Novel desulfurization spray gun

A desulfurization spray gun and the technology of the spray gun are applied in the field of desulfurization spray guns for molten iron pretreatment, which can solve the problems such as the inability to use a torpedo tanker, and achieve the effects of reducing the spray iron loss, shortening the spraying time, and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

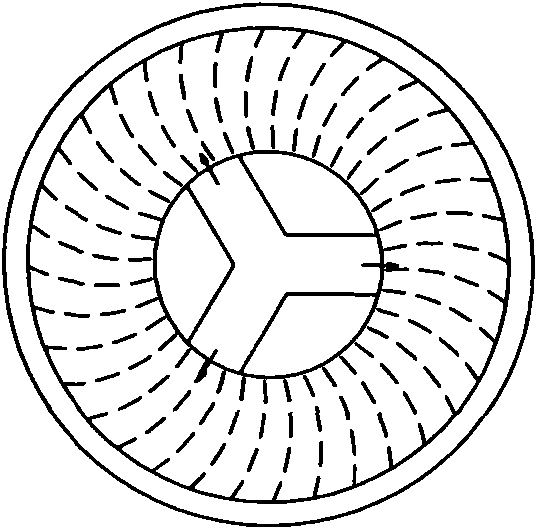

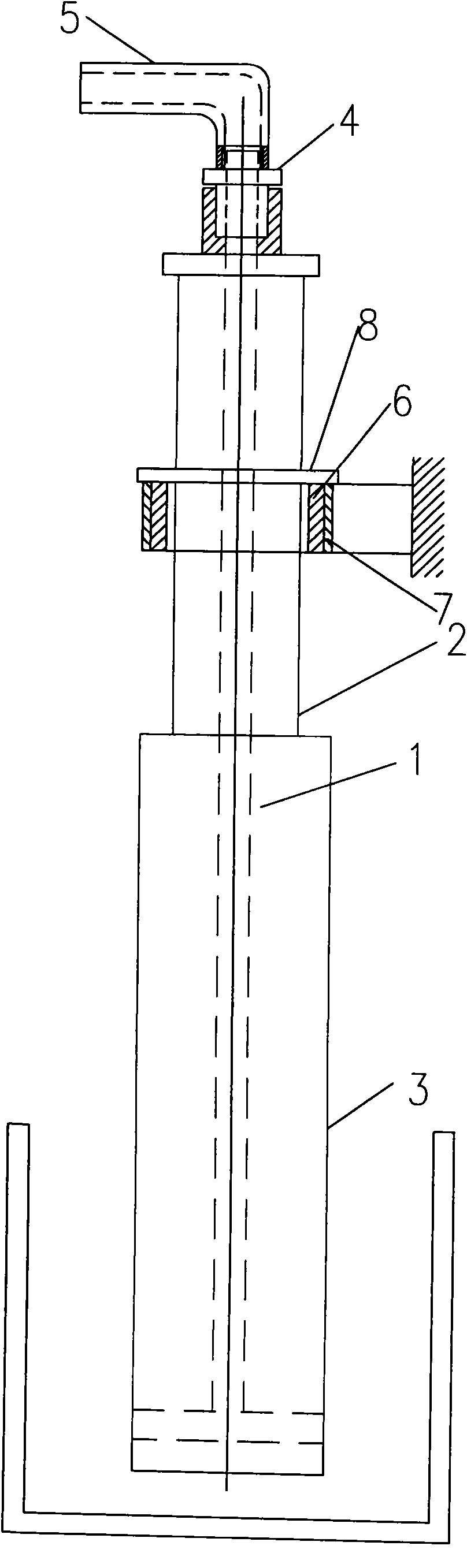

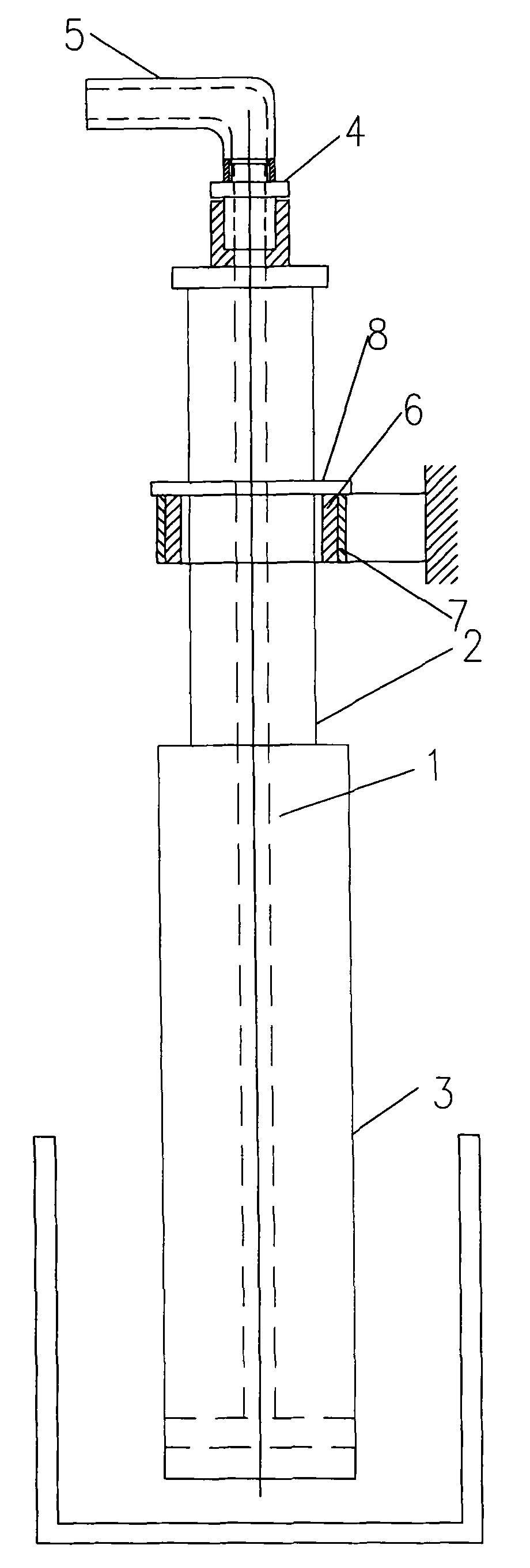

[0009] The desulfurization spray gun of the present invention includes an internal spray gun inner tube 1, an external refractory material layer 3, a body 2 arranged between the spray gun inner tube 1 and the refractory material layer 3, and several spray guns are opened at the bottom of the refractory material layer 3 The hole communicates with the inner hole of the spray gun inner tube 1, and is characterized in that: it also includes a swivel joint 4 arranged between the body 2 and the spray hose 5; the swivel joint 4 is a hollow stepped shaft, and its top is connected with the hose 5 is fixedly connected, and its lower part is connected with the body 2, and can rotate with the body 2. The desulfurization spray gun of the present invention is connected with a rotary joint between the spray hose 5 and the body 2, so that the bottom end of the spray gun can move freely in the molten pool by the force of its own jet gas when spraying, and the spray gun gives the molten The poo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com