Horizontal dense-phase circulating fluidizing dry-tower desulfurization device

A circulating fluidization and desulfurization device technology, applied in the field of environmental engineering, can solve the problems of increasing the chance of collision between desulfurizing agent and flue gas, increasing the chance of collision between desulfurizing agent and flue gas, and occupying a large area, so as to save power consumption , easy maintenance and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

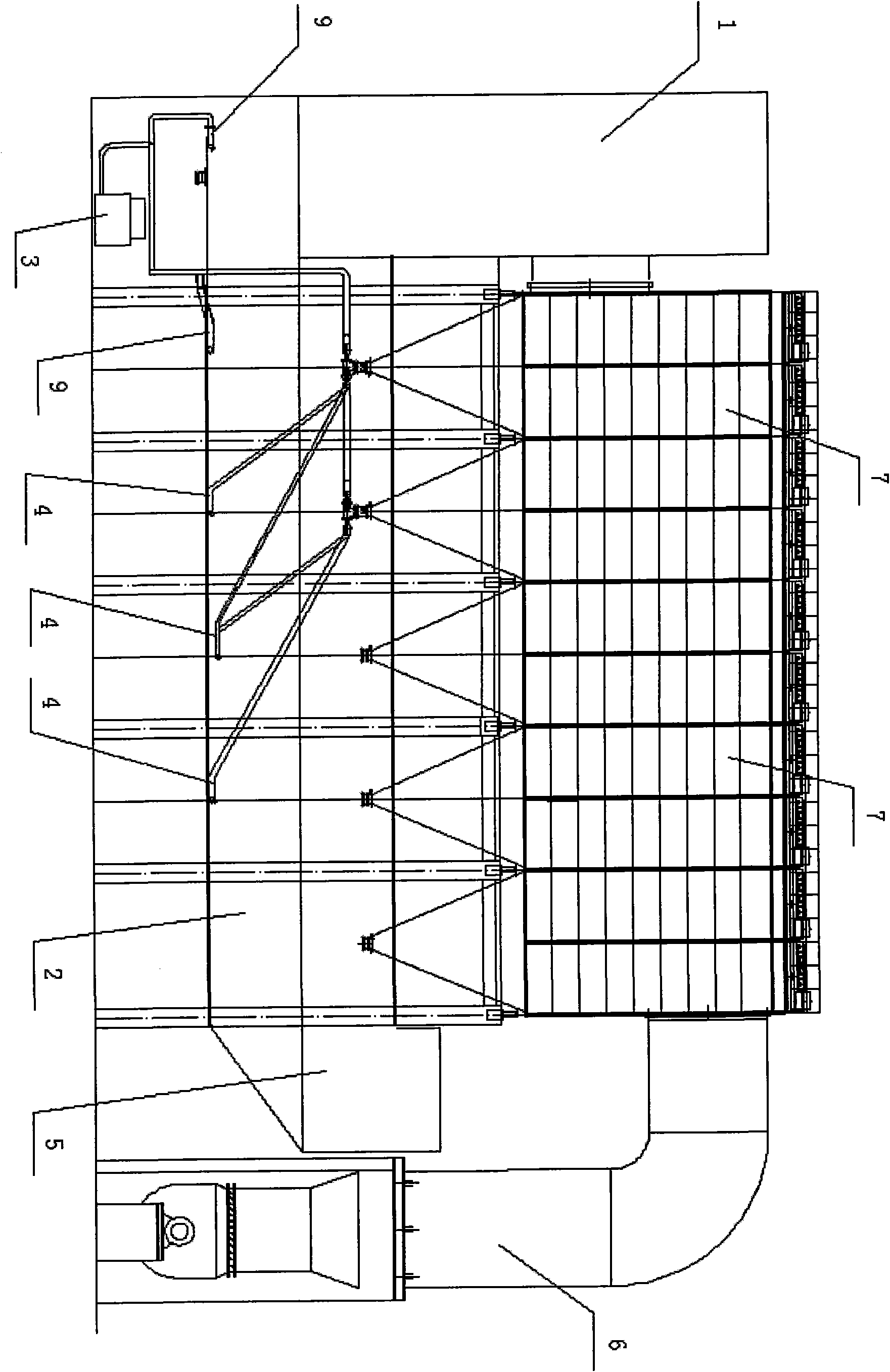

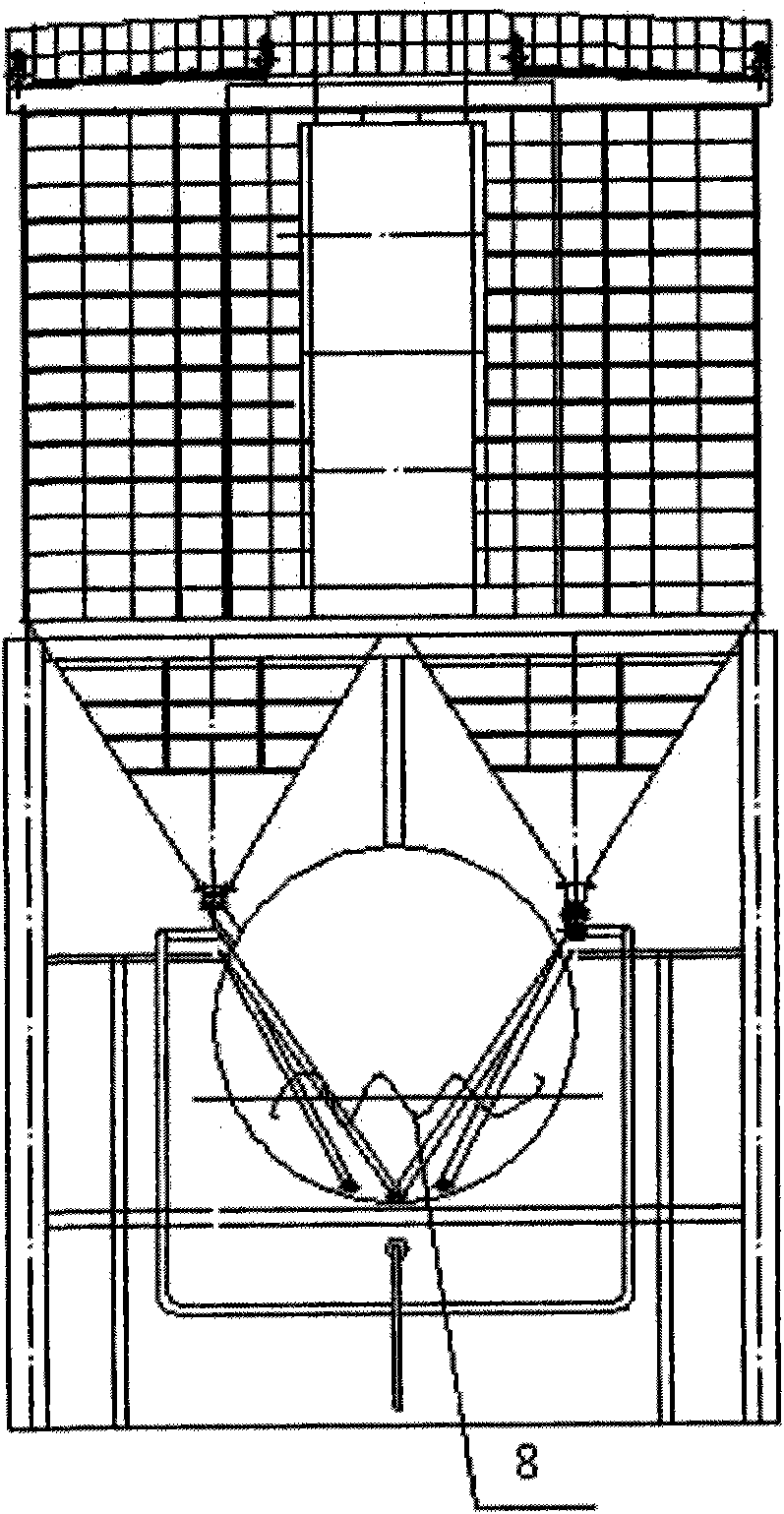

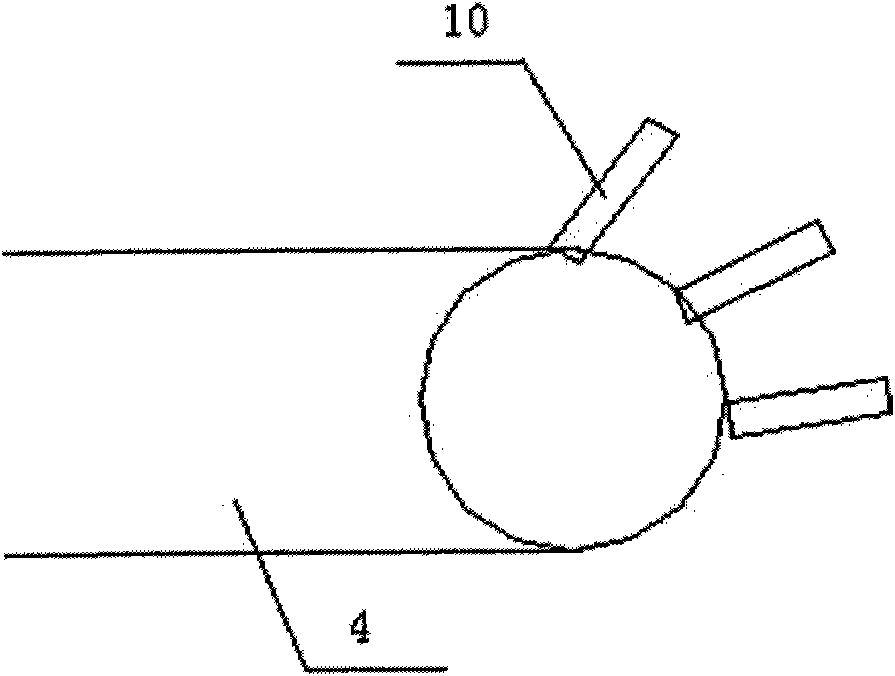

[0029] like figure 1 As shown, the present invention is a horizontal dense-phase circulating fluidized dry tower desulfurization device. Compressor 6, bag filter 7; the circulating fluidized chamber 1 of the present invention is vertical, and is arranged at the leftmost end of the device, and the flue gas and desulfurizing agent fully contact and react in the circulating fluidized chamber 1 to realize desulfurization. The dense-phase chamber 2 is horizontal, set on the right side of the circulating fluidized chamber 1, and communicated with the circulating fluidized chamber 1; and because the horizontal part is arranged under the bag filter, it saves space for the detachment device area. The bag filter 7 is above the dense phase chamber 2 . The desulfurizing agent separated from the bag filter 7 can enter the dense phase chamber 2 again to realize r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com