Laser cutting method for electronic ceramic substrate

A technology of laser cutting and electronic ceramics, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low cutting efficiency and crack generation, and achieve the effect of reducing thermal stress, reducing cracks, and reducing heat-affected zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

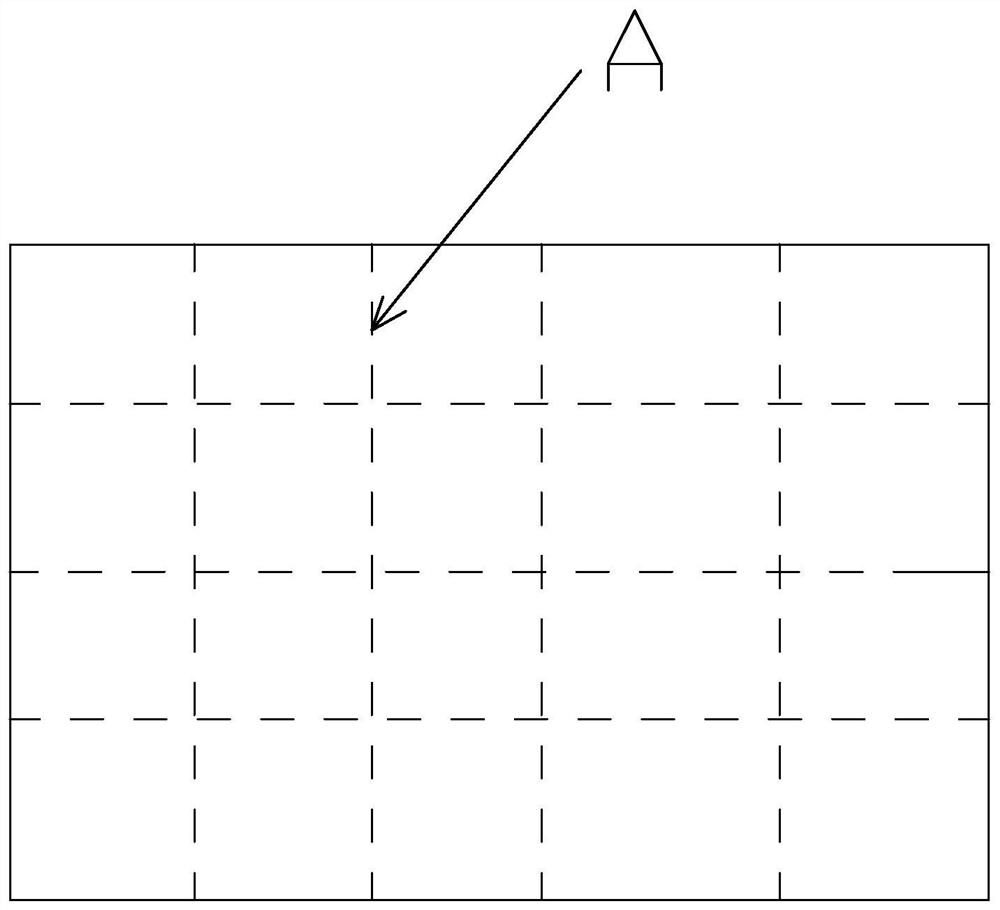

[0031] refer to figure 1 and figure 2 , a 3mm aluminum nitride ceramic substrate laser cutting method, comprising the following preparation steps:

[0032] (1) Place the ceramic substrate to be cut in CO 2 The cutting platform of the laser cutting machine is fixed;

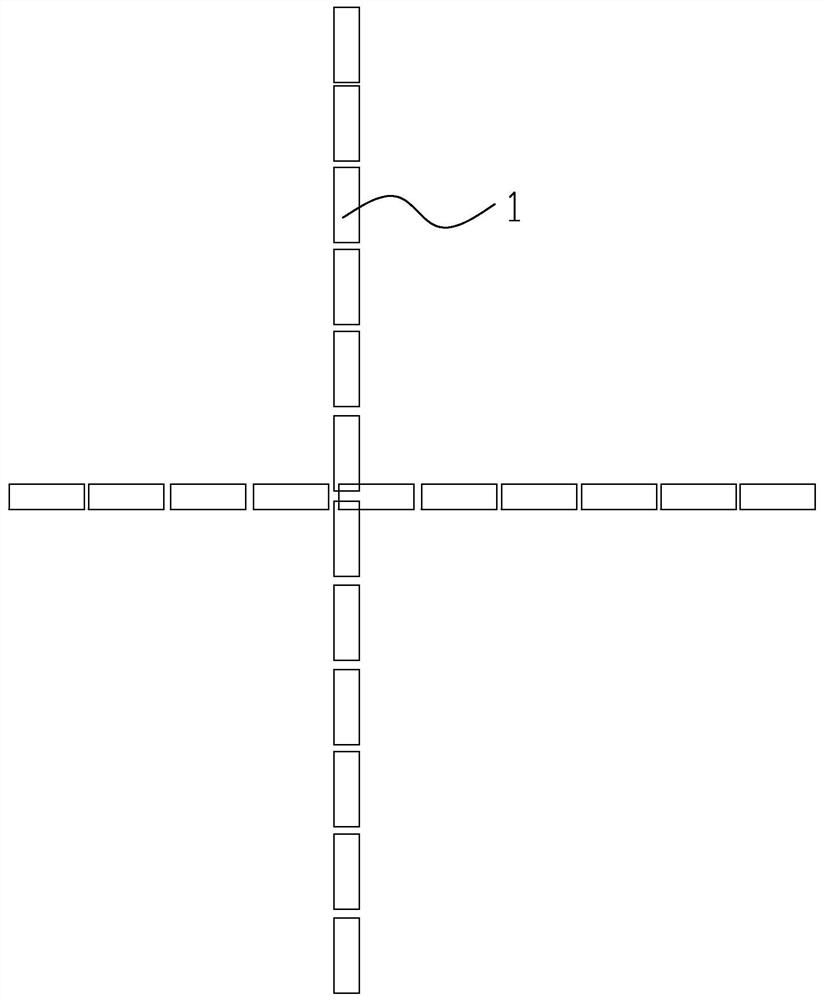

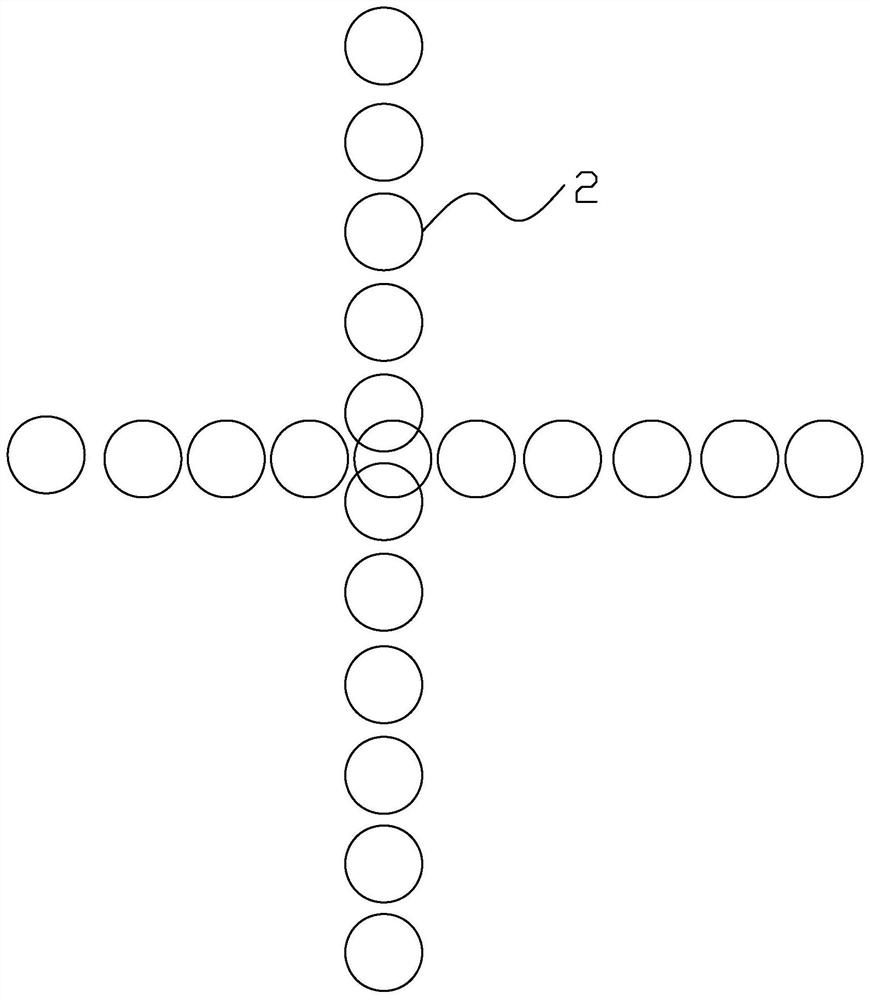

[0033] (2) Adjust CO 2 The parameters of the laser cutting machine: adjust the duty cycle to 45%, and the laser energy to 50J; by adjusting the parameters of the laser cutting machine, the laser spots are arranged in a continuous moment 1 at the slit of the ceramic substrate during laser cutting, and the cutting The depth of the slit is 0.05mm, and the width of the slit is 0.01mm; the cutting speed of the laser cutting machine is set to 2mm / s;

[0034] (3) Start the laser cutting machine to cut the ceramics. During cutting, auxiliary nitrogen gas is used to remove the molten material. The auxiliary gas is sprayed into the slit through the auxiliary gas nozzle. The auxiliary gas nozzle is non-coaxial auxiliary...

Embodiment 2

[0039] A laser cutting method for electronic alumina ceramic substrates, using a laser cutting processing system for cutting processing, using a CO with an output power of 250W 2 For the laser cutting machine 5, the output mode of the laser is pulsed. The specific steps are:

[0040] (1) Place the alumina ceramic substrate to be cut on the cutting platform 6 of the laser cutting machine and fix it; the thickness of the alumina ceramic substrate is 2mm, and the purity of alumina is 96%;

[0041] (2) Adjust the parameters of the laser cutting machine: adjust the duty cycle to 47%, the laser energy to 35J; the pulse frequency to 50hz;

[0042] (3) Start the laser cutting machine to cut the ceramics, the depth of the kerf is 0.07mm, and the width of the kerf is 0.02mm. Non-coaxial sub-axis gas nozzles are used to assist in cutting. Specifically, refer to Figure 5, the diameter of the nozzle is 1.5mm, nitrogen is used as the auxiliary gas, the gas pressure is 25pa, the cutting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com