Catalytic double-alkali desulphurization and dust removal process

A technology of desulfurization and dust removal and dual-alkali method, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve problems such as the failure of long-term continuous operation of equipment and fouling of desulfurization and dust removal towers for circulating fluids, and promote rapid precipitation. , avoid secondary pollution, solve the effect of thickening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

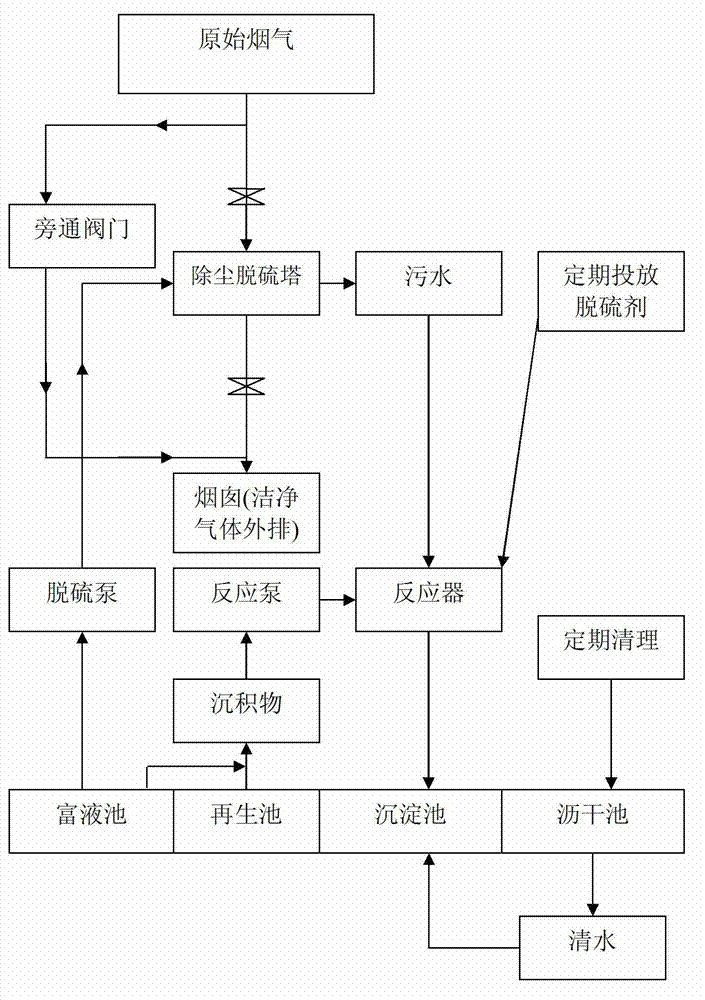

[0032] Embodiment 1: see figure 1 , the present invention adopts catalytic double-alkali desulfurization and dust removal process, utilizes different desulfurization and dust removal towers, enters the inner cavity from the top of the dust removal and desulfurization tower to form a spray-like lye, reacts with the original flue gas to form sewage, and discharges sewage from the bottom of the dust removal and desulfurization tower The original flue gas enters the inner cavity through the bottom of the dust removal and desulfurization tower, and after reacting with the sprayed lye, the clean gas is discharged from the top of the dust removal and desulfurization tower.

[0033] First, NaOH is added to the rich solution pool to form a solution with a pH value of about 11, and the NaOH consumption can be regularly replenished by detecting the pH value. At the same time, add washing powder or detergent to this solution, and add Na 3 PO 4 , NaOH solution with washing powder, deter...

Embodiment 2

[0044] Example 2: see figure 1 , the content is basically the same as in Example 1, and the similarities are not repeated. The difference is: 1 kilogram of washing powder and detergent are added in 100 tons of NaOH solution (1 kilogram of washing powder and detergent), and 500 ~ 1000 kg Na 3 PO 4 .

Embodiment 3

[0045] Embodiment 3: see figure 1 , content is basically the same as embodiment 1, and similarity is not repeated, and difference is: only add 1 kilogram of washing powder in 100 tons of NaOH solutions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com