Screw electric inductor

A technology of inductors and spiral shapes, applied in the field of spiral inductors, can solve problems such as Q reduction, inability to use high-frequency inductors, and increased capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

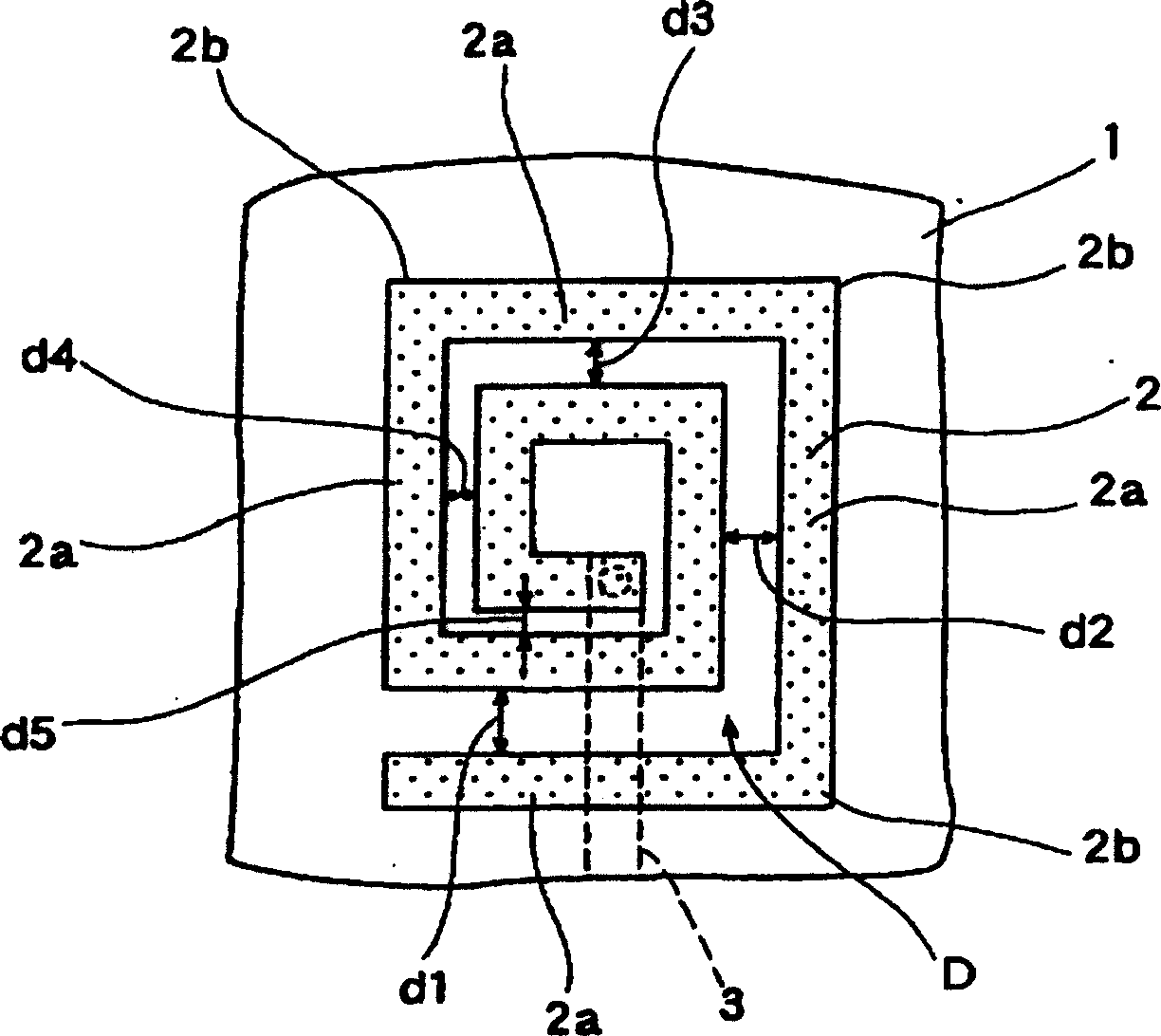

[0021] The drawings of the spiral inductor of the present invention will be described. figure 1 is a plan view of the spiral inductor of the present invention.

[0022] Next, according to figure 1 The structure of the spiral inductor of the present invention is described. On one side of a flat insulating substrate 1 such as alumina, a conductor 2 formed of a conductive pattern made of a thin film or the like is provided, and the conductor 2 is formed so that a gap D is maintained between adjacent conductors. of square (quadrilateral) swirl shapes.

[0023] In addition, an insulating substrate other than alumina may be used for the insulating substrate 1, and the conductor 2 may be formed by a method other than thin film printing or the like.

[0024] The entire conductor 2 is formed with a constant width (the same width), and the interval D is formed so as to become narrower from the outer side to the inner side of the spiral shape.

[0025] In addition, the interval D in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com