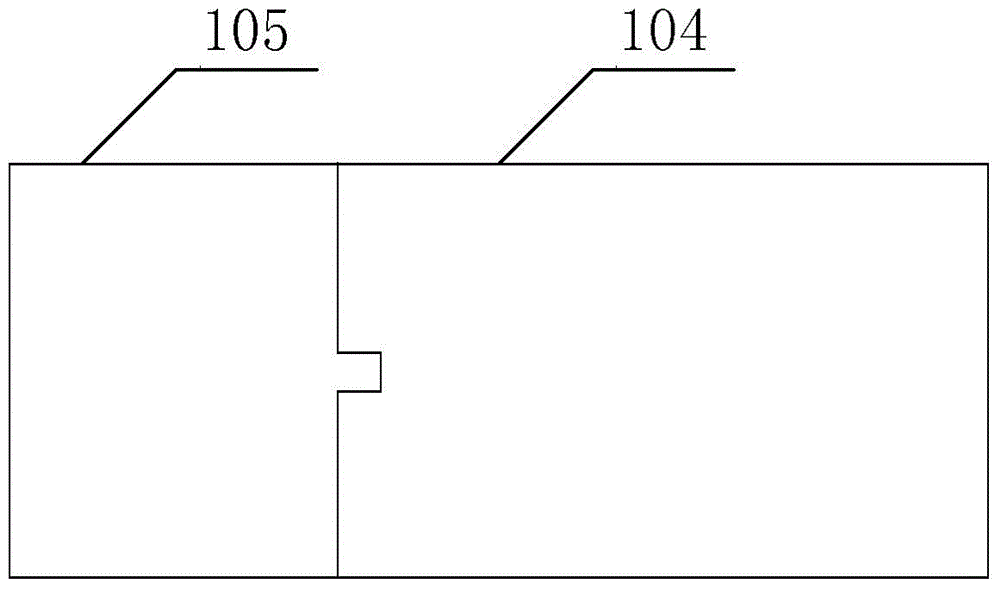

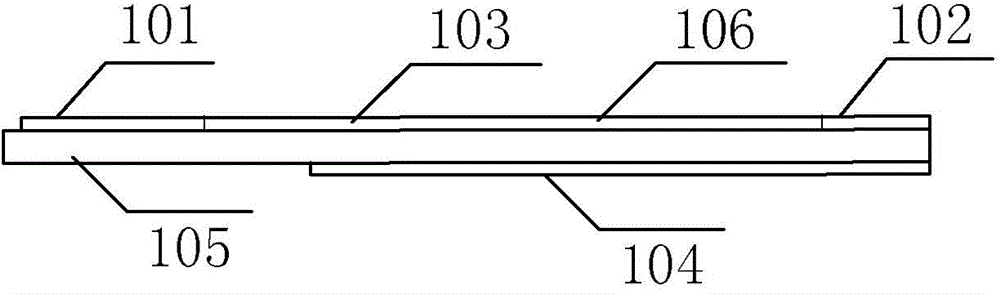

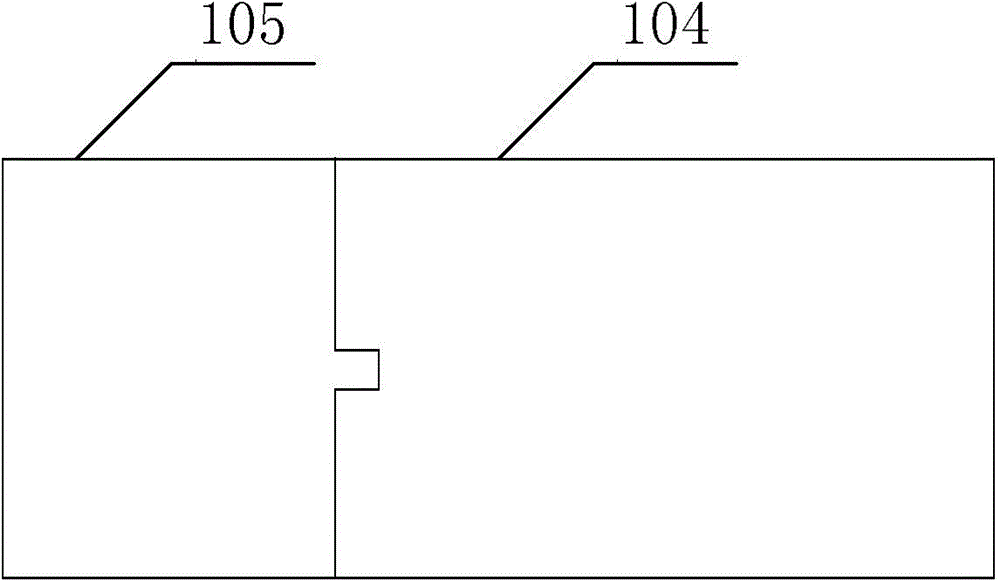

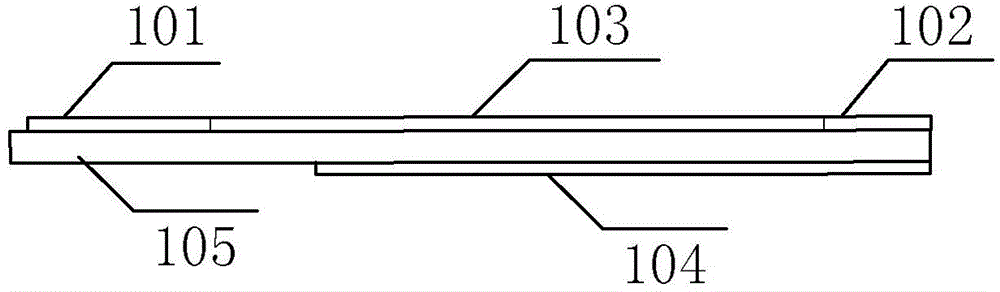

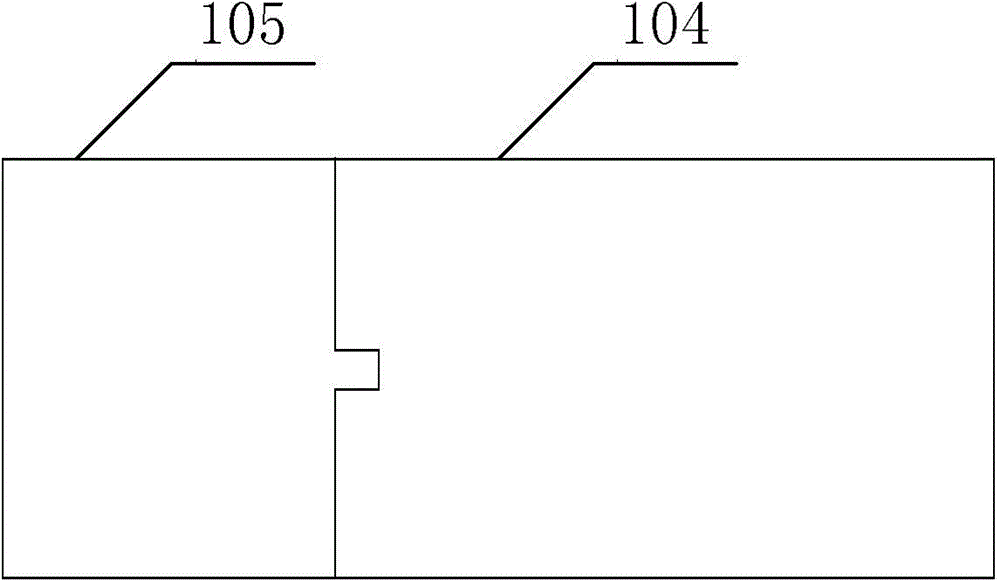

The invention provides an UWB (ultra wide band) antenna with a dual resistance band function, and relates to an UWB antenna. The UWB antenna comprises a medium substrate (105), a radiating unit (101), an impedance matching input microstrip wire (102), a folding line type EBG (electromagnetic band gap) structure (103), a cross type EBG structure (106) and a metal grounding plate (104), wherein the radiating unit (101), the impedance matching input microstrip wire (102), the folding line type EBG structure (103) and the cross type EBG structure (106) are arranged on the medium substrate, and the metal grounding plate (104) is arranged under the medium substrate. The UWB antenna has the advantages that by utilizing the radiating unit, the impedance matching input microstrip wire and the metal grounding plate, the pass band bandwidth required by the UWB is realized; by arranging the two groups of EBG structures, the dual resistance band property is realized; the two resistance bands are respectively arranged near 5.2GHz and 6.8GHz, and the interference of an UWB system on an RFID (radio frequency identification) system (6.8GHz) and a WLAN (wireless local area network) system (5.15-5.35GHz) is inhibited.

Owner:HARBIN HESON SCI & TECH

Automatic material lifting device

ActiveCN109366196AIncrease productivityHigh feed accuracyWork clamping meansLarge fixed membersEngineeringContinuous operation

The invention discloses an automatic material lifting device. The automatic material lifting device comprises a base plate, four corners of the upper surface of the base plate are connected with fourcorners of the lower surface of a jig plate through stand columns correspondingly to form a rectangular frame, four material channels are arranged on the jig plate, a jacking portion comprises a movable plate, several jacking columns are installed on the movable plate, the corresponding jacking column can push each raw material to move upwards along the corresponding material channel, each limiting portion comprises a limiting plate, the limiting plates are attached to the upper surfaces of limiting columns, the limiting plates are used for limiting the height of the raw materials, each pressing portion comprises a bidirectional pressing block and two sliding blocks, the bidirectional pressing blocks run downwards, and the sliding blocks horizontally slide and clamp profiles correspondingly. The automatic material lifting device has the effects that material lifting for automatic production is achieved, the production efficiency is high, and the automatic material lifting device is suitability for large-scale continuous operation.

Owner:DONGGUAN SHENGXIANG PRECISION METAL

Dual-stopband UWB (Ultra-wide Bandwidth) antenna with steep stopbands

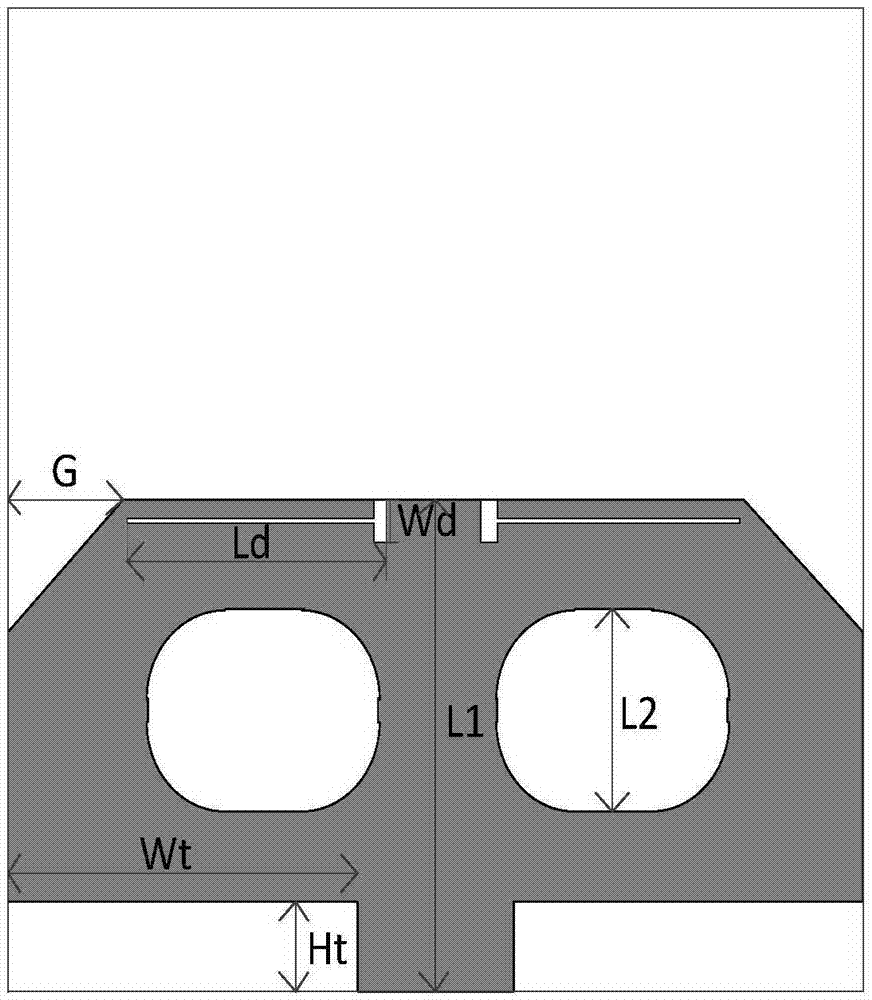

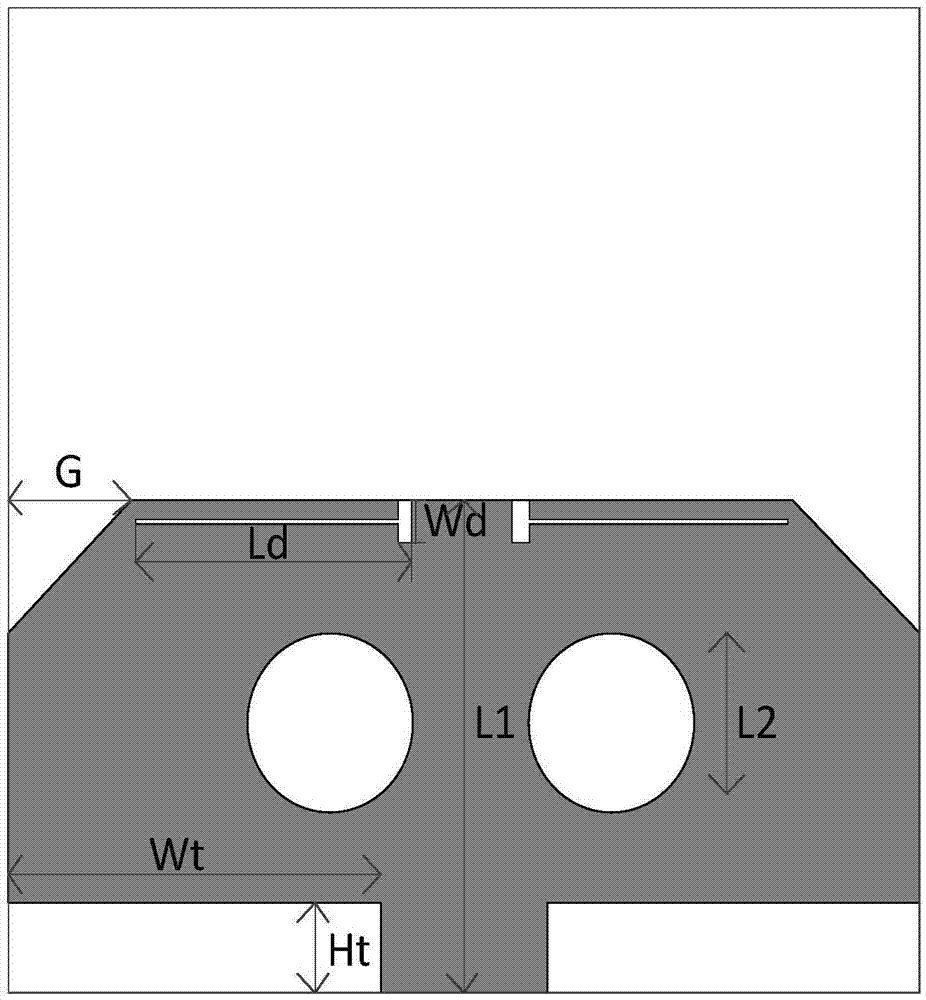

InactiveCN104681965ASimple designCompact structureRadiating elements structural formsAntenna couplingsDielectric substrateLocal area network

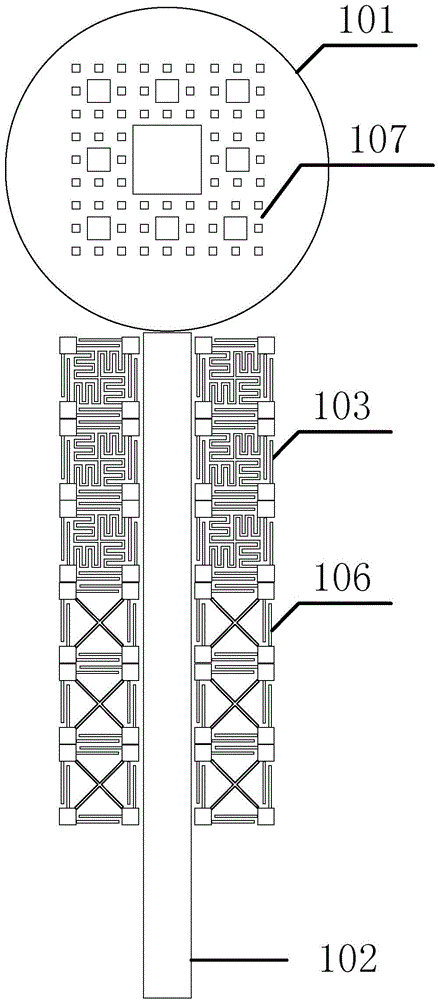

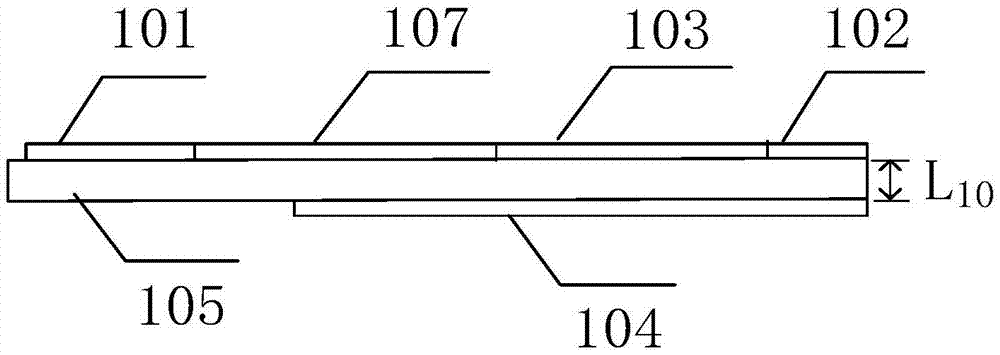

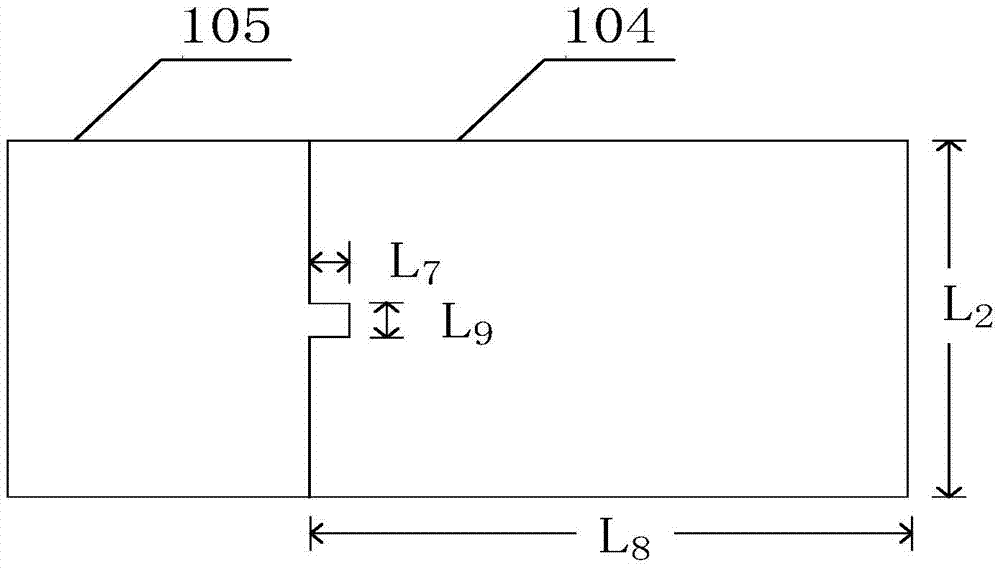

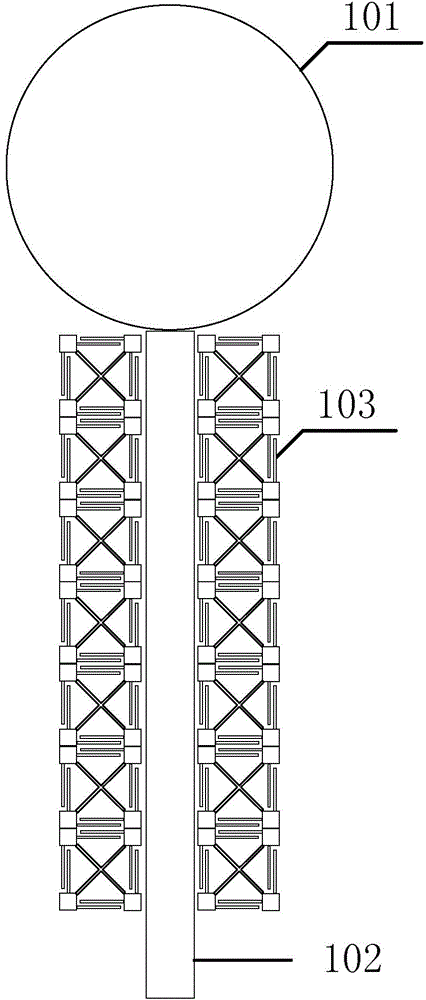

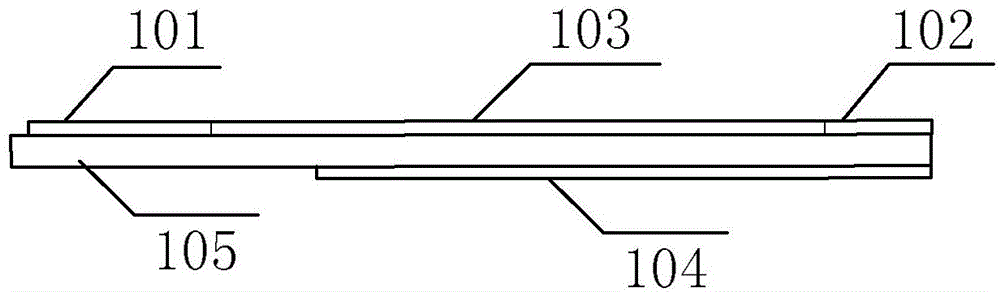

The invention relates to a dual-stopband UWB (Ultra-wide Bandwidth) antenna with steep stopbands, relating to a UWB antenna. The dual-stopband UWB antenna with the steep stopbands, is formed by a dielectric substrate (105), a radiating element (101) above the dielectric substrate, a square etching fractal structure (107), an impedance matching input microstrip line (102), a fold line type EBG (Electromagnetic Band Gap) structure (103), a criss cross EBG structure (106) and a metal earth plate (104) under the dielectric substrate. According to the dual-stopband UWB antenna with the steep stopbands, the radiating element, the impedance matching input microstrip line and the metal earth plate are utilized to realize passband width required by UWB, and the dual-stopband characteristic of the steep stopbands is realized by utilizing the two groups of EBG structures and the square etching fractal structure above the radiating element. According to the antenna provided by the invention, the two stopbands are respectively close to 5.2Ghz and 6.8GHz, so that the interference of a UWB system on an RFID (Radio Frequency Identification Device) system (6.8GHz) and a WLAN (Wireless Local Area Network) system (5.15-5.35GHz) is restrained.

Owner:HARBIN HESON SCI & TECH

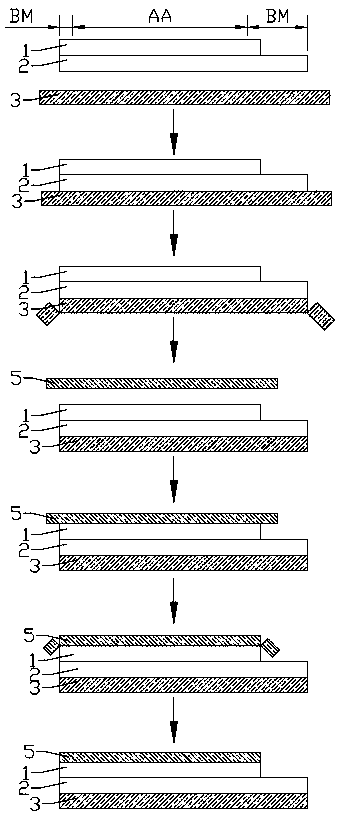

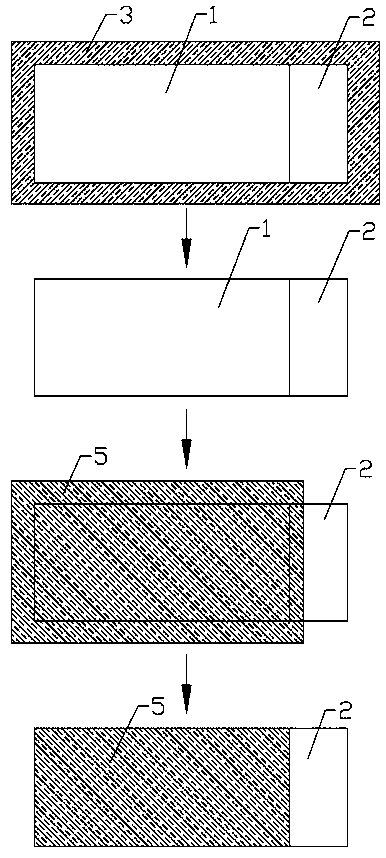

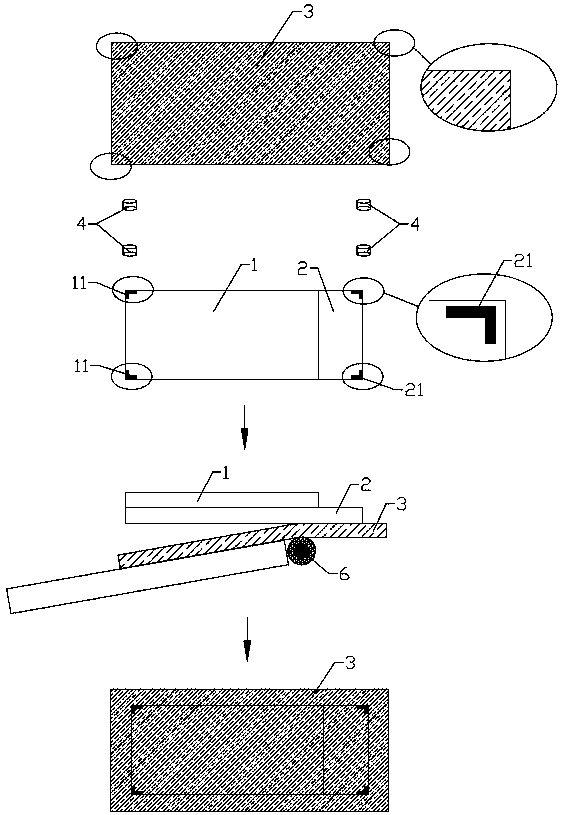

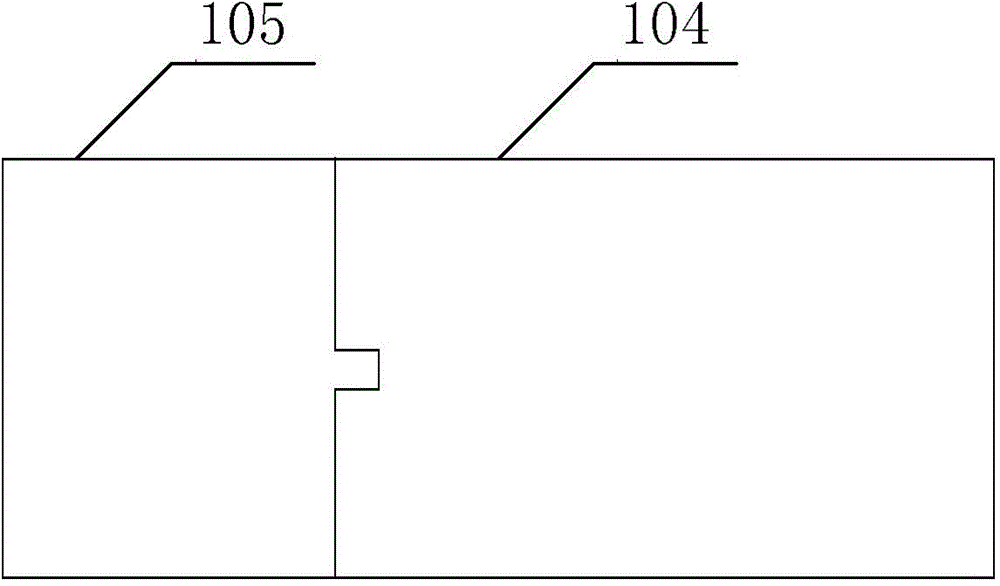

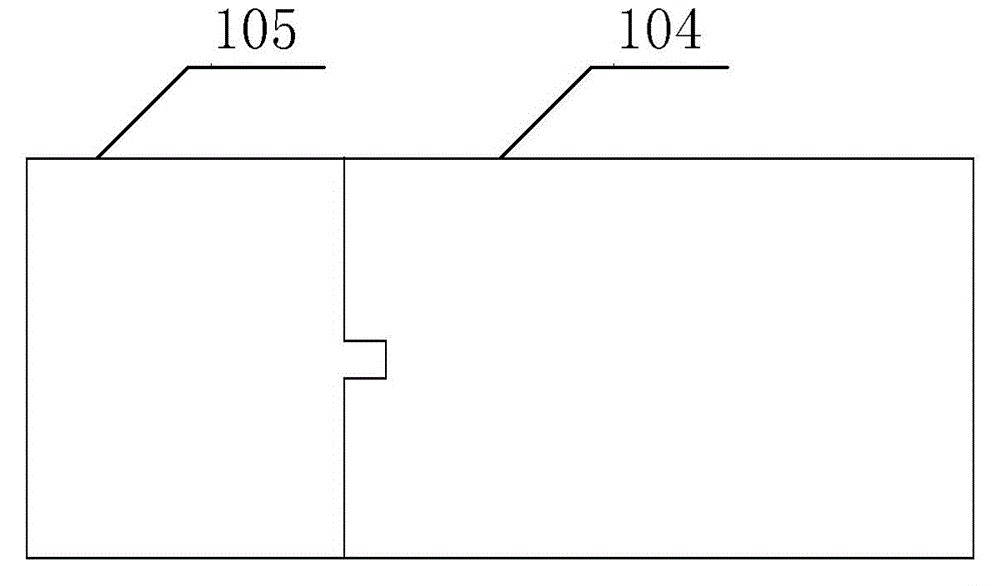

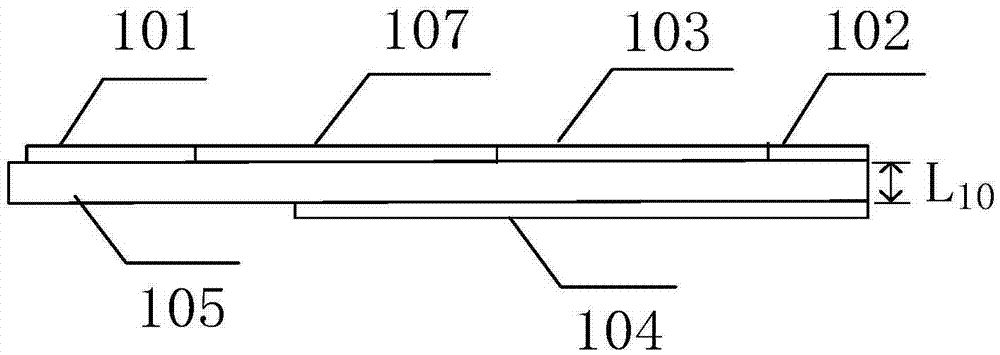

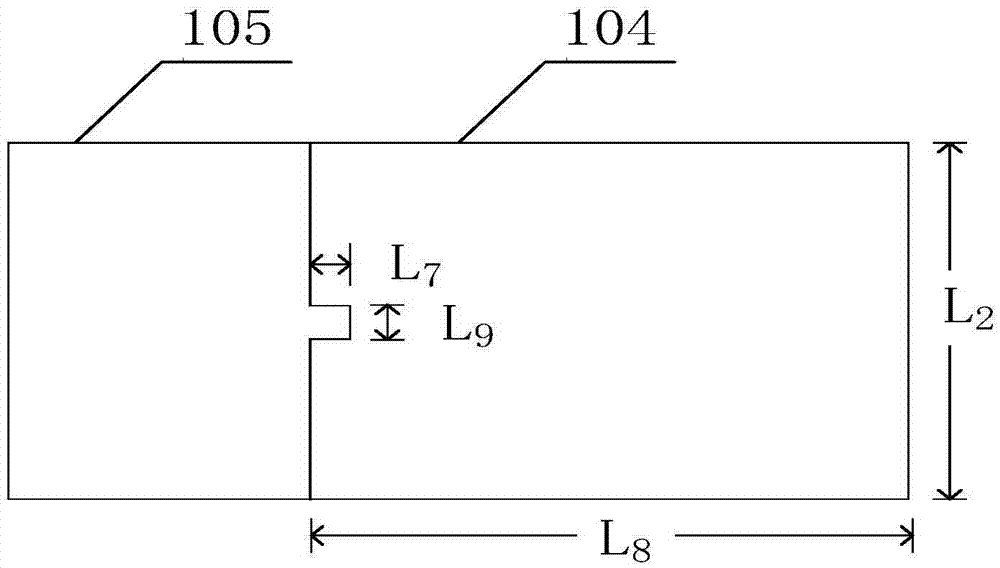

Polarizer attaching and cutting integrated method and equipment for liquid crystal display panel

InactiveCN108845439ARealize the purpose of narrowing the designHas widthNon-linear opticsLiquid-crystal displayEngineering

The invention provides a polarizer attaching and cutting integrated method and equipment for a liquid crystal display panel. The method comprises the following steps: providing an upper substrate anda lower substrate stacked together, as well as a lower polarizer of which the size is larger than that of the lower substrate, wherein the lower substrate is provided with a first alignment mark, andthe lower polarizer is provided with a third alignment mark; providing a CCD (Charge Coupled Device) visual system, sampling the first alignment mark and the third alignment mark, and attaching the lower polarizer onto the lower substrate; sampling an edge mark of the lower substrate by utilizing the CCD visual system, and cutting the lower polarizer; providing an upper polarizer of which the sizeis larger than that of the upper substrate, wherein the upper substrate is provided with a second alignment mark, and the upper polarizer is provided with a fourth alignment mark; sampling the secondalignment mark and the fourth alignment mark by utilizing the CCD visual system, and attaching the upper polarizer onto the upper substrate; sampling the edge mark of the upper substrate by utilizingthe CCD visual system, and cutting the upper polarizer. According to the method and equipment disclosed by the invention, the requirement on the polarizer attaching and cutting accuracy is low, and the method and equipment are applicable to narrow border display.

Owner:TRULY SEMICON

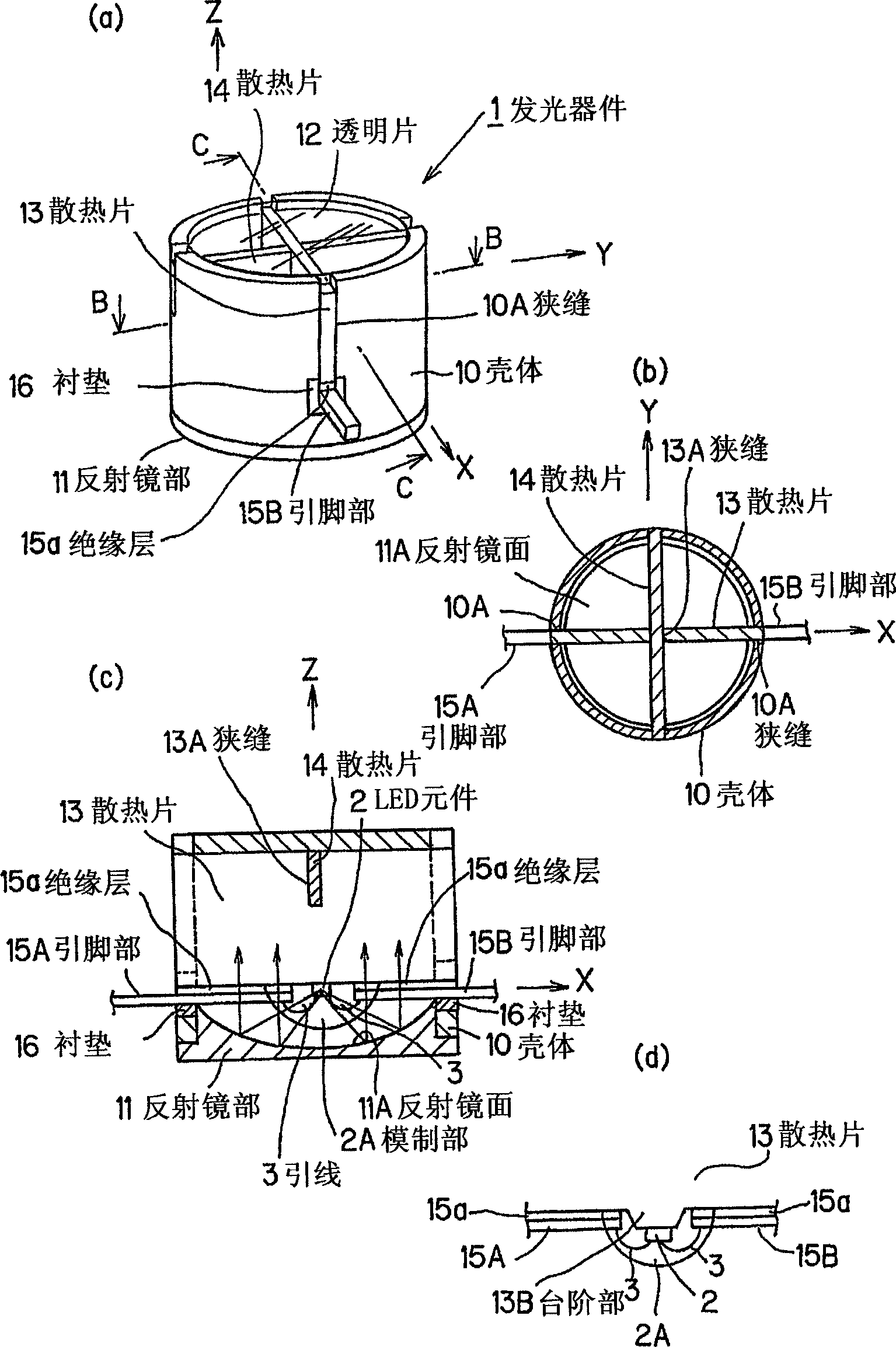

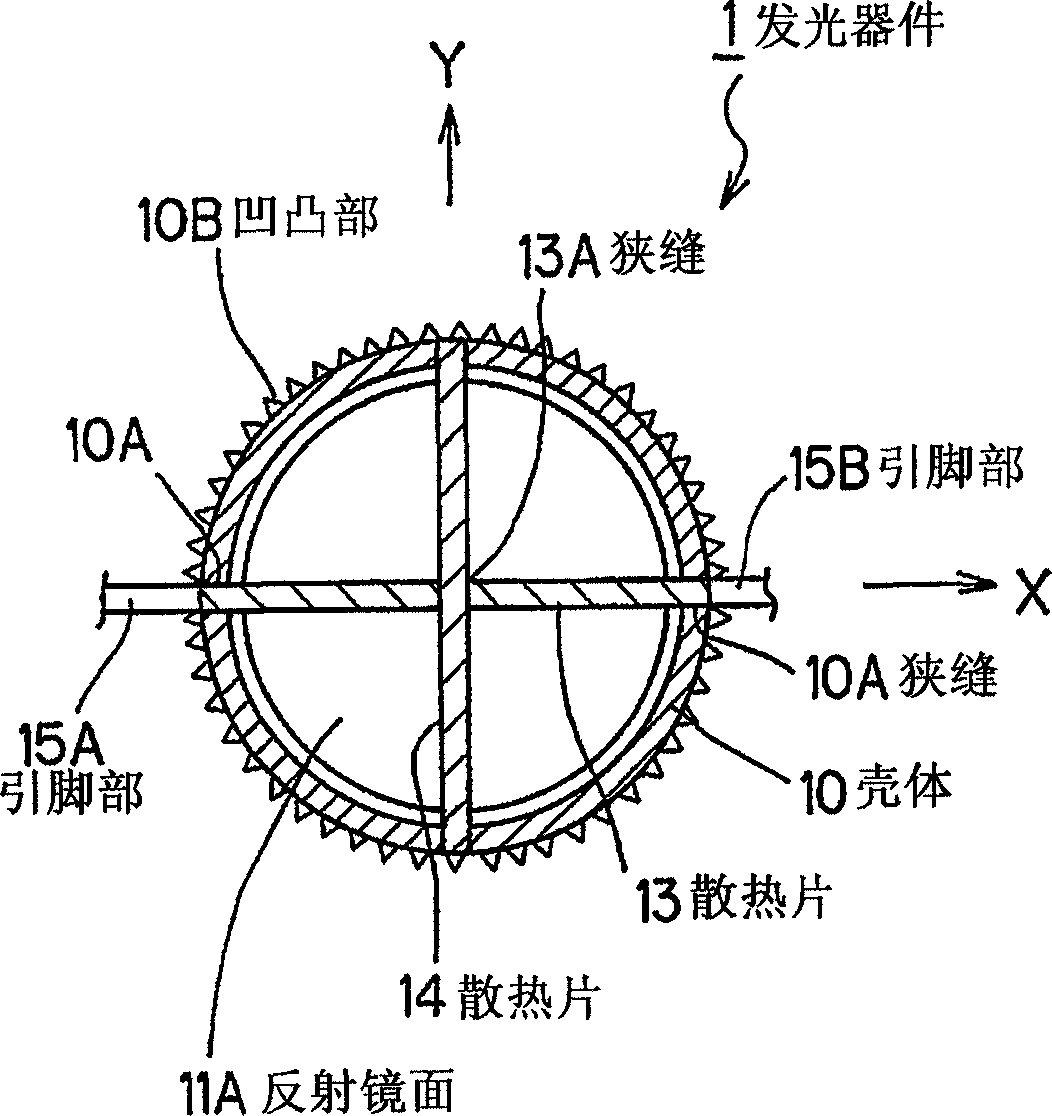

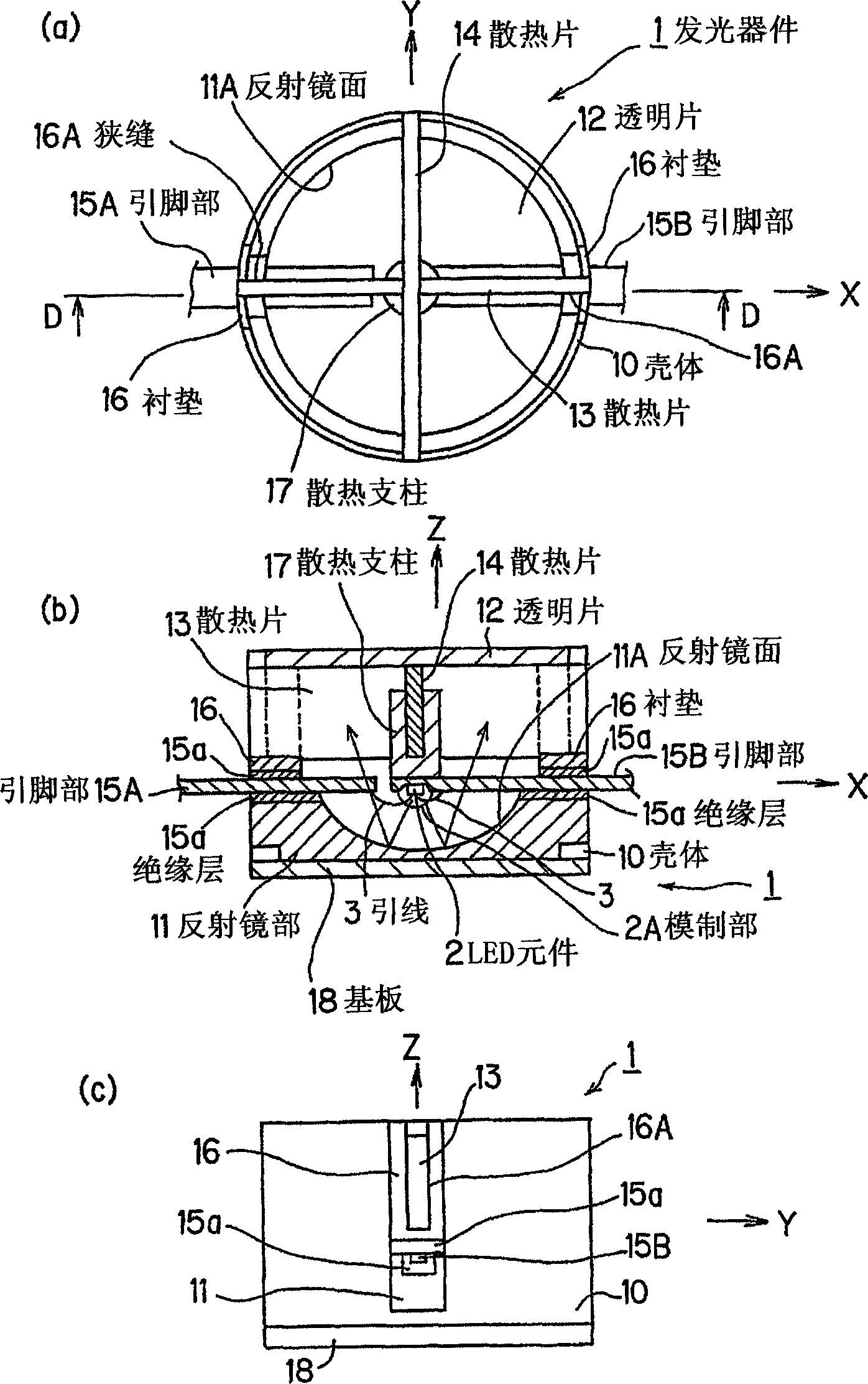

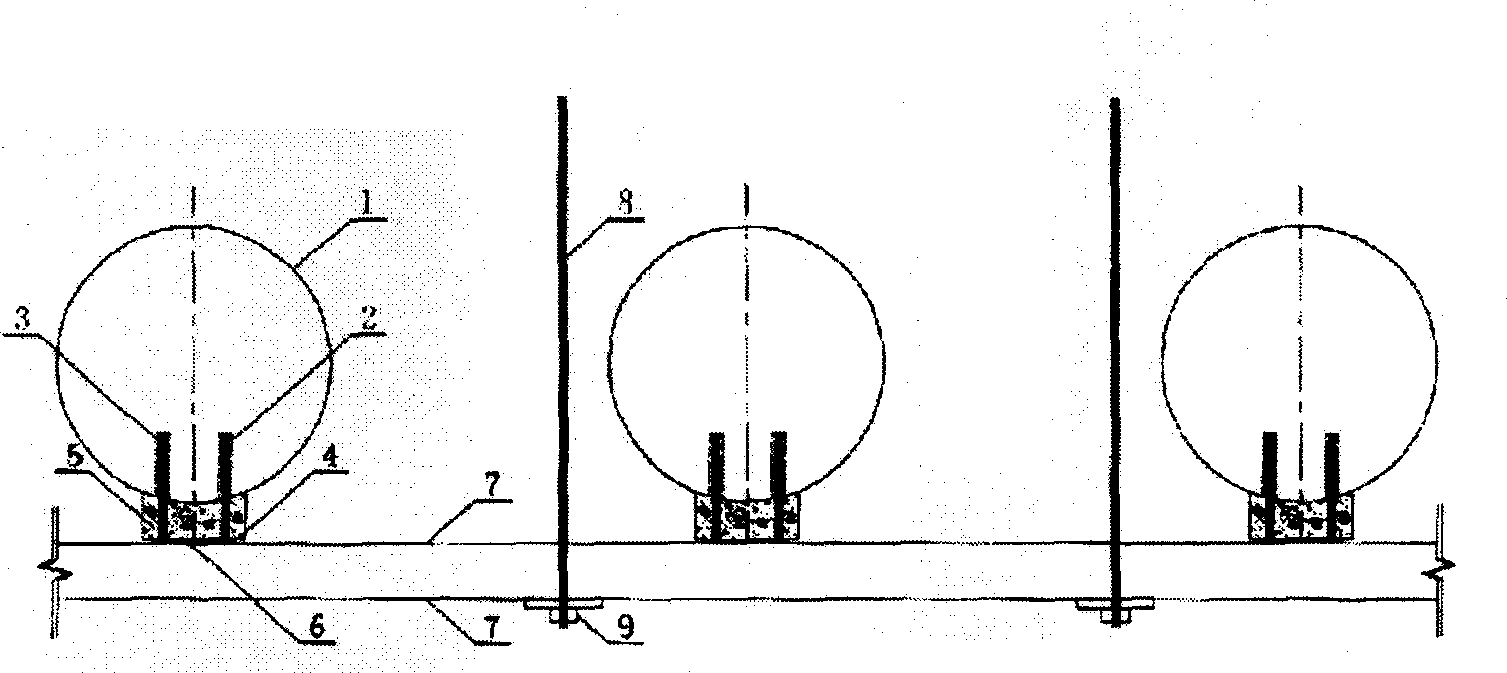

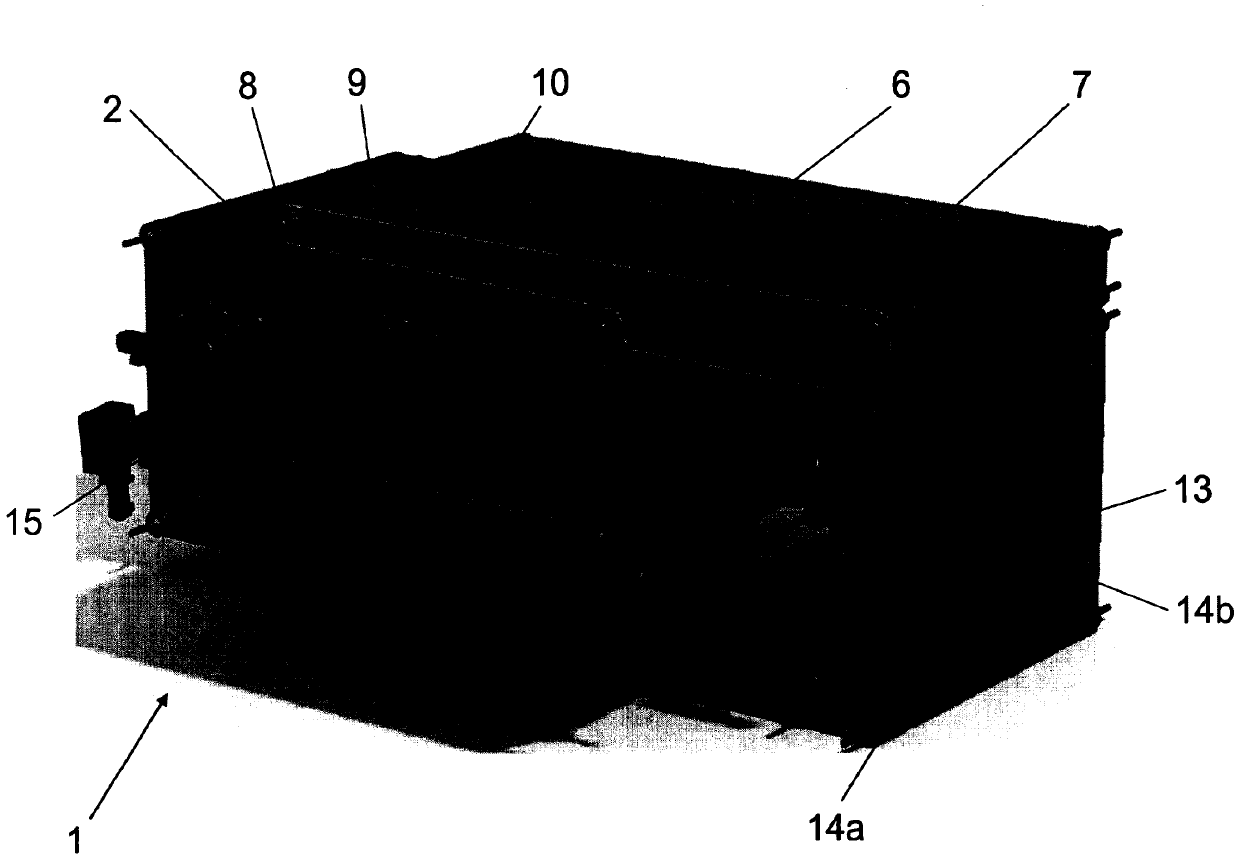

Light emitting apparatus

InactiveCN1875494AWith cooling widthHas widthSolid-state devicesSemiconductor devicesInsulation layerMetallic materials

There is provided a reflectance-type light emitting device having an excellent heat radiation property and capable of using a high-power light emitting element, minimizing the irradiation efficiency lowering of reflected light, and collecting / irradiating a large-output light with a high efficiency. The light emitting device includes: a case (10) made of a metal material and having an excellent heat radiation property; a reflecting mirror unit (11) formed so as to be engaged with the lower portion of the case (10); a light-transparent transparent plate (12) covering the upper surface of the case (10); heat radiation plates (13, 14) made of a metal material having an excellent heat conductivity and inserted into the case (10); an LED element (2) mounted on the heat radiation plate (13); lead portions (15A, 15B) fixed to the heat radiation plate (13) via an insulation layer (15a) so as to serve as power supply members for supplying power to the LED element (2); and a spacer (16) made of an insulating material for insulation between the lead portions (15A, 15B) and the case (10).

Owner:TOYODA GOSEI CO LTD

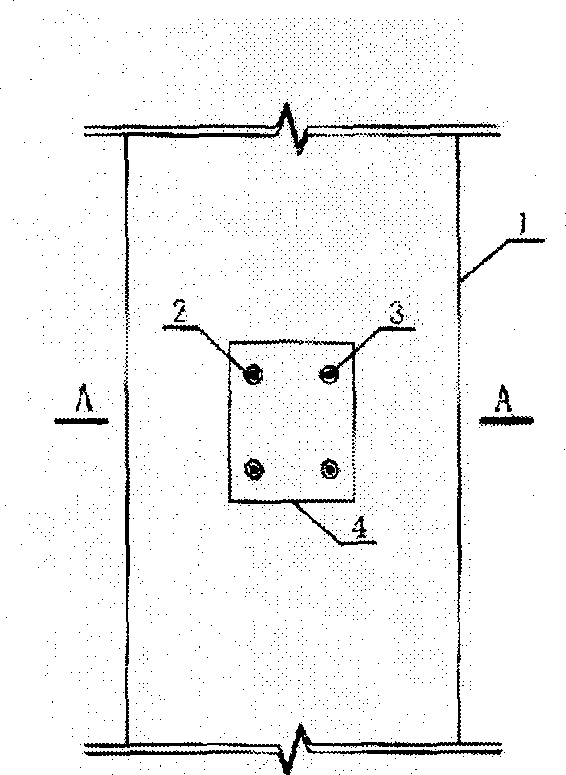

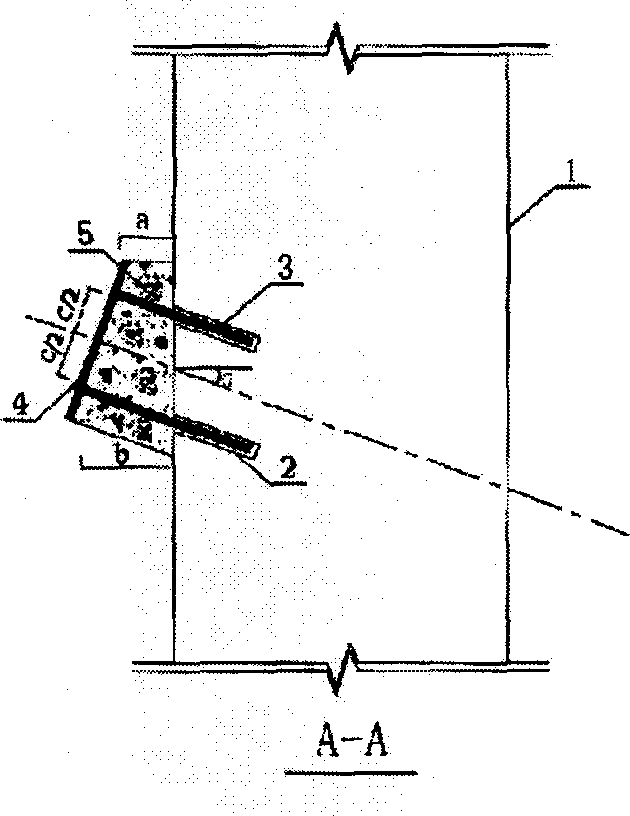

Concrete combined cushion wedge for supporting waist beam for pile anchoring system, and its constrection method

The invention relates to a foundation pit engineering of constructing by pile-anchor timbering system. And the invention provides a concrete combined padding wedge, mainly comprising inner and outer parts, where the inner part is composed of bores, reinforcing steel bars and cement mortar, where the reinforcing steel bars are inserted in bores on the wall protection pile and the cement mortar is poured for anchoring; and the outer part is composed of concrete and steel padding plate, where the outer and inner steel plates are located and welded together, and the concrete is poured so that the reinforcing steel bars, steel padding plates and cast-in-site concrete form the combined padding wedge. At the time of concrete construction, firstly locating reinforcing steel bars, cutting holes and then anchoring the reinforcing steel bars with cement mortar and welding with the steel padding plates and moulding the cast-in- site concrete to form the concrete combined padding wedge. And its beneficial effects: effectively reducing wale section size and reducing engineering cost; assuring the whole wale stability, having stronger vertical load bearing ability and improving safety and stability of constructing course.

Owner:DALIAN UNIV OF TECH

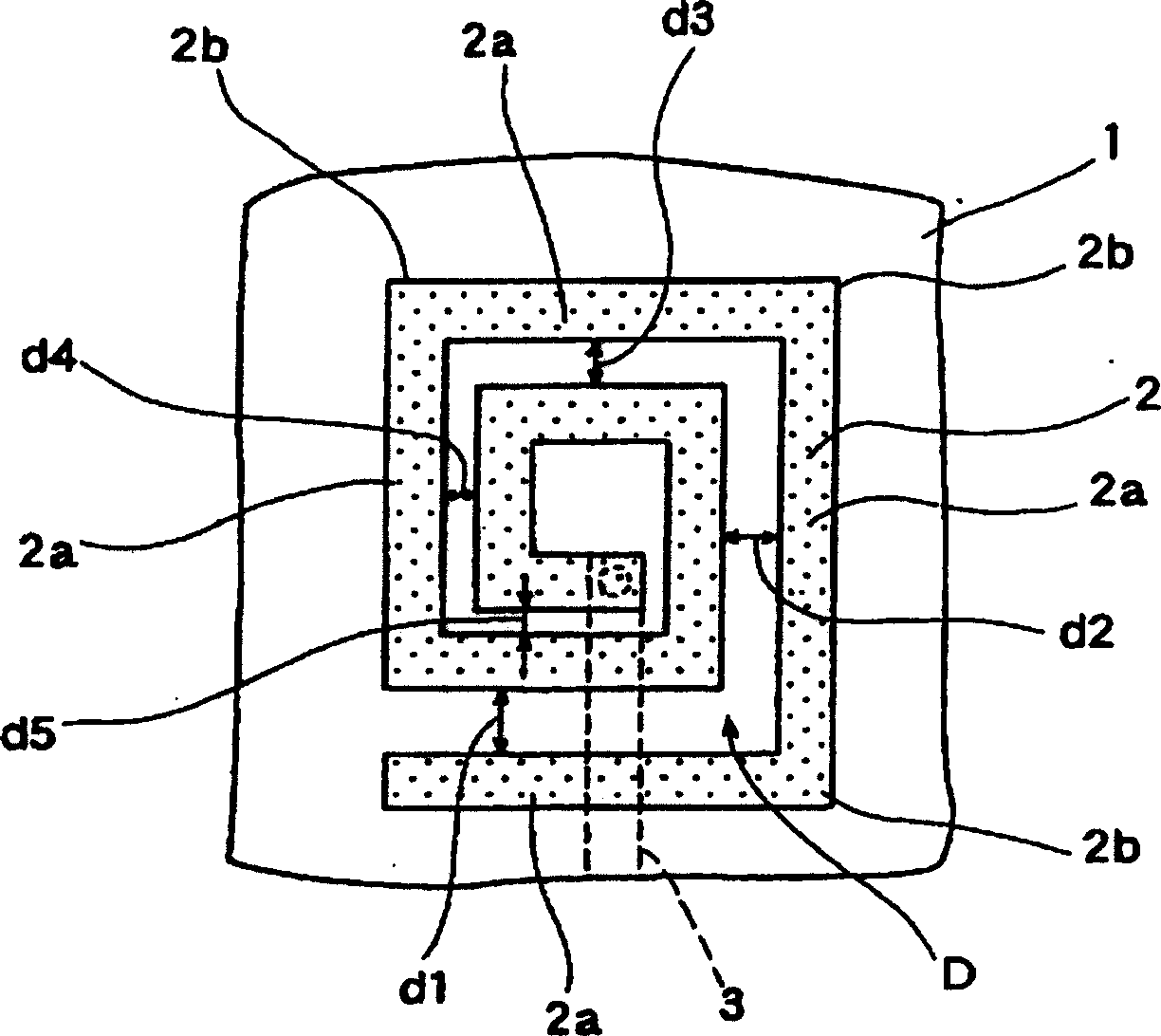

Screw electric inductor

Provided is a spiral inductor capable of increasing the Q thereof as much as possible while suppressing the deterioration of a self resonance frequency as much as possible. The spiral inductor is provided with a flat sheet type insulating substrate 1, and a conductor 2 formed of a conductor pattern on at least one side of the insulating substrate 1 and arranged spirally while retaining an interval D between the neighboring conductive patterns so as to have a given width. The interval d5 of inside of the spiral shape is formed so as to be narrower than another interval d1 of the outside of the spiral shape whereby the winding diameter of the conductor 2 positioned at the inside of the spiral shape becomes big and connection between the conductors becomes dense, thereby increasing an inductance and, as a result, the Q (Quality factor) can be increased.

Owner:ALPS ALPINE CO LTD

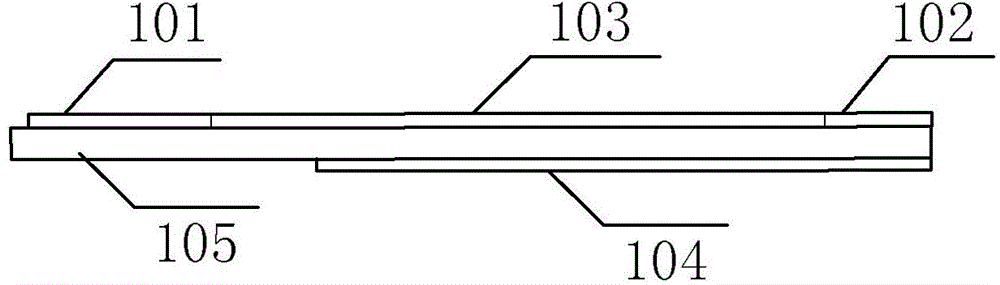

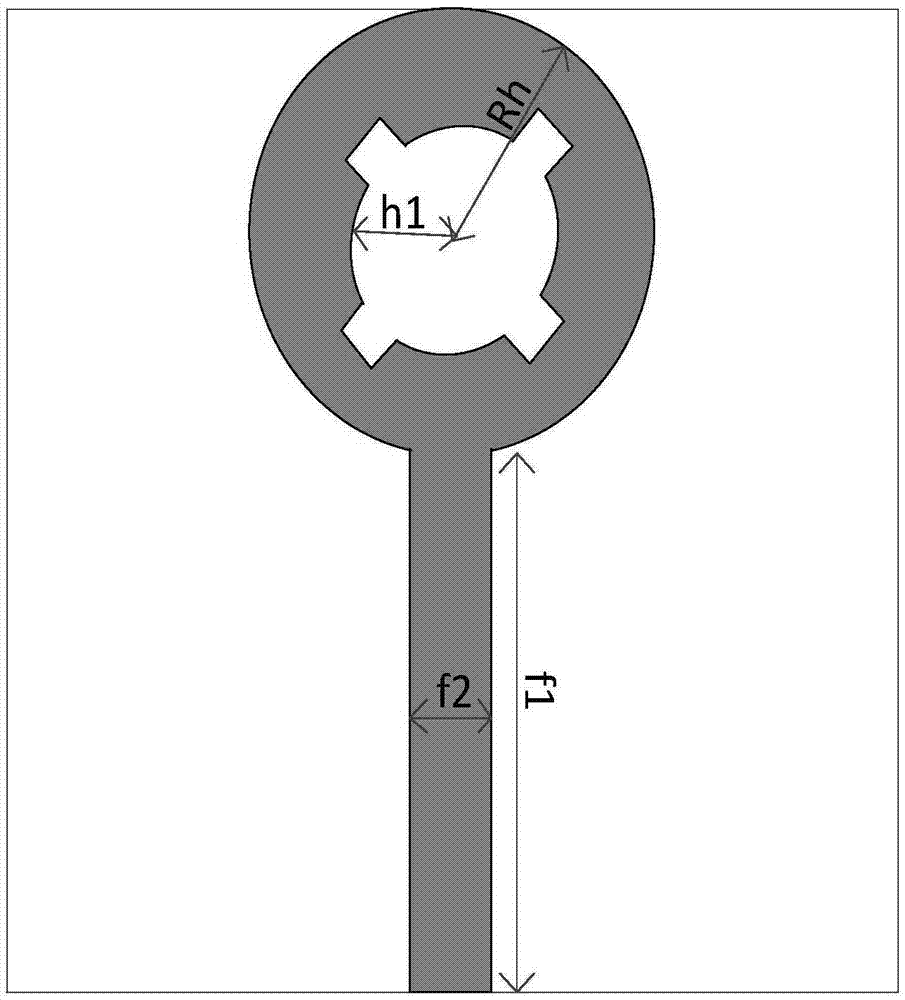

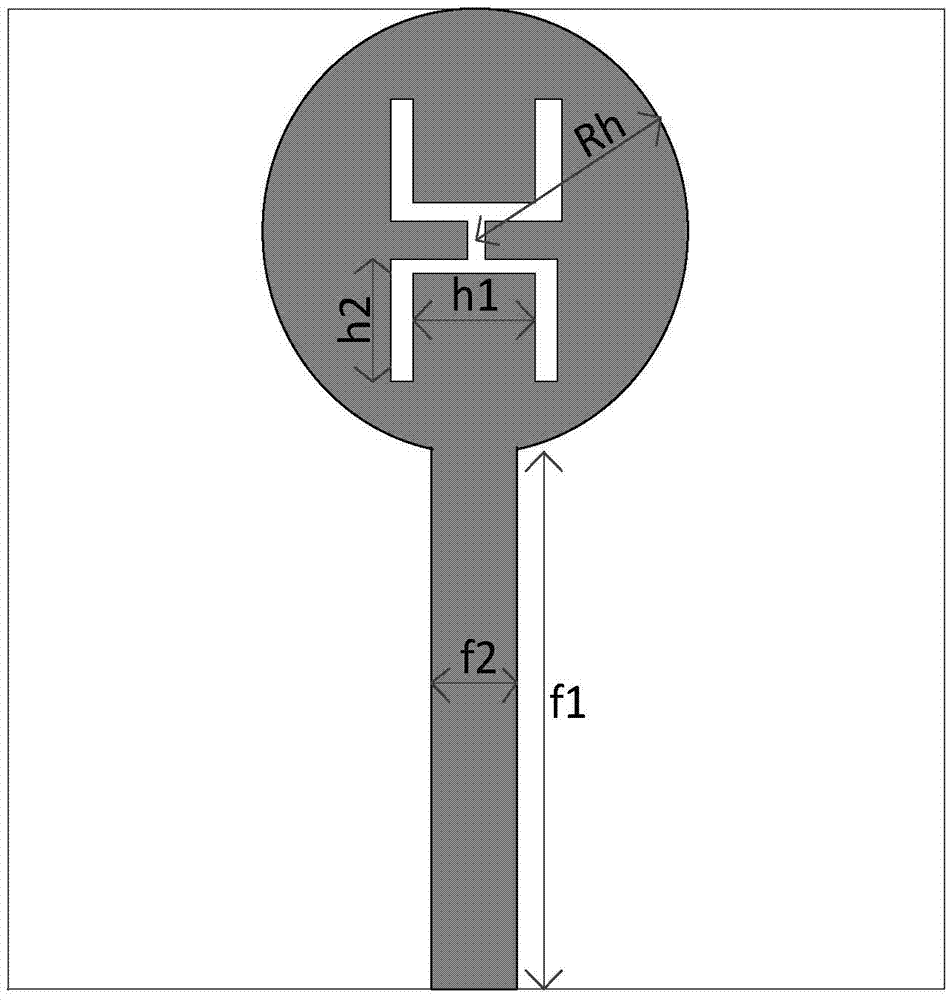

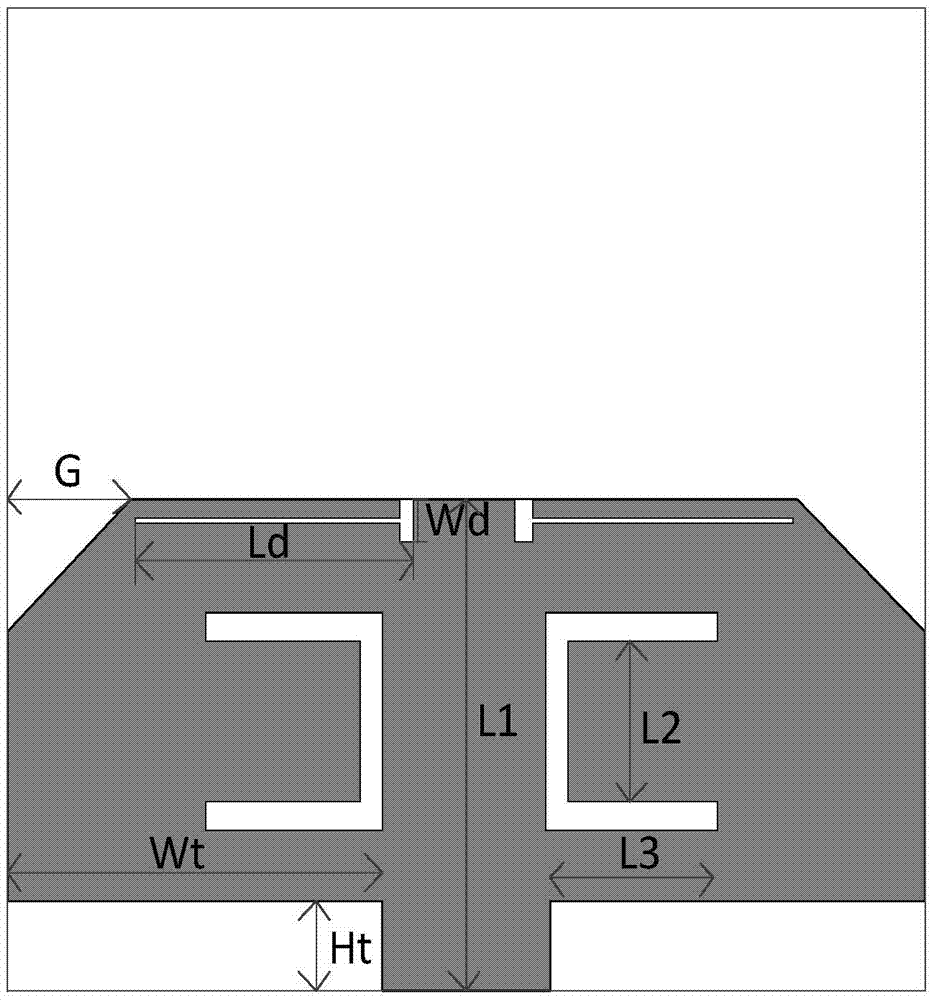

UWB (Ultra-wideband) band-notch antenna with steep stop band

InactiveCN104681956ASimple designCompact structureRadiating elements structural formsAntenna couplingsUltra-widebandDielectric substrate

The invention discloses a UWB (ultra-wideband) band-notch antenna with a steep stop band and relates to a UWB band-notch antenna. The UWB band-notch antenna comprises a dielectric substrate (105), a radiating element (101), a square etching fractal structure (106), an impedance matching input microstrip line (102) and a cross type EBG (Electromagnetic Band Gap) structure (103) which are arranged on the dielectric substrate, and a metal ground plate (104) which is arranged under the dielectric substrate. According to the UWB band-notch antenna, the pass band width, which conforms to UWB requirements, is implemented through the radiating element, the impedance matching input microstrip line and the metal ground plate, and the steep stop band is formed by utilizing the cross type EBG structure (103) and the square etching fractal structure on the radiating element. The stop band of the antenna related by the invention is close to 6.8 Ghz, so that the mutual interference with an RFID (Radio Frequency Identification Device) system (6.8 Ghz) is avoided.

Owner:HARBIN HESON SCI & TECH

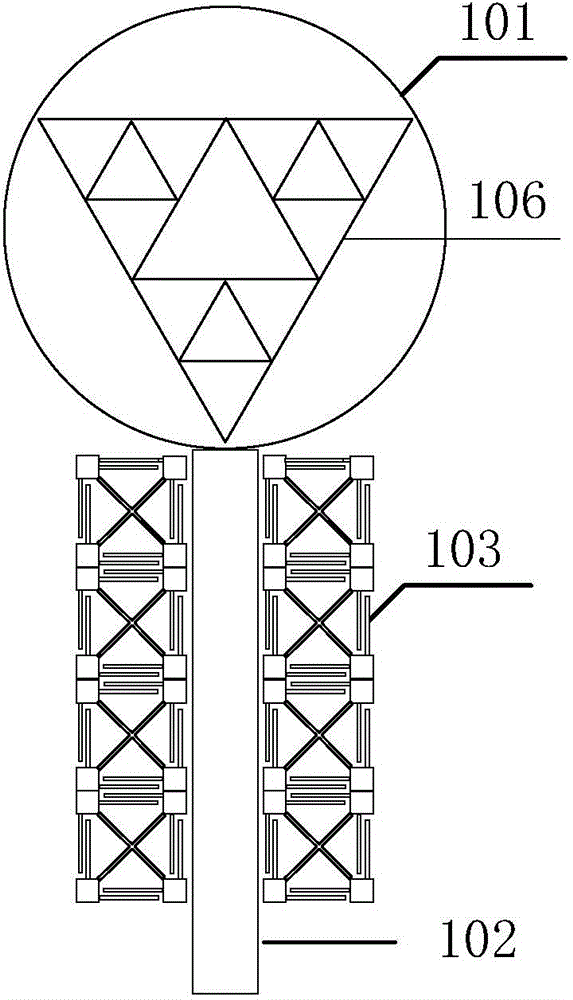

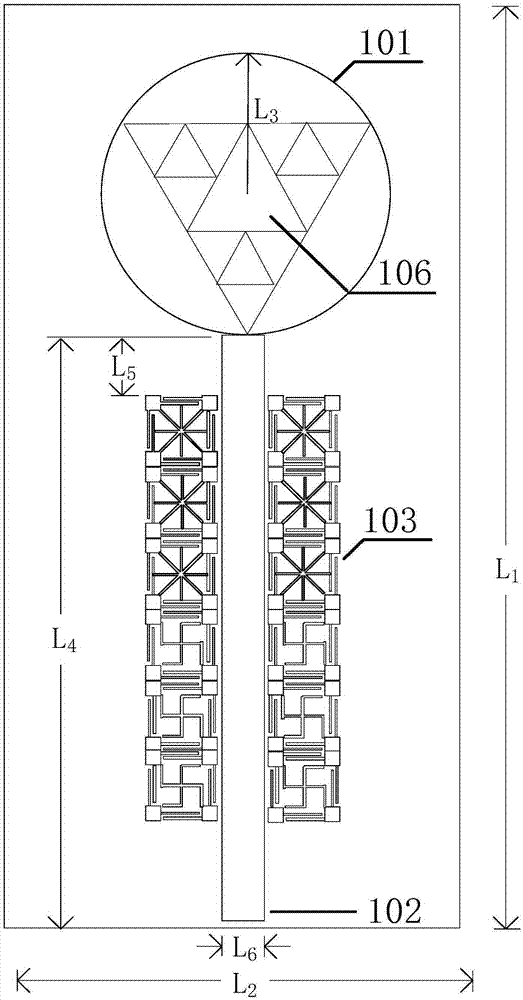

Novel attenuation band steep UWB (Ultra Wide Band) band-notch antenna

InactiveCN104681966ASimple designCompact structureRadiating elements structural formsAntenna couplingsUltrasound attenuationDielectric substrate

The invention discloses a novel attenuation band steep UWB (Ultra Wide Band) band-notch antenna, and relates to an UWB band-notch antenna. The novel attenuation band steep UWB band-notch antenna is formed by a dielectric substrate (105), a radiation unit (101) on the dielectric substrate, a Sierpinski triangular fractal structure (106), an impedance matching input micro-strip line (102), a cross-shaped EBG (Electromagnetic Band Gap) structure (103) and a metal grounding plate (104) under the dielectric substrate. According to the novel attenuation band steep UWB band-notch antenna disclosed by the invention, passband width required by UWB can be realized by utilizing the radiation unit, the impedance matching input micro-strip line and the metal grounding plate, and a steep attenuation band is formed by utilizing the cross-shaped EBG structure (103) and the Sierpinski triangular fractal structure on the radiation unit; the frequency of an antenna attenuation band is about 6.8Ghz, and the mutual interference with an RFID (Radio Frequency Identification device) system (the frequency is 6.8Ghz) is avoided.

Owner:HARBIN HESON SCI & TECH

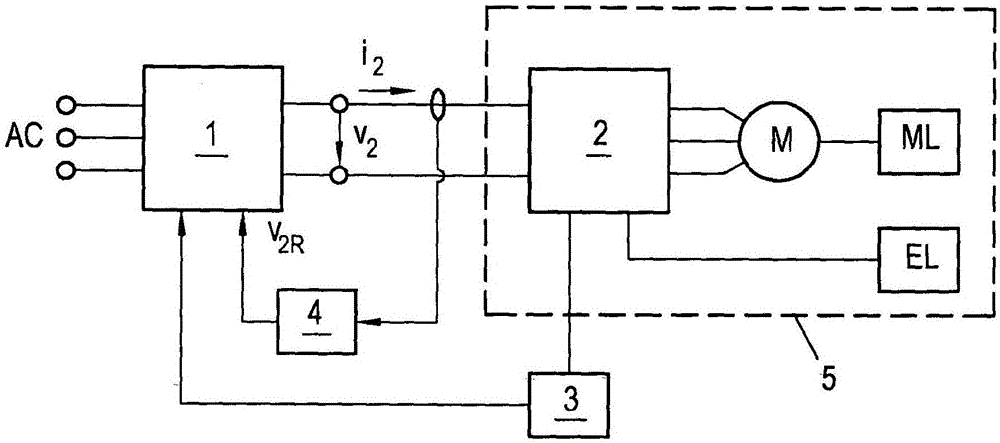

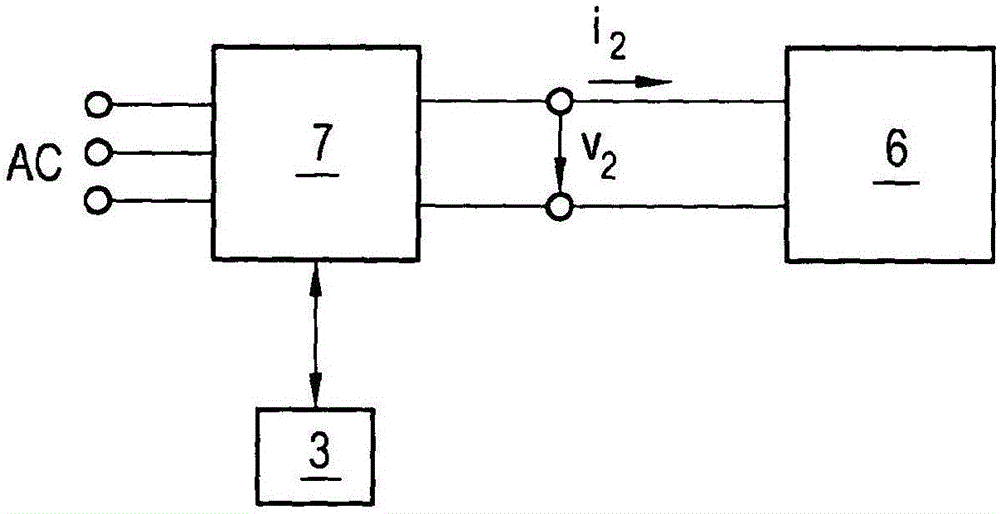

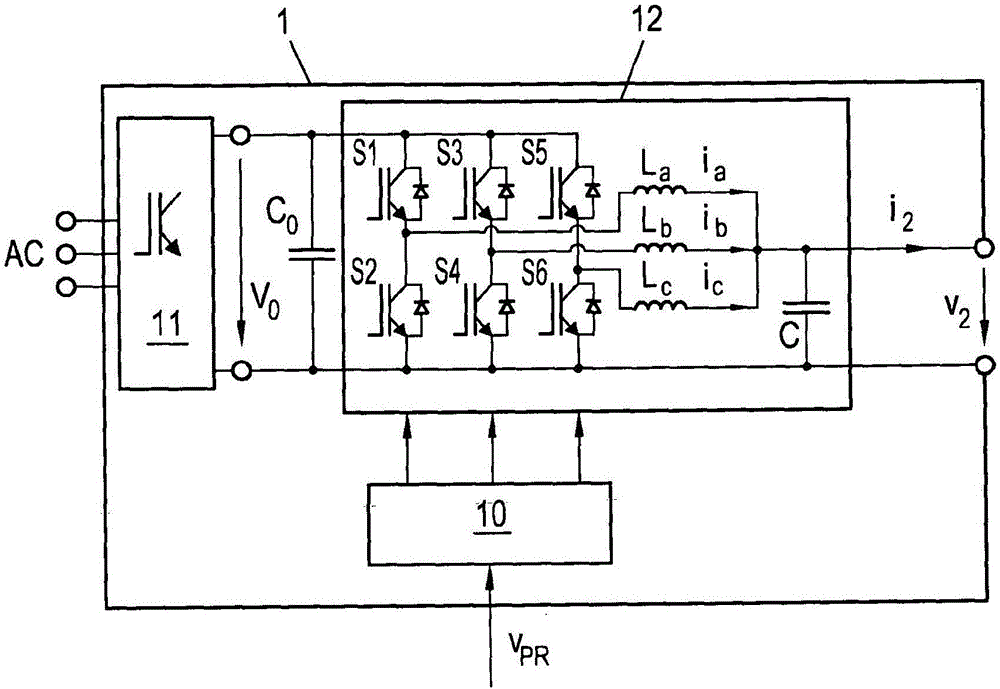

Method and controller for model predictive control of multi-phase dc/dc converter

ActiveCN106164689ANarrow finite control setNarrow solution spaceSimulator controlDc-dc conversionThe chokesOptimization problem

For an easily implementable method for model predictive control of a DC / DC converter, and a corresponding controller, with which the optimization problem of the model predictive control can also be solved sufficiently quickly with large prediction horizons, the optimization problem is divided into two optimization problems by a model predictive output variable control and a model predictive choke current control being implemented in the control unit (10), wherein the strands of the multi-phase DC / DC converter (12) for the output variable control are combined into a single strand and a time-discrete state space model is produced therefrom and the output variable control predicts the input voltage (uv,k+1) of the next sampling step (k+1) for this single strand on the basis of a first cost function (Jv) of the optimization problem of the output variable control, said input voltage being given to the choke current control as a setpoint and the choke current control therefrom determining the necessary switch positions of the switches (S1, S2, S3, S4, S5, S6) of the strands of the multi-phase DC / DC converter (12) for the next sampling step (k+1) on the basis of a second cost function (Ji) of the optimization problem of the choke current control.

Owner:AVL LIST GMBH

Automobile exhaust manifold silencer

InactiveCN106555656AEasy to separateQuick releaseExhaust apparatusSilencing apparatusButt jointAdhesive

The invention discloses an automobile exhaust manifold silencer which comprises a main body, an air inlet pipe and an end cover. A silencer core body is fixed in the main body, and both ends of the silencer core body run through the end part of the main body and the middle part of the end cover. An annular groove is arranged in the open end face of the main body. An extension part which matches the annular groove is arranged in the middle part of the seal end of the end cover. An inclined face A is arranged at the upper part of the seal end face of the end cover. An inclined face B which shares the same inclination direction with the inclined face A is arranged on the end face of the main body. The inclined face A, the outer wall of the extension part and the inclined face B form an annular filling groove. The end part of the silencer core body is in butt joint with an intake pipe. A helical diversion trench is arranged in the inner wall of the intake pipe in the direction, which points to the main body, of the axis. On the seal end face of the end cover, an L-shaped contact face is formed on the outer wall between the extension end and a projection. Through a metal adhesive in the filling groove, the outer wall is completely separated from the inside of the main body to ensure that the airtightness of the silencer.

Owner:CHONGQING ZHANRUI AUTOMOBILE FITTING FACTORY

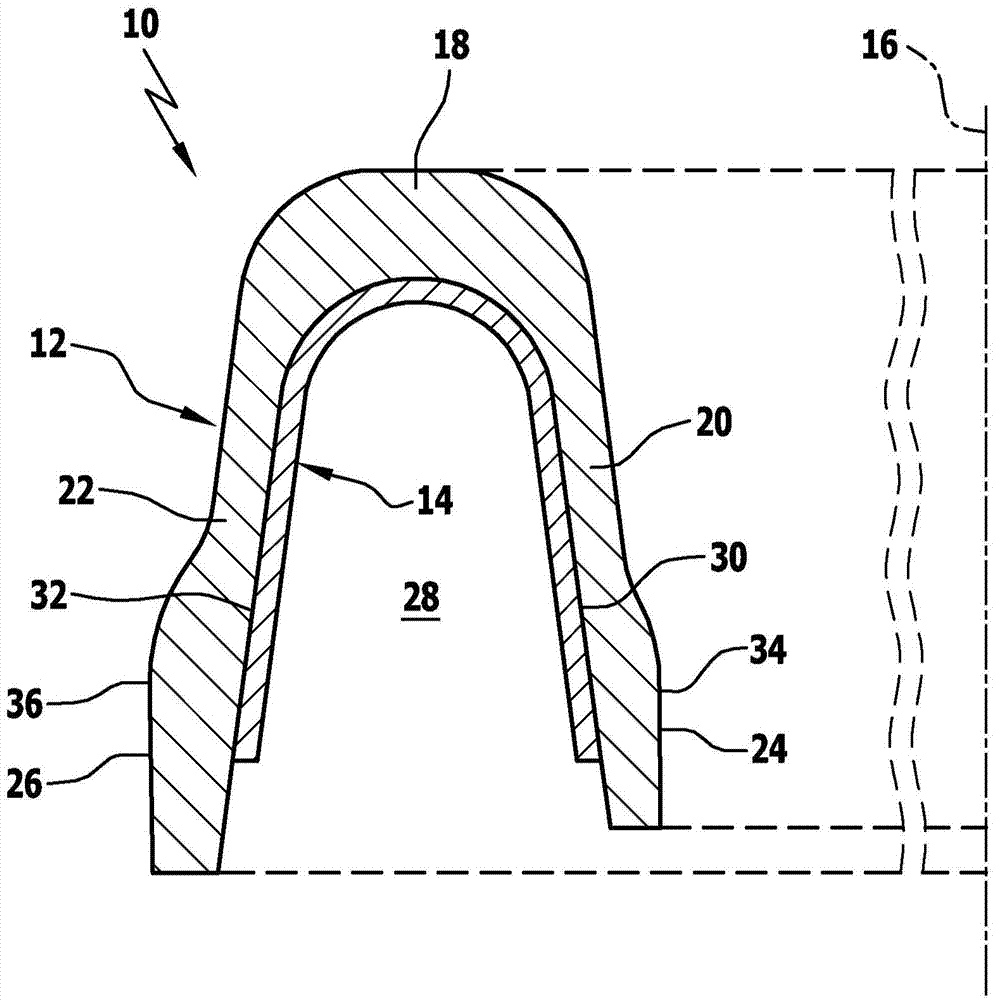

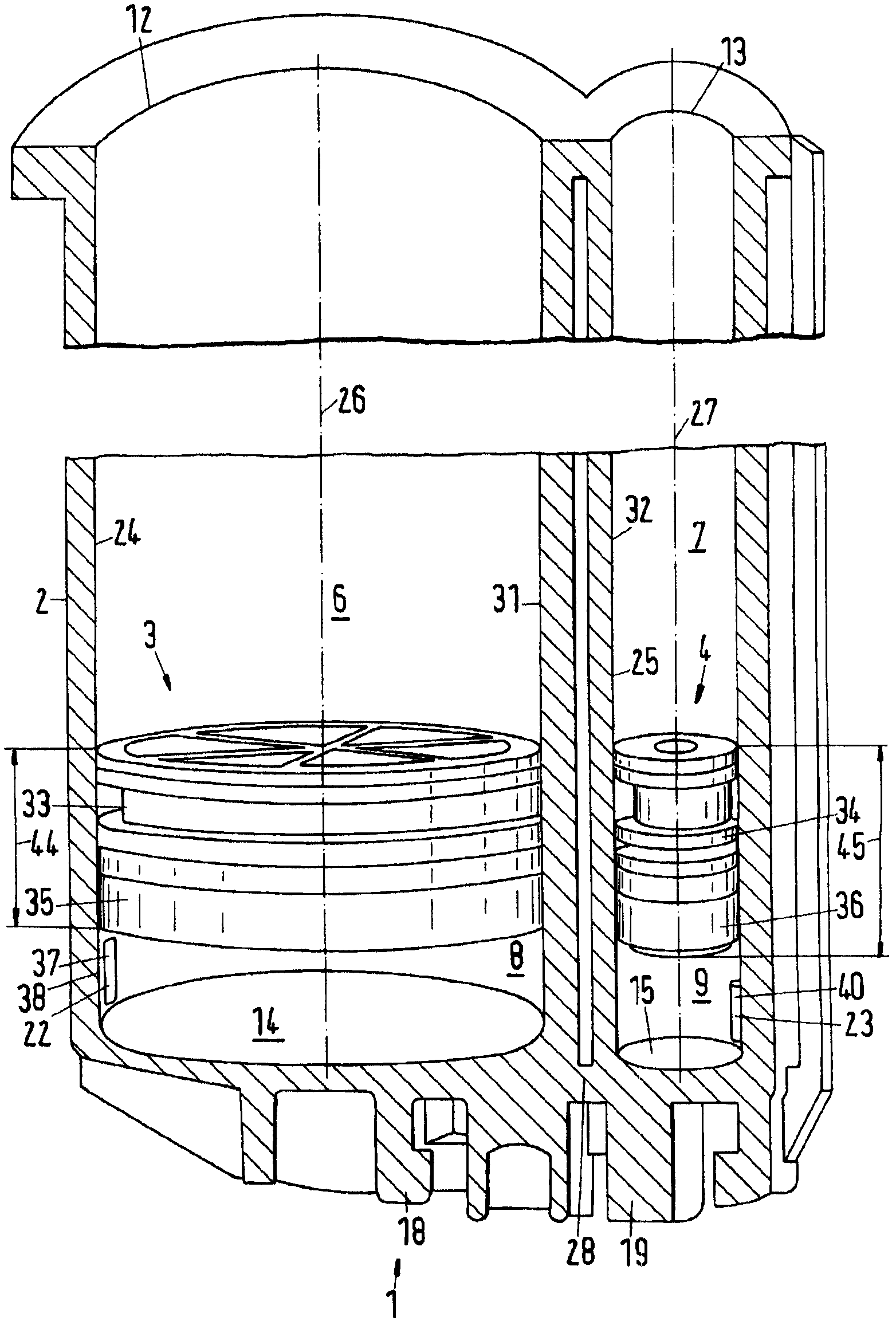

Sealing ring for pressure control valve

ActiveCN104854384AFriction minimizationHas widthEngine sealsCombustion enginesThermoplasticTurbocharger

The present invention relates to a sealing ring (10) for a pressure control valve for controlling the charge pressure in an internal combustion engine with a turbocharger, comprising • - a sealing body (12) which is rotationally symmetrical with respect to a cylinder axis (16) and is made of a material which comprises as main constituent one or more perfluorinated thermoplastics, wherein the sealing body (12) has a substantially U-shaped cross-sectional profile with an apex region (18) and two sealing lips (20, 22) which, starting from the apex region (18), extend parallel to one another or with an opening angle at least approximately in the direction of the cylinder axis (16); and • - a spring element (14) which is rotationally symmetrical with respect to the cylinder axis (16) and is made of steel and has a substantially U-shaped cross-sectional profile, wherein the spring element (14) is arranged between the sealing lips (20, 22) of the sealing body (10) in such a way that it bears directly against the mutually facing surfaces (30, 32) thereof.

Owner:ELRINGKLINGER AG

Face-painting product having function of dispelling stria gravidarum and method for preparing the same

ActiveCN101152138BPromote absorptionPenetrate more fasterCosmetic preparationsToilet preparationsCentella asiatica extractCollagen i

The present invention relates to a cosmetic product with dispelling striae gravidarum effectiveness and a manufacturing method. Nutrient components synergy and can repair the elastic fiber effectively. Sweet almond oil and olive oil in the formula are rich in unsaturated fatty acid, which is totally identical with fats secretory of human; so essential fatty acid is added; the skin is repaired. Vitamin E has anti-aging and antioxidant effectiveness; small molecule faba bean peptide and nanometer parcel epidermal growth factor biomimetic peptide have strong physiological excitation signal whichis easily absorbed by the skin; so the skin is stimulated to compose collagen which markedly amends the striae gravidarum. Centella asiatica extract can promote the composition of collagen I and III and can promote the composition of polysaccharide, which effective prevents and repairs the striae gravidarum.

Owner:天津盛世永业科技发展有限公司

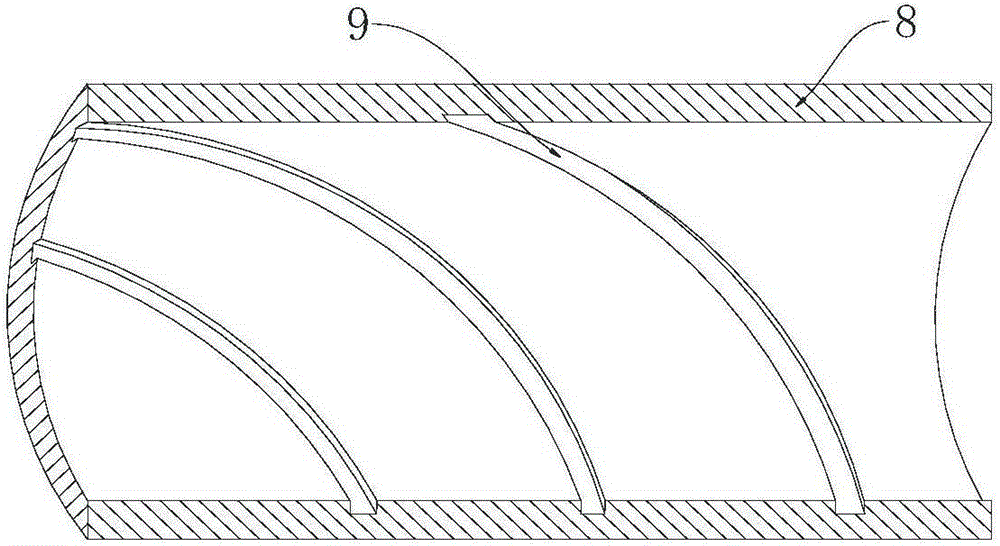

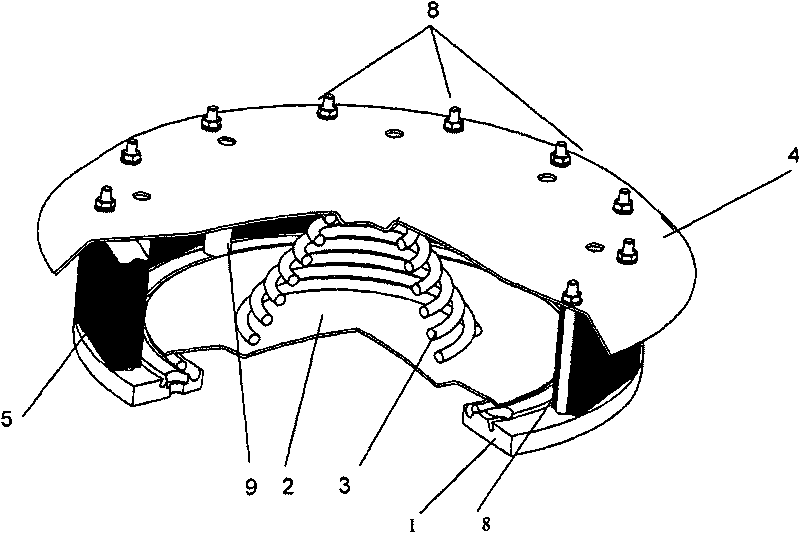

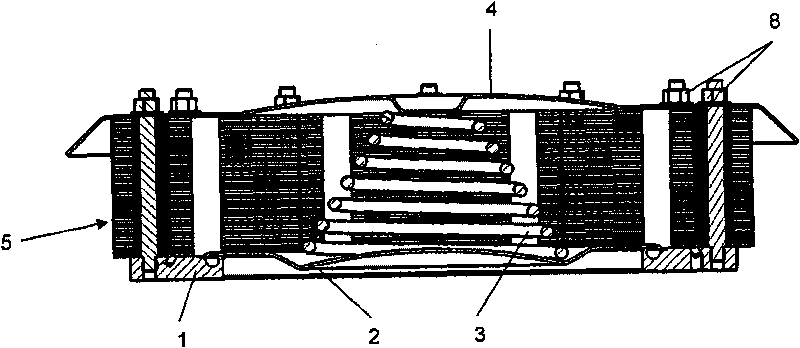

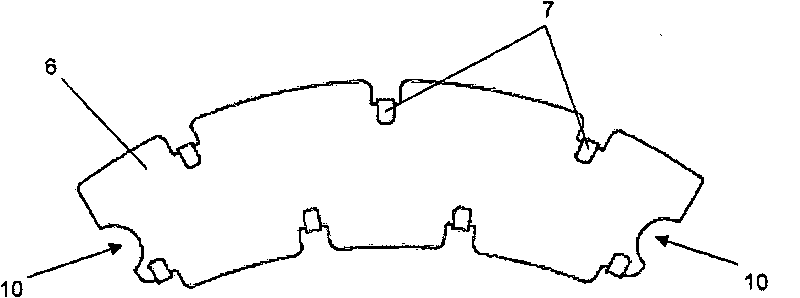

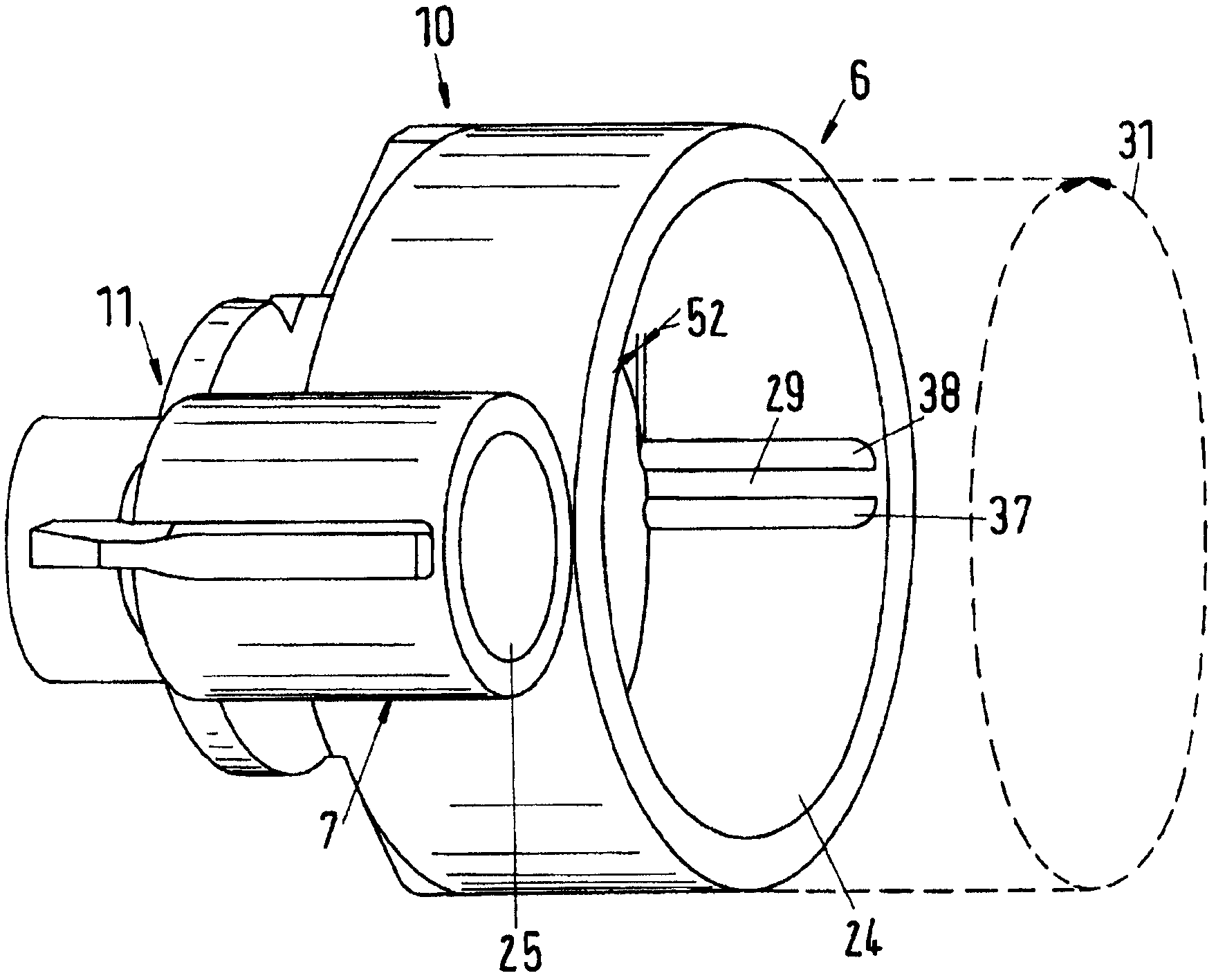

Flame filter

InactiveCN101721780ASmall processing consumptionImprove securityExhaust apparatusSilencing apparatusEngineeringRelief valve

The invention relates to a flame filter, especially used as a flame blocking device penetrated by the gas or used on an explosion pressure relief valve for enclosing a gas-filled space, the flame filter comprises stacked and flat boards (6) which are closely stacked, wherein, the adjacent boards (6) can determine flow gases for gas oriented in parallel with the plane. In order to implement the improved stability and safety for multi-time connection explosions, each board (6) is equipped with crimped sections (7), each section (7) is directly positioned on the boards (6).

Owner:HOERBIGER KOMPRESSORTECHNIK HLDG GMBH

UWB (Ultra wide band) band-notch antenna with steep stop band

InactiveCN104682004ASimple designCompact structureRadiating elements structural formsSlot antennasDielectric substrateImpedance matching

The invention provides a UWB (ultra wide band) band-notch antenna with a steep stop band, and relates to a UWB band-notch antenna. The antenna is composed of a dielectric substrate (105), a radiating element (101) arranged on the dielectric substrate, a square etching fractal structure (106), an impedance matching input microstrip line (102), a fold line type EBG (Electromagnetic Band Gap) structure (103) and a metal grounding plate (104) below the dielectric substrate. The UWB band-notch antenna with the steep stop band disclosed by the invention realizes the bandpass width required by UWB by using the radiating element, the impedance matching input microstrip line and the metal grounding plate, and forms the steep stop band by using the fold line type EBG structure and the square etching fractal structure on the radiating element. The antenna stop band that the invention relates to is near 5.2 GHz, which avoids the mutual interference with a WLAN (Wireless Local Area Network) system (5.15-5.35 GHz).

Owner:HARBIN HESON SCI & TECH

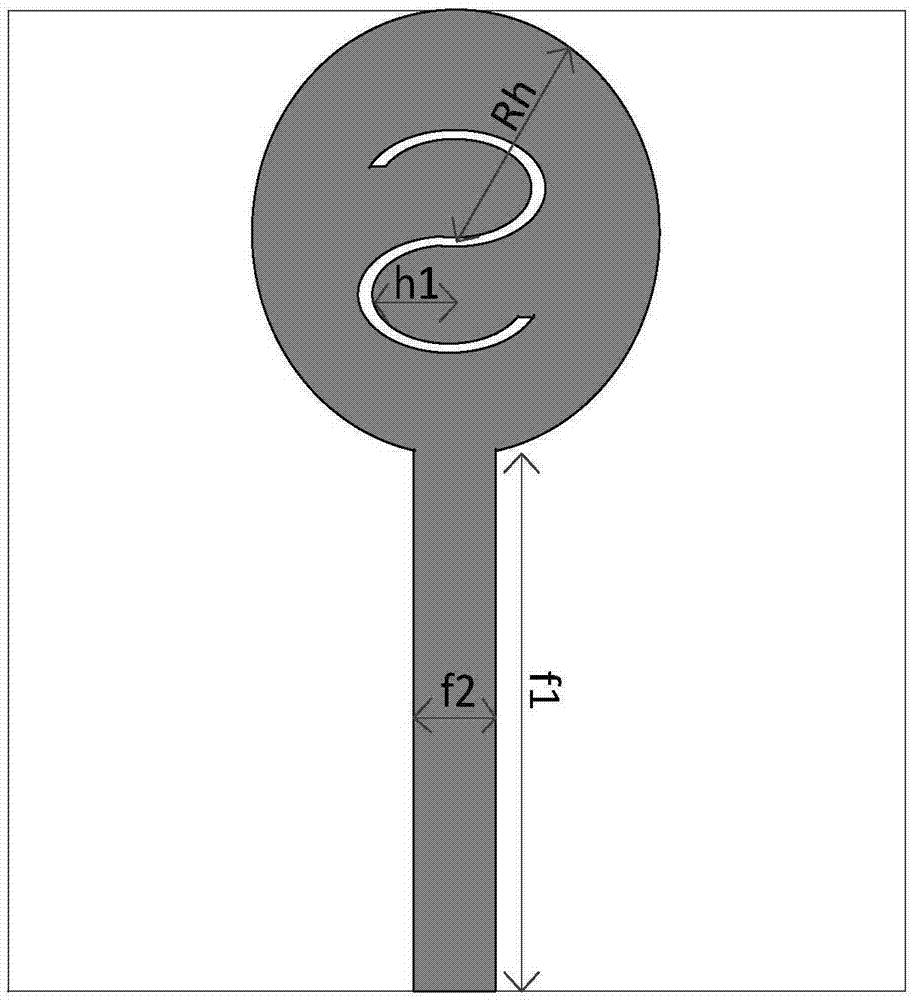

Novel stop band steep ultra wide band (UWB) antenna

InactiveCN106876942ASimple designCompact structureRadiating elements structural formsAntenna couplingsFrequency bandDielectric substrate

A novel stop band steep UWB antenna relates to a UWB band-stop antenna of which the notch frequency band is located at the WLAN and WiMAX frequency bands, and is composed of a dielectric substrate (106), a radiation unit (101) formed on the dielectric substrate, an impedance matching input microstrip line (102) and a defected ground structure (DGS) (107). A groove is notched on the radiation unit (101) on the dielectric substrate, and the DGS is composed of T-shaped grooves (104) and square grooves (105). The novel stop band steep UWB antenna of the present invention realizes the passband bandwidth required by the UWB by utilizing the radiation unit, the impedance matching input microstrip line and a metal grounding plate, utilizes the circular radiation unit to improve the stop band attenuation inhibition, and utilizes the DGS and the groove on the radiation unit to realize the notch characteristic. The stop band of the antenna involved in the present invention is nearby 3.7 GHz and 5.75 GHz, thereby avoiding the mutual interference of a WLAN system and a WiMAX system.

Owner:HARBIN FEIYU TECH

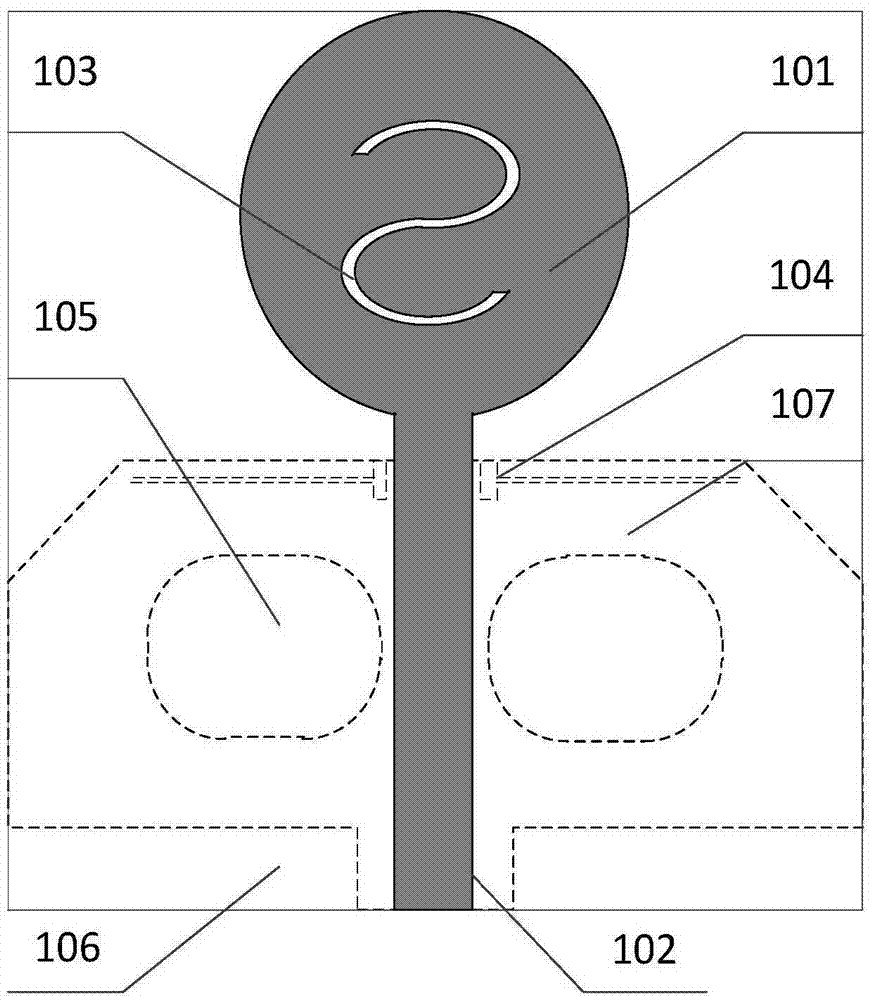

Ultra wide band antenna with dual-stop band function

InactiveCN106876945ASimple designCompact structureRadiating elements structural formsAntenna couplingsPhysicsFrequency band

An ultra wide band antenna with a dual-stop band function relates to an ultra wide band band-stop antenna of which the notch frequency band is located at the WLAN and WiMAX frequency bands, and is composed of a dielectric substrate (106), a radiation unit (101) formed on the dielectric substrate, an impedance matching input microstrip line (102) and a defected ground structure (DGS). An S-shaped groove (103) is notched on the radiation unit (101) on the dielectric substrate, and the DGS is composed of a T-shaped groove (104) and a rounded rectangular groove structure (105). The ultra wide band antenna with the dual-stop band function of the present invention realizes the passband bandwidth required by the ultra wide band by utilizing the radiation unit, the impedance matching input microstrip line and a metal grounding plate, utilizes the circular radiation unit to improve the stop band attenuation inhibition, and utilizes the DGS and the S-shaped groove on the radiation unit to realize the band stop characteristic. The stop band of the antenna involved in the present invention is nearby 3.7 GHz and 5.75 GHz, thereby avoiding the mutual interference of a WLAN system and a WiMAX system.

Owner:HARBIN FEIYU TECH

Novel dual-notch ultra wide band (UWB) antenna

InactiveCN106876944ASimple designCompact structureSimultaneous aerial operationsRadiating elements structural formsDielectric substrateImpedance matching

A novel dual-notch UWB antenna relates to a UWB band-stop antenna of which the notch frequency band is located at the WLAN and WiMAX frequency bands, and is composed of a dielectric substrate (106), a radiation unit (101) formed on the dielectric substrate, an impedance matching input microstrip line (102) and a defected ground structure (DGS) (107). A groove (103) is notched on the radiation unit (101) on the dielectric substrate, and the DGS is composed of a T-shaped groove (104) and a circular groove structure (105). The novel dual-notch UWB antenna of the present invention realizes the passband bandwidth required by the UWB by utilizing the radiation unit, the impedance matching input microstrip line and a metal grounding plate, utilizes the circular radiation unit to improve the stop band attenuation inhibition, and utilizes the DGS and the groove on the radiation unit to realize the notch characteristic. The stop band of the antenna involved in the present invention is nearby 3.7 GHz and 5.75 GHz, thereby avoiding the mutual interference of a WLAN system and a WiMAX system.

Owner:HARBIN FEIYU TECH

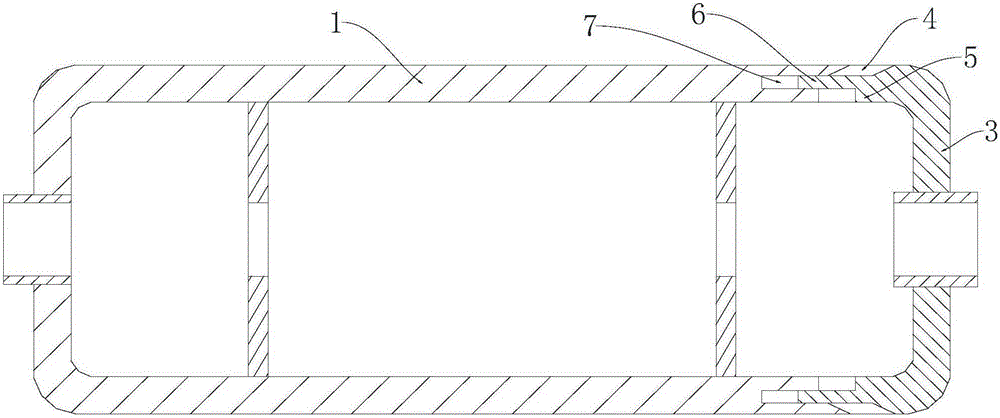

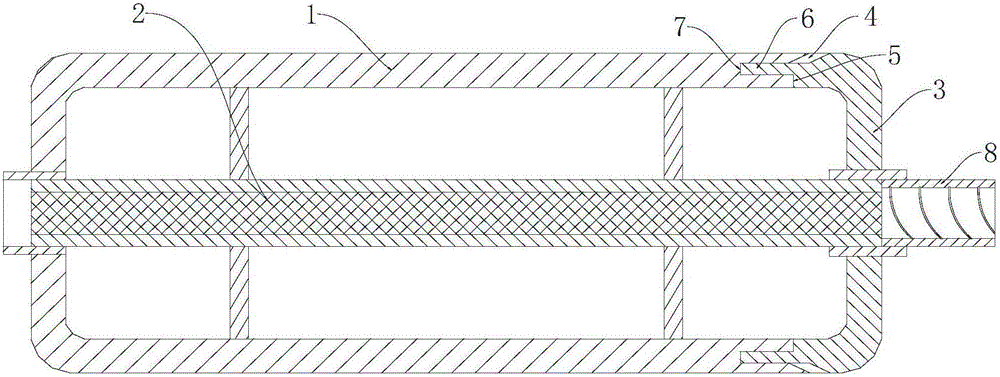

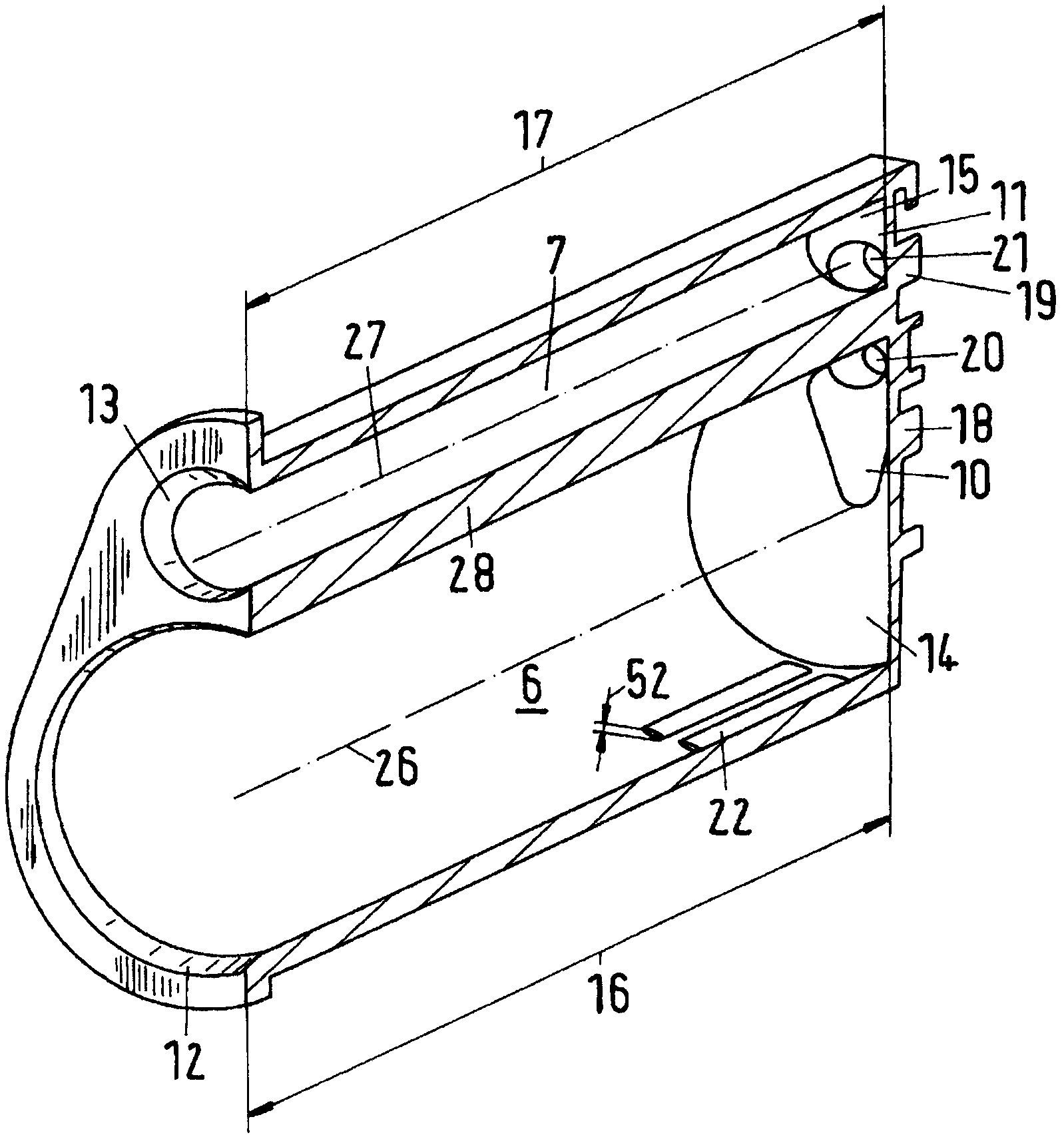

Multicomponent cartridge with venting apparatus

InactiveCN102482024AAllow escapeHas heightLiquid surface applicatorsInternal combustion piston enginesMechanical engineeringPiston

The invention relates to a multi-component cartridge (1) comprising a first reservoir (6) for a first component (8), and a second reservoir (7) for a second component (9), wherein the first reservoir (6) is separate from the second reservoir (7). The first reservoir (6) is arranged adjacent to the second reservoir (7). In the first reservoir (6), a first piston (3) is movably accommodated, and in the second reservoir (7), a second piston (4) is movably accommodated. Each of the first or second reservoirs is provided with a filling end (12, 13) and a discharge end (14, 15). The first and second reservoirs (6, 7) are connected to each other at least at the discharge end (14, 15). The first and second reservoirs (6, 7) have a first and second longitudinal dimension (16, 17) extending between the respective filling end (12, 13) and the corresponding discharge end (14, 15). The first reservoir (6) has a first inside wall (24), and the second reservoir (7) has a second inside wall (25), wherein the discharge end (14, 15) opens into a discharge element (18, 19) in a mouth. Upstream from the mouth (20, 21), a ventilation element (22, 23) is arranged on at least one of the inside walls (24, 25) of at least one of the first or second reservoirs (6, 7), wherein the ventilation element (22, 23) extends over maximally one third of the longitudinal dimension (16, 17) of the reservoir (6, 7).

Owner:SULZER MIXPAC AG

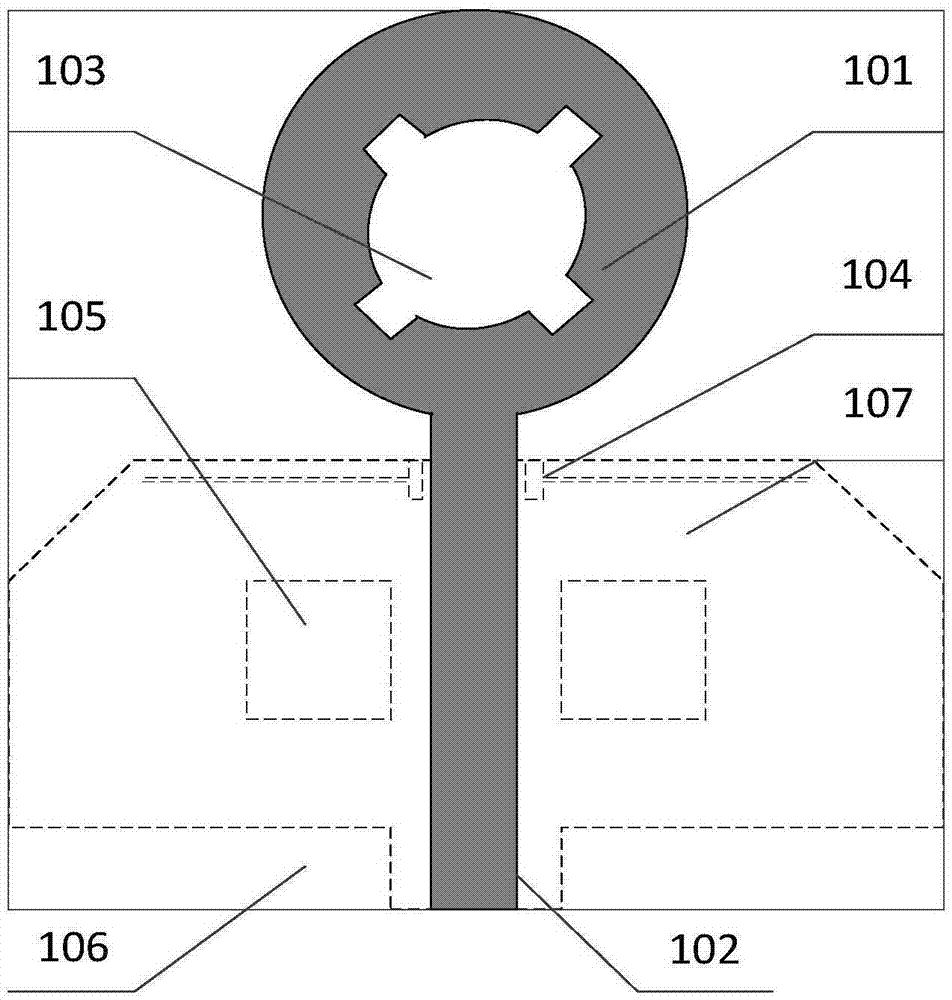

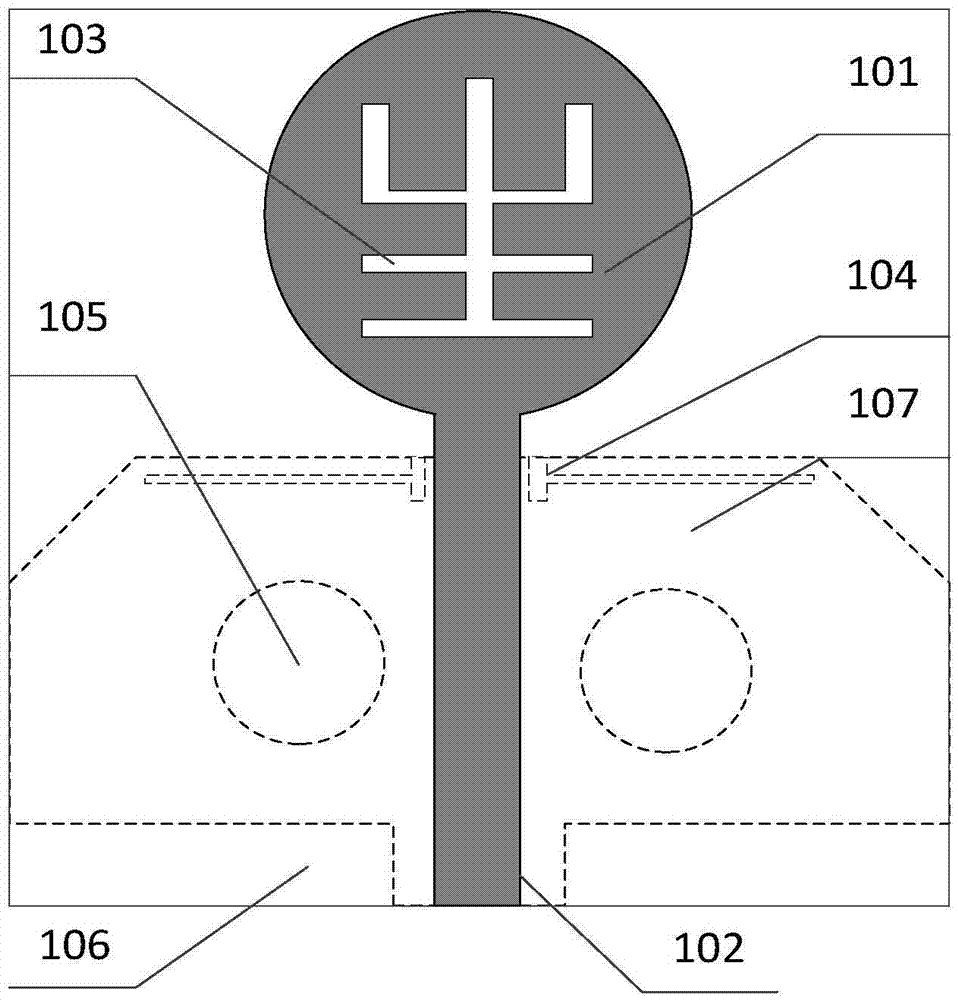

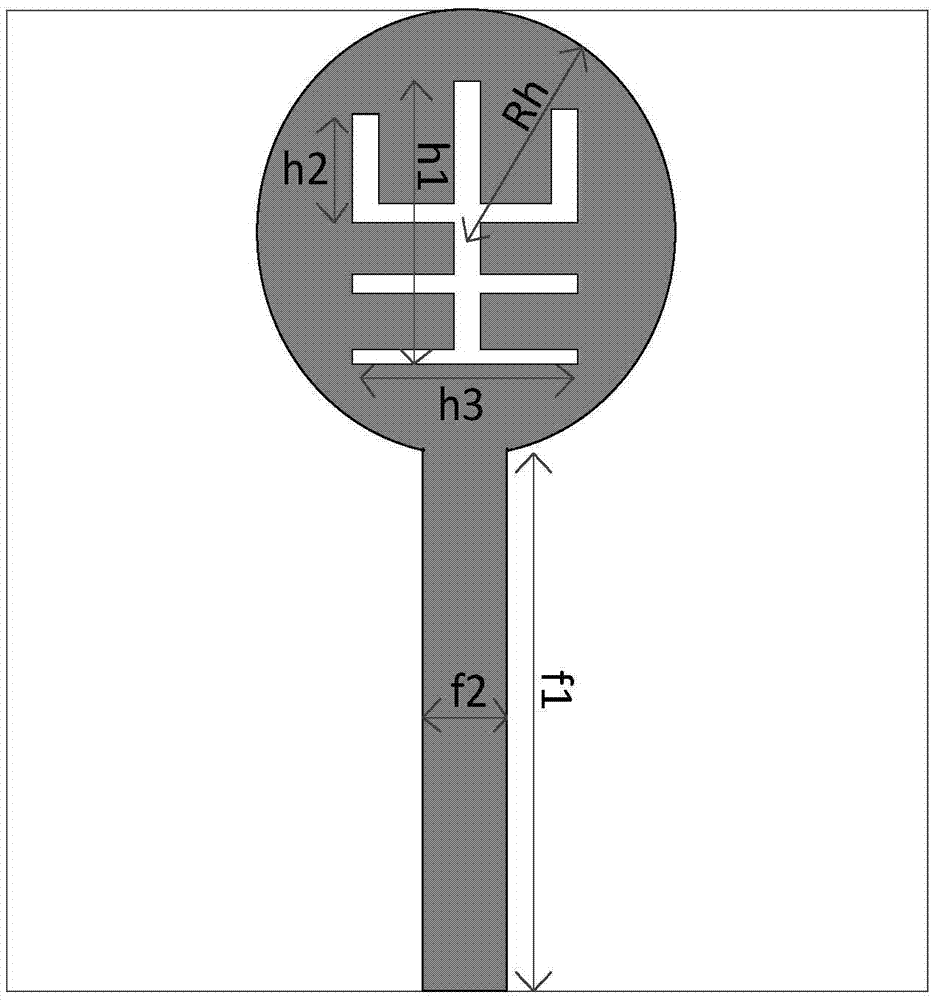

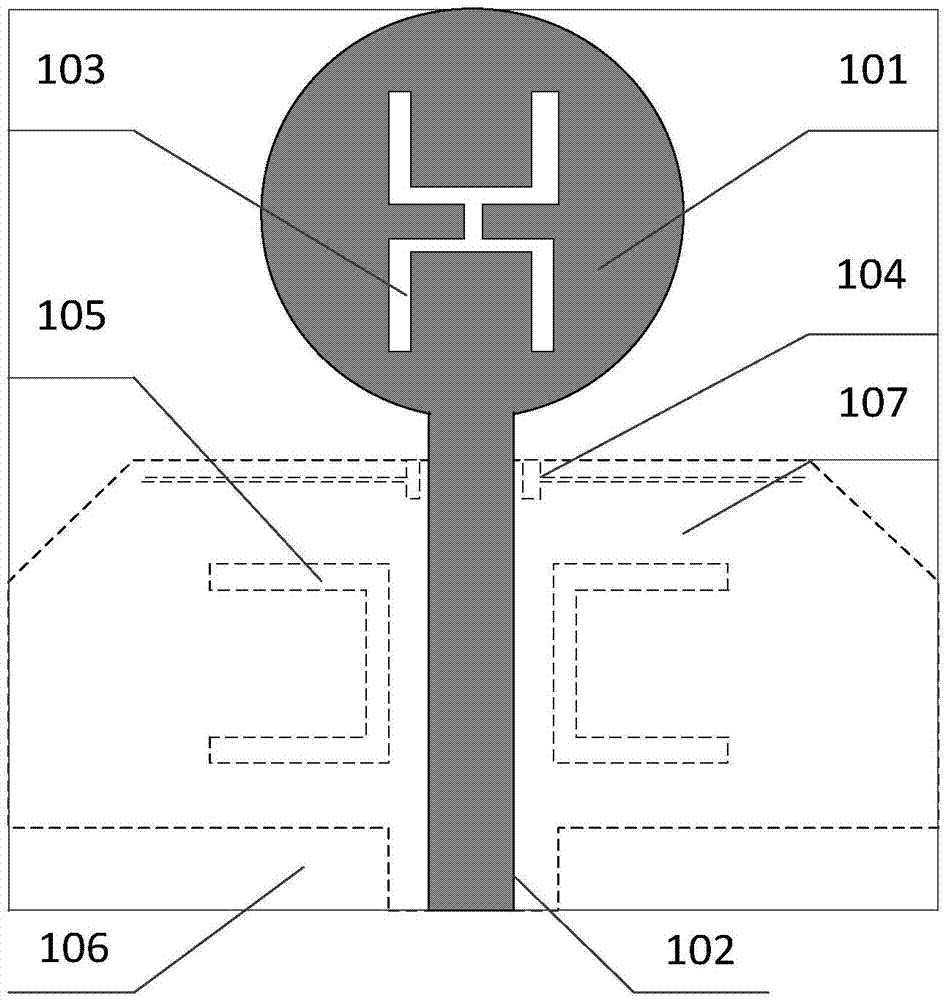

Stop band steep dual-notch ultra wide band (UWB) antenna

InactiveCN106876988ASimple designCompact structureSimultaneous aerial operationsRadiating elements structural formsChinese charactersDielectric substrate

A stop band steep dual-notch UWB antenna relates to a UWB band-stop antenna of which the notch frequency band is located at the WLAN and RFID frequency bands, and is composed of a dielectric substrate (105), a radiation unit (101) on the dielectric substrate, an impedance matching input microstrip line (102), a cross-shaped electromagnetic band gap (EBG) structure (103), an EBG structure (107) shaped like a Chinese character mi and a metal grounding plate (104) under the dielectric substrate. The stop band steep dual-notch UWB antenna of the present invention realizes the passband bandwidth required by the UWB by utilizing the radiation unit, the impedance matching input microstrip line and the metal grounding plate, utilizes the circular radiation unit with a circular fractal structure to improve the stop band attenuation inhibition, and utilizes the EBG structures to realize the band stop characteristic. The stop band of the antenna involved in the present invention is nearby 5.2 GHz and 6.8 GHz, thereby avoiding the mutual interference of a WLAN system and an RFID system.

Owner:HARBIN HESON SCI & TECH

Ultra wideband band-notch antenna based on crossed type EBG (Electromagnetic Band Gap) structure

InactiveCN104681963ASimple designCompact structureRadiating elements structural formsAntenna couplingsUltra-widebandDielectric substrate

The invention discloses an ultra wideband band-notch antenna based on a crossed type EBG (Electromagnetic Band Gap) structure, relating to an ultra wideband band-notch antenna. The antenna comprises a dielectric substrate (105), a radiating element (101), an impedance matching input microstrip line (102) and a crossed type EBG structure which are arranged on the dielectric substrate, and a metal earthing plate (104) arranged under the dielectric substrate. The ultra wideband band-notch antenna realizes passband width required by UWB (ultra wideband) by using the radiating element, the impedance matching input microstrip line and the metal earthing plate, and realizes band stop characteristic by using the crossed type EBG electromagnetic band gap structure. According to the ultra wideband band-notch antenna disclosed by the invention, a stop band is near 6.8Ghz, and the mutual interference with an RFID (Radio Frequency Identification) system is avoided.

Owner:HARBIN HESON SCI & TECH

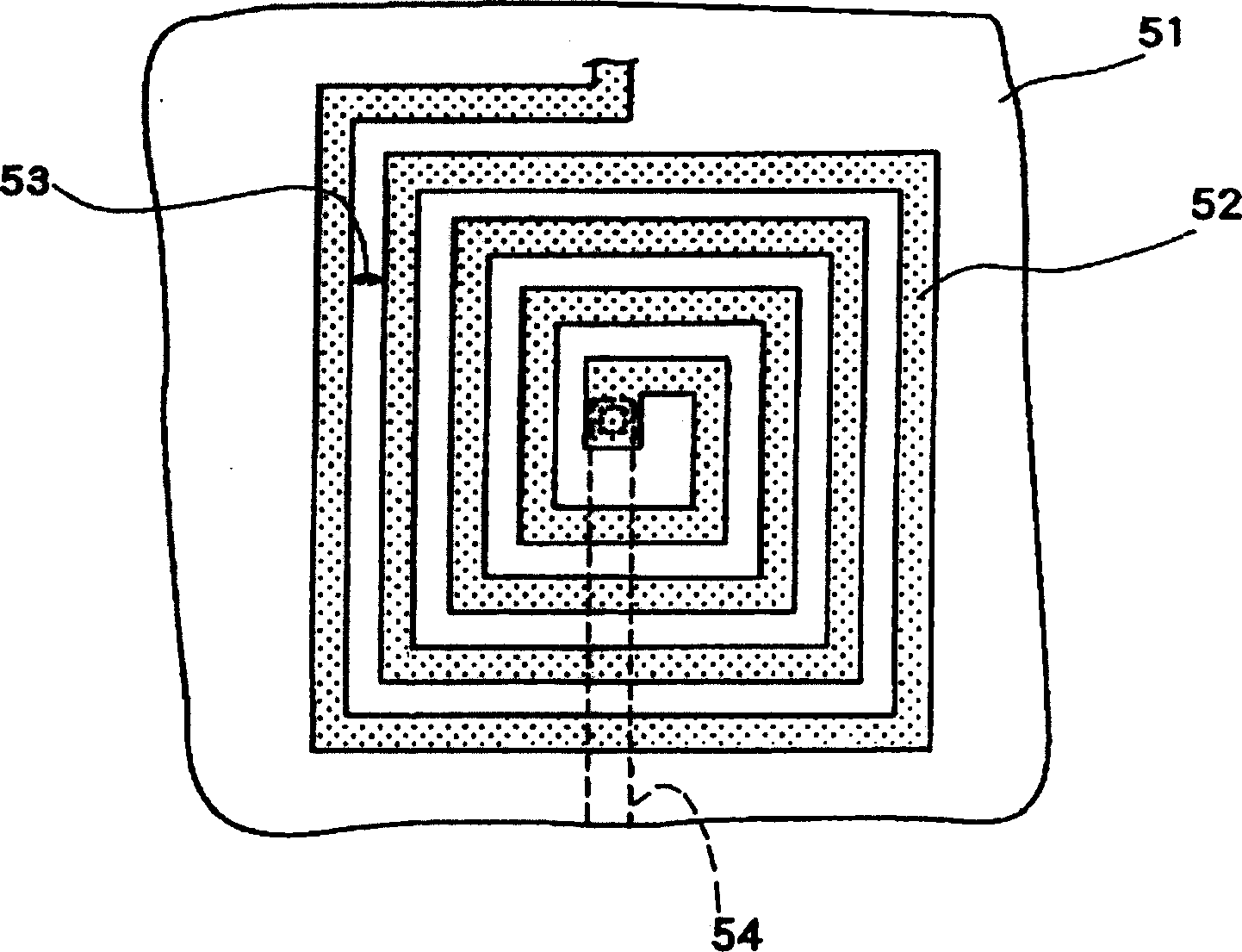

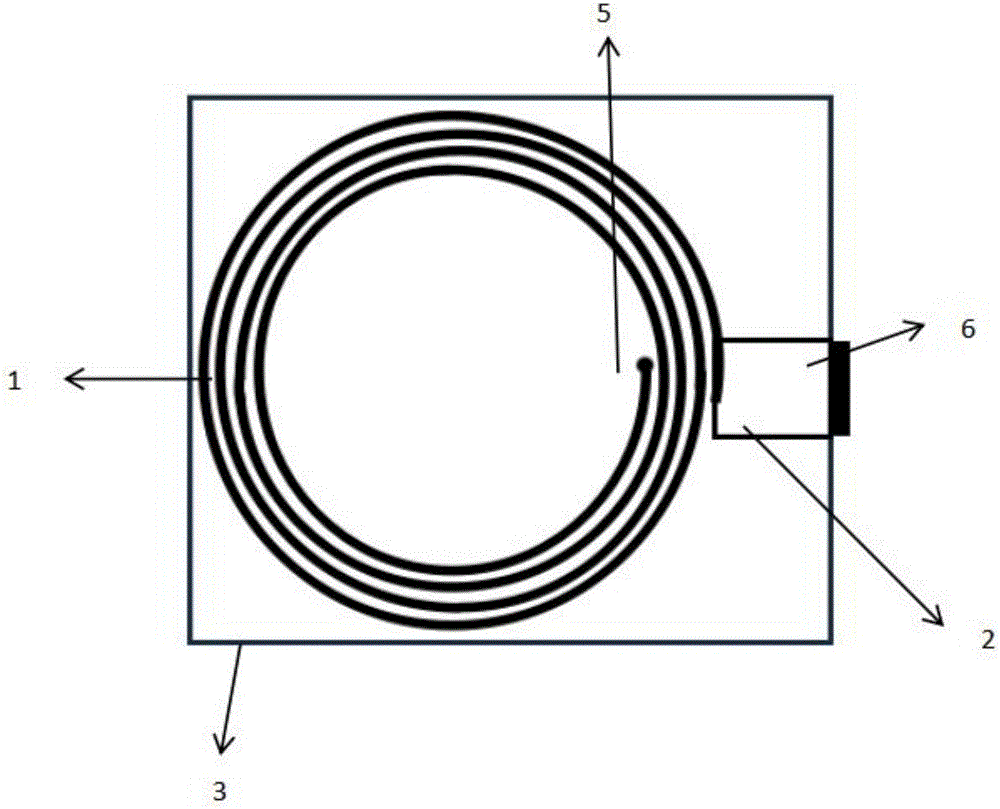

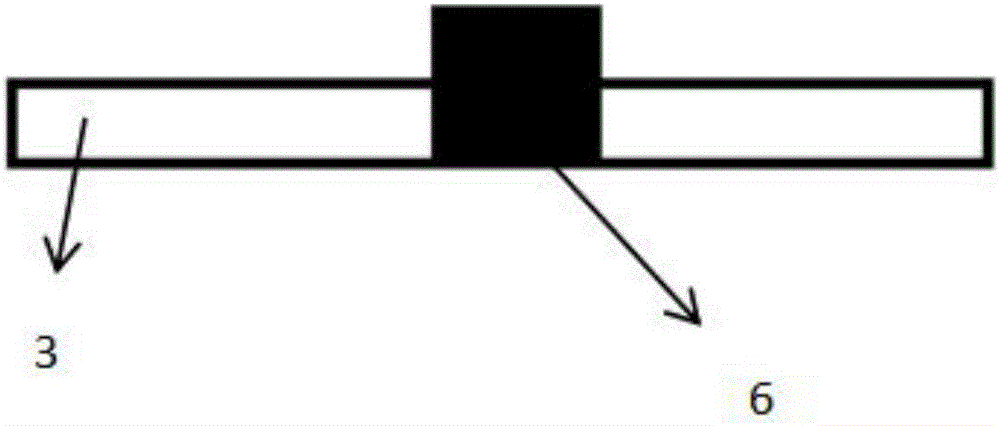

Low-field nuclear magnetic resonant antenna

InactiveCN106299708AReduce volumeReduce complexityAntenna feed intermediatesCapacitancePoor mobility

The invention relates to a low-field nuclear magnetic resonant antenna. The antenna is a nuclear magnetic resonant antenna acting in the range of 5-10 Mhz and comprises a spiral coil, a resonant capacitor, a substrate, an SMA interface and an ideal ground plane. The antenna generates a nanovolt voltage under excitation of a space electromagnetic wave, the curvature of a spiral coil patch is nonuniform, the patch has a certain width, a metal patch resonant capacitor of 1 millimeter is connected with the spiral coil patch to jointly form a resonant unit, the patch is placed on an FR4 material, and the ideal ground plane is a larger patch on a lower surface of the antenna substrate. The antenna can be used for receiving a weak signal generated after water molecules are stimulated, the antenna is small in size and is portable, the complexity of an antenna structure and the precision limitation of the antenna are reduced, so that the fabrication cost of the antenna is reduced, and the problem of poor mobility of nuclear magnetic resonant equipment is solved.

Owner:BEIJING UNIV OF TECH

Novel dual-stop band ultra wide band (UWB) antenna

InactiveCN106876947AHas widthSimultaneous aerial operationsRadiating elements structural formsDielectric substrateImpedance matching

A novel dual-stop band UWB antenna relates to a UWB band-stop antenna of which the notch frequency band is located at the WLAN and WiMAX frequency bands, and is composed of a dielectric substrate (106), a radiation unit (101) formed on the dielectric substrate, an impedance matching input microstrip line (102) and a defected ground structure (DGS) (107). Two connected U-shaped grooves (103) are contained by the radiation unit (101) on the dielectric substrate, and the DGS is composed of T-shaped grooves (104) and U-shaped groove structures (105). The novel dual-stop band UWB antenna of the present invention realizes the passband bandwidth required by the UWB by utilizing the radiation unit, the impedance matching input microstrip line and a metal grounding plate, utilizes the circular radiation unit to improve the stop band attenuation inhibition, and utilizes the DGS to realize the band-stop characteristic. The stop band of the antenna involved in the present invention is nearby 3.7 GHz and 5.75 GHz, thereby avoiding the mutual interference of a WLAN system and a WiMAX system.

Owner:HARBIN FEIYU TECH

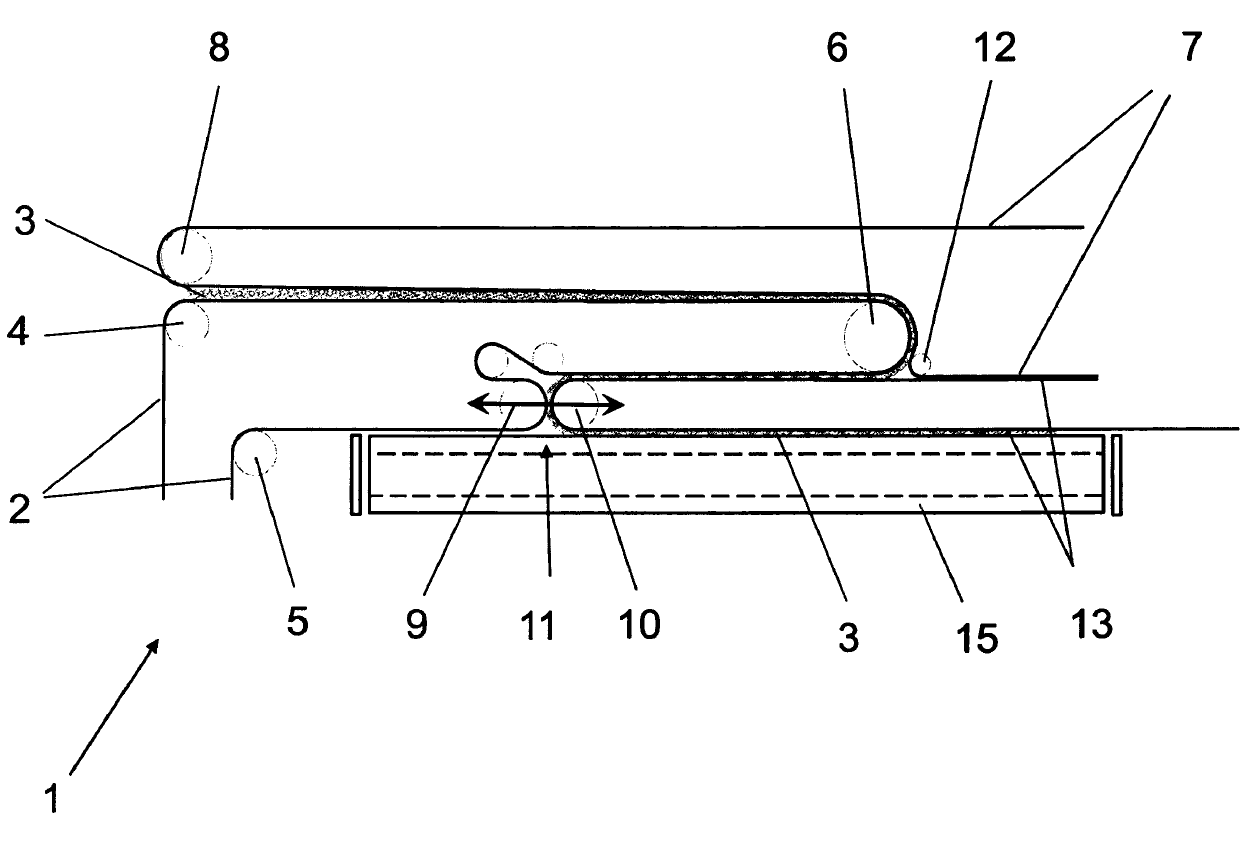

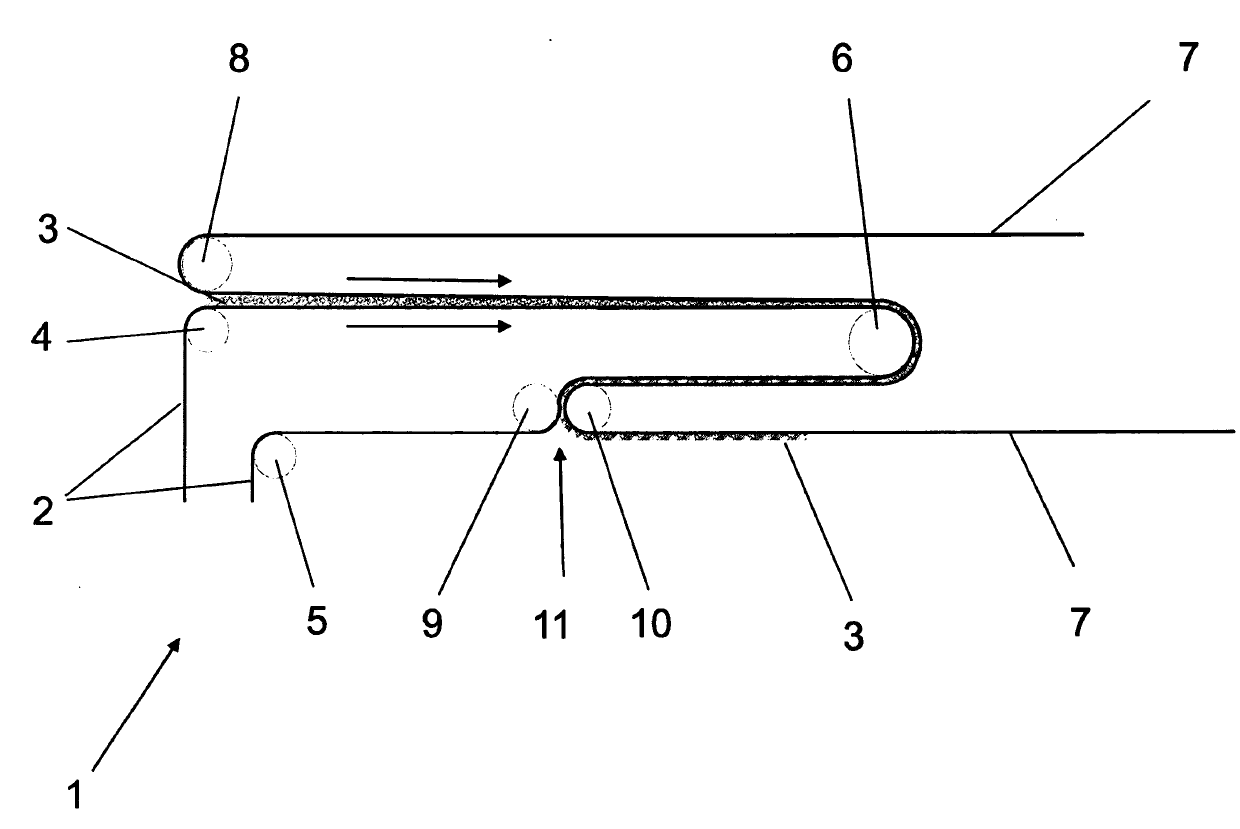

Cross Lap-forming device

InactiveCN104178932AAvoid air vorticesAvoid vortexLap forming devicesNon-woven fabricsEngineeringNonwoven fabric

The invention relates to a cross lap-forming device to form a non-woven fabric through several layers of fibrous webs, the cross lap-forming device comprises at least one endlessly revolving input belt (2), which conveys the fibrous webs (3) from an input area of the cross lap-forming device (1) to a laying gap (11) of a laying support, the cross lap-forming device also comprises another endlessly revolving belt which cooperates with the laying support, and the endlessly revolving belt and the input belt (2) lay the fibrous webs (3) on an output belt (15). The invention is characterized in that the endlessly revolving belt is available as an air-permeable belt having at least one air-impermeable edge.

Owner:TRUETZSCHLER GMBH & CO KG

Ultra wide band antenna based on electromagnetic band gap (EBG) structure

InactiveCN106876930ASimple designCompact structureRadiating elements structural formsAntenna earthingsDielectric substrateImpedance matching

An ultra wide band antenna based on an EBG structure relates to an ultra wide band (UWB) band-stop antenna of which the notch frequency band is located at the WLAN and RFID frequency bands, and is composed of a dielectric substrate (105), a radiation unit (101) on the dielectric substrate, an impedance matching input microstrip line (102), an EBG structure (103) shaped like a Chinese character mi, a broken line type EBG structure (107) and a metal grounding plate (104) under the dielectric substrate. The ultra wide band antenna based on the EBG structure of the present invention realizes the passband bandwidth required by the UWB by utilizing the radiation unit, the impedance matching input microstrip line and the metal grounding plate, utilizes the circular radiation unit with a Sierpinski triangular fractal structure to improve the stop band attenuation inhibition, and utilizes the EBG structures to realize the band stop characteristic. The stop band of the antenna involved in the present invention is nearby 5.2 GHz and 6.8 GHz, thereby avoiding the mutual interference of a WLAN system and an RFID system.

Owner:HARBIN HESON SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com