Regeneration production method of scrap rubber

A production method and waste rubber technology, which is applied in the field of waste rubber regeneration technology, can solve the problems of low regeneration rate and rubber swelling degree, and achieve the effects of reducing energy, ensuring stability, and improving fracture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

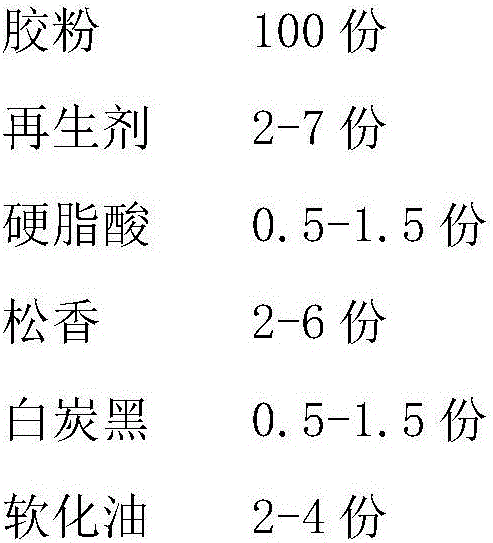

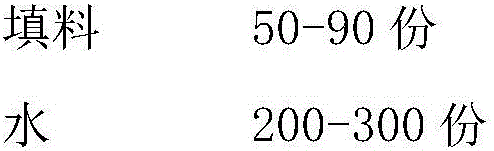

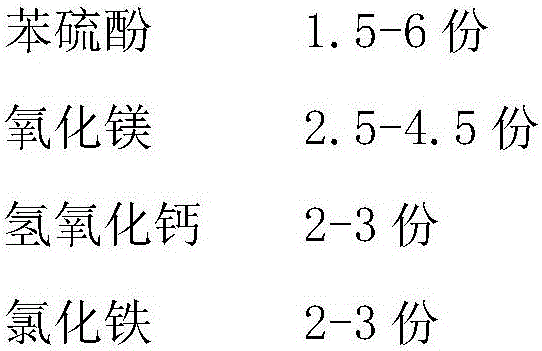

Embodiment 1

[0032] A waste rubber regeneration production method, comprising cleaning, crushing, impurity removal, screening, stirring, desulfurization, quenching, refining, and tablet forming, the tablet forming sequentially includes one plate pressing and two roll forming; the Plate pressing includes an upper plate and a lower plate, the outlet of the lower plate is connected to a roller press, the temperature of the lower plate is controlled at 95-115°C, the temperature of the upper plate is controlled at 105-125°C, and the upper plate is carried out every 10s at most Plate pressing, the moving speed of the lower plate is 10-30m / min, the length of the upper plate and the lower plate is 2-5m; the minimum distance between the upper plate and the lower plate is h during plate pressing, the first The distance h1 between the two rollers in the second rolling press satisfies the relationship: 0.5h<h1<0.8h, the speed of the rollers is 30-50m / min, and the distance h2 between the two rollers in ...

Embodiment 2

[0037] A waste rubber regeneration production method, comprising cleaning, crushing, impurity removal, screening, stirring, desulfurization, quenching, refining, and tablet forming, the tablet forming sequentially includes one plate pressing and two roll forming; the Plate pressing includes an upper plate and a lower plate, the outlet of the lower plate is connected to a roller press, the temperature of the lower plate is controlled at 95-115°C, the temperature of the upper plate is controlled at 105-125°C, and the upper plate is carried out every 10s at most Plate pressing, the moving speed of the lower plate is 10-30m / min, the length of the upper plate and the lower plate is 2-5m; the minimum distance between the upper plate and the lower plate is h during plate pressing, the first The distance h1 between the two rollers in the second rolling press satisfies the relationship: 0.5h<h1<0.8h, the speed of the rollers is 30-50m / min, and the distance h2 between the two rollers in ...

Embodiment 3

[0042] A waste rubber regeneration production method, comprising cleaning, crushing, impurity removal, screening, stirring, desulfurization, quenching, refining, and tablet forming, the tablet forming sequentially includes one plate pressing and two roll forming; the Plate pressing includes an upper plate and a lower plate, the outlet of the lower plate is connected to a roller press, the temperature of the lower plate is controlled at 95-115°C, the temperature of the upper plate is controlled at 105-125°C, and the upper plate is carried out every 10s at most Plate pressing, the moving speed of the lower plate is 10-30m / min, the length of the upper plate and the lower plate is 2-5m; the minimum distance between the upper plate and the lower plate is h during plate pressing, the first The distance h1 between the two rollers in the second rolling press satisfies the relationship: 0.5h<h1<0.8h, the speed of the rollers is 30-50m / min, and the distance h2 between the two rollers in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com