Sealing ring for pressure control valve

A technology of pressure regulation and sealing ring, applied in the field of pressure regulating valve, can solve the problems of unsatisfactory shape stability of sealing ring, shortened service life, leakage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

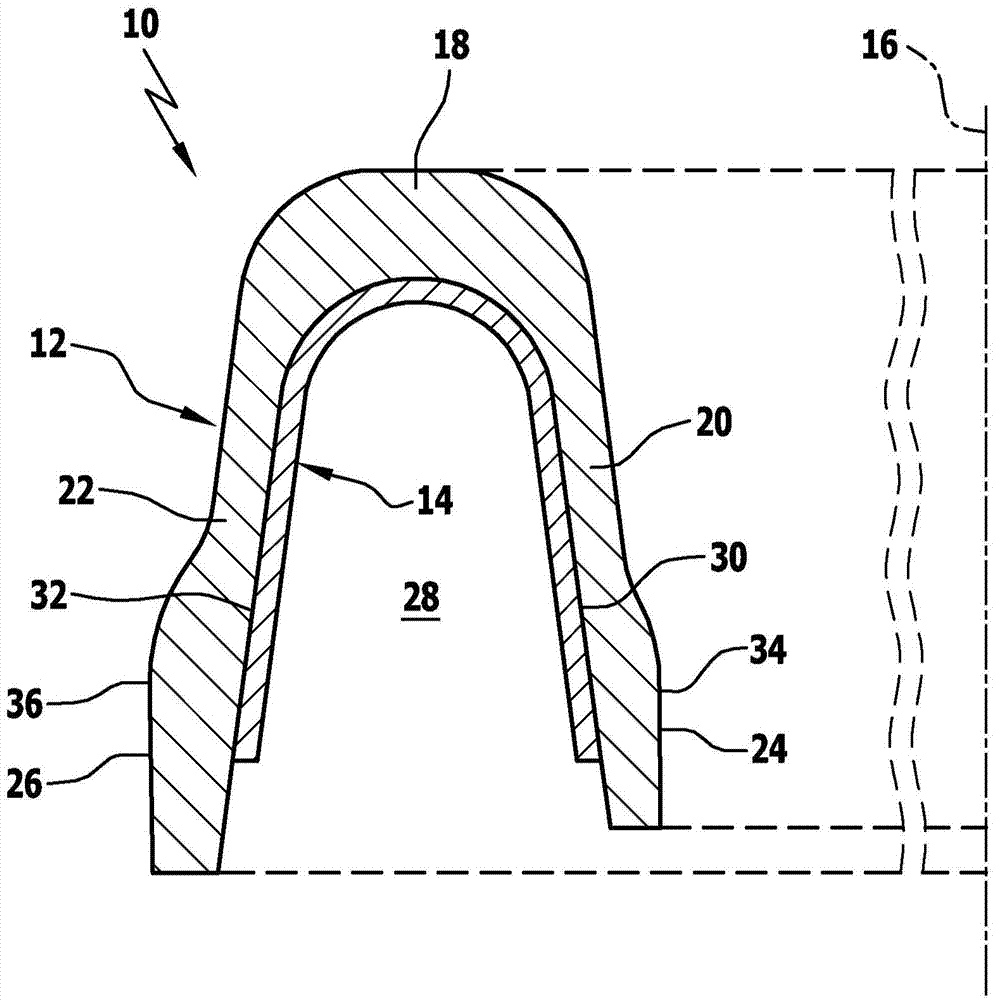

[0035] figure 1 A schematic cross-sectional view of an embodiment of a sealing ring according to the invention, generally designated 10 , is shown. The sealing ring 10 consists of two parts, namely, a sealing body 12 made of a material having one or more perfluorinated thermoplastics as main components and a spring element 14 made of steel, wherein the two The parts 12 and 14 are formed rotationally symmetrically with respect to the cylinder axis 16 .

[0036] The sealing body 12 has a substantially U-shaped cross-sectional profile with a top region 18 and two sealing lips 20 and 22 , which extend from the top region 18 approximately along the cylinder axis 16 with an opening angle of approximately 15°. direction extension. In this case, the inner sealing lip 20 facing the cylinder axis 16 has an inner sealing surface 24 , and the sealing lip 22 facing away from the cylinder axis 16 has an outer sealing surface 26 . When the sealing ring 10 is fixed on the valve cylinder in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com