Environmentally-friendly composite rubber regenerant and preparation method thereof

A technology for compounding rubber and rejuvenating agent, applied in building insulation materials, building components, buildings, etc., can solve the problems of processing technology, product performance and price, and affect the application of replacing coal tar, so as to shorten the rubber desulfurization time, improve the Rubber desulfurization effect, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

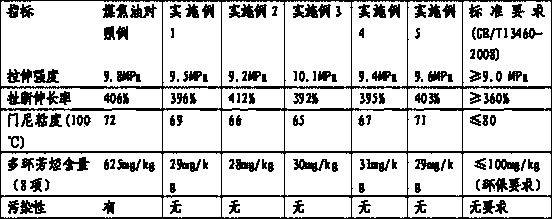

[0009] A kind of preparation method of environment-friendly type biomass composite rubber regenerant, each specific example parameter is as table 1, and concrete steps are as follows:

[0010] (1) Prepare raw materials according to mass percentage: vegetable oil pitch 55-80%, molasses 10-30%, vegetable phenol 5-15%; the vegetable oil pitch is ricinseed oil pitch, linseed oil pitch, cottonseed oil pitch, At least one of tung seed oil asphalt or hemp seed oil asphalt, usually one, or multiple mixtures, such as castor seed oil asphalt mixed with linseed oil asphalt, cottonseed oil asphalt mixed with hemp seed oil asphalt; The molasses mentioned is at least one of the by-product molasses liquids produced by cane sugar, beet sugar, and xylitol, usually one or more in combination; the plant phenols are urushiol, guaiacol, and cashew shellol Or at least one kind of phenolized lignin, usually one kind, or mixed use of multiple kinds, such as the mixed use of glucosinolate and cardanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com