An integrated barrel for producing chitin

A chitin and cylinder technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve the problem of not producing chitin, save energy, improve heat transfer, and achieve high efficiency. mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

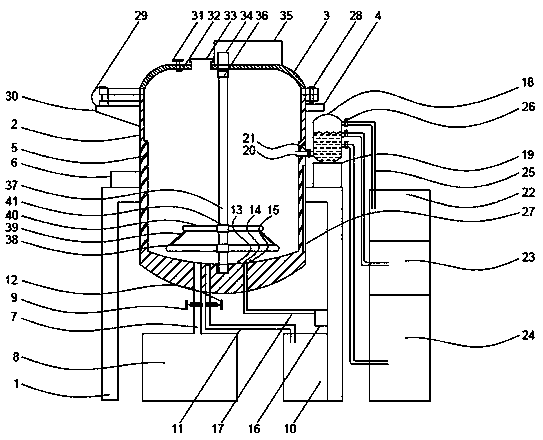

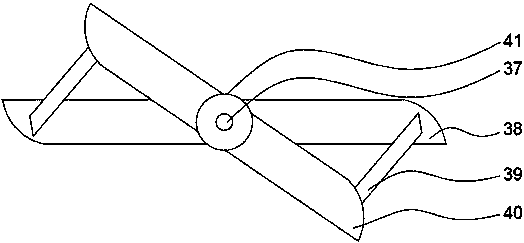

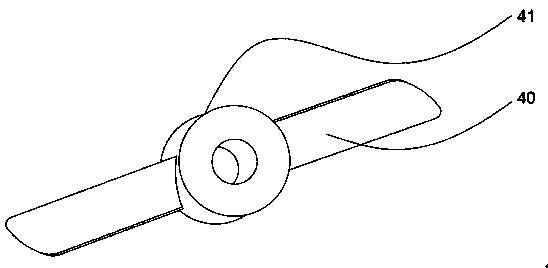

[0020] Such as Figure 1-4 As shown, an integrated barrel for producing chitin includes a bracket 1, a cylinder body 2, and a cylinder cover 3. The bracket 1 is distributed around the cylinder body 2 and supports the cylinder body 2. The upper right part of the cylinder body 2 is provided with a controller 4 There is an observation window 27 on the right side of the cylinder body 5; a heating tube 5 is arranged on the inner wall of the cylinder body 2, and a high-temperature steam is circulated in the heating tube 5, and the heating tube 5 is connected with a heater 6 fixed on the left side of the cylinder body 2 The bottom of the cylinder 2 is a concave circular design, the bottom of the cylinder 2 is provided with a discharge pipe 7 and a waste liquid pipe 11, and one end of the discharge pipe 7 and the waste liquid pipe 11 runs through the bottom of the cylinder 2 and the inside of the cylinder 2 The other ends of the discharge pipe 7 and the waste liquid pipe 11 are respec...

Embodiment 2

[0027] Such as Figure 1-4 Shown, a kind of integrated barrel for producing chitin, when producing, firmly fix cylinder body 2 and clean cylinder body 2 with support 1, hold acid, Alkali, distilled water. The raw materials are fed into the cylinder body 2 from the feeding port 33 provided on the cylinder cover 3, and then the feeding port 33 is closed to seal the cylinder cover 3. Turn on the heater 6 to heat the material in the cylinder 2, and at the same time turn on the motor 35 to start the stirring part, and control the automation process through the controller 4. During the production process, the valve 12 of the waste liquid pipe can be controlled to discharge the waste liquid, and the cylinder 2 can be monitored in real time. The pressure, temperature, pH value, viscosity and other physical and chemical indicators of the inner material liquid are used to adjust the reaction conditions, and the processes of alkali boiling, water washing, acid leaching, and water washin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com