Hybrid waveguide laser and method for manufacturing hybrid waveguide laser

一种波导激光器、波导的技术,应用在半导体激光器、激光器、激光器零部件等方向,能够解决高制造成本等问题,达到低阈值、小器件尺寸、改善散热的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

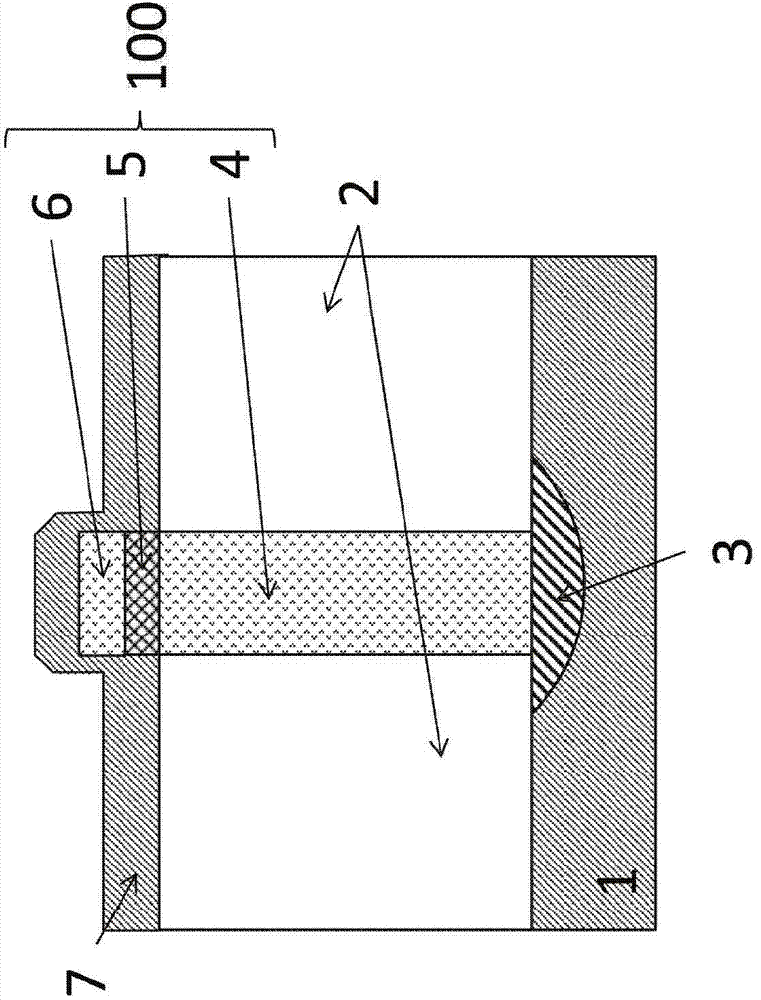

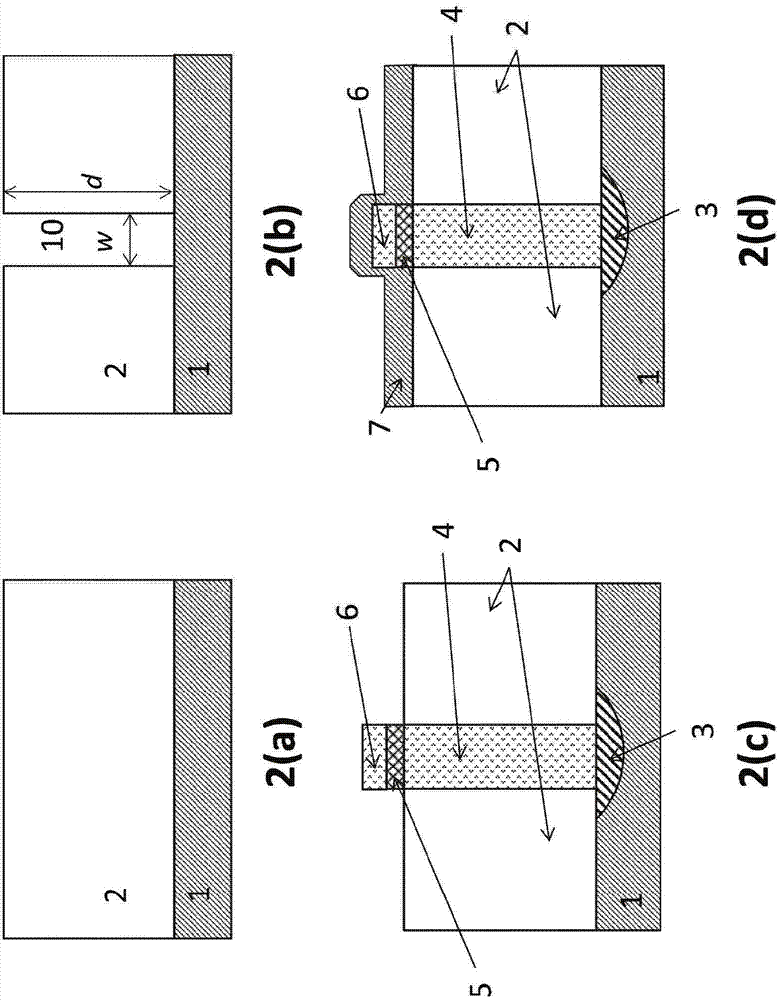

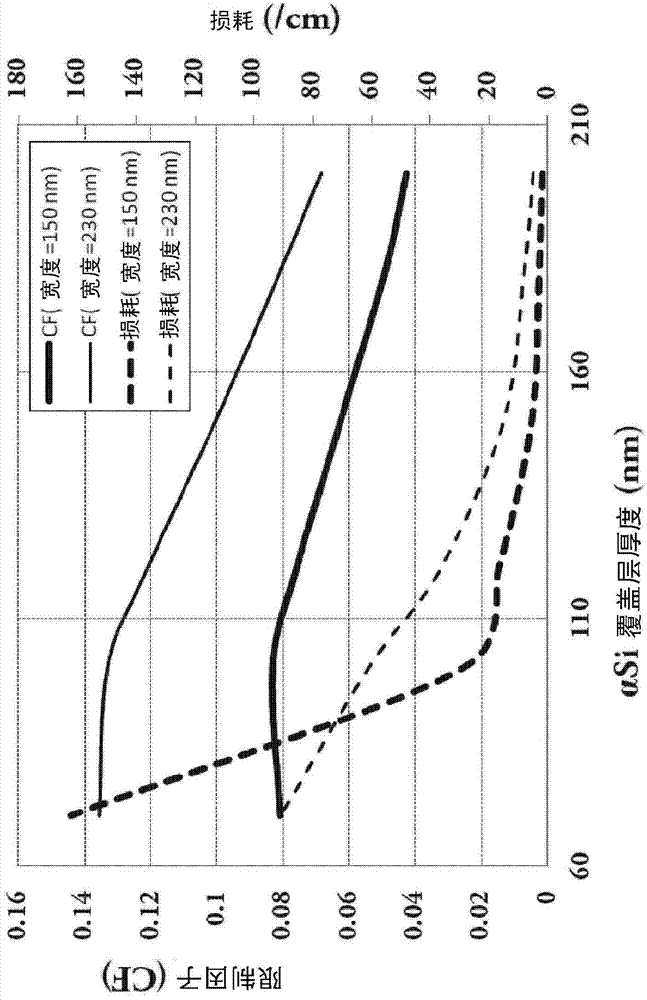

[0033] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the disclosure and how it may be practiced in certain embodiments. However, it is understood that the present disclosure may be practiced without these specific details. In other instances, well-known methods, procedures and techniques have not been described in detail so as not to obscure the present disclosure. Although the present disclosure will be described with respect to particular embodiments and with reference to certain drawings, the present disclosure is not limited thereto. The drawings included and described herein are schematic and do not limit the scope of the present disclosure. It should also be noted that in the drawings, the size of some of the elements may be exaggerated for illustrative purposes and therefore not drawn on scale.

[0034] The present invention will be described with respect to particular embodiments and wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com