High sulfur-content sewage negative pressure gas stripping desulfurization and sulfur-containing tail gas purifying apparatus and technology thereof

A tail gas purification device and high-sulfur technology, applied in water/sewage treatment, degassed water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of large consumption of natural gas or nitrogen chemicals, and operation and maintenance of reinjection systems Problems such as increasing cost and high pressure of reinjection of sulfur-containing wastewater have achieved the effect of reducing energy consumption, labor intensity and high automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

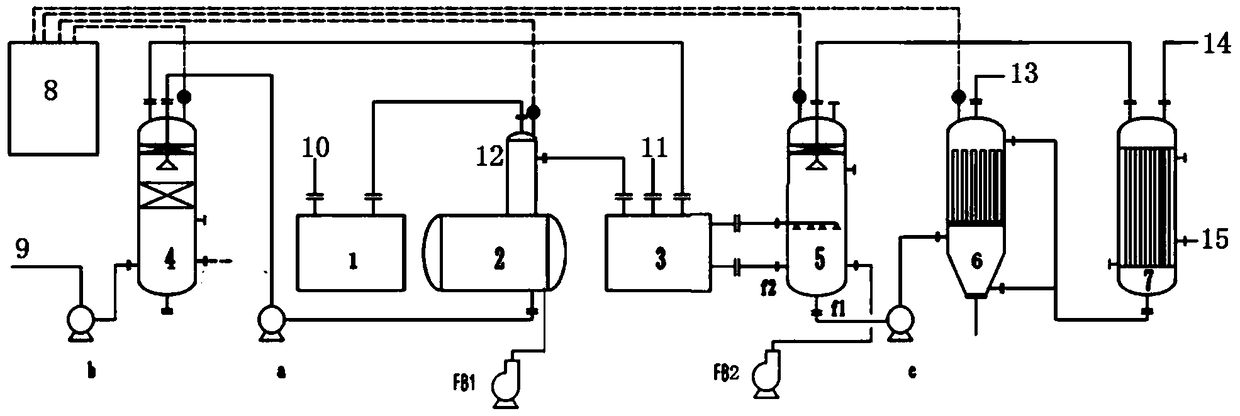

[0029] Such as figure 1 Shown is a schematic structural diagram of a negative pressure stripping desulfurization and sulfur-containing tail gas purification device for high-sulfur sewage, including a PLC control system 8, and also includes a pH adjustment device 1, a pretreatment device 2, a negative pressure stripping device 3 and Fine desulfurization device 4, oxidation regeneration device 5, sulfur separation device 6 and heat exchange system 7, the pH adjustment device 1 is a pH adjustment tank, the pretreatment device 2 is a pretreatment tank, and the negative pressure gas The extraction device 3 is a negative pressure stripping tank, the fine desulfurization device 4 is a fine desulfurization tank, the oxidation regeneration device 5 is an oxidation regeneration tank, and the sulfur separation device 6 is a sulfur separation tank. Valves are provided at the water inlet and outlet of the pH adjustment tank 1, pretreatment tank 2, negative pressure stripping tank 3, fine d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com