Calcium-based ionic liquid for flue gas desulfurization, desulfurizer and preparation method of desulfurizer

A technology of ionic liquid and desulfurizer, applied in the field of comprehensive utilization of resources, can solve the problems of low utilization rate and high viscosity, and achieve the effects of controlling cost, large specific surface area and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

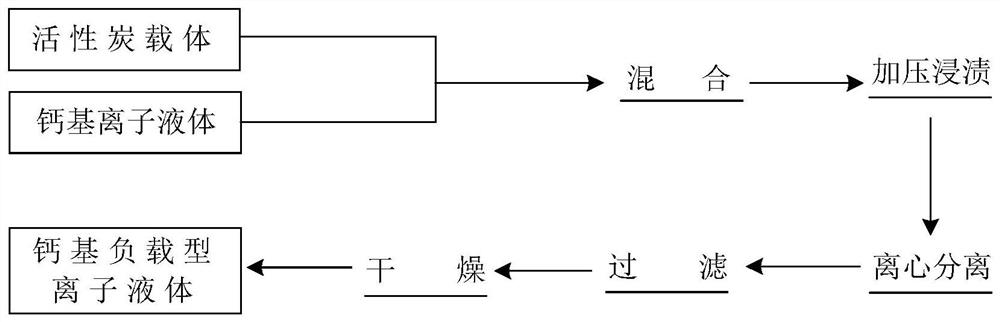

[0034] Provide the preparation process of desulfurizing agent of the present invention below, concrete steps comprise:

[0035] Step 1, under the condition of nitrogen protection, calcium chloride CaCl 2 , 1-butyl-3-methylimidazolium chloride salt ionic liquid [Bmin]Cl and ethanol are mixed in a molar ratio (2-4): 4:1 to obtain a mixture A;

[0036] Step 2: Stir the mixture A under the protection of nitrogen gas. The stirring conditions are: 90-95° C., magnetic stirring for 24-36 hours, the mixture A gradually changes from a crystalline state to a uniform liquid state, and a mixture B is obtained.

[0037] Step 3, after the mixture B is centrifuged, the upper layer liquid is taken to stand for stratification, wherein the centrifugation condition is: centrifugation at 3000-4000 r / min for 2-3 minutes.

[0038] Step 4, using a pear-shaped separating funnel to separate the water phase and the ionic liquid phase, further removing the water phase, and drying to obtain a calcium-bas...

Embodiment 1

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] refer to figure 1 The method for preparing a desulfurizing agent for flue gas desulfurization in this embodiment includes the following steps:

[0045] Step 1, raw material pretreatment, take an appropriate amount of activated carbon and wash it 3 times, put it into a pulverizer after drying, and pass through a 40-60 mesh sieve to obtain activated carbon particles with the required particle size;

[0046] Step 2, N 2 Under protective conditions, calcium chloride CaCl was added to the three-necked flask at a molar ratio of 4:4:1 2 , 1-butyl-3-methylimidazolium chloride salt ionic liquid [Bmin]Cl and ethanol. The three-necked flask was placed in a magnetically stirred water bath, and stirred continuously at 90°C for 36h.

[0047] Step 3, after centrifuging the liquid mixture at 3000r / min for 3min, using a pear-shaped separating funne...

Embodiment 2

[0053] The method for preparing a desulfurizing agent for flue gas desulfurization in this embodiment comprises the following steps:

[0054] Step 1, raw material pretreatment, take an appropriate amount of activated carbon and wash it 3 times, put it into a pulverizer after drying, and pass through a 40-60 mesh sieve to obtain activated carbon particles with the required particle size;

[0055] Step 2, N 2 Under protective conditions, calcium chloride CaCl was added to the three-necked flask in a molar ratio of 3:4:1 2 , 1-butyl-3-methylimidazolium chloride salt ionic liquid [Bmin]Cl and ethanol. The three-necked flask was placed in a magnetic stirring water bath, and the stirring was continued for 28 h at 92 °C.

[0056] Step 3, after centrifuging the liquid mixture at 4000r / min for 2min, using a pear-shaped separating funnel to separate the water phase and the ionic liquid phase, removing the water phase, and vacuum-drying at 100°C for 9h to obtain calcium for flue gas de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com