Magnetic attraction-oxidation desulfurizing agent and preparation method

A technology of oxidative desulfurization and magnetic adsorption, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, alkali metal oxides/hydroxides, etc., can solve the problem of excessive vehicle exhaust emissions, air pollution, and unprepared magnetic adsorption- Oxidative desulfurization agent and other issues to achieve the effect of reducing desulfurization cost, avoiding energy waste, and improving catalytic oxidation desulfurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

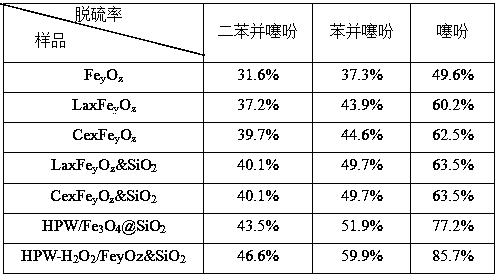

Examples

Embodiment 1

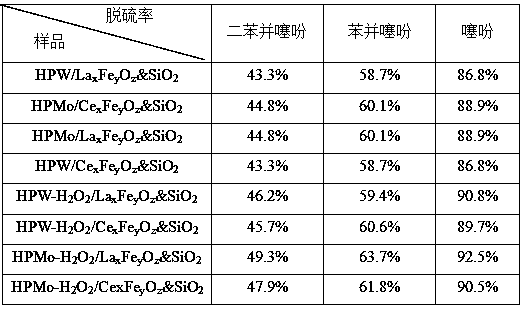

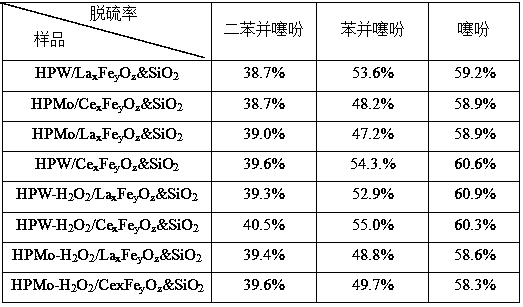

[0039] Embodiment 1: HPW / La x Fe y o z &SiO 2 Synthesis

[0040] Synthesis of silanized ferromagnetic composite oxide LaxFeyOz&SiO according to the synthesis method of Comparative Example 4 2 .

[0041] Under the conditions of normal temperature, normal pressure and stirring, phosphotungstic acid was added to water according to the mass ratio of 0.01:1, and the pH value of the solution was adjusted to 4.0 to obtain solution A. The silanized magnetic iron composite oxide LaxFeyOz&SiO 2 According to the mass ratio of 20:1, it was added to solution A, shaken and stirred for 0.5h, dried into powder at a temperature of 120°C, and then roasted at a temperature of 300°C for 24h to obtain an adsorption-oxidation desulfurizer, recorded as HPW / LaxFeyOz&SiO 2 .

Embodiment 2

[0042] Example 2: HPMo / La x Fe y o z &SiO 2 Synthesis

[0043] Synthesis of silanized ferromagnetic composite oxide LaxFeyOz&SiO according to the synthesis method of Comparative Example 4 2 .

[0044] Under the conditions of normal temperature, normal pressure and stirring, phosphomolybdic acid was added to water according to the mass ratio of 0.01:1, and the pH value of the solution was adjusted to 4.0 to obtain solution A. The silanized magnetic iron composite oxide LaxFeyOz&SiO 2 According to the mass ratio of 20:1, it was added to solution A, shaken and stirred for 0.5h, dried into powder at a temperature of 120°C, and then roasted at a temperature of 300°C for 24h to obtain an adsorption-oxidation desulfurizer, recorded as HPMo / LaxFeyOz&SiO 2 .

Embodiment 3

[0045] Embodiment 3: HPW / Ce x Fe y o z &SiO 2 Synthesis

[0046] Synthesis of silanized ferromagnetic composite oxide CexFeyOz&SiO according to the synthesis method of Comparative Example 5 2 .

[0047] Under the conditions of normal temperature, normal pressure and stirring, phosphotungstic acid was added to water according to the mass ratio of 0.01:1, and the pH value of the solution was adjusted to 4.0 to obtain solution A. The silanized magnetic iron composite oxide CexFeyOz&SiO 2 According to the mass ratio of 20:1, it was added to solution A, shaken and stirred for 0.5h, dried into powder at a temperature of 120°C, and then roasted at a temperature of 300°C for 24h to obtain an adsorption-oxidation desulfurizer, recorded as HPW / CexFeyOz&SiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com