Automobile exhaust manifold silencer

A technology of automobile exhaust and muffler, which is applied in the direction of muffler, exhaust device, engine components, etc. It can solve the problems of reducing the noise reduction function of the muffler core, short service life of the muffler, and large power loss of the muffler, etc., to achieve noise reduction The effect of maintaining stable function, increasing damage rate, and convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

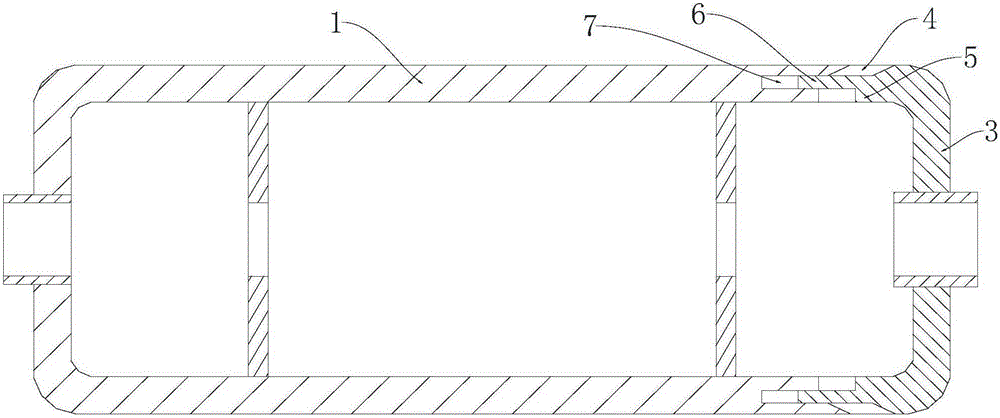

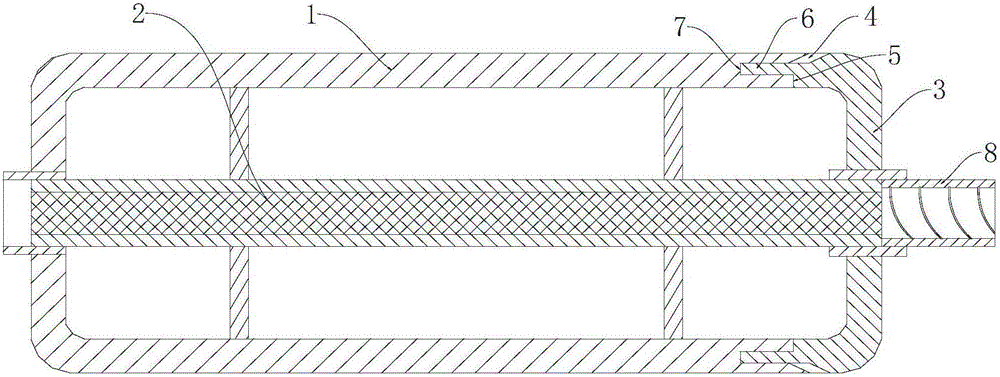

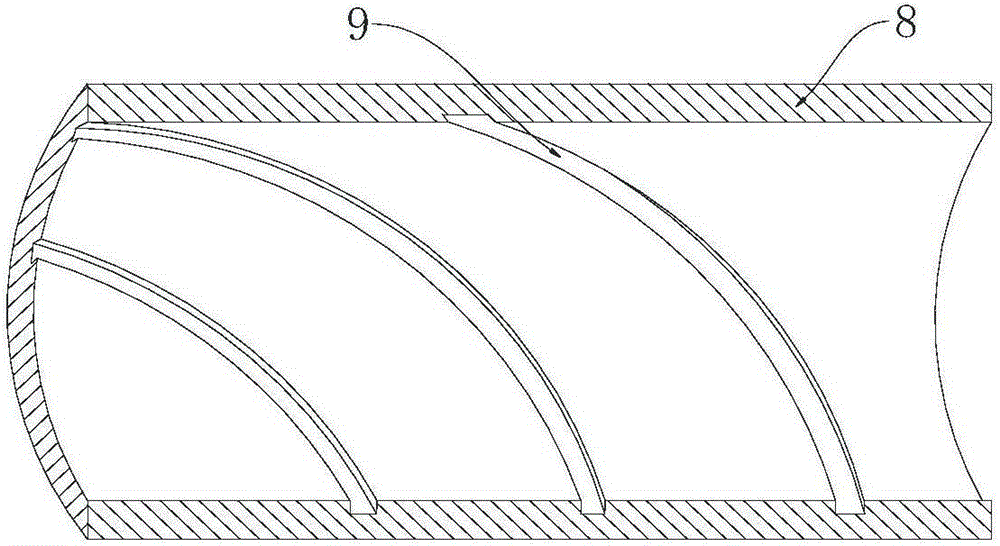

[0021] Such as Figure 1 to Figure 3 As shown, this embodiment includes a main body 1 with one end open and an end cap 3 for sealing the open end. The sound-absorbing core 2 is fixed in the main body 1 and its two ends pass through the end of the main body 1 and the middle of the end cap 3 respectively. An annular groove 7 with a rectangular cross-section is formed on the open end surface of the main body 1, and an extension 6 cooperating with the annular groove 7 is provided in the middle of the sealing end of the end cover 3, and is provided on the upper part of the sealing end surface of the end cover 3. There is an inclined surface A, and the inclined surface A is inclined along the axis of the end cover 3 in a direction away from its axis. The end surface of the main body 1 is provided with an inclined surface B with the same inclined direction as the inclined surface A, and the inclined surface A, the outer wall of the extension part 6 and the inclined surface B are forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com