Desulfurization method and desulfurization device for industrial mixed gas

A technology of mixed gas and desulfurization equipment, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., and can solve problems such as complex processes, regeneration of organic sulfur hydrolyzing agents and hydrogen sulfide adsorbents, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

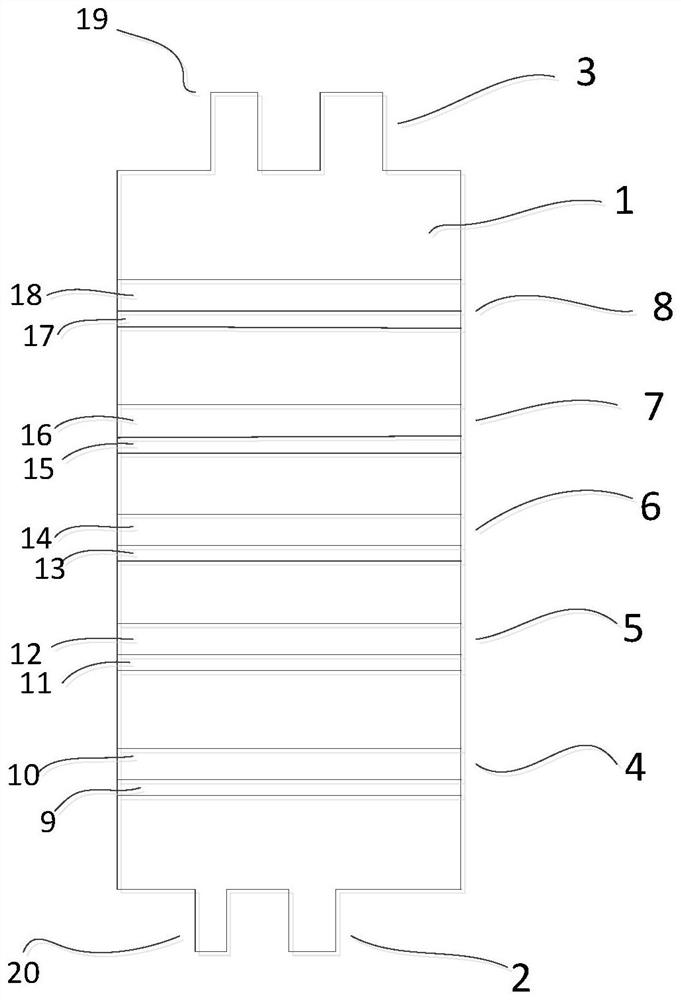

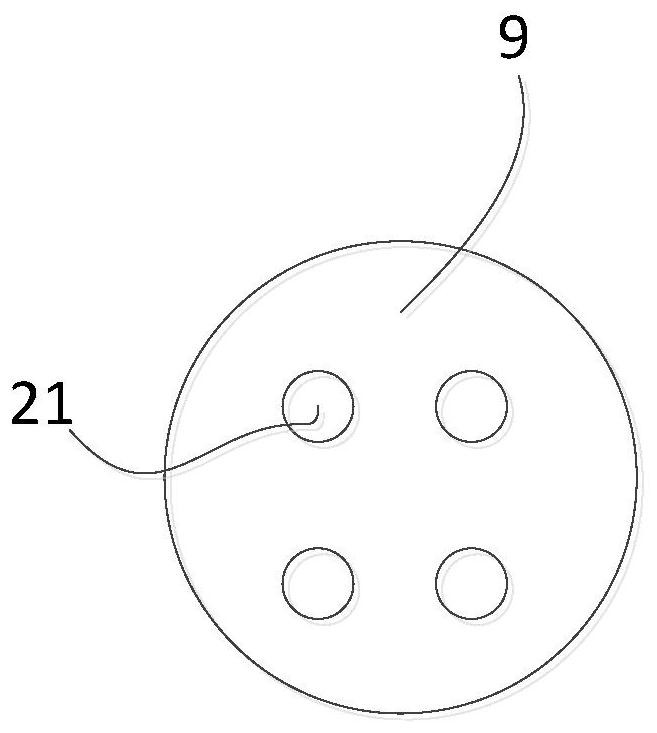

[0050] like figure 1 As shown, the present invention provides a desulfurization device, comprising: a tank body 1, which is provided with a desulfurization gas inlet 2 and a desulfurization gas outlet 3; an organic sulfur hydrolysis layer 5, a deoxidation layer 6 and a hydrogen sulfide adsorption layer 7, which are arranged on the Inside the tank body 1, and arranged in sequence along the axial direction of the tank body 1, the desulfurization air inlet 2 is located at the end of the tank body 1 close to the organic sulfur hydrolysis layer 5, and the desulfurization air outlet 3 is located at the end of the tank body 1 close to the organic sulfur hydrolysis layer 5. The tank body 1 is close to one end of the hydrogen sulfide adsorption layer 7 .

[0051] In the desulfurization device of the present invention, optionally, the desulfurization device may be a desulfurization tower. In the present invention, the organic sulfur hydrolysis layer 5, the deoxidation layer 6 and the h...

Embodiment 2

[0081] like figure 1 As shown, the present embodiment provides a desulfurization method for industrial mixed gas, comprising the following steps:

[0082] 1) Desulfurization step: the 60°C industrial mixed gas (wherein the industrial mixed gas contains 200 mg / Nm 3 COS, 0.5% (volume content) oxygen, 25% (volume content) carbon monoxide, 5% (volume content) hydrogen, 15% (volume content) carbon dioxide, with nitrogen as the balance gas) for 5000h -1 The volume air velocity is passed into the tank 1 from the desulfurization air inlet 2 at the bottom of the desulfurization tower, and successively passes through the filter layer 4 (the filter layer 4 is filled with 4A molecular sieve), the organic sulfur hydrolysis layer 5 (the organic sulfur hydrolysis layer 5 is filled with K 2 CO 3 / Ti-Al 2 O 3 Hydrolysis agent), deoxidation layer 6 (deoxidation layer 6 is filled with honeycomb ceramic carrier and platinum metal deoxidizer 14), hydrogen sulfide adsorption layer 7 (hydrogen s...

Embodiment 3

[0086] like figure 1 As shown, the present embodiment provides a desulfurization method for industrial mixed gas, comprising the following steps:

[0087] 1) Desulfurization step: the 70 ℃ industrial mixed gas (in which the industrial mixed gas contains 180 mg / Nm 3 COS, 0.7% (volume content) oxygen, 27% (volume content) carbon monoxide, 2% (volume content) hydrogen, 13% (volume content) carbon dioxide, with nitrogen as the balance gas) for 3000h -1 The volume air velocity is passed into the tank body 1 from the desulfurization air inlet 2 at the bottom of the desulfurization tower, and successively passes through the filter layer 4 (the filter layer 4 is filled with 13X molecular sieves), the organic sulfur hydrolysis layer 5 (the organic sulfur hydrolysis layer 5 is filled with K 2 C 2 O 4 / Ti-MgAl 2 O 4 Hydrolyzing agent), deoxidizing layer 6 (deoxidizing layer 6 is filled with honeycomb ceramic carrier supporting palladium metal deoxidizer), hydrogen sulfide adsorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com