Energy-saving and efficiency-improving device of wet desulphurization spray tower

A wet desulfurization, spray tower technology, applied in separation methods, chemical instruments and methods, gas treatment and other directions, can solve the problems of waste of slurry, inability to mix the slurry with flue gas, and inability to achieve high-efficiency desulfurization, and improve work efficiency. Efficiency, effect of shortening desulfurization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Attached below Figure 1-9 The present invention is further described with embodiment:

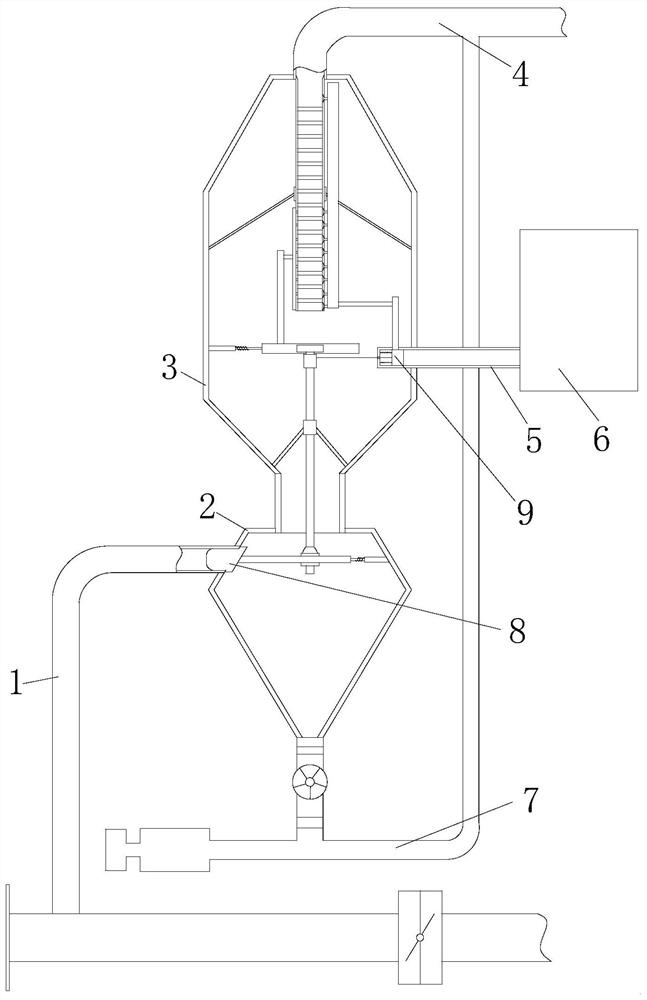

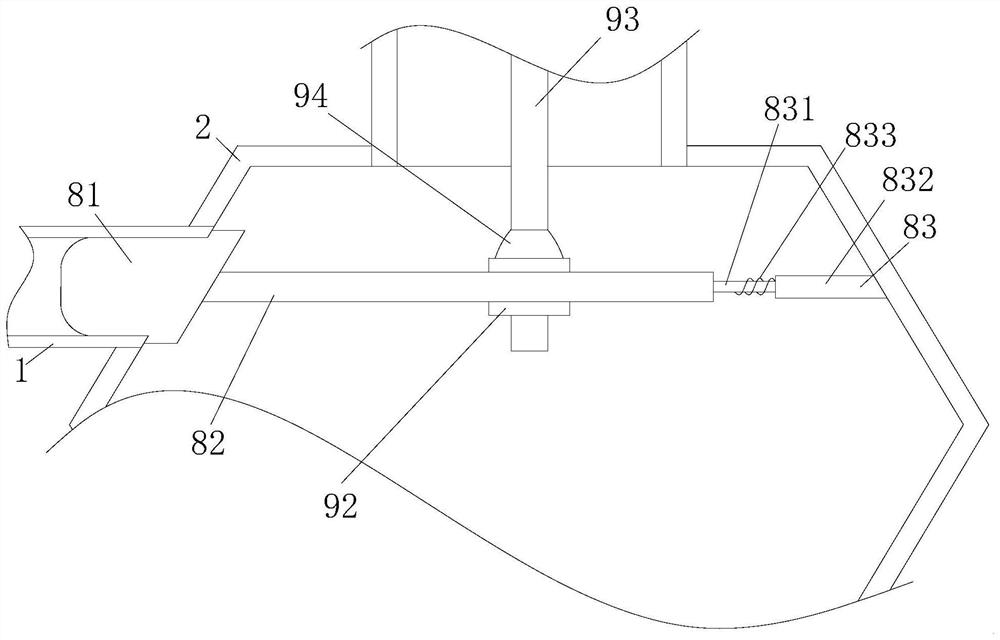

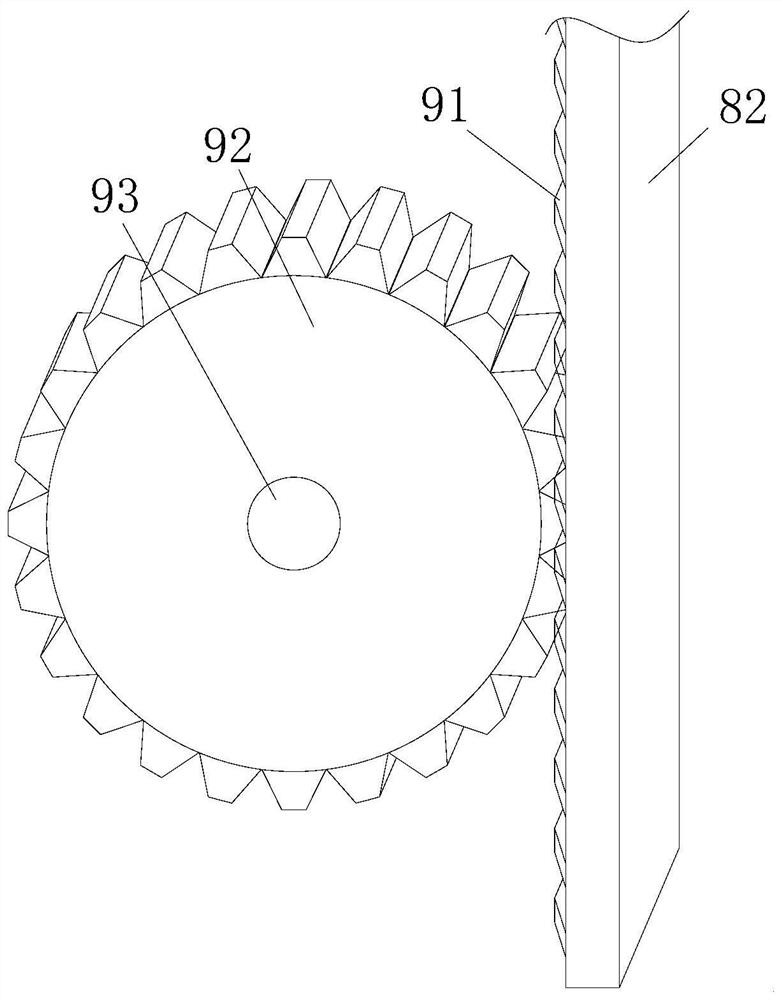

[0035]A device for energy saving and efficiency improvement of a wet desulfurization spray tower, comprising a coke oven flue 1, the coke oven flue 1 is communicated with an external induced draft fan, the free end of the coke oven flue 1 is communicated with a No. 1 desulfurization tank 2, and a The top of the No. 2 desulfurization tank 2 is connected with a No. 2 desulfurization tank 3, the top of the No. 2 desulfurization tank 3 is connected with a dust collector connection pipe 4, and the side wall of the No. 2 desulfurization tank 3 is connected with a desulfurization agent connection pipe 5, desulfurization The free end of the agent connection pipe 5 is inserted into the desulfurization agent storage tank 6, and the desulfurization agent storage tank 6 is provided with a booster. The present invention improves the structure of the existing wet desulfurization spray tower. Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com