Polarizer attaching and cutting integrated method and equipment for liquid crystal display panel

A liquid crystal display panel, polarizer attachment technology, applied in optics, nonlinear optics, instruments, etc., can solve the problem that the display module cannot achieve a narrow frame, and cannot eliminate the tolerance of the polarizer attached.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

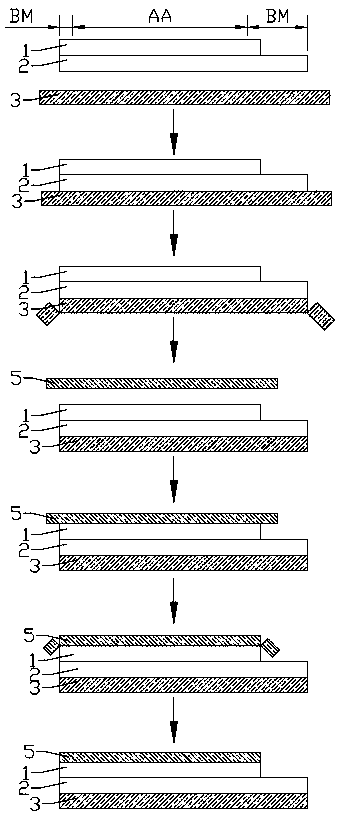

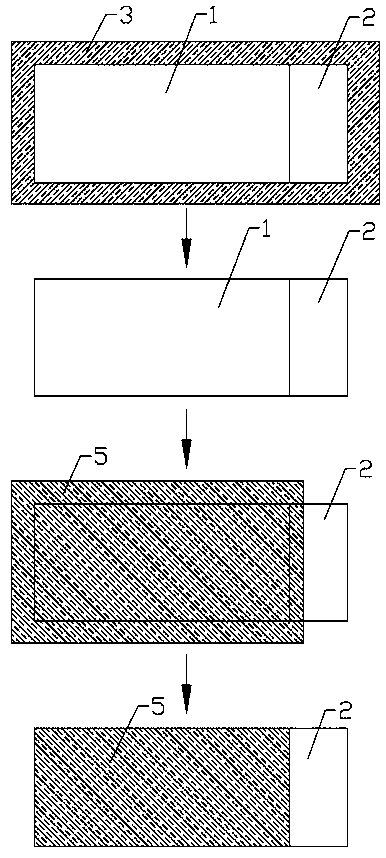

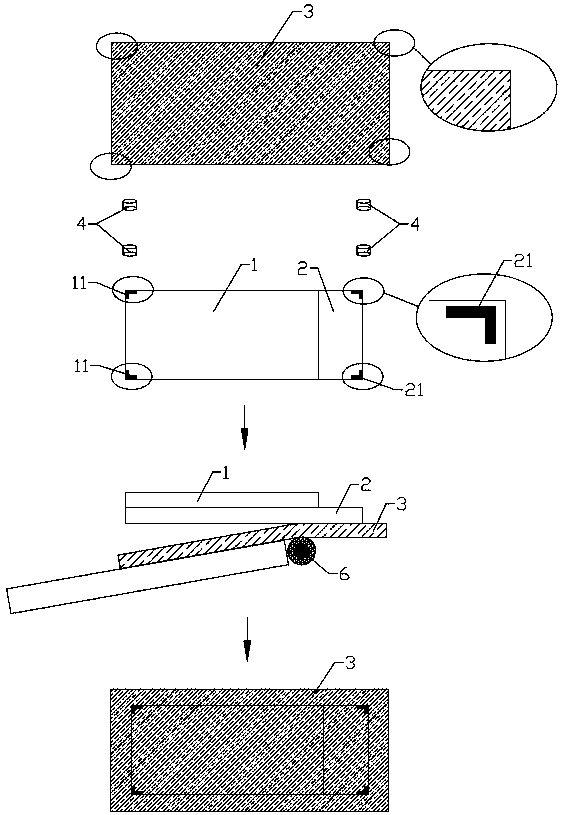

[0037] combine Figure 1-Figure 3 As shown, Embodiment 1 of the present invention provides an integrated method for attaching and cutting polarizers of a liquid crystal display panel. The liquid crystal display panel has a display area AA and a non-display area BM surrounding the periphery of the display area, including the following steps: S1: providing The upper substrate 1 and the lower substrate 2 arranged in layers, and the lower polarizer 3 whose size is larger than the lower substrate 2, the lower substrate 2 is provided with a first alignment mark 21, and the lower polarizer 3 is provided with a third pair of Position mark; S2: provide a CCD vision system 4 to take the first alignment mark 21 and the third alignment mark, attach the lower polarizer 3 on the lower substrate 2 and away from the side of the upper substrate 1; S3: use CCD The vision system 4 takes the mark on the edge of the lower substrate 2, and cuts the lower polarizer 3; S4: providing an upper polarize...

Embodiment 2

[0045] combine Figure 1-Figure 4 with Figure 8 As shown, Embodiment 2 of the present invention provides an integrated equipment for attaching and cutting polarizers for liquid crystal display panels. The structures of polarizers and liquid crystal display panels are as described in Embodiment 1, wherein the size of polarizers is larger than that of liquid crystal display panels. The liquid crystal display panel has a display area AA and a non-display area BM surrounding the periphery of the display area. The liquid crystal display panel includes an upper substrate 1 and a lower substrate 2 stacked from top to bottom, formed on the upper substrate 1 and away from the lower substrate 2. The upper polarizer 5, the lower polarizer 3 formed on the lower substrate 2 and away from the upper substrate 1, the device includes a first biasing module 100, a first cutting module 200, a second biasing module 300, a second cutting module 400 and a CCD vision system 4, the first polarizing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com