Biogas fermentation stirring and biogas desulfurization method

A biogas fermentation and biogas desulfurization technology, applied in biochemical equipment and methods, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problems of poor desulfurization effect, easy blockage, low investment, etc. problem, to achieve the effect of good stirring effect, less equipment in the tank, and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

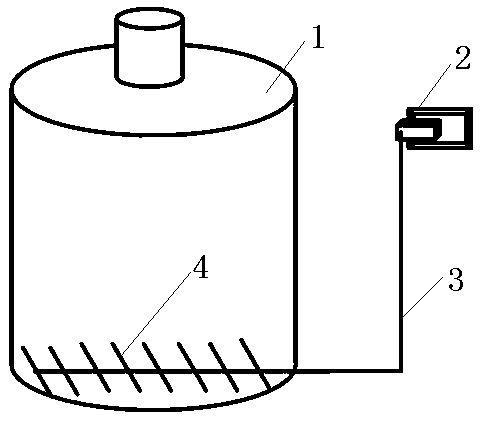

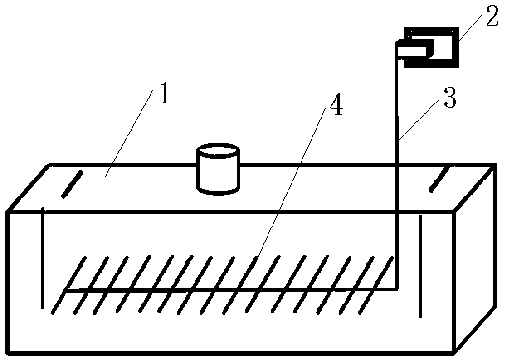

[0027] A method for biogas fermentation stirring and biogas desulfurization, using a blower 2 to blow compressed air into the biogas fermentation reactor 1 through the gas distributor 4 at the bottom of the biogas fermentation reactor 1, and using the rising effect of the air to cool the feed liquid in the biogas fermentation reactor 1 Perform mixing and stirring, control the stirring time and frequency, the air escapes from the fermentation feed liquid and enters the head space of biogas fermentation reactor 1, and the domesticated microorganisms in the head space of biogas fermentation reactor 1 use the oxygen in the air to oxidize hydrogen sulfide to generate elemental sulfur or sulfuric acid Salt.

[0028] In the present invention, the blower 2 and the air pipe 3 are placed outside the biogas fermentation reactor 1 , and the blower 2 is connected to the air distributor 4 at the bottom of the biogas fermentation reactor 1 through the air pipe 3 .

[0029] In the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com