Horizontal semi-dry desulfurization box process technology

A technology of semi-dry desulfurization and process technology, which is applied in the purification device of combustion equipment flue gas and the process field of horizontal semi-dry desulfurization box, which can solve the problem of high investment and operation costs and the impact of circulating semi-dry flue gas desulfurization technology Problems such as promotion and application, to achieve the effect of reduced one-time investment, simple equipment processing and production, and convenient maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will be described in detail in conjunction with the technical solutions in the embodiments of the present invention:

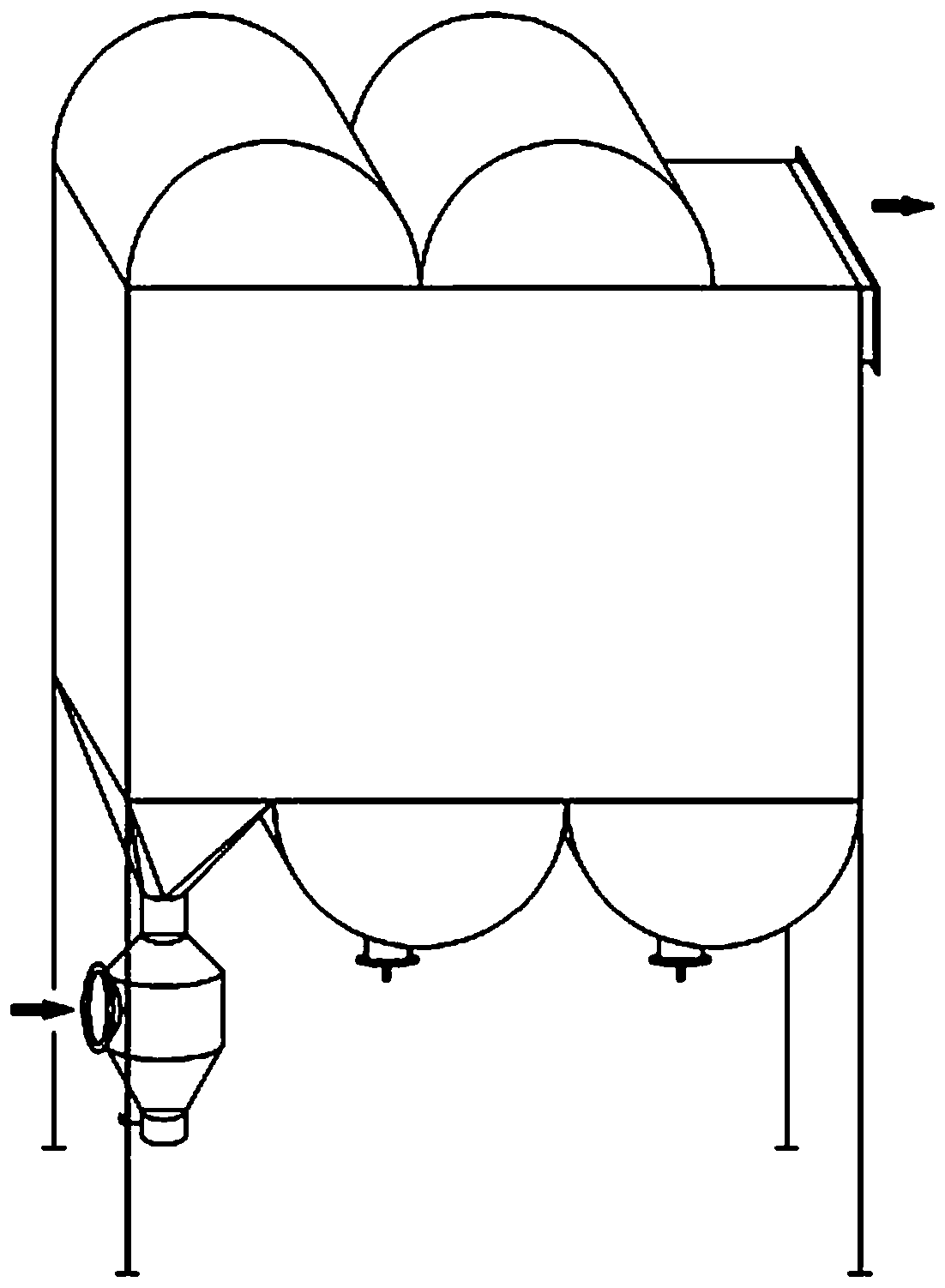

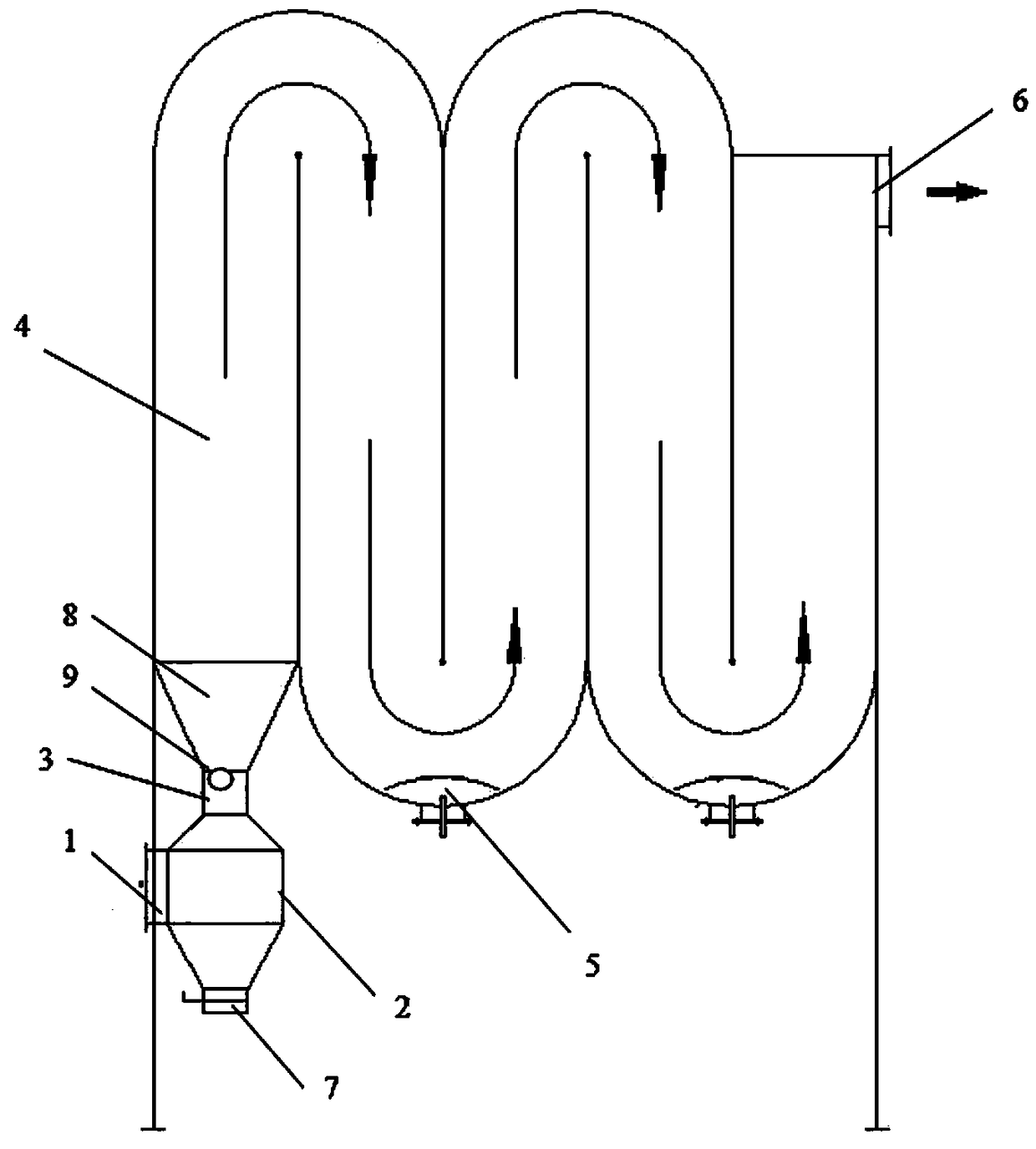

[0025] see figure 1 , figure 2 As shown, a desulfurization device realizing semi-dry desulfurization box process technology, said desulfurization device is provided with flue gas inlet 1, desulfurization reactor 2, Venturi throat 3, desulfurization box 4, flow Chemical bed 5, flue gas outlet 6, the bottom of the desulfurization reactor 1 tank is provided with a soot cleaning port 7, and the tank top 8 shrinks to ensure that the gentle slope is above 60°, and its caliber is the same as that of the Venturi throat 2. The diameter of the Venturi throat pipe 2 is set according to the flow velocity of 20-30m / s of the flue gas volume, which is reduced by about 30m / s compared with the design flow velocity of the semi-dry desulfurization tower throat pipe of 50-60m / s, which greatly reduces To avoid the resistance loss of the system, the throat h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com