Method for regenerating ruthenium hydrogenation catalyst

A hydrogenation catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve fine chemical industry and partial hydrogenation catalyst regeneration inappropriate, Unable to deal with catalyst high boilers, limitations, and insufficient effects, etc., to achieve beneficial effects for maintenance and operation, performance recovery, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

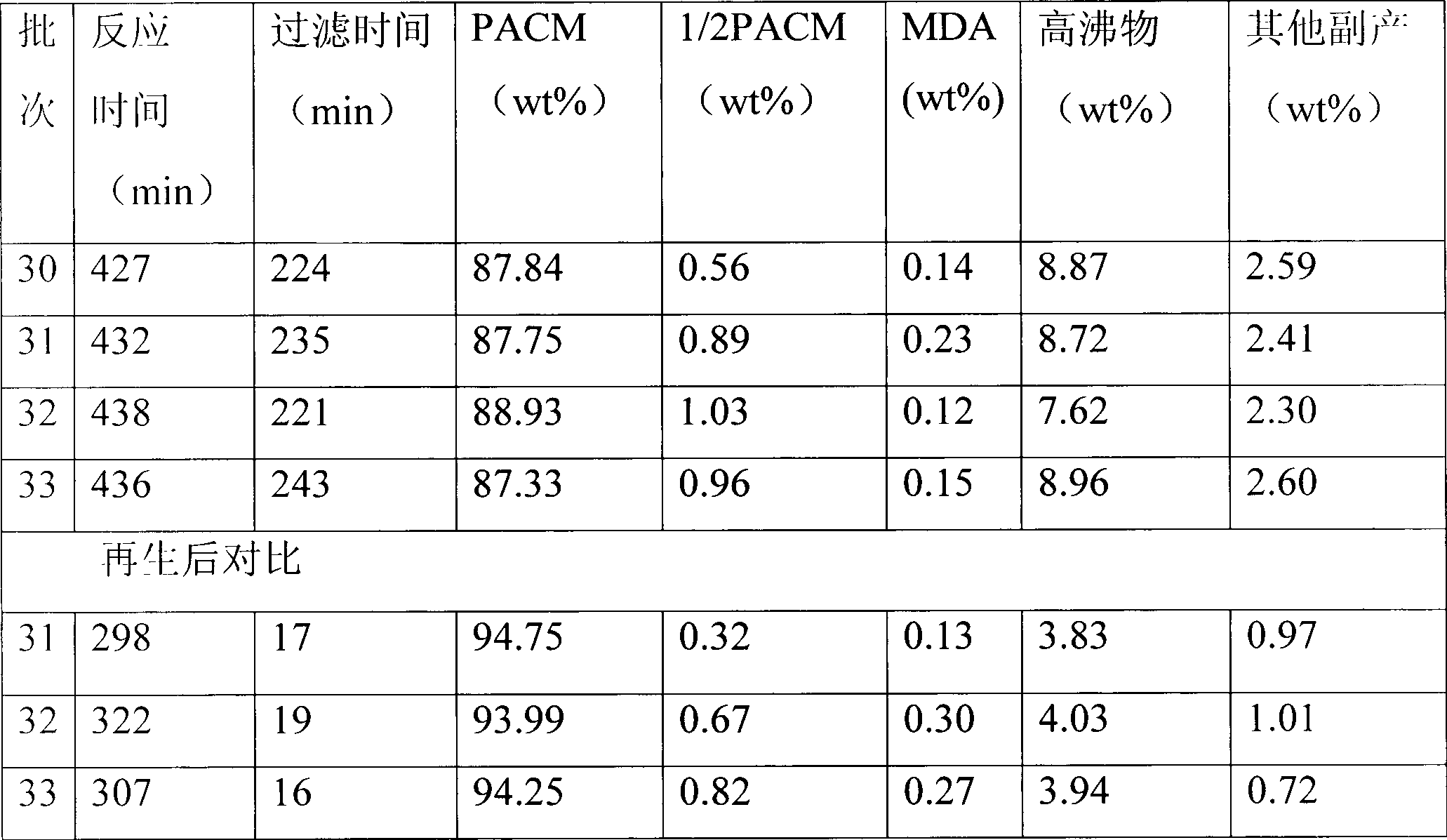

[0032] MDA (p-diaminodiphenylmethane) hydrogenation to PACM (p-diaminodicyclohexylmethane) catalyst regeneration evaluation, the hydrogenation reaction process is as follows:

[0033] In a high-pressure reactor with a volume of 2L, add ruthenium / activated carbon (the content of metal ruthenium is 5wt%, based on the total weight of the catalyst) catalyst 12.5g, feed MDA 250g and methanol 250g each time, airtightly replace the air, and fill with hydrogen , at a temperature of 160°C and a pressure of 60 bar, start the hydrogenation reaction and calculate the reaction time, and stop the reaction when the reaction no longer absorbs hydrogen. The product was sampled and analyzed by capillary gas chromatography, and except for the solvent, the composition of other main components is shown in Table 1.

[0034] The quantitative analysis of the MDA hydrogenation product uses an instrument for gas chromatography, and the analysis conditions are:

[0035] The initial temperature is 50°...

Embodiment 2

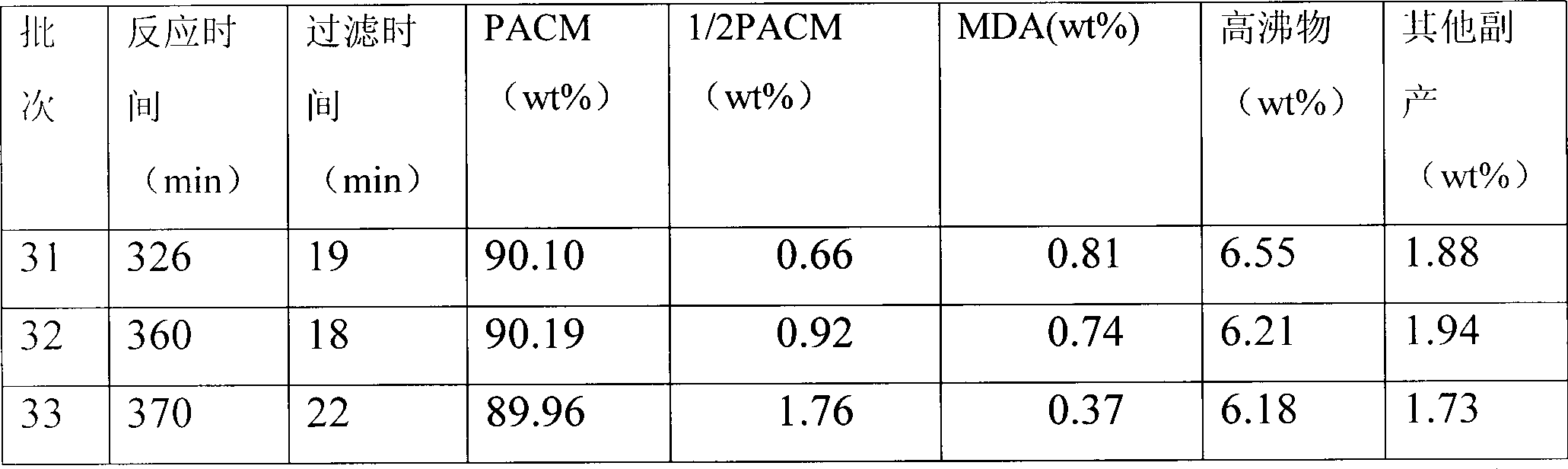

[0063] MDA hydrogenation to PACM, deactivated Ru / TiO 2 (The content of metal ruthenium is 5wt%, based on the total weight of the catalyst) Catalyst regeneration evaluation, MDA hydrogenation reaction with reference to Example 1.

[0064] Before the regeneration operation of the catalyst, 40 batches have been applied mechanically, the reaction time is prolonged by 200%, and the by-product of high boilers (polyamines containing four rings or more than four rings) is 17%. The catalyst regeneration method is as follows:

[0065] a) In an ultrasonic cleaner with a volume of 2L, add deactivated ruthenium / TiO 2 (5wt%) catalyst 12.5g, add 500g methanol, under the protection of nitrogen at 150°C, pressure 0.5MPa, ultrasonic frequency 100KHz, power 300w, after ultrasonic 2h, filter to remove the solvent.

[0066] b) adding pH to the ultrasonic cleaning machine is 20wt% (NH 4 ) 2 RuCl 6 (Bailingwei, GR grade, 99%) aqueous solution 500g, at 150°C, 0.5MPa, keep the ultrasonic frequenc...

Embodiment 3

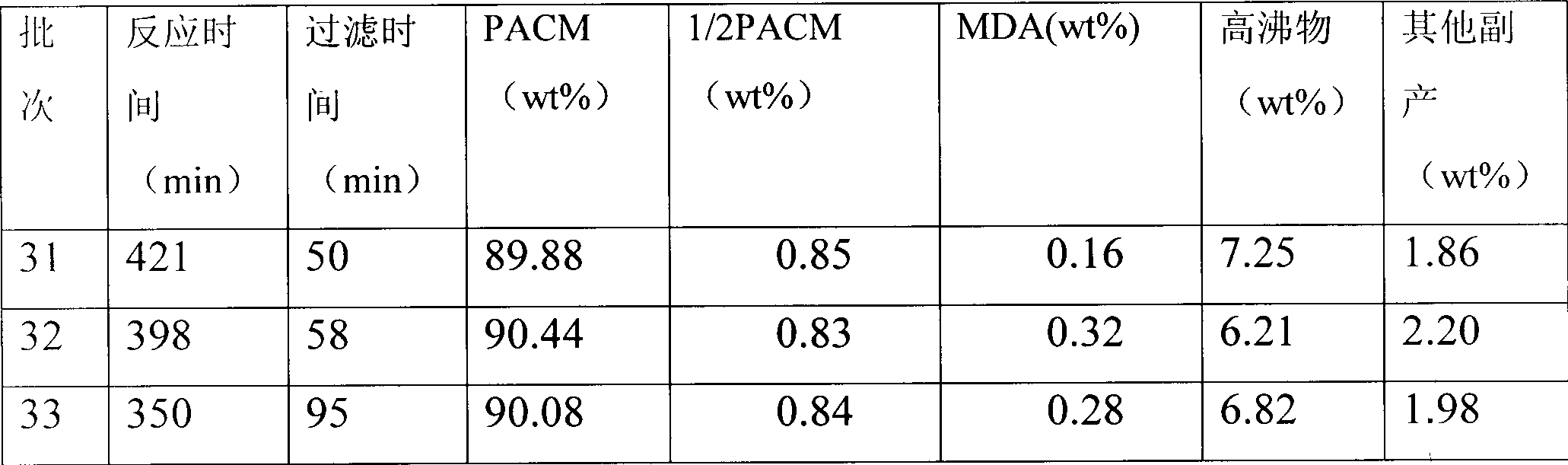

[0072] Catalyst regeneration evaluation for hydrogenation of aniline to cyclohexylamine, the hydrogenation reaction is as follows:

[0073] In a 2L autoclave, add Ru / Al 2 o 3 Catalyst (the content of metal ruthenium is 3wt%, based on the total weight of the catalyst) 6g, 500g of aniline is fed each time, the air is replaced after airtight, and hydrogen is charged. At a temperature of 140°C and a pressure of 50bar, the hydrogenation reaction is started and Calculate the reaction time, and the reaction stops when the reaction no longer absorbs hydrogen. The product was sampled and analyzed by capillary gas chromatography, and except for the solvent, other key components were found in the table below, expressed in weight percentage.

[0074] The instrument used for quantitative analysis of aniline hydrogenation reaction product is gas chromatography, and the analysis conditions are:

[0075]

[0076] The initial temperature is 50°C, kept for 2 minutes, then raised to 80°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com