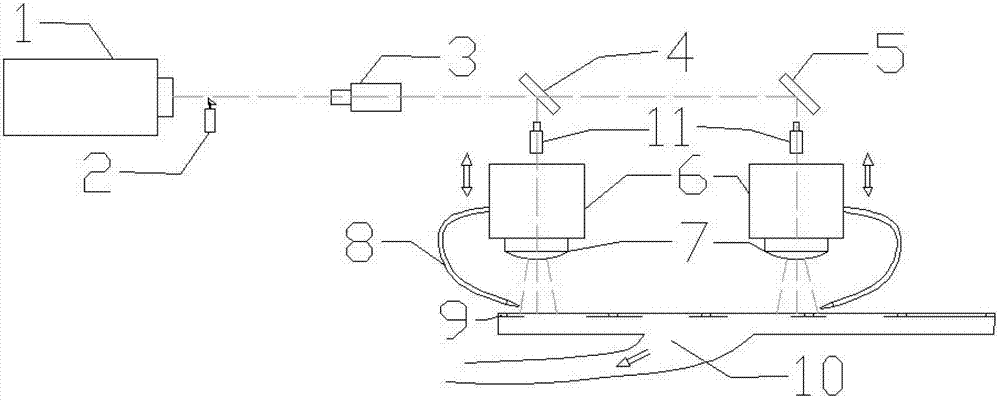

Laser processing method and laser processing equipment

A laser processing method and laser processing technology, which are applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of low efficiency and large grinding rod loss, achieve small pulse width, suppress the generation of microcracks, and improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

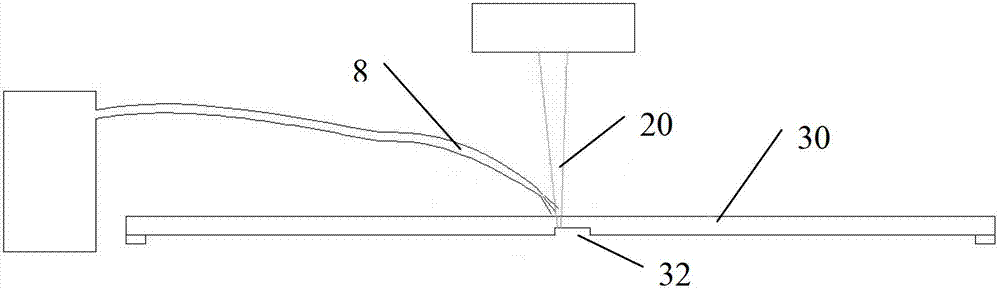

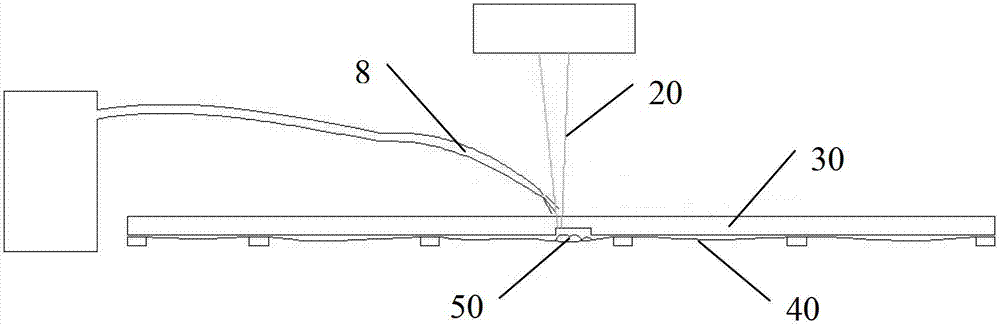

[0027] The laser cutting technology of the present invention is a heat removal cutting process using laser as an energy source. Specifically, the present invention utilizes the high power density output of the pulsed laser at the focal point to instantly gasify or melt the material at the laser focal point, thereby realizing material removal. The material heat removal area extends to form a heat removal surface, thereby realizing cutting and separation of materials.

[0028] The cutting process of the present invention first irradiates and scans laser light on or near a predetermined cutting start surface of the workpiece to thermally remove material from the cutting start surface of the workpiece. After the cutting starting surface of the workpiece is removed by heat, the internal material of the workpiece is exposed to form a new surface. Then irradiate and scan the laser on the formed new surface to further remove material, and finally the material of the workpiece on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com