Environment-friendly reclaiming agent for rubber reclaiming and preparation method thereof

A regenerant and environmental-friendly technology, which is applied in the field of environmentally-friendly regenerant and its preparation, can solve the problems of non-environmental protection and poor regenerant effect, and achieve the effects of reducing production costs, basically no rebound in Mooney viscosity, and lowering the desulfurization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Put 100 parts by mass of environmentally friendly aromatic oil in a heating and stirring container, heat it to 130°C, and stir for 5 minutes; add 0.6 parts by mass of Stir at 110°C for 10 minutes; then add 0.07 parts by mass of copper chloride, stir at 120°C for 9 minutes; stop heating, and cool the material to room temperature within 10 minutes to obtain a solid rubber environmental protection regenerant.

Embodiment 2

[0025] Put 100 parts by mass of pine tar in a heating and stirring container, heat it to 80°C while stirring, and stir for 4 minutes; add 1 part by mass of Stir at 100°C for 7 minutes; then add 0.1 parts by mass of barium stearate, stir at 90°C for 10 minutes; stop heating, and cool the material to room temperature within 60 minutes to obtain a solid rubber environmental protection regenerant.

Embodiment 3

[0027] Put 100 parts by mass of naphthenic oil in a heating and stirring container, heat it to 90°C while stirring, and stir for 3 minutes; add 5 parts by mass of Stir at 100°C for 11 minutes; then add 0.3 parts by mass of magnesium hydroxide, stir at 90°C for 10 minutes; stop heating, and cool the material to room temperature within 30 minutes to obtain a liquid rubber environmental protection regenerant.

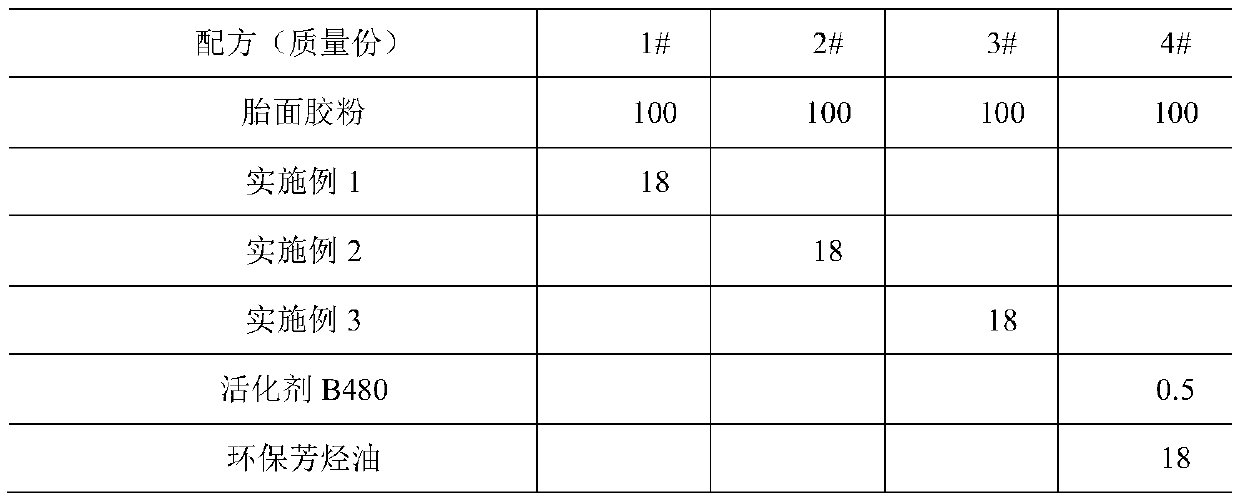

[0028] In order to compare with the currently commonly used formula 4, the same rubber powder was used to prepare reclaimed rubber according to formula 1#, 2#, 3# and 4# under the same process conditions.

[0029] Desulfurization formula

[0030]

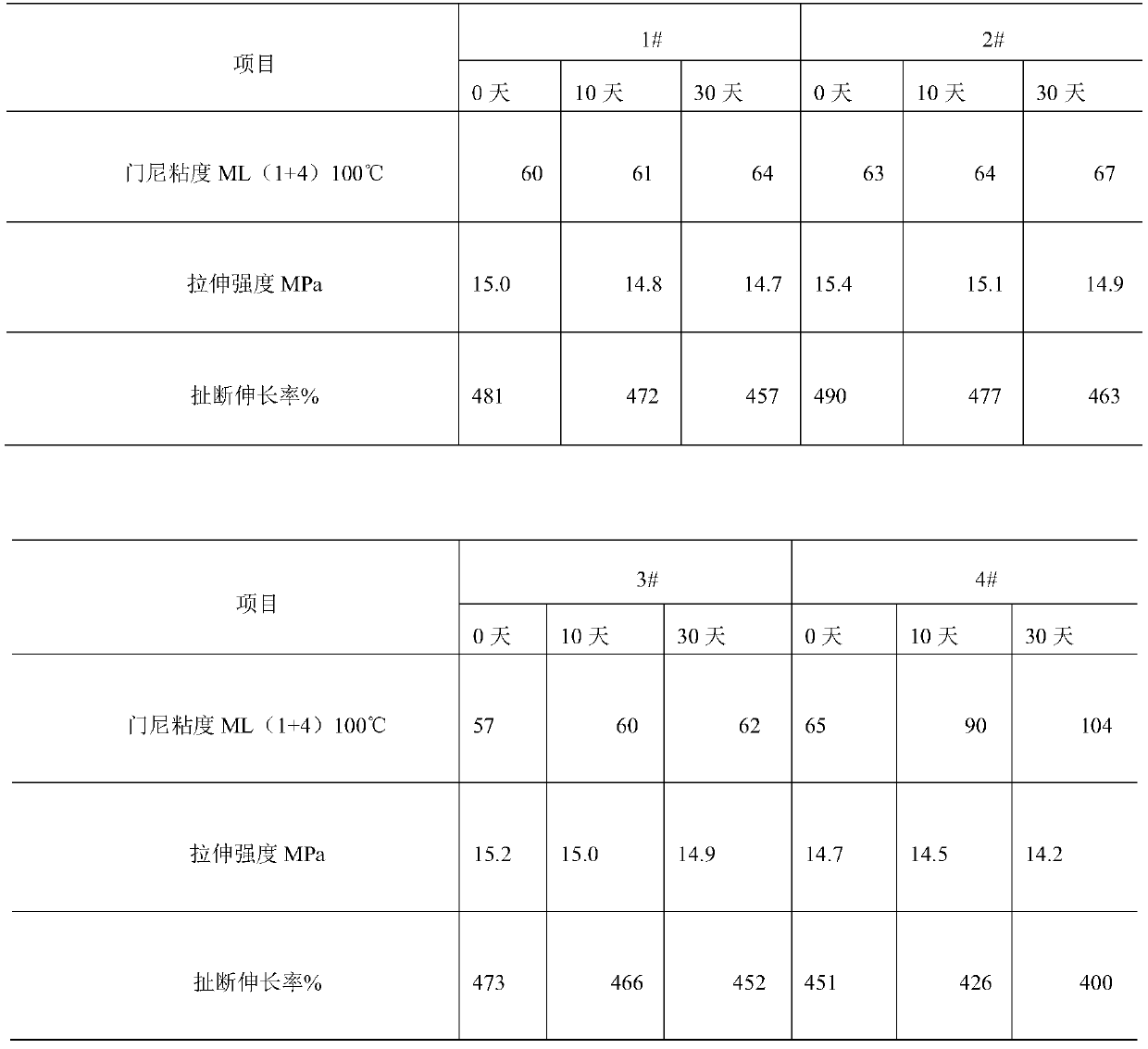

[0031] Comparison of Mechanical Properties and Mooney Viscosity Rebound

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com