Flue gas semidry desulfurization method and device

A semi-dry desulfurization and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc. It can avoid scaling and clogging, improve desulfurization efficiency, and ensure desulfurization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

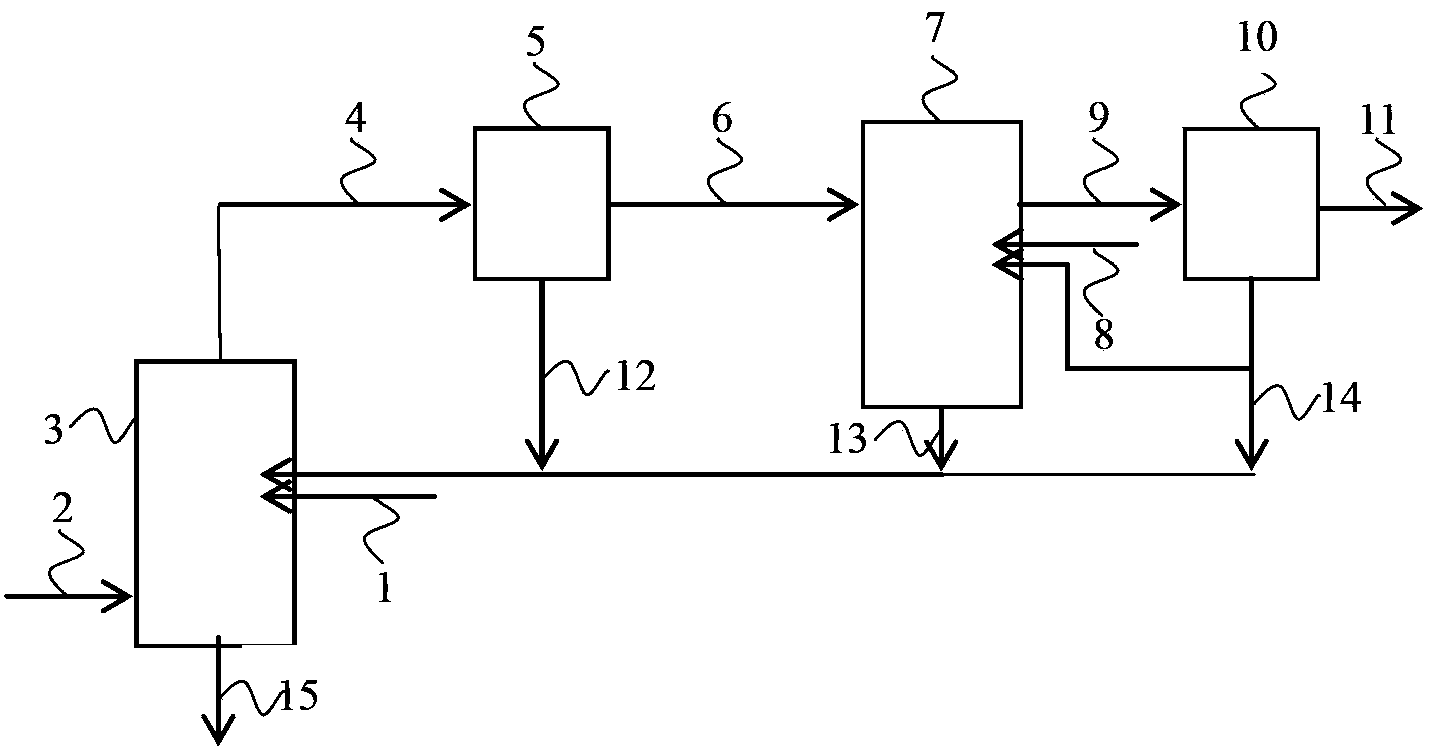

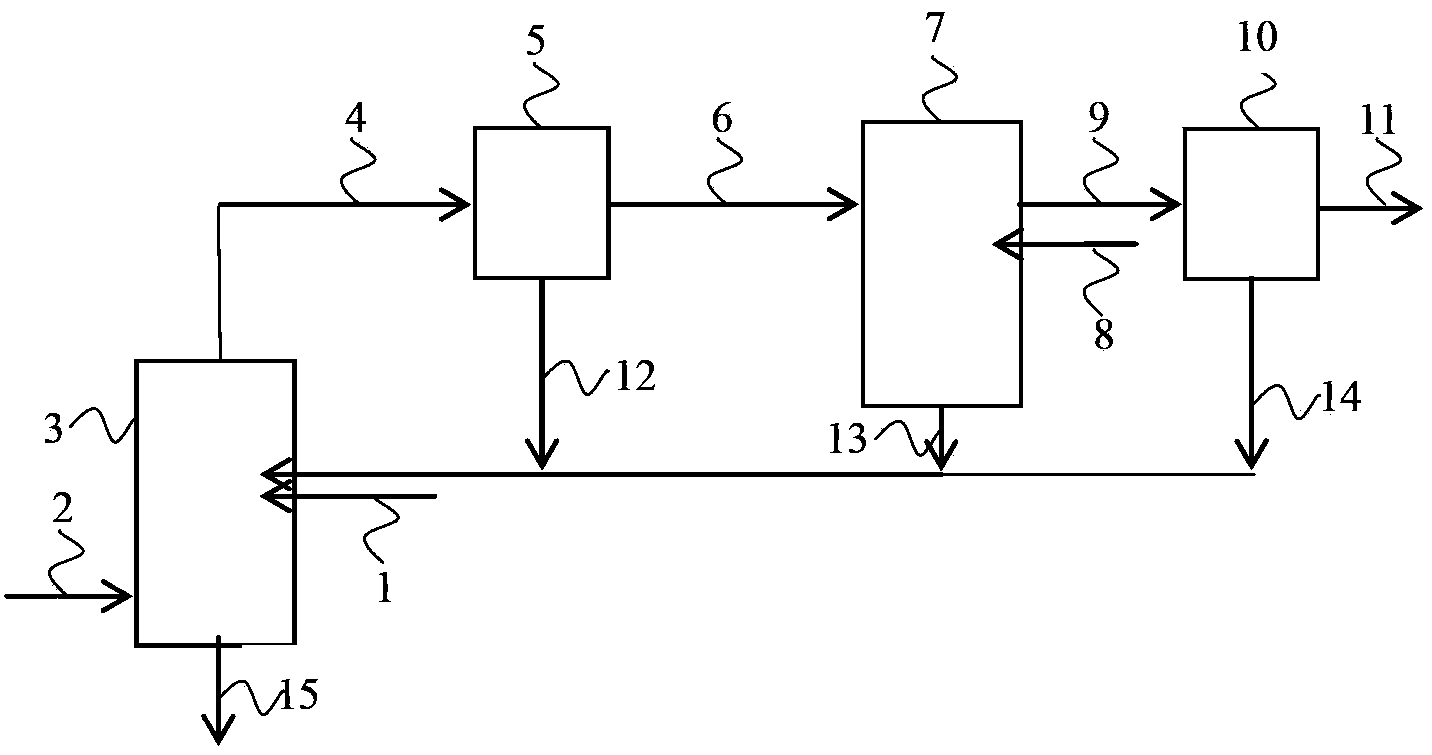

[0035] Such as figure 1 Shown is an example of a process flow diagram of a treatment method represented by an embodiment of the present invention. Calcium oxide dry powder desulfurization agent according to the requirement of calcium sulfur ratio 1.1 (the amount is calculated according to the flue gas volume and the concentration of sulfur dioxide in the flue gas), through the desulfurizer inlet 1, the flue gas adjusted to 5% by water steam passes through the flue gas The gas inlet 2 enters the front-stage desulfurization tower 3, and contacts and reacts in the front-stage desulfurization tower 3. After the reaction, the flue gas that has been desulfurized once passes through the flue gas inlet 4 of the front-stage dust collector, and is dust-removed in the front-stage dust collector 5. The flue gas after dust removal The gas passes through the flue gas inlet 6 of the rear-stage desulfurization tower after being conditioned by water steam, and then enters the rear-stage desulf...

Embodiment 2

[0037] The desulfurization process flow is basically the same as in Example 1, except that figure 1 The desulfurizing agent recovered as shown, the desulfurizing agent 12 recovered by the pre-stage dust collector, the desulfurizing agent 13 recovered by the post-stage desulfurization tower, and the desulfurizing agent 14 recovered by the post-stage dust collector are sent to the front-stage desulfurization tower 3 by screw feeder and circulated to the front-stage desulfurization tower 3 for reuse , and the inlet is the desulfurizer inlet 01 of the front desulfurization tower.

Embodiment 3

[0039] The desulfurization process flow is basically the same as in Example 1, except that figure 1 The desulfurizing agent recovered as shown, the desulfurizing agent 12 recovered by the pre-stage dust collector, the desulfurizing agent 13 recovered by the post-stage desulfurization tower, and the desulfurizing agent 14 recovered by the post-stage dust collector are mixed and circulated to the front-stage desulfurization through screw feeder pressure feeding and air transportation Tower 3 is used again, and the inlet is the desulfurizer inlet 01 of the former desulfurization tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com