Ultrasonic desulfuration, denitration and dust removal method

An ultrasonic and denitrification technology, applied in the fields of desulfurization, denitration and dust removal, can solve the problems of less related research, high cost, poor effect of desulfurization, denitration and dust removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

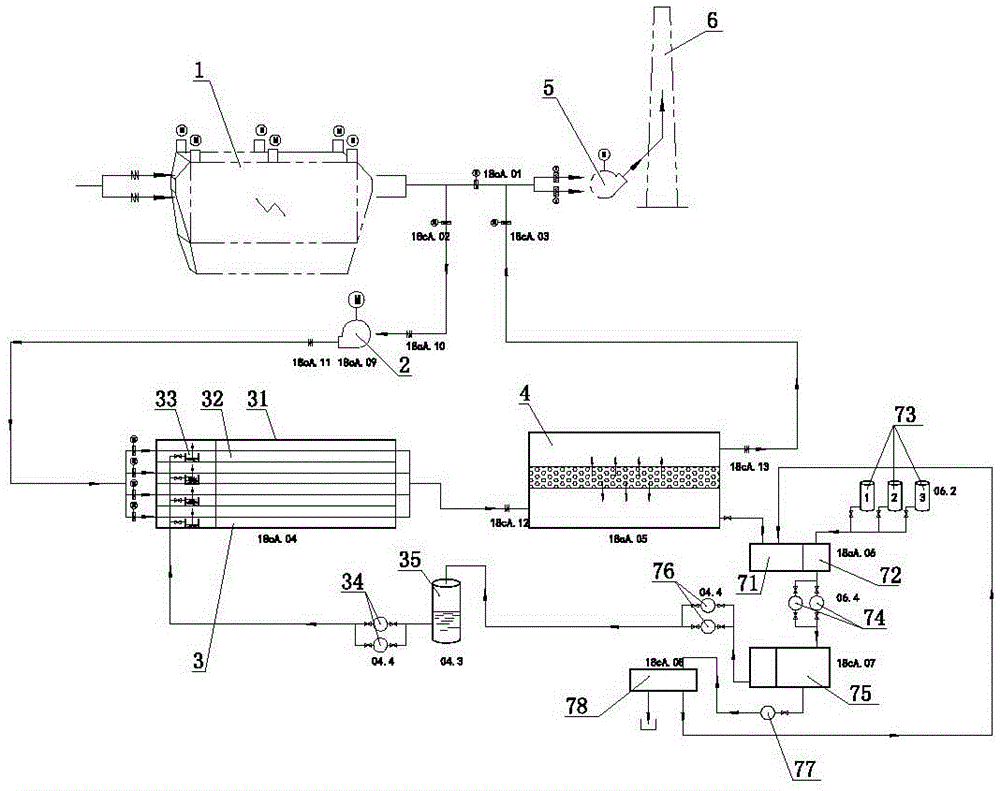

[0037] Such as figure 1 As shown, the methods of ultrasonic desulfurization, denitrification and dust removal are:

[0038] (1) The flue gas that has undergone electrostatic dust removal is sent to the ultrasonic device 3 through the fan 2, and the device for electrostatic dust removal of the flue gas is the waste gas treatment electrostatic precipitator 1 . The ultrasonic device 3 includes a housing 31, which has more than two flue gas passages 32, and each flue gas passage 32 is connected to a desulfurization liquid pool, and an ultrasonic generator (not shown) is installed on the desulfurization liquid pool. The desulfurization liquid storage tank 35 is connected by the pump 34, and the desulfurization liquid is filled in the desulfurization liquid storage tank 35. According to the weight ratio, the desulfurization liquid is composed of 8% calcium chloride, 3% white mud, 8% sodium hydroxide, 0.5% Barium oxide, 0.8% calcium oxide, 10% sodium oxide, 9% potassium permanganate...

Embodiment 2

[0065] The desulfurization solution of the present embodiment consists of 25% calcium chloride, 2% white mud, 4% sodium hydroxide, 1.2% barium oxide, 1% calcium oxide, 5% sodium oxide, 10% Potassium permanganate, 7% lithium peroxide, 9% ferrous sulfate heptahydrate, 23% water, 3% lithium hydroxide, 5% sodium fluorosilicate, 4% sodium carbonate and 0.8% of ethylenediamine phosphate. Others are the same as in Example 1.

Embodiment 3

[0067] The desulfurization solution of the present embodiment consists of 13.8% calcium chloride, 2.5% white mud, 6% sodium hydroxide, 0.8% barium oxide, 0.9% calcium oxide, 7% sodium oxide, 5% Potassium permanganate, 8% lithium peroxide, 11% ferrous sulfate heptahydrate, 25% water, 5% lithium hydroxide, 4% sodium fluorosilicate, 10% sodium carbonate and 1% of ethylenediamine phosphate. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com