Patents

Literature

37 results about "Sulfate minerals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The sulfate minerals are a class of minerals that include the sulfate ion (SO₄²⁻) within their structure. The sulfate minerals occur commonly in primary evaporite depositional environments, as gangue minerals in hydrothermal veins and as secondary minerals in the oxidizing zone of sulfide mineral deposits. The chromate and manganate minerals have a similar structure and are often included with the sulfates in mineral classification systems.

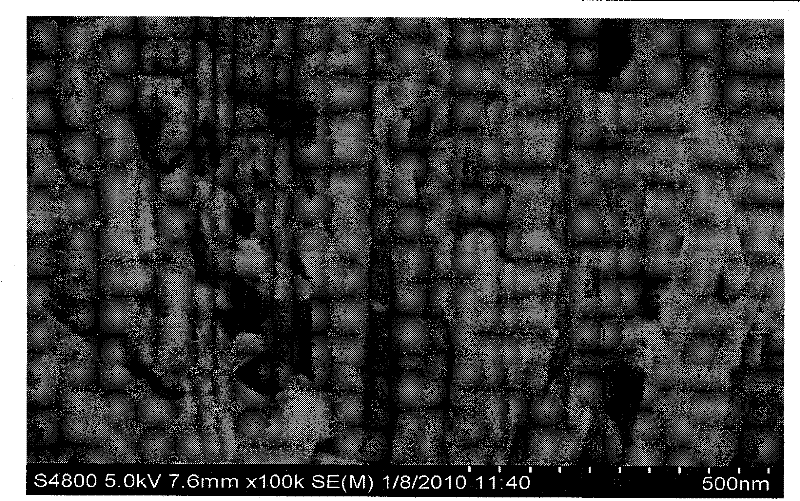

Treating material for polluted water, method for production thereof and use thereof

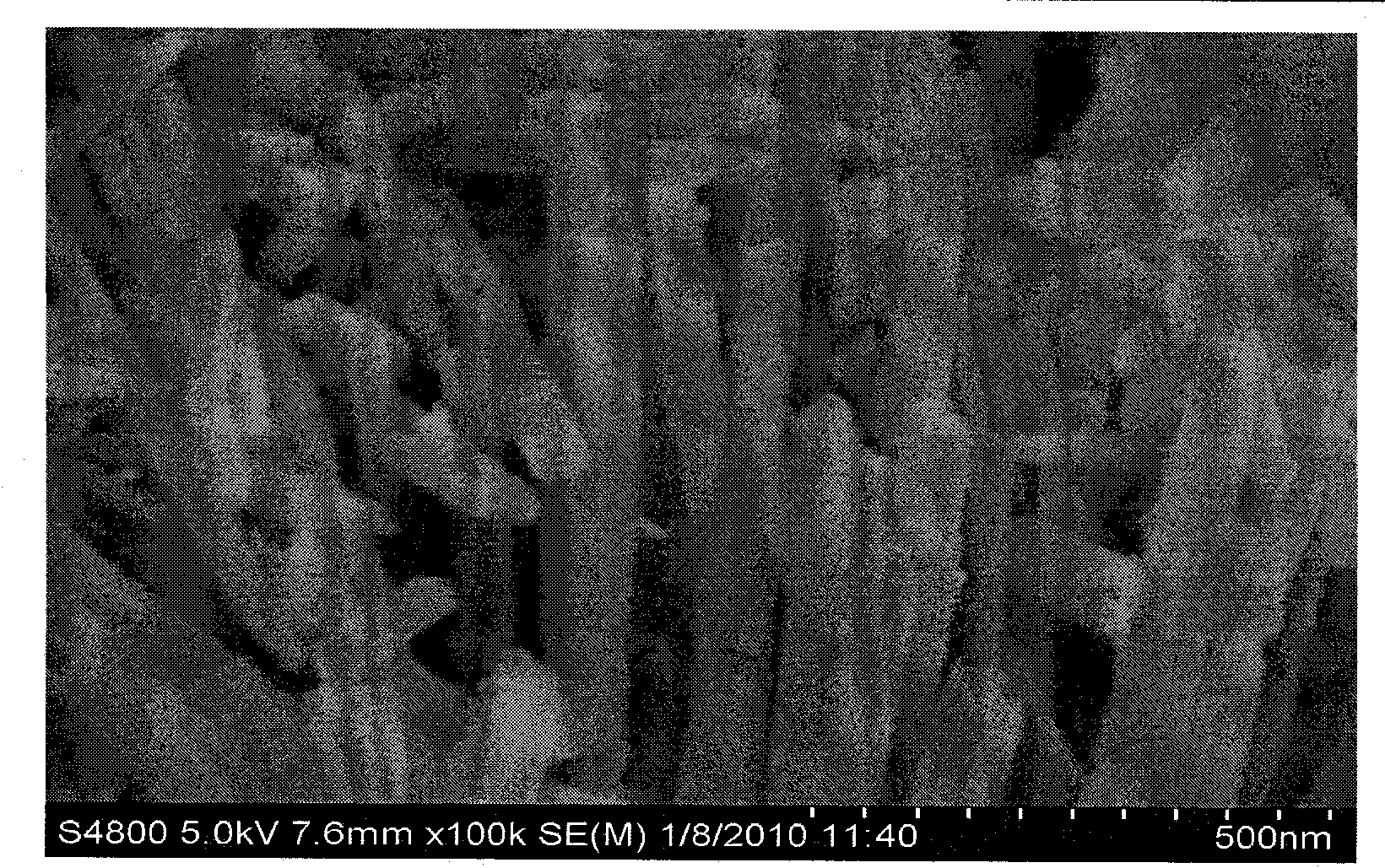

InactiveCN1798704AReduce loadEfficient methodPhysical/chemical process catalystsSilicon compoundsFiberSilicic acid

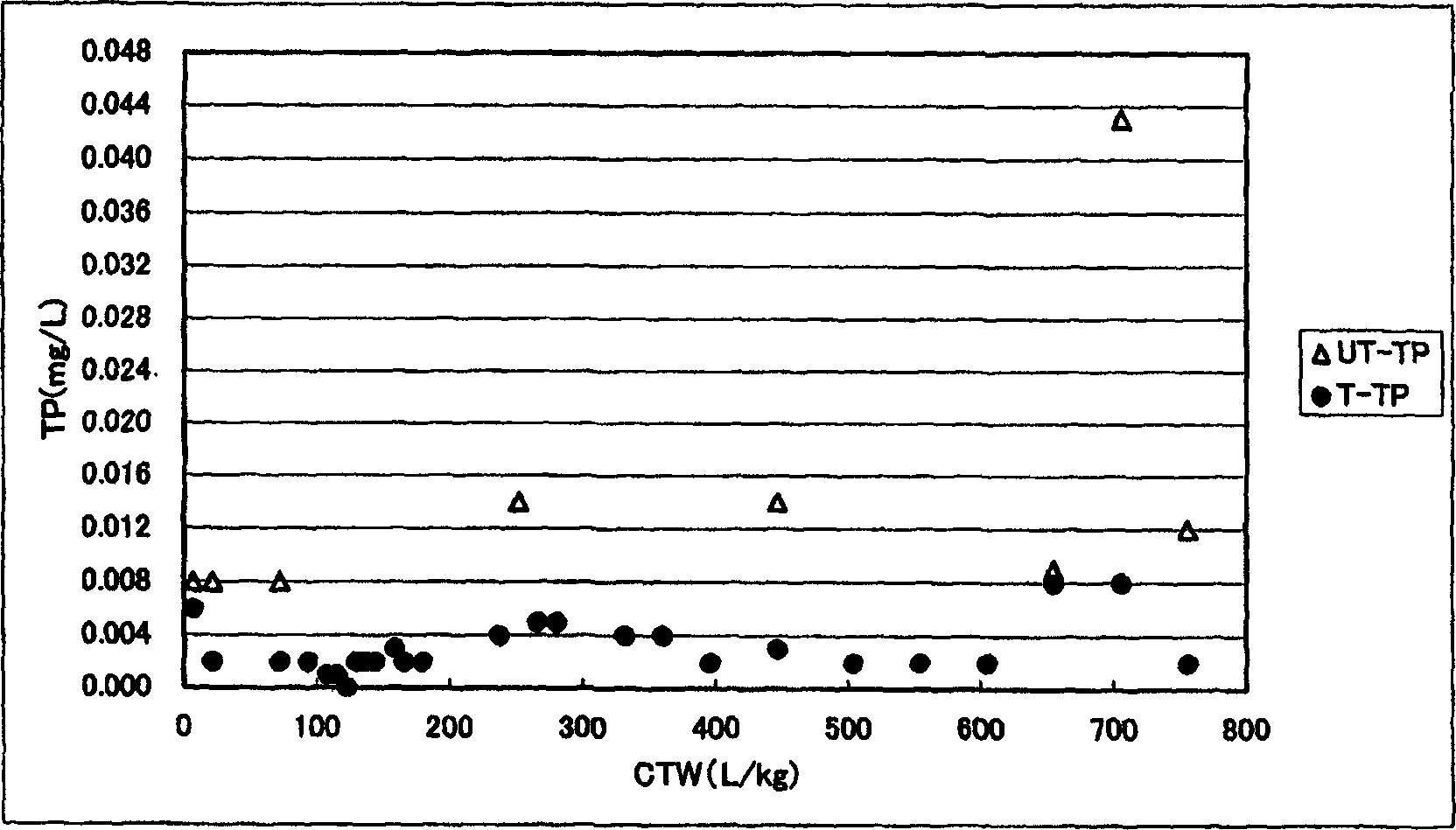

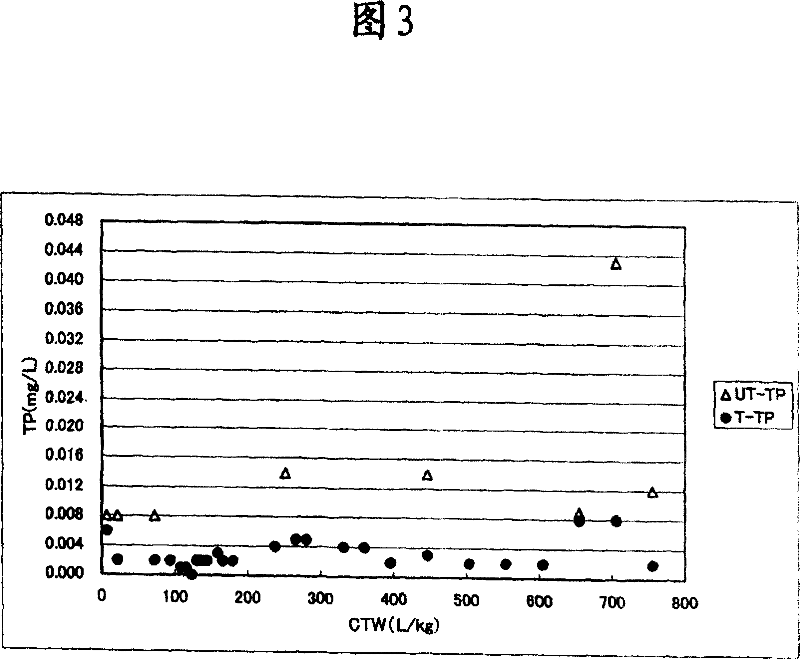

A treating material for treating a polluted water containing, as a hazardous substance, arsenic, lead, cadmium, antimony, uranium, phosphorus, fluorine or the like, which comprises an oxygen-containing iron compound carried on a material containing a silicic acid based fiber or a silicate based fiber; a method for producing the treating material which comprises contacting and reacting a silicate based fiber, such as rock wool, with an iron-containing acidic water; and a method for treating the polluted water witch comprises contacting the treating material with the polluted water. The treating material has a fine structure wherein the above oxygen-containing iron compound is attached in a sheath form on the surface of a fiber reduced in an alkali component and increased in a silicic acid component as compared to, for example, rock wool. The oxygen-containing iron compounds include schwertmannite, ferrihydrite, akaganeite, amorphous hydrous iron oxide and fired ferric sulfate.

Owner:NIPPON STEEL CHEMICAL CO LTD

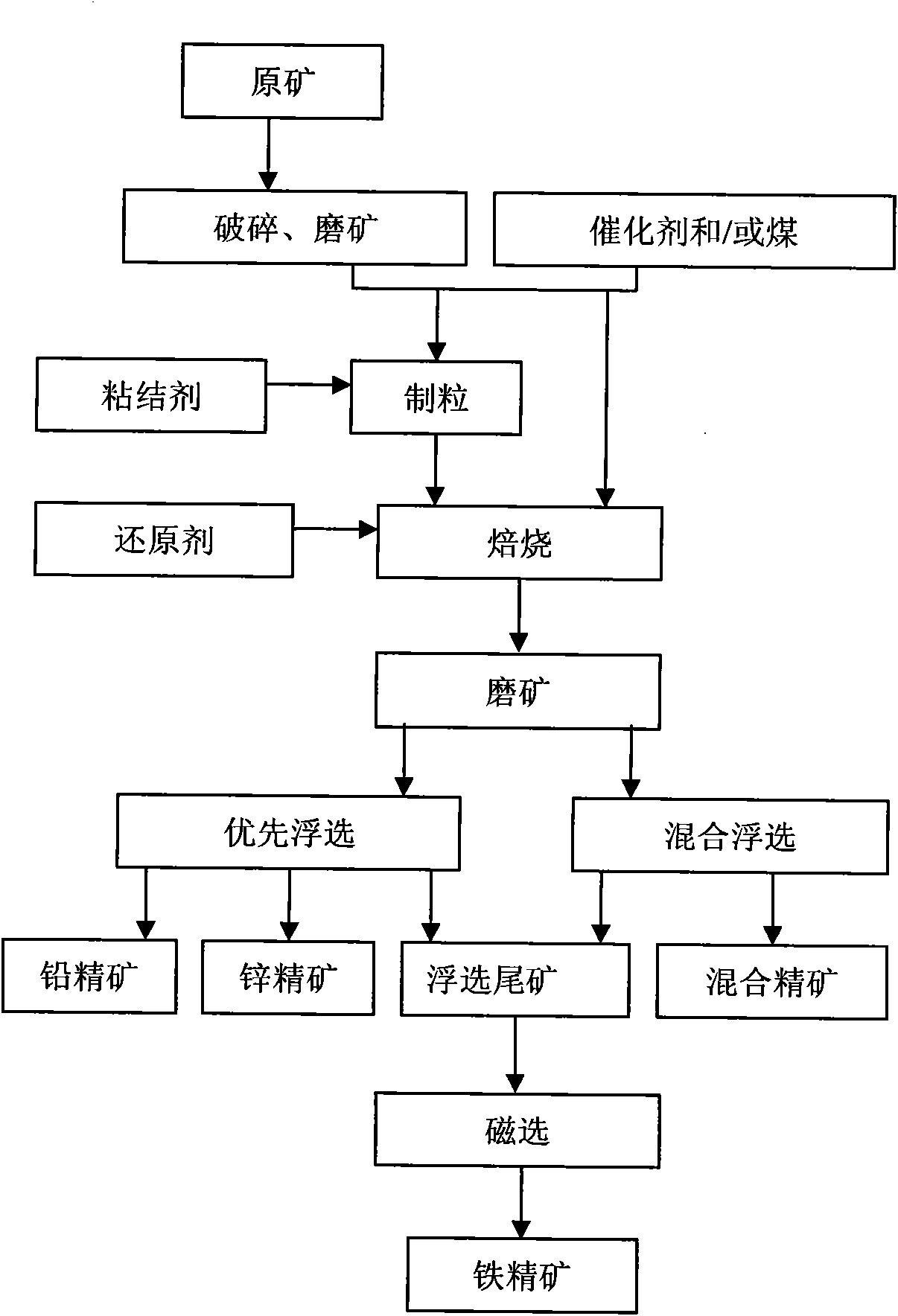

Beneficiation method of lead-zinc oxide mine difficult to beneficiate

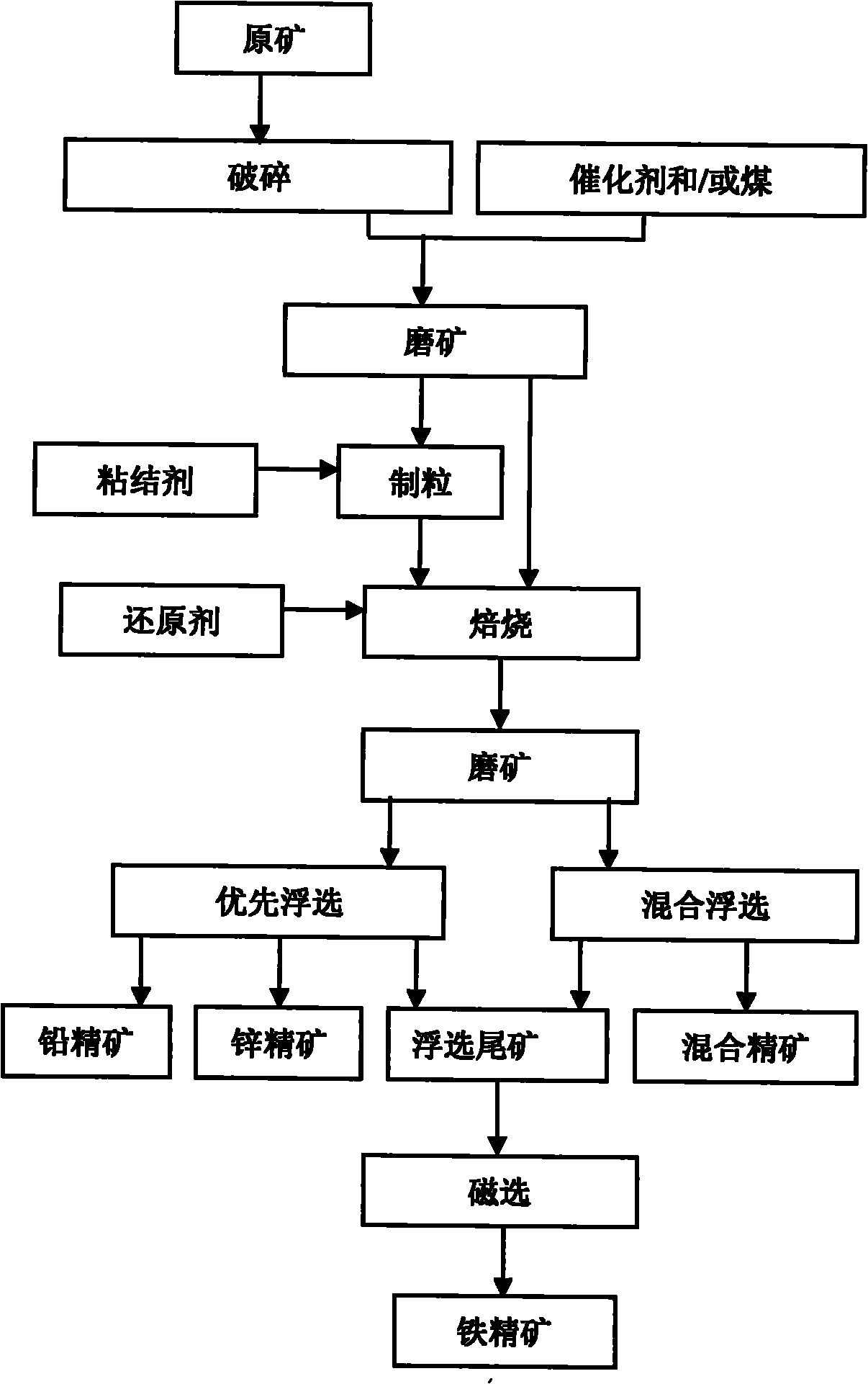

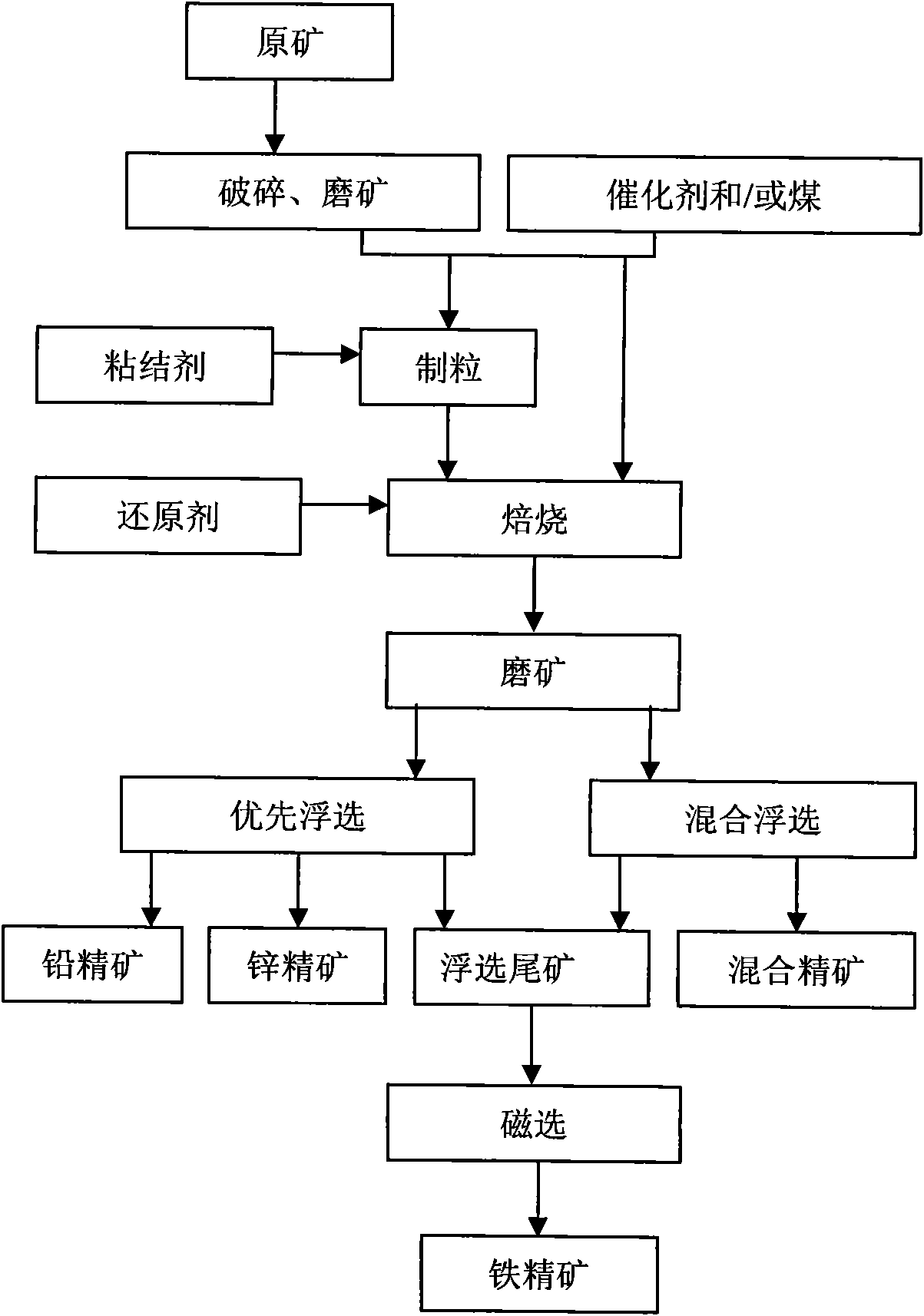

ActiveCN101934246AImprove resource utilizationSimplify subsequent processingWet separationSulfide mineralsDiiron Trioxide

The invention relates to a beneficiation method of a lead-zinc oxide mine difficult to beneficiate, which comprises the steps of crushing ores of the lead-zinc oxide mine difficult to beneficiate, grinding ores, uniformly mixing the ores, a catalyst and coal and then roasting; or crushing the ores of the lead-zinc oxide mine difficult to beneficiate, grinding the ores with the catalyst and the coal, and roasting so as to transform the lead-zinc oxide ores difficult to beneficiate into sulfide minerals easy to float as well as weak-magnetism iron trioxide minerals into strong-magnetism ferroferric oxide; floating by adopting a method for floating lead-zinc sulfate minerals to obtain lead concentrate, zinc concentrate or lead-zinc concentrate; and recovering iron ore concentrate by carrying out a magnetic method on tailings left after beneficiating lead-zinc minerals. The method can synthetically recover useful elements in the ores of the lead-zinc oxide mine difficult to beneficiate and has the characteristics of high concentrate grade and high recovery rate.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Process for preparing potash magnesium sulphate fertilizer with kalium containing sulfate

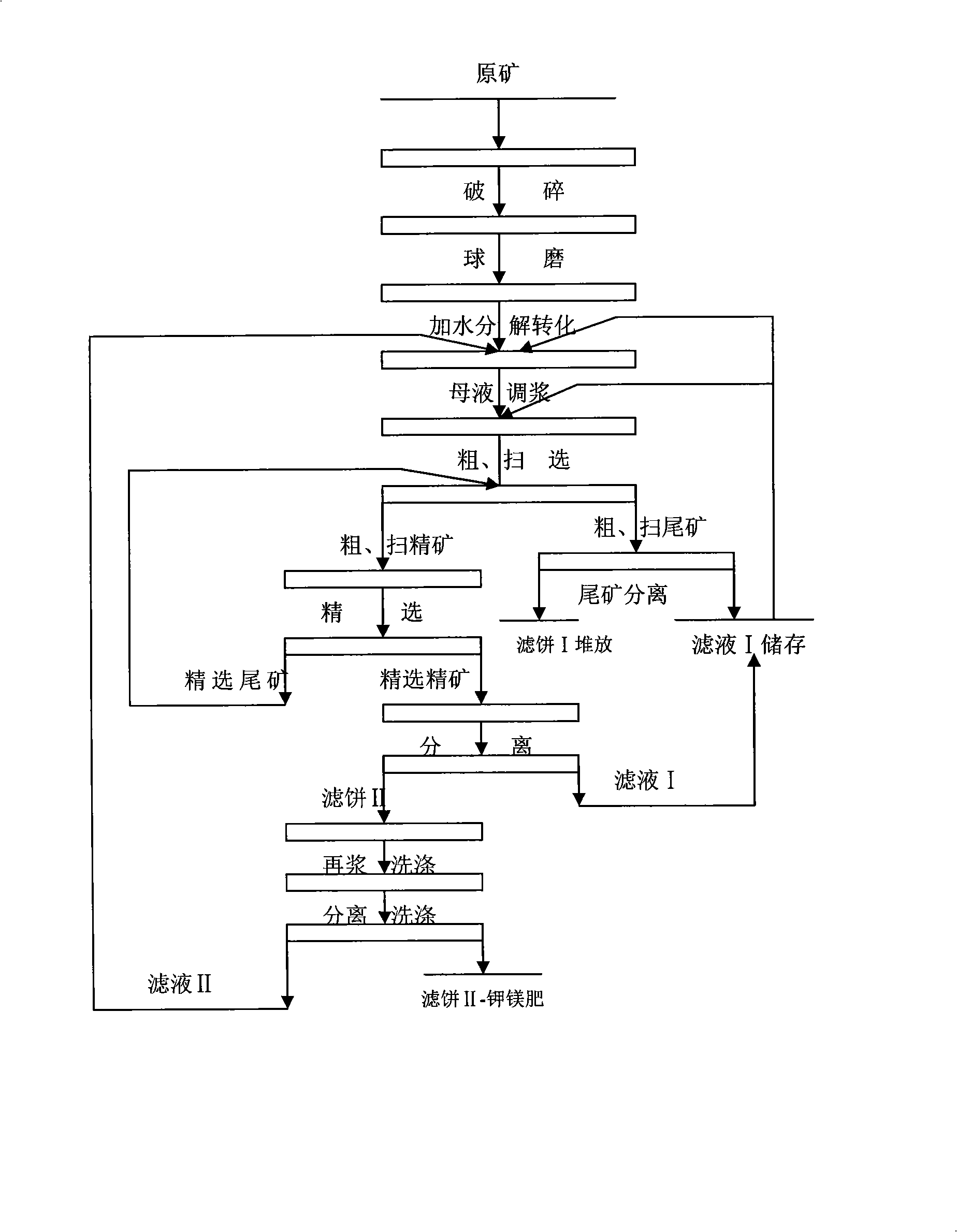

InactiveCN101318845AImprove Potassium YieldHigh yieldMagnesium fertilisersPotassium fertilisersDecompositionTemperature and pressure

The invention provides a method for preparing a potash magnesium sulphate fertilizer by utilizing potassium-bearing sulfate mineral, which takes the potassium-bearing sulfate mineral obtained by solarization of sulphate type salt lake potassium-containing brine water as a raw material to prepare potash magnesium sulphate fertilizer products in accordance with national potash magnesium sulphate fertilizer product standard, through processes such as crushing, grinding ore, decomposing and converting, floatation and separation, secondary pulp washing and so on. The method utilizes decomposing mother liquor and secondary pulp washing liquid to decompose raw material ores, the circulating utilization ratio of the decomposing mother liquor is more than or equal to 80 percent, and the circulating utilization ratio of the secondary pulp washing liquid reaches 100 percent, thereby improving yield of potassium, reducing water amount for decomposition and reducing the water consumption of ton-product by 30 to 70 percent compared with other methods for producing the potash magnesium sulphate fertilizer. The whole production process is carried out at normal temperature and pressure, which reduces energy consumption; and the quality of the potash magnesium sulphate fertilizer products meets or exceeds national standard (GB / T20937-2007) for potash magnesium sulphate fertilizer qualified products.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

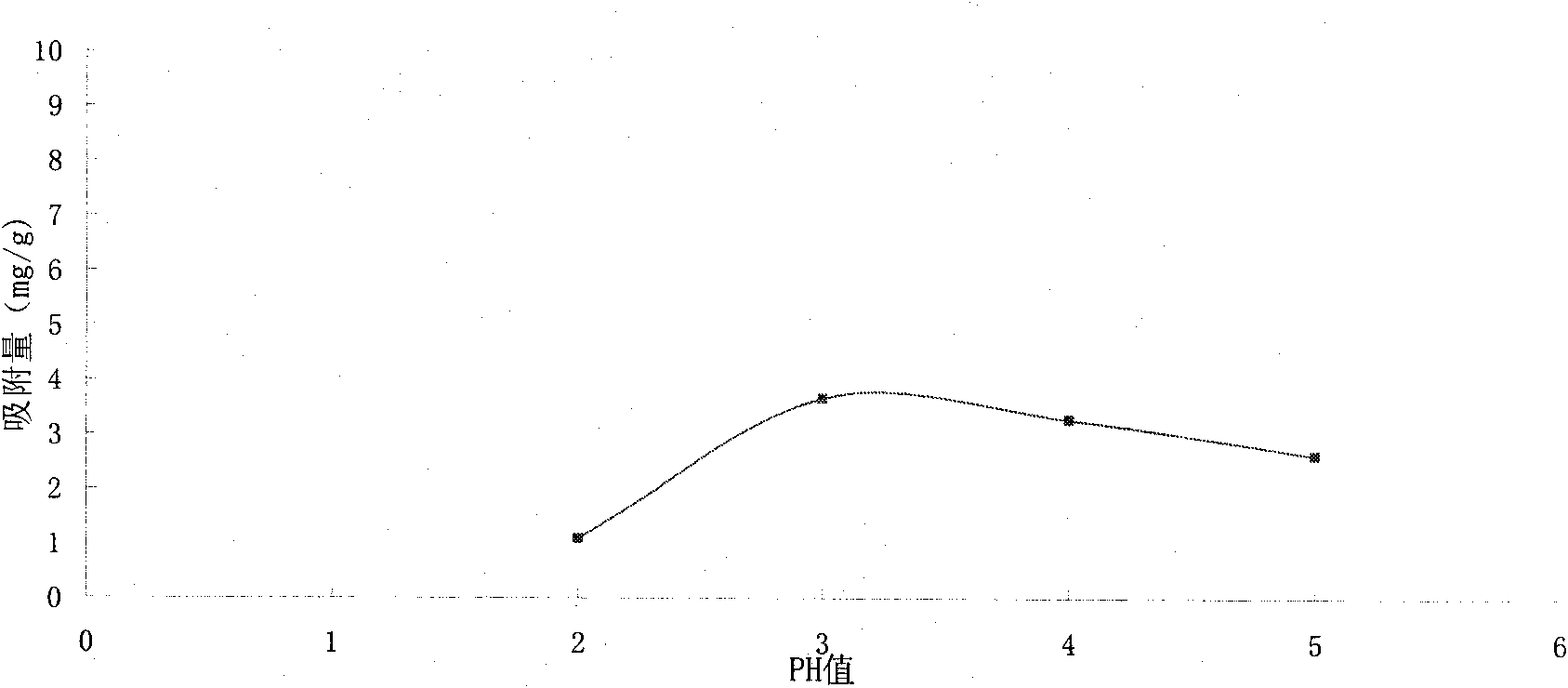

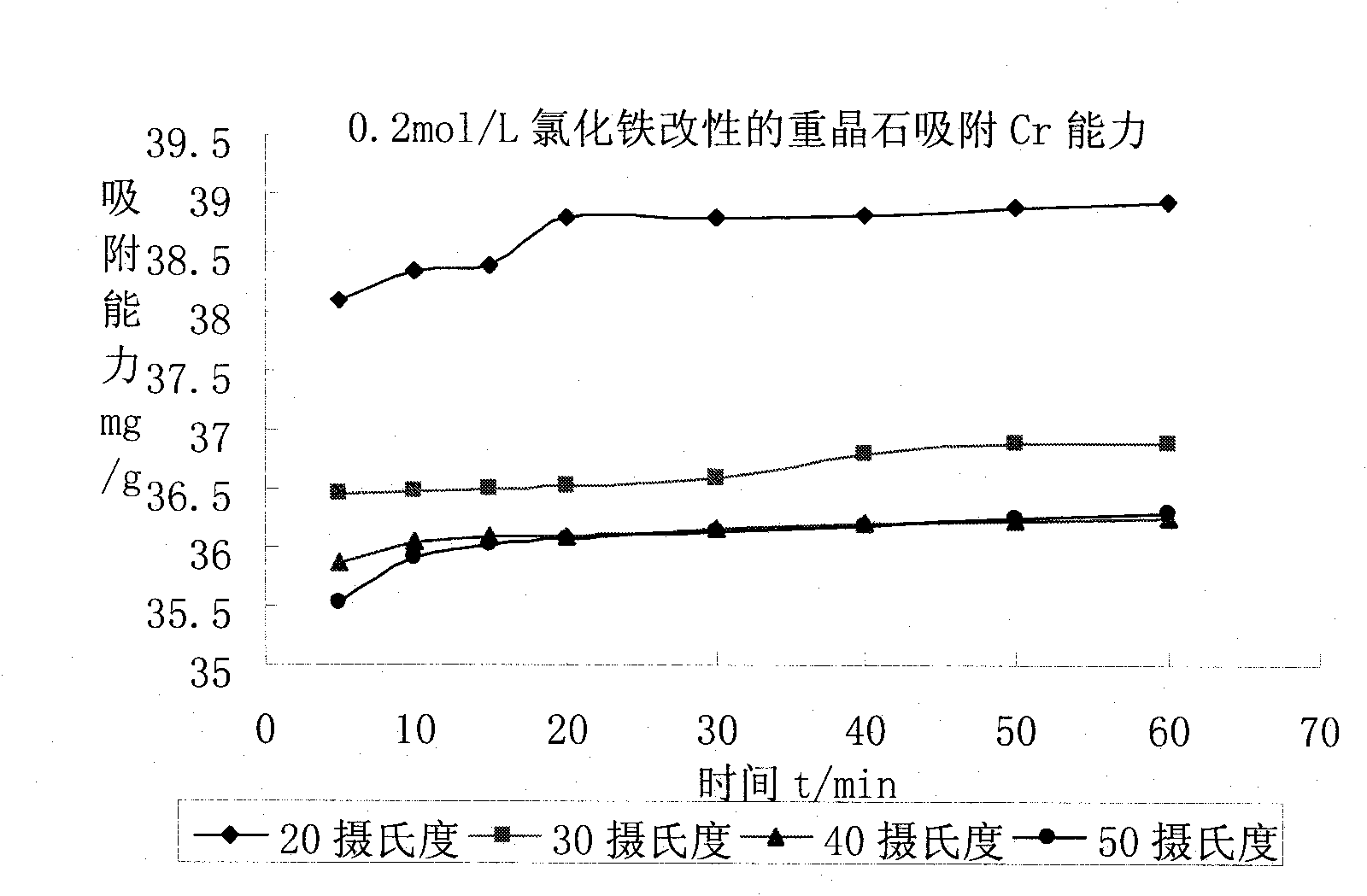

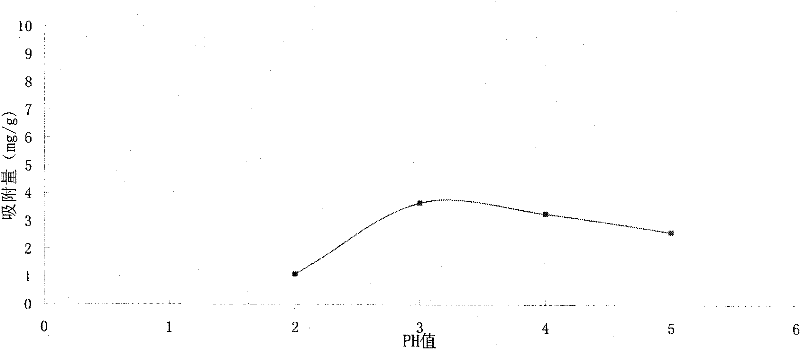

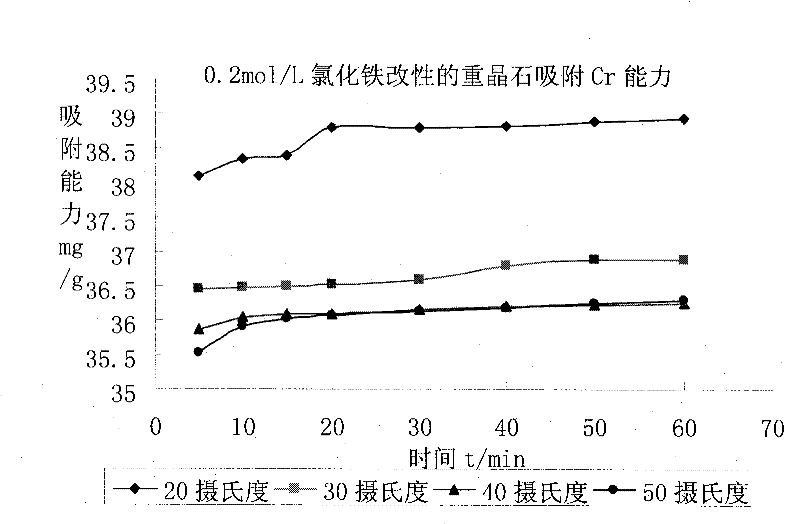

Method for treating chromium-containing wastewater by using barite adsorbent

InactiveCN101898107AAbundant resourcesLow priceOther chemical processesWater contaminantsChromium CompoundsWater baths

The invention discloses a method for treating chromium-containing wastewater by using barite adsorbent. The method comprises the following steps of: fusing, crushing and screening a barite mineral material, reacting the barite mineral material by using ferric chloride solution to generate the barite adsorbent for removing chromium ions from sewage containing 50 to 150 mg / L of chromium compound, and shaking the barite adsorbent for 1 hour in a 20 DEG C water bath thermostatic oscillator when the pH is 3 to 4, wherein the removal rate of the chromium ions in the sewage is over 99 percent; and adding a proper amount of barium chloride powder into the barite adsorbent for treating the high chromium content sewage so as to improve the removal rate of the chromium ions. The method has the advantages that: the barite is a most common barium-rich sulfate mineral, the globe surface has rich resources and the cost is low, so the method is convenient for popularization and application; and the barite adsorbent has simple preparation process, convenient operation and high adsorption rate of the chromium ions in the wastewater, can be repeatedly regenerated and recycled, and meets the energy conservation and emission reduction requirements.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

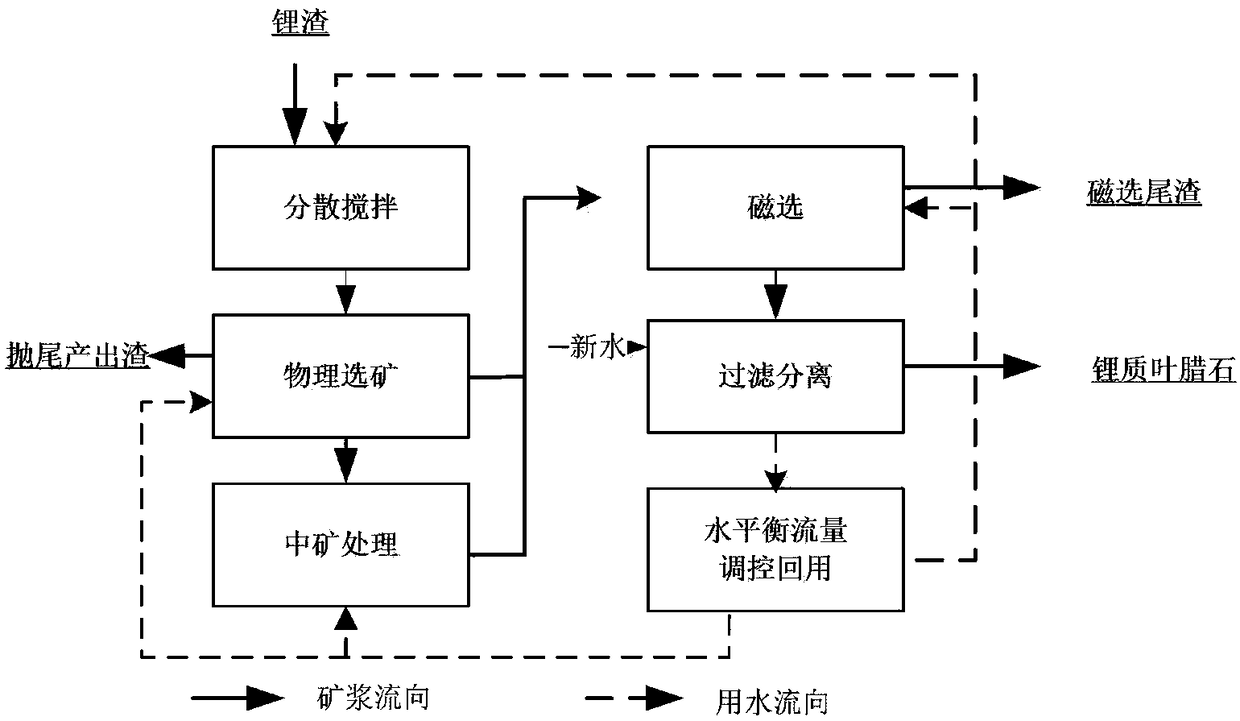

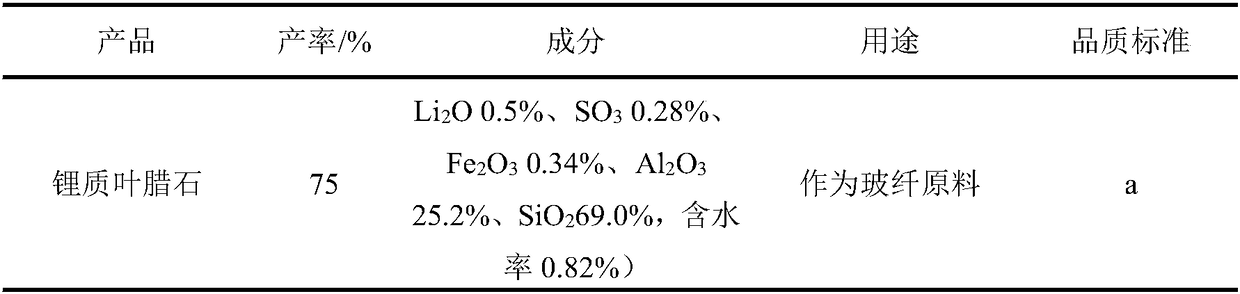

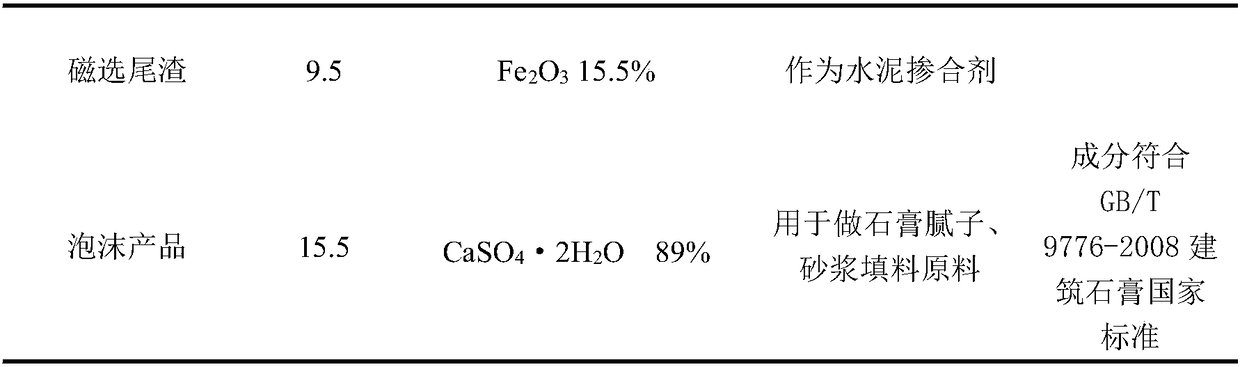

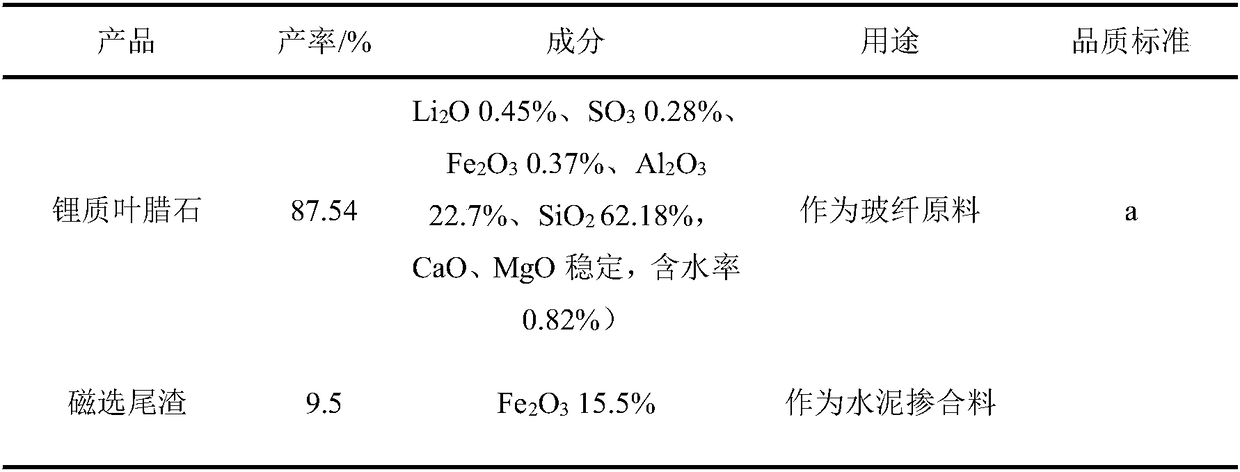

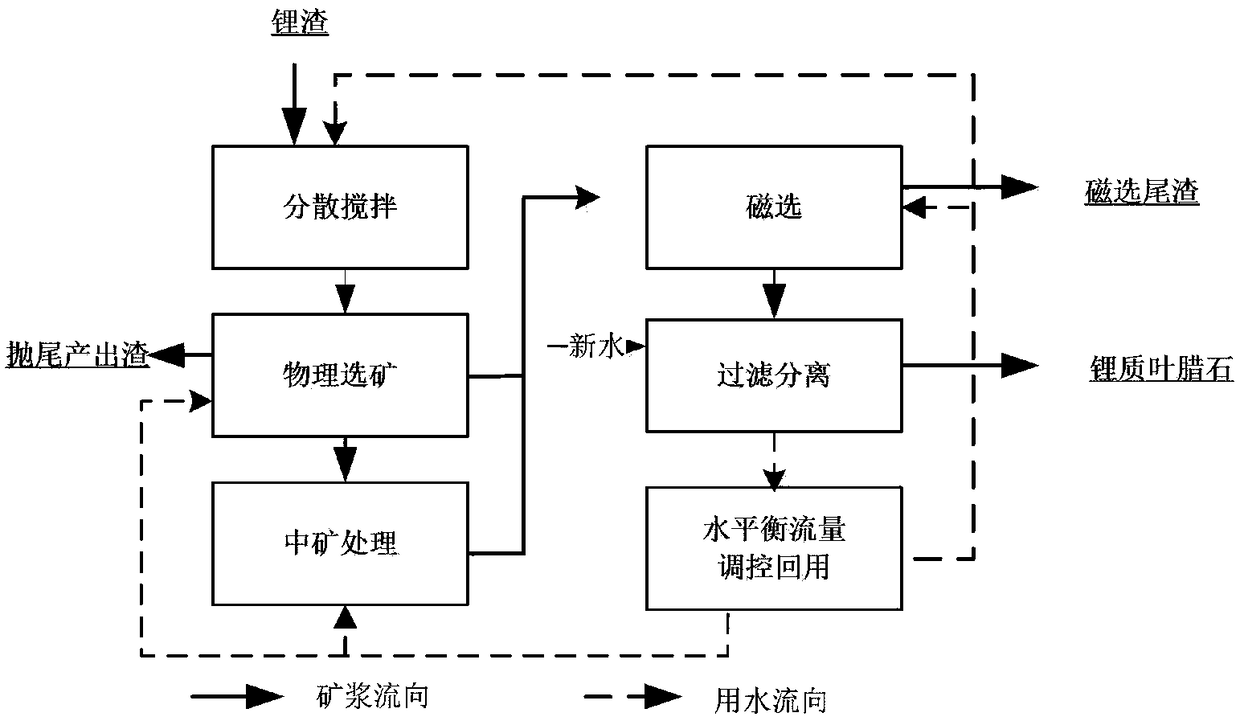

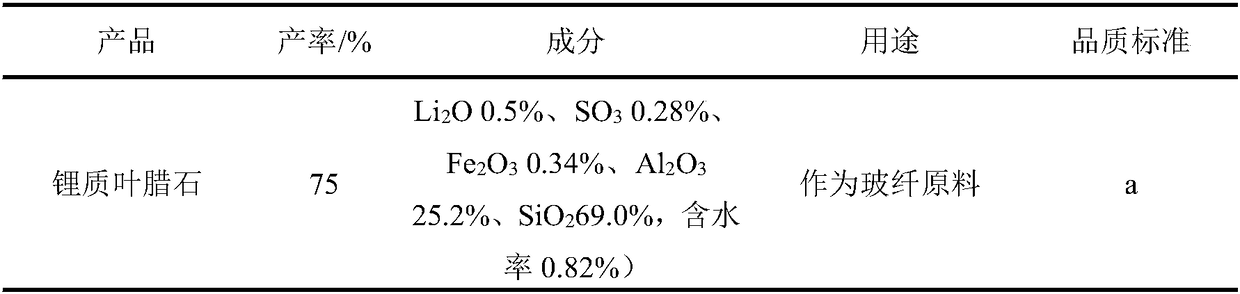

High-valued comprehensive utilization method of lithium slag

The invention provides a high-valued comprehensive utilization method of lithium slag, in particular to mineral waste residues obtained by lithium extraction of spodumene by a sulfuric acid method. The high-valued comprehensive utilization method comprises the following steps: firstly, carrying out size mixing and stirring on the lithium slag and enabling sulfate mineral in the lithium slag to bein a dispersed suspension state; secondly, carrying out desulfurizing treatment on a product obtained in the first step by using a physical ore dressing mode to obtain desulfurized slurry and tailingdiscarding produced slag and enabling the sulfur content of slag phase in the desulfurized slurry to be smaller than or equal to 0.5 percent; thirdly, under the condition that the magnetic field strength is 0.5 to 2.0T, carrying out magnetic separation on the desulfurized slurry obtained in the second step to obtain magnetic separation slurry and magnetic separation tailings and reducing the content of ferric oxide in the magnetic separation slurry to be smaller than or equal to 0.05 percent; then concentrating, filtering and drying the obtained magnetic separation slurry to obtain a pyrophyllite raw material for glass fibers. The treatment method of the lithium slag, disclosed by the invention, has the advantages of greenness and environmental protection, obvious economic benefits and capability of realizing the leap of high-valued recycling of the lithium slag.

Owner:TIANQI XINLONG CO LTD

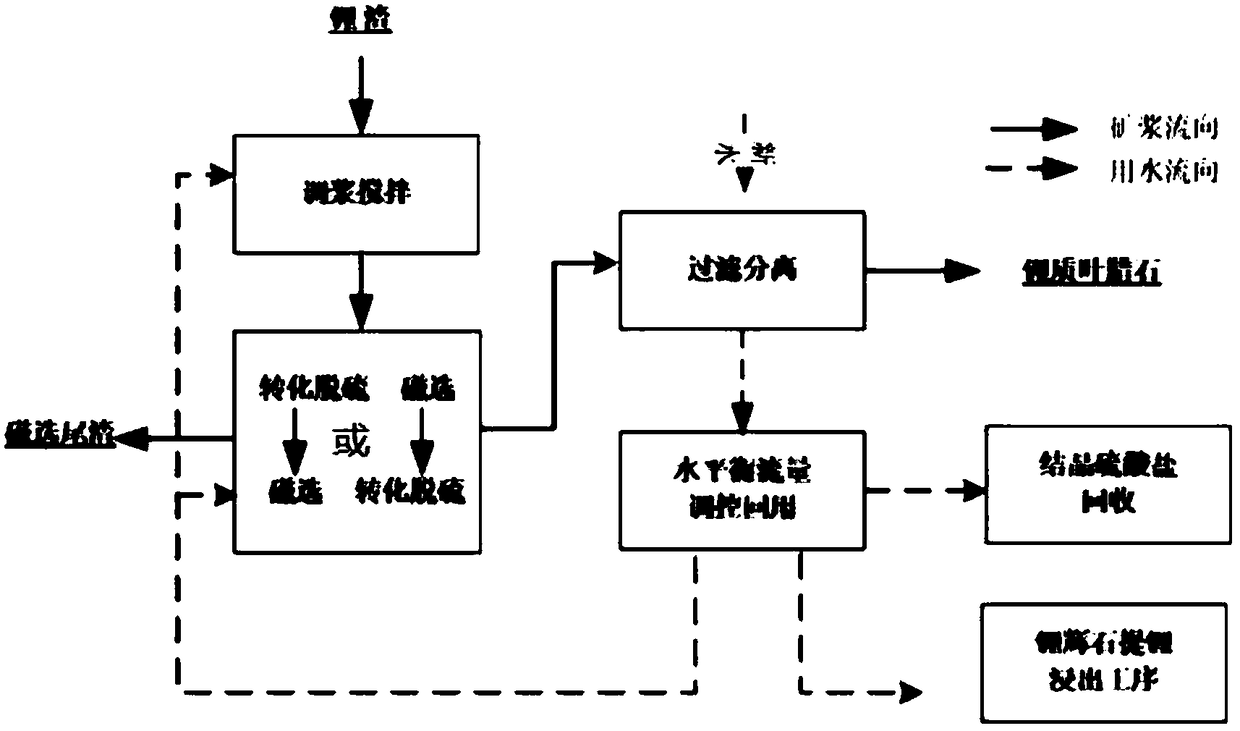

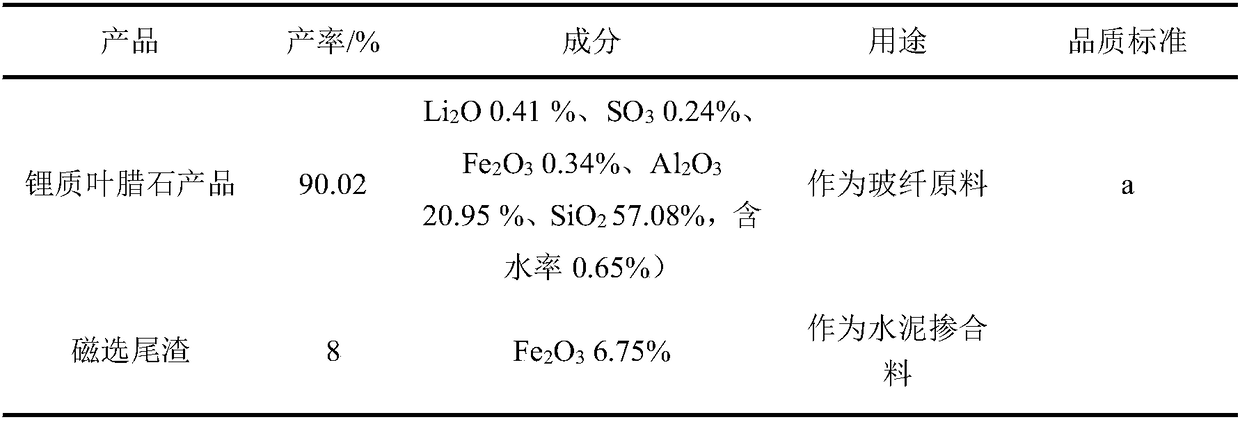

Full-phase high-valued recycling method for lithium slag

ActiveCN108273826ARealize inner loopAchieving zero emissionsSolid waste managementSolid waste disposalAfter treatmentSlag

The invention provides a full-phase high-valued recycling method for lithium slag. The lithium slag is ore slag obtained after spodumene is subjected to the lithium leaching procedure for lithium extraction through a sulfuric acid method. The full-phase high-valued recycling method for the lithium slag includes the following steps that firstly, the lithium slag is subjected to size mixing and stirring, and sulfate minerals in the lithium slag are made to be in a dispersed and suspended state; secondly, matter obtained in the first step is subjected to reaction treatment and wet type magnetic separation treatment in any sequence through soluble carbonate; and thirdly, slurry obtained after treatment in the second step is concentrated, filtered and dried, pyrophyllite raw materials for glassfibers are obtained. When the full-phase high-valued recycling method for the lithium slag is used for treating the lithium slag, efficiency is high, generation of three wastes is avoided, spanning of high-valued recycling of the lithium slag is achieved, and remarkable economic benefits and environmental protection benefits are achieved.

Owner:TIANQI XINLONG CO LTD

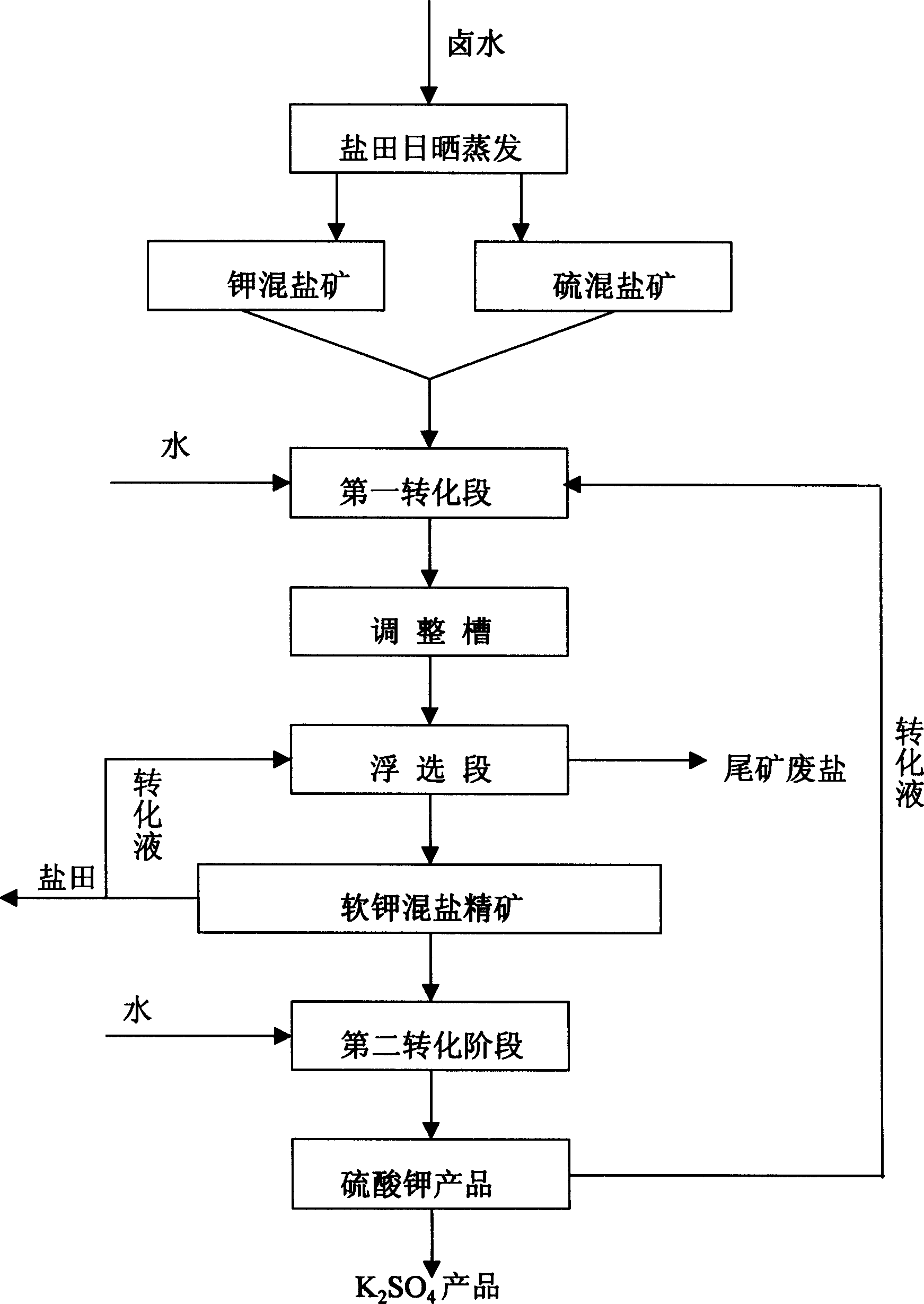

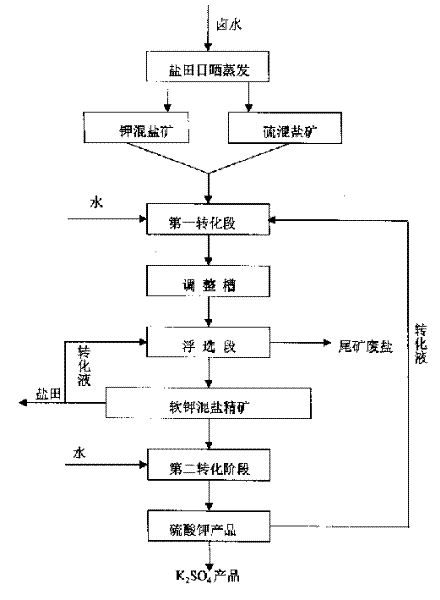

Potassium sulfate preparing process from sulfate-type salt lake bittern

InactiveCN1548372AAdaptable to changeWhite colorDouble sulfate preparationFlotationSalt lakeChloride

The present invention is one method of preparing potassium sulfate with sulfate type lake bittern resource. The preparation process includes the following steps: shining bittern to obtain mixed sulfate mineral with sodium chloride, schoenite, magnesium sulfate and potassium chloride as main components and mixed potassium salt mineral with sodium chloride, potassium chloride, magnesium sulfate and carnallite as main components; mixing these two kinds of mineral and converting with water at normal temperature to obtain coarse mixed schoenite mineral; floating the mixed schoenite mineral to obtain concentrated mixed schoenite mineral; adding water to the high-grade concentrated mixed schoenite mineral and decomposing directly to obtain potassium sulfate product; water washing the tailing to obtain industrial salt. The technological process is power saving and low in cost, and has other advantages.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Process for co-producing lithium carbonate and potassium salt with lithium-containing nanofiltration water

ActiveCN108275703APrevent crystallizationSimple processing technologyAlkali metal chloridesLithium carbonates/bicarbonatesLithium carbonateSulfate minerals

The invention discloses a process for co-producing lithium carbonate and potassium salt with lithium-containing nanofiltration water. The process comprises the following steps: (1) separating magnesium sulfate subtype salt lake brine with a nano-filtering film to obtain the lithium-containing nanofiltration water; (2) distilling the lithium-containing nanofiltration water to obtain the finished product brine; (3) adsorbing and purifying the finished product brine with strong alkali anion exchange resin to obtain purified brine; (4) distilling the purified brine to obtain a sodium chloride refined salt and a salt-potassium co-saturated brine; (5) cooling and crystalizing the salt-potassium co-saturated brine to obtain industrial potassium chloride and lithium-enriched brine; (6) adding a carbonate solution into the lithium-enriched brine, precipitating and crystalizing at the temperature of 80 to 100 DEG C to obtain the finished product industrial lithium carbonate. By adopting the process, the magnesium sulfate subtype salt lake brine is adjusted, the salt field process is simplified, the crystallization and precipitation of mineral sulfate are avoided; the potassium salt machiningprocess is improved, lithium carbonate and potassium salt coproduction can be realized by further adsorption and purification.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

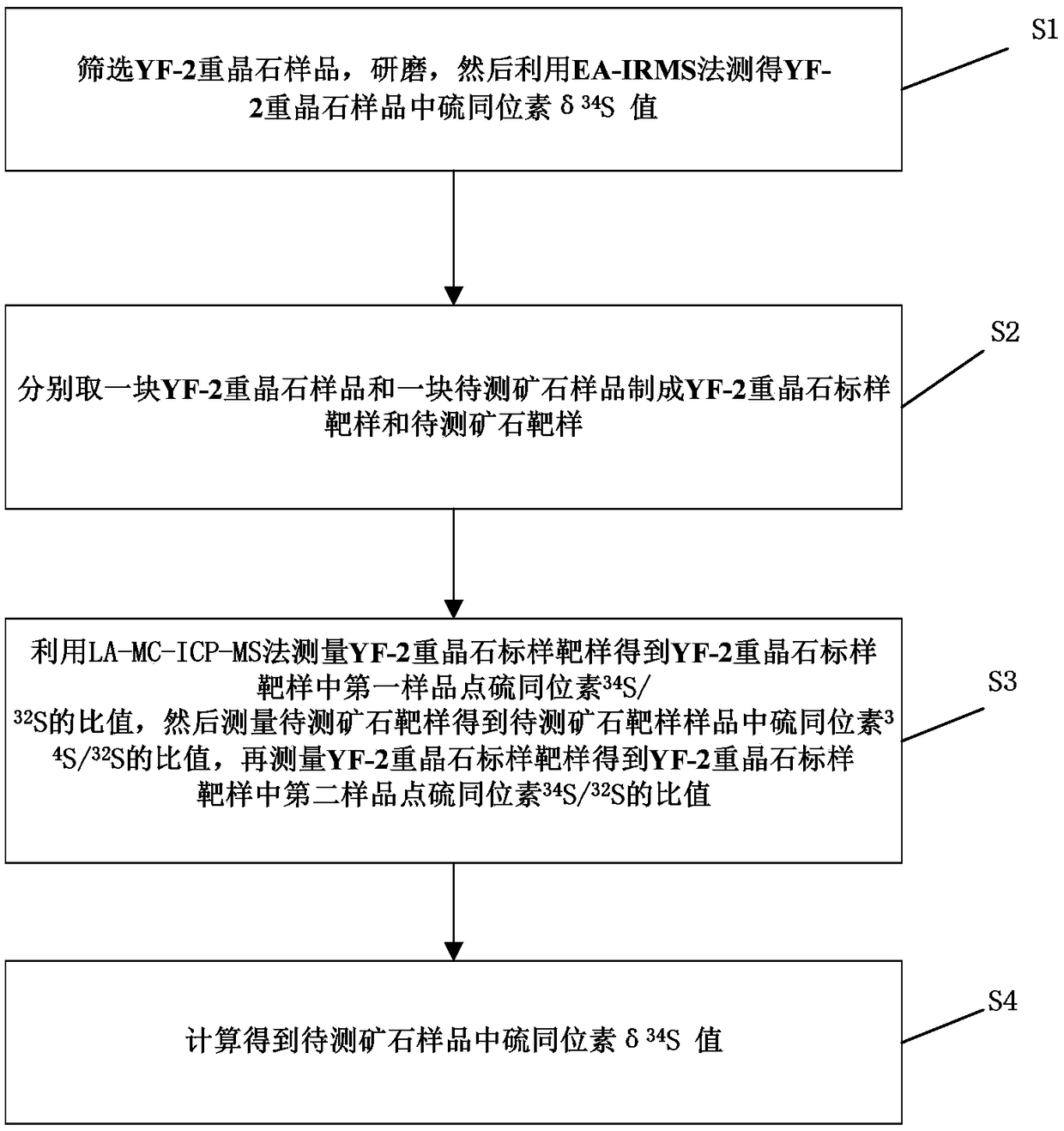

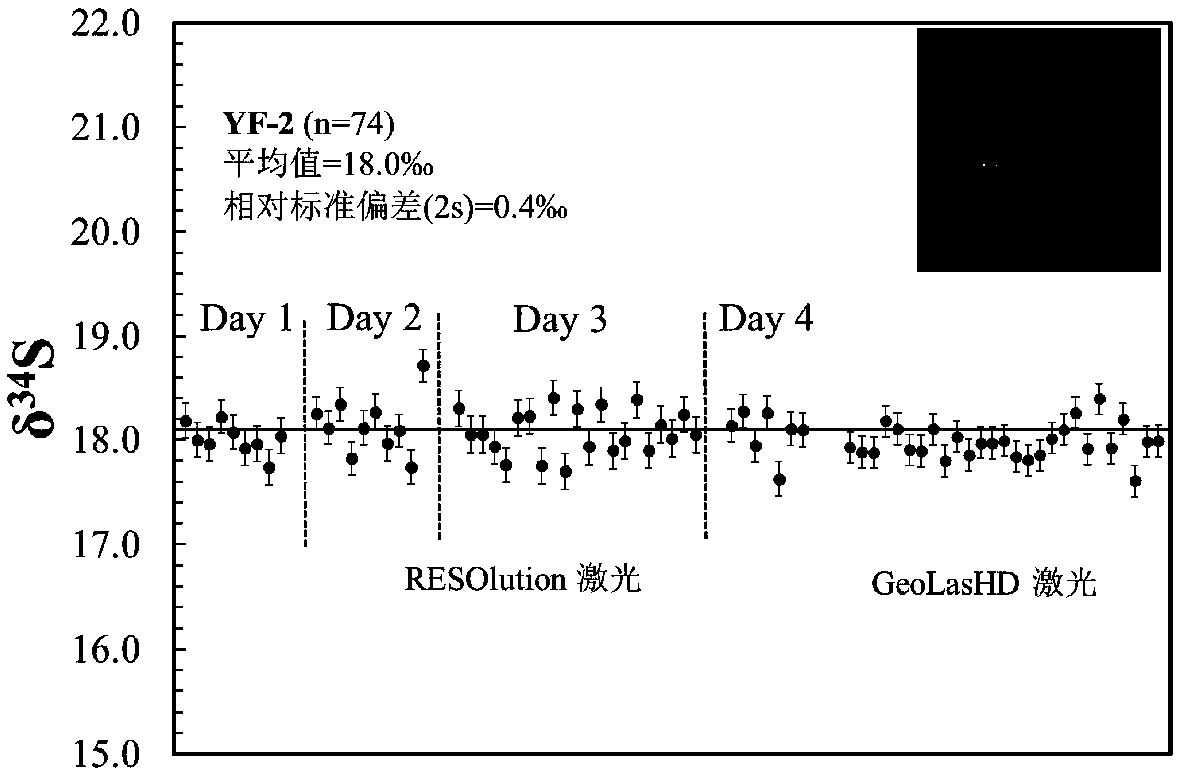

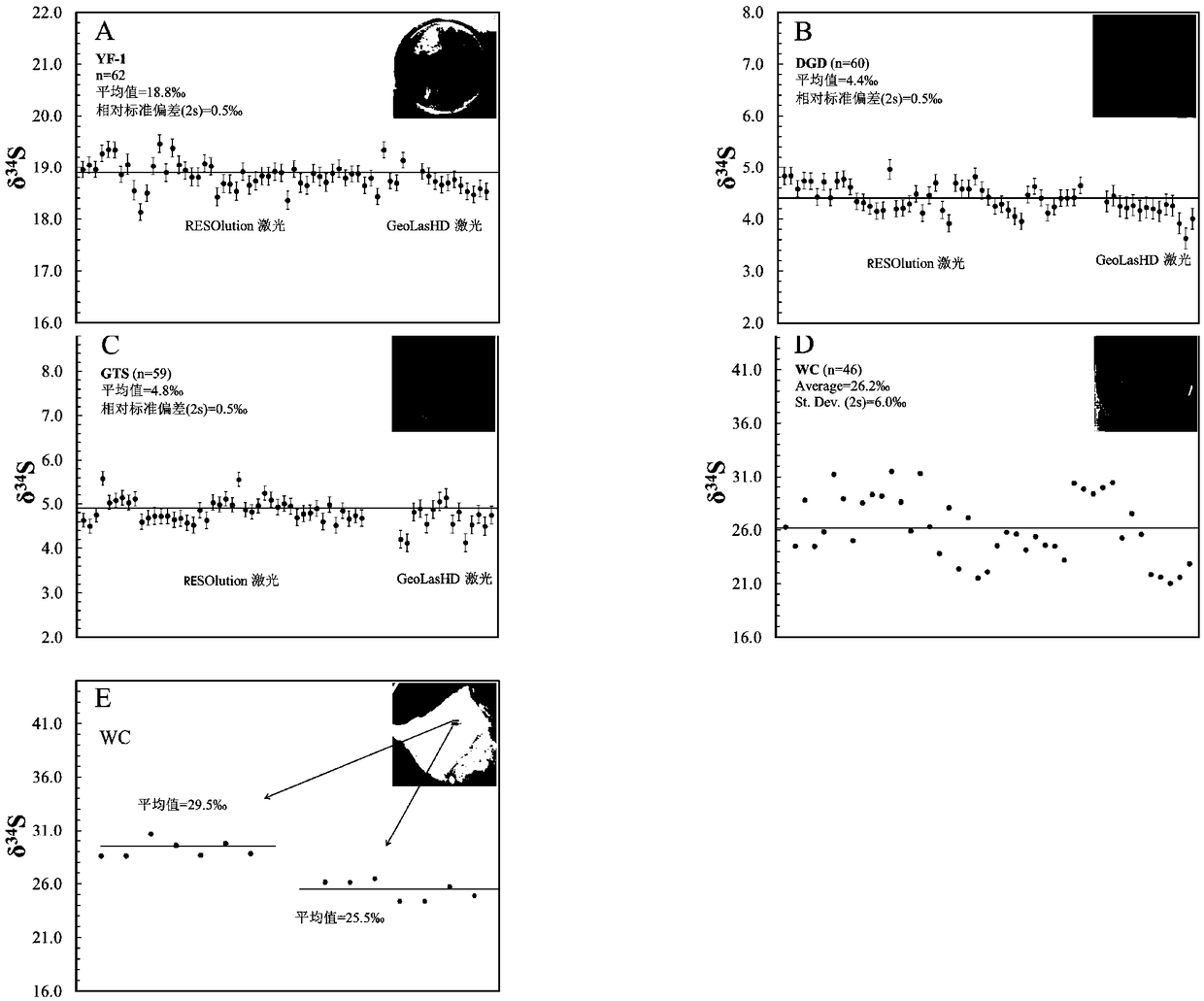

Method for determining sulfur isotope in sulfate minerals by using YF-2 barite as standard sample

InactiveCN109406616AEffectively corrects for mass discriminationMeet the needs of analyzing sulfur isotopes in sulfate mineralsPreparing sample for investigationMaterial analysis by electric/magnetic meansSulfurSulfate minerals

The invention provides a method for determining sulfur isotope in sulfate minerals by using YF-2 barite as a standard sample. The method comprises the following steps that a YF-2 barite sample is screened and ground, and a sulfur isotope delta<34>S value in the YF-2 barite sample is measured by an EA-IRMS method; a piece of YF-2 barite sample and a piece of sample of ore to be measured are taken to be manufactured into a YF-2 barite standard sample target sample and a target sample of the ore to be measured; an LA-MC-ICP-MS method is adopted to first measure the YF-2 barite standard sample target sample to obtain the ratio of <34>S / <32>S of the sulfur isotope of a first sample point in the YF-2 barite standard sample target sample, then the target sample of the ore to be measured is measured to obtain the ratio of <34>S / <32>S of the sulfur isotope in the sample of the target sample of the ore to be measured, and then the YF-2 barite standard sample target sample is measured to obtain the ratio of <34>S / <32>S of the sulfur isotope of a second sample point in the YF-2 barite standard sample target sample; and the sulfur isotope delta<34>S value in the ore sample to be measured is calculated and obtained. The method can accurately determine the sulfur isotope in the sulfate minerals, provides a uniform and matrix-matched standard sample for the in-situ determination of the isotopeby the LA-MC-ICP-MS method, and effectively corrects the quality discrimination in the measurement.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Geopolymer-based artificial flood control stone prepared from all wastes and preparation method thereof

The invention discloses a geopolymer-based artificial flood control stone prepared from all wastes and a preparation method of the geopolymer-based artificial flood control stone. The geopolymer-basedartificial flood control stone comprises the following raw materials in parts by weight: 288-412 parts of a waste silicon-aluminum material; 85-150 parts of alkali-containing waste; 29-75 parts of waste sulfate mineral; 1501-1860 parts of recycled aggregate; 216-241 parts of reclaimed water; 0-2 parts of waste fiber; and 0-5 parts of crop waste. The process is simple, the prepared artificial flood control stone has no appearance defect; the stone has the advantages of large volume density, high strength (more than 34 MPa), good weathering resistance, freezing resistance and abrasion resistance and the like, is convenient to throw, good in integrity, strong in stability, freeze-thaw resistance, weathering resistance and high-speed sand-containing water flow abrasion resistance in the usingprocess, is not easy to lose under high-speed water flow, and is an ideal substitute product for natural stone standby stone prevention.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

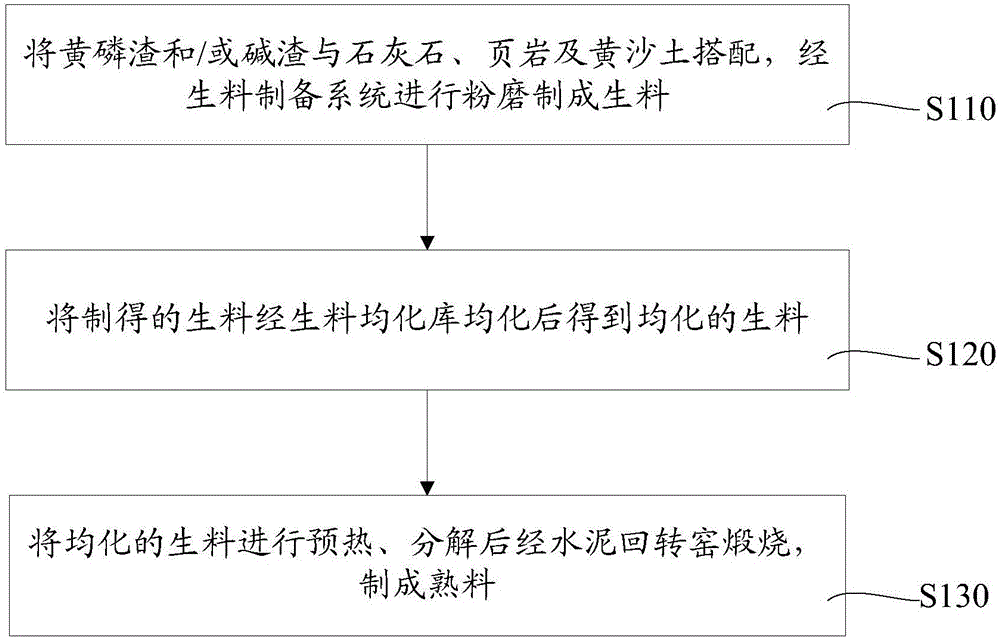

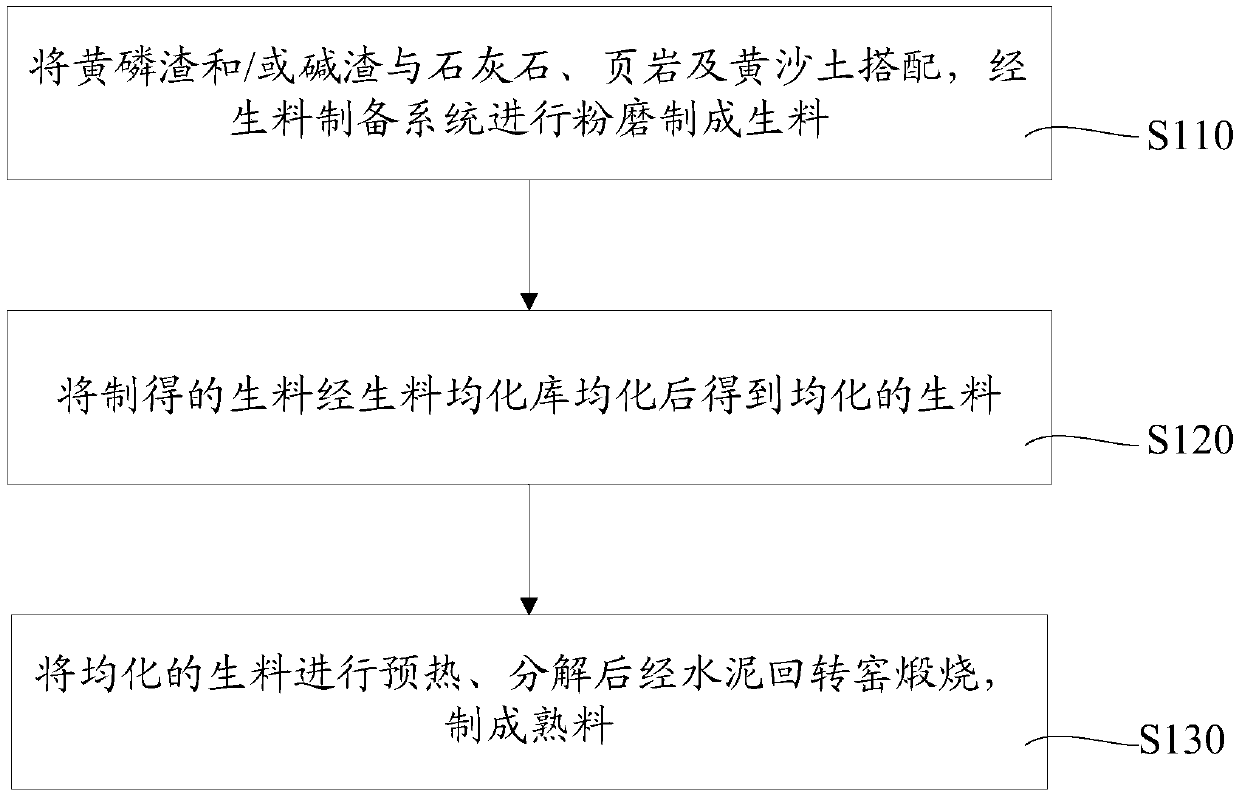

Cement clinker and production method thereof

The invention relates to a production method of cement clinker. The production method is characterized by comprising the steps that yellow phosphorus slag and / or alkaline slag and limestone, shale and sandy loess are mixed, and ground into raw material by a raw material preparation system. The production method of the cement clinker comprises the following steps of recycling the yellow phosphorus slag and / or the alkaline slag, quickly reacting sulfur and alkaline compounds enriched by a rotary kiln system and a preheater system, and balancing the sulfur and alkaline ratio, so that the SO2 (sulfur dioxide) gas is effectively cured, the refractory sulfate mineral is generated, the standard discharge is realized, the solid-phase reaction degree in the rotary kiln is improved, the particle forming of the clinker in calcining is denser, and the quality of the clinker is more stable. The production method of the cement clinker has the advantages that by compounding the industrial solid wastes to prepare the raw material, the high-investment equipment is not used, the standard discharge is realized, the burnability of the cement raw material is improved, and the energy consumption of the clinker is decreased; the yellow phosphorus slag and the alkaline slag are industrial waste slag, the pollution by industrial waste slag is eliminated by the desulfurizing of the waste slag in the cement kiln, and the effect of changing wastes into valuables is realized.

Owner:华润水泥(合浦)有限公司

Method for treating chromium-containing wastewater by using barite adsorbent

InactiveCN101898107BAbundant resourcesLow priceOther chemical processesWater contaminantsChromium CompoundsWater baths

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

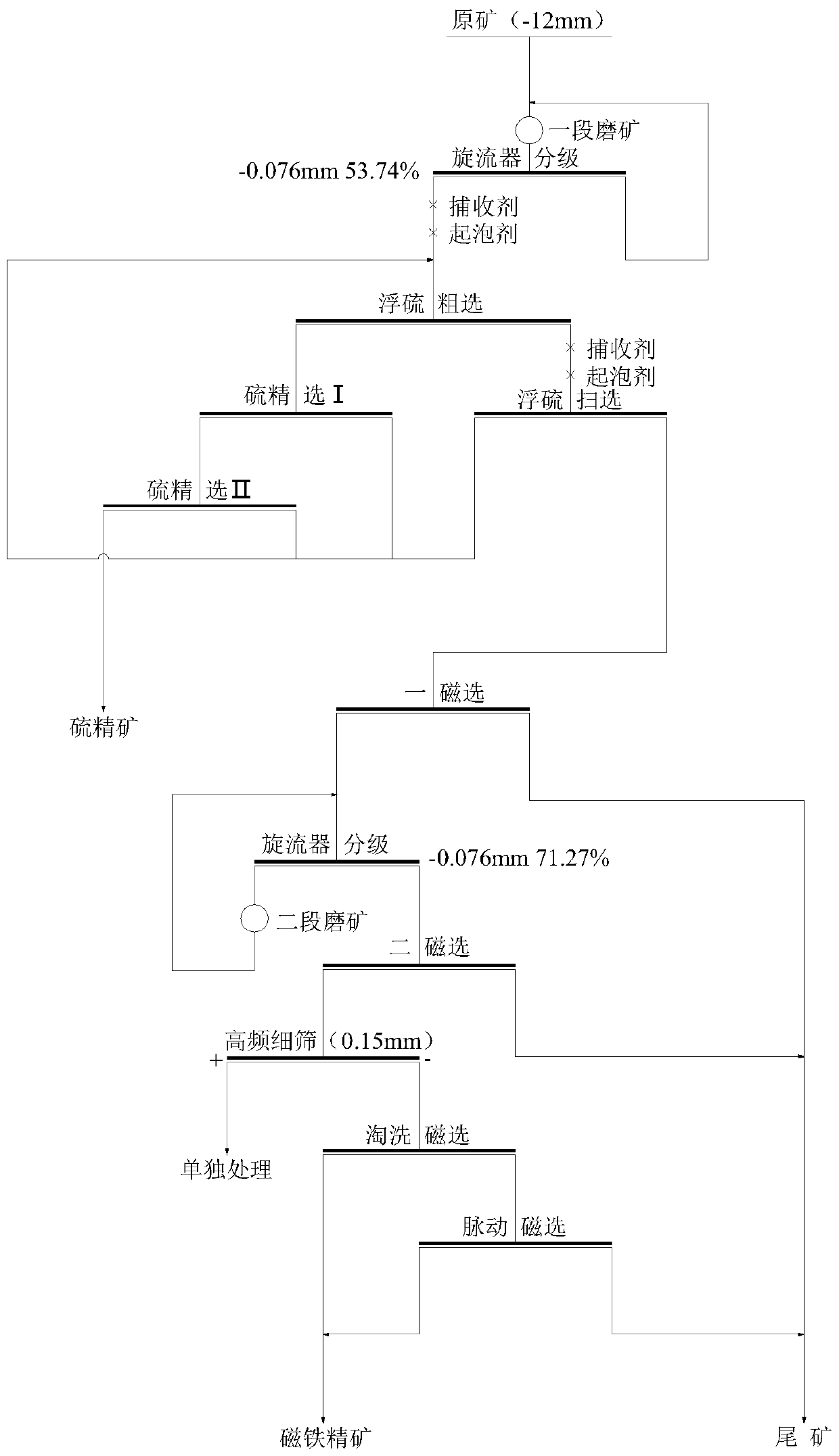

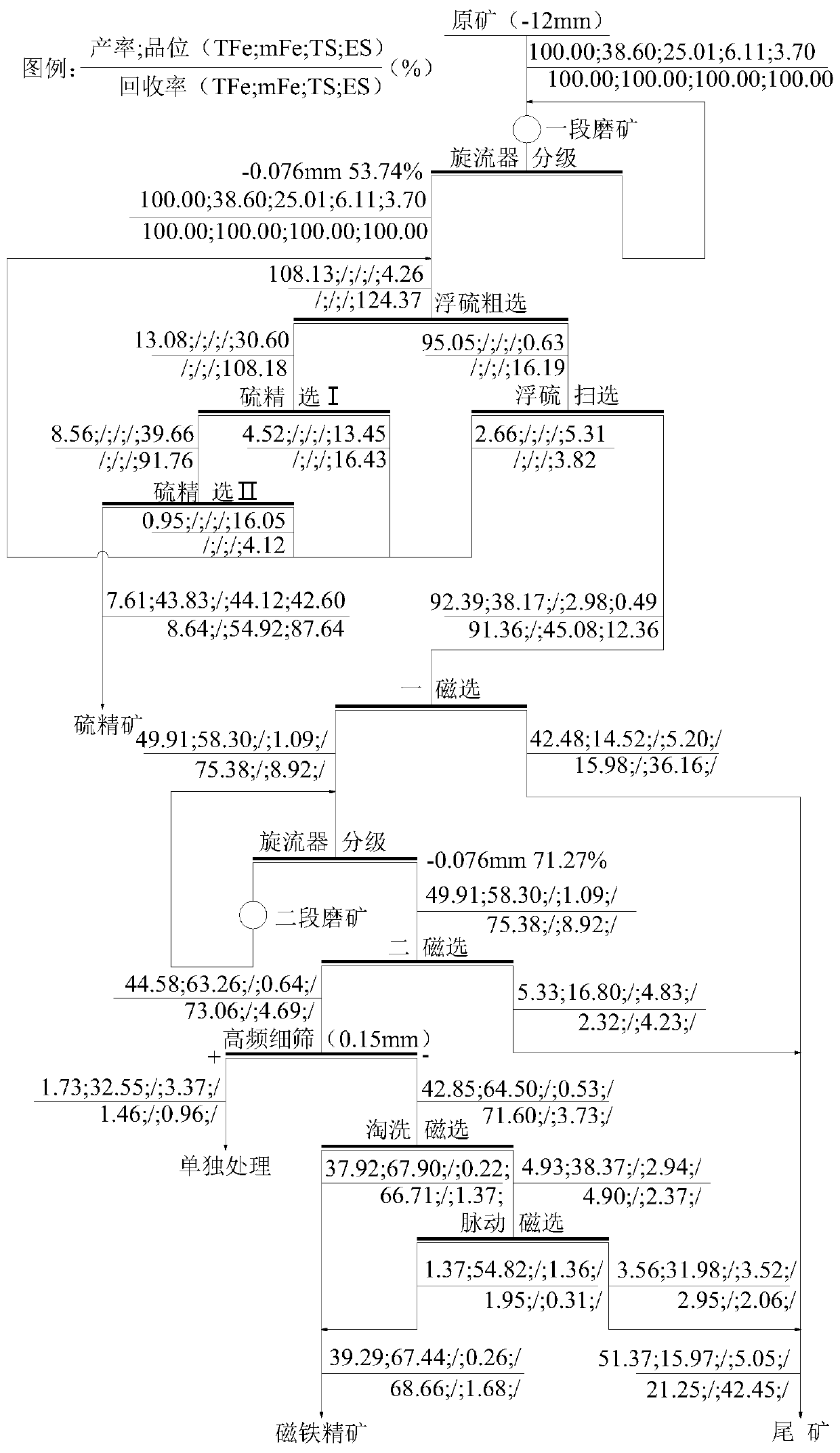

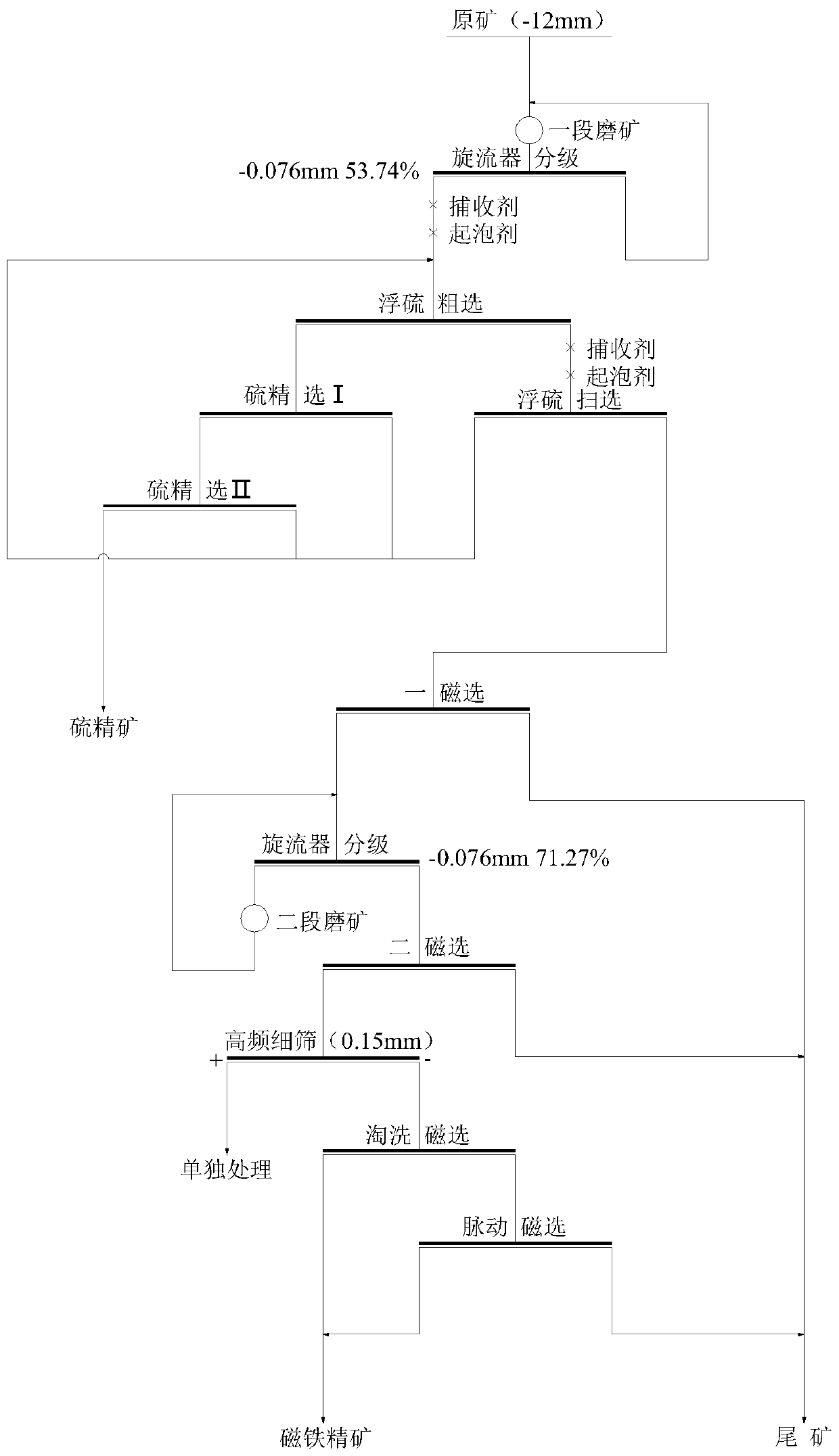

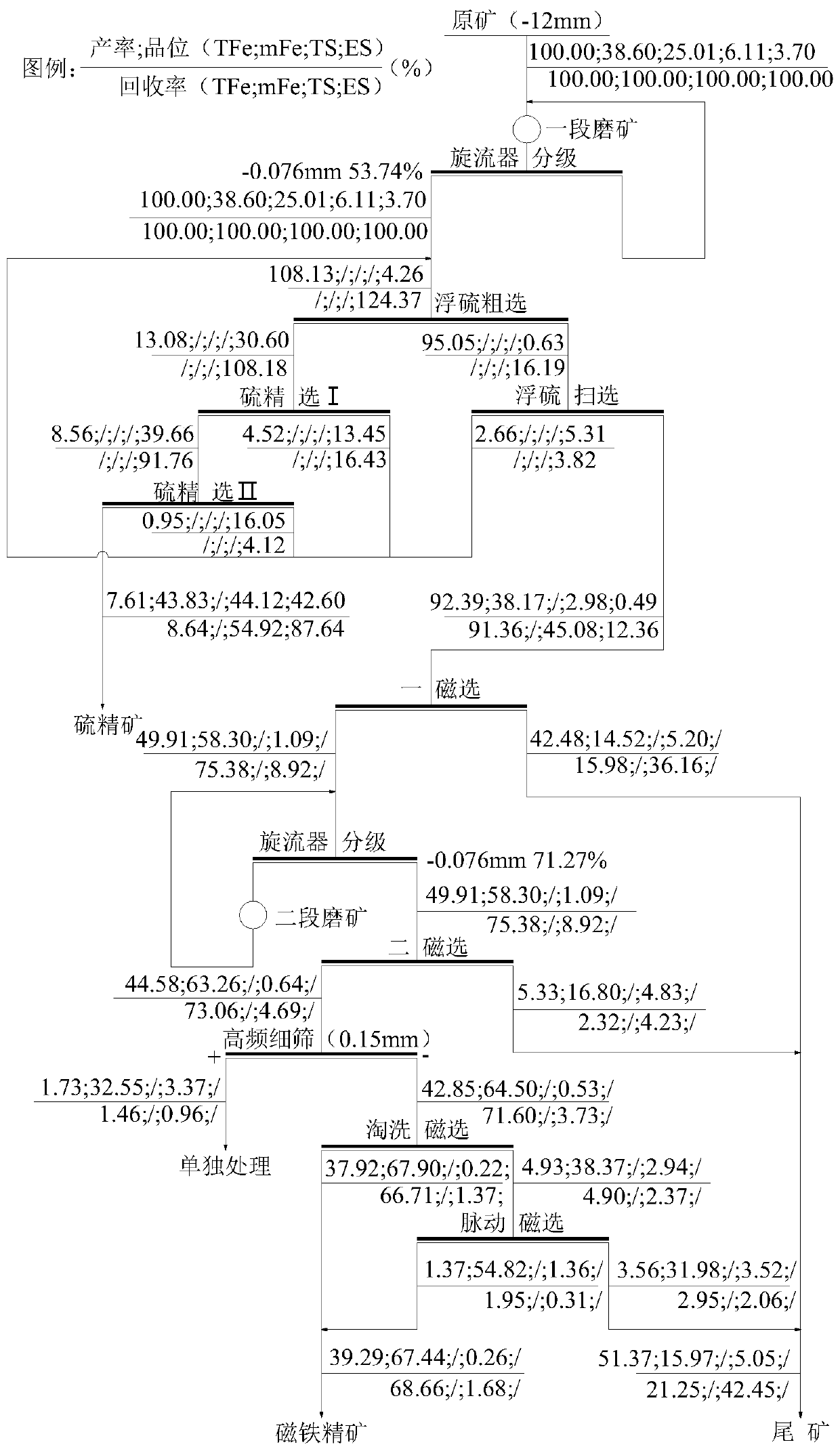

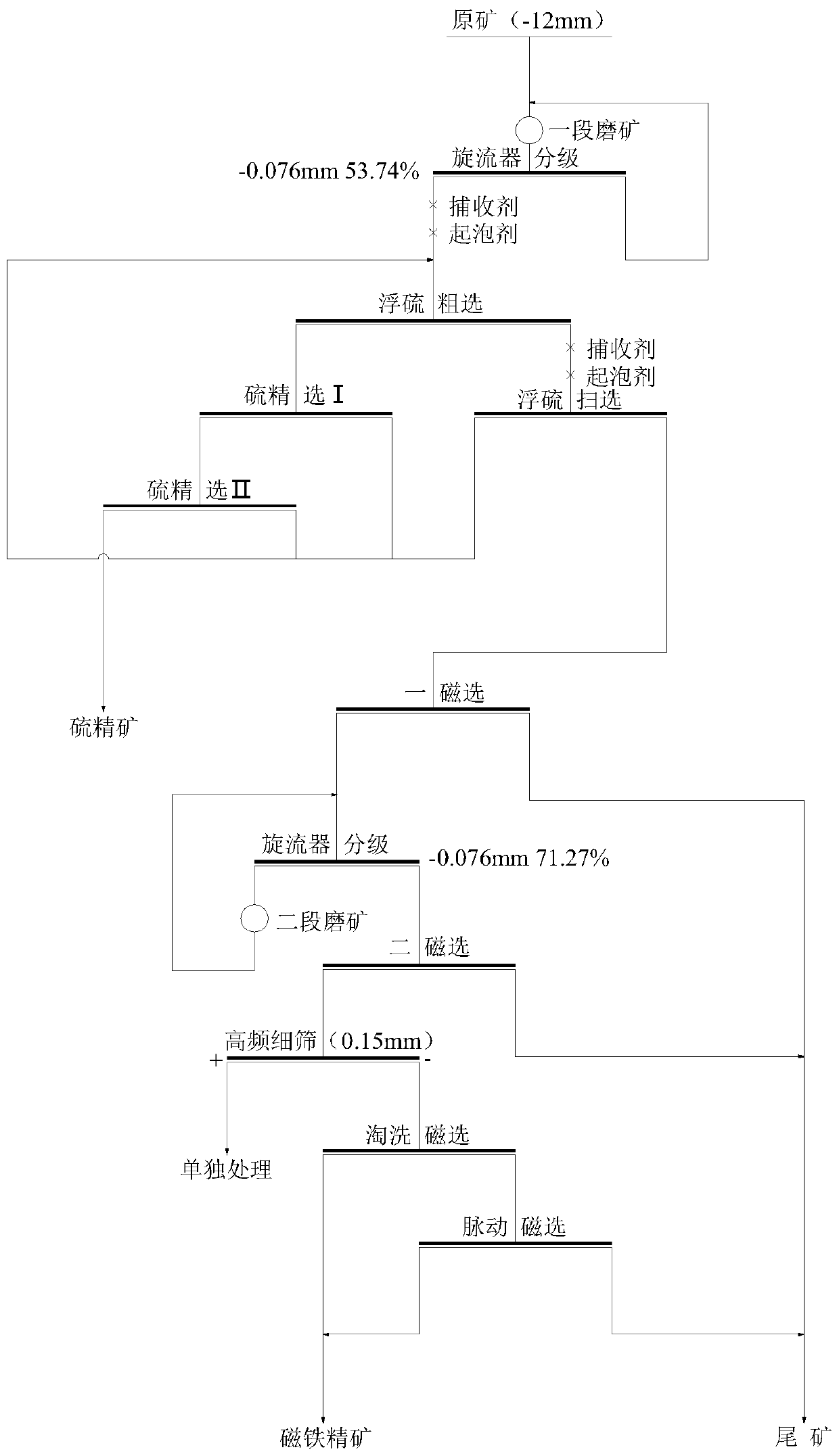

Separation method of high-sulfate iron ore

ActiveCN109746118ALow overflow concentrationAdd magnetic roll effectSievingScreeningIronstoneElutriation

The invention discloses a separation method of high-sulfate iron ore. The method includes the following steps: firstly, performing primary ore grinding-classification on the high-sulfate iron ore, anddischarging primary classification overflow products, wherein the ore grinding particle size is controlled at -0.076mm 50%-55%; performing flotation on the primary classification overflow products, selecting sulfides, and obtaining a sulfur concentrate with a TS grade being greater than or equal to 40.0%; carrying out primary low-intensity magnetic separation on floating sulfur tailings to obtaina primary low-intensity magnetic separation iron concentrate, carrying out secondary ore grinding-classification on the primary low-intensity magnetic separation iron concentrate, and carrying out secondary low-intensity magnetic separation on secondary classification overflow products to obtain a secondary low-intensity magnetic separation iron concentrate; performing high-frequency fine screening-elutriation magnetic separation-pulsating magnetic separation and scavenging combined process on the secondary magnetic separation iron concentrate to obtain a magnetite concentrate, and removing sulfur from the sulfates to enter tailings. The scheme of the invention can effectively remove sulfur from the sulfates in the iron ore, can realize efficient separation of magnet minerals and sulfateminerals, realizes sulfur reduction of the iron concentrate, and also ensures the recovery rate of magnetic iron.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

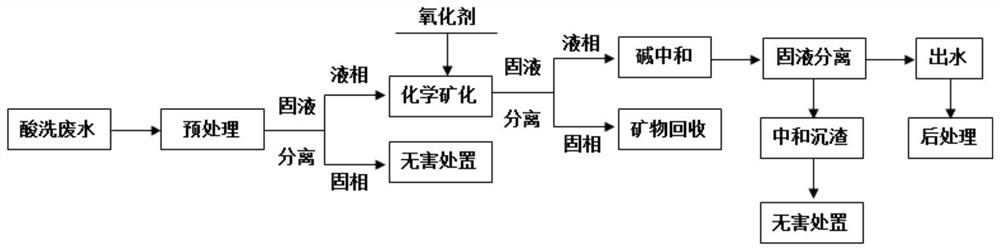

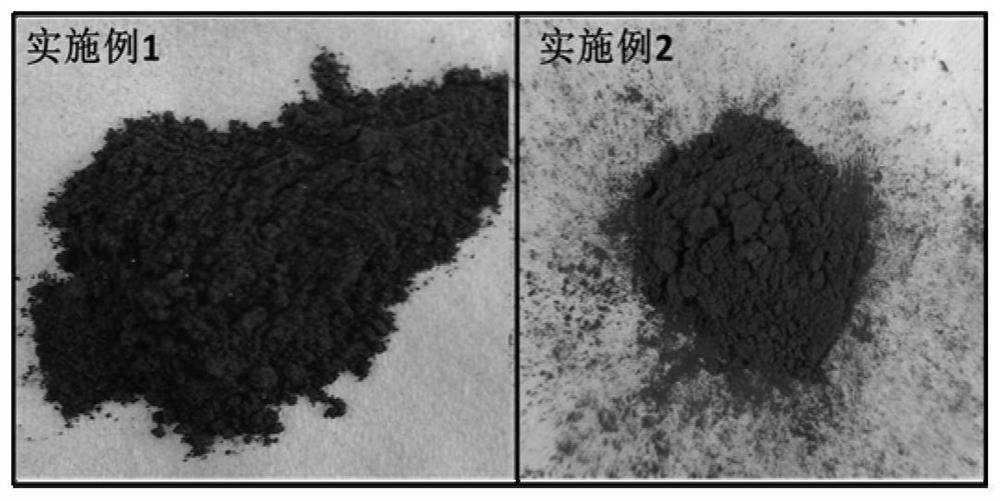

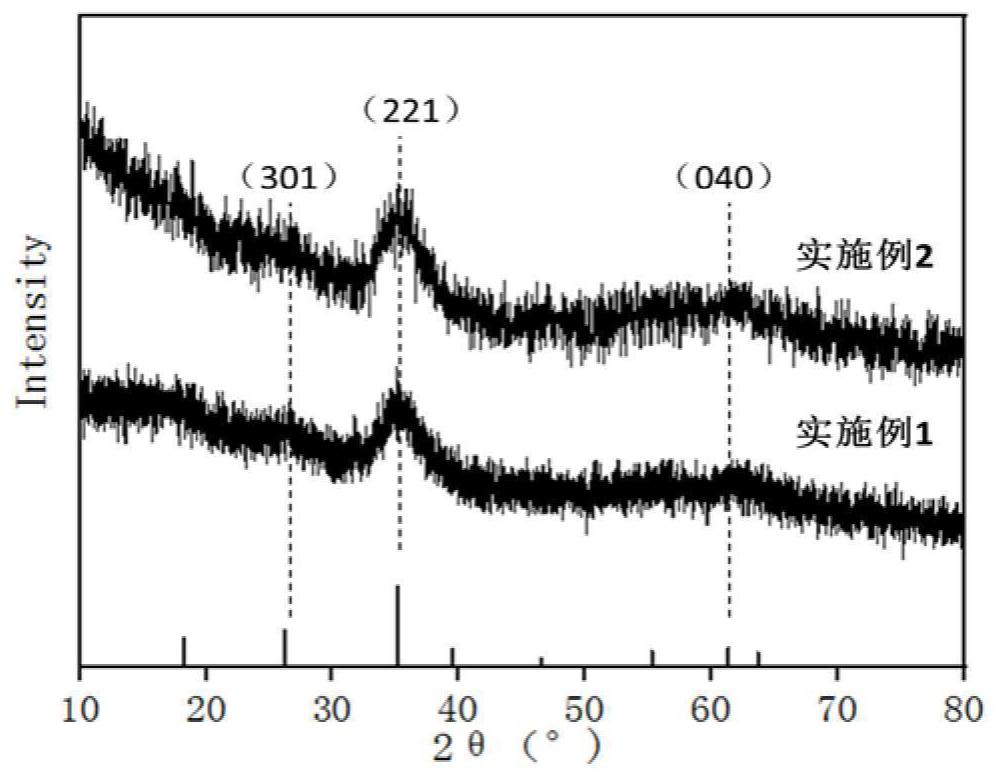

Method for treating stainless steel pickling wastewater and synchronously synthesizing secondary iron minerals

PendingCN112978994ALow costReduce alkali consumptionOther chemical processesWater contaminantsIron sulfateSulfate minerals

The invention discloses a method for treating stainless steel pickling wastewater and synchronously synthesizing secondary iron minerals, which belongs to the field of sewage treatment. The specific process is chemical mineralization combined with alkali neutralization treatment and comprises the following detailed treatment steps of firstly, pretreating the pickling wastewater, adding an oxidizing agent into the pretreated liquid phase for chemical mineralization treatment, collecting the generated secondary iron mineral precipitate, then carrying out alkali neutralization treatment on the solution part, and increasing the pH value to be neutral. According to the technology, efficient treatment of the stainless steel pickling wastewater can be achieved, the alkali consumption can be remarkably reduced through the technology, the amount of generated toxic neutralization sediment is reduced, meanwhile, hydroxyl ferric sulfate minerals with excellent adsorption performance are recycled, and the technology is an economical and efficient technology for treating the stainless steel pickling wastewater.

Owner:NANJING AGRICULTURAL UNIVERSITY

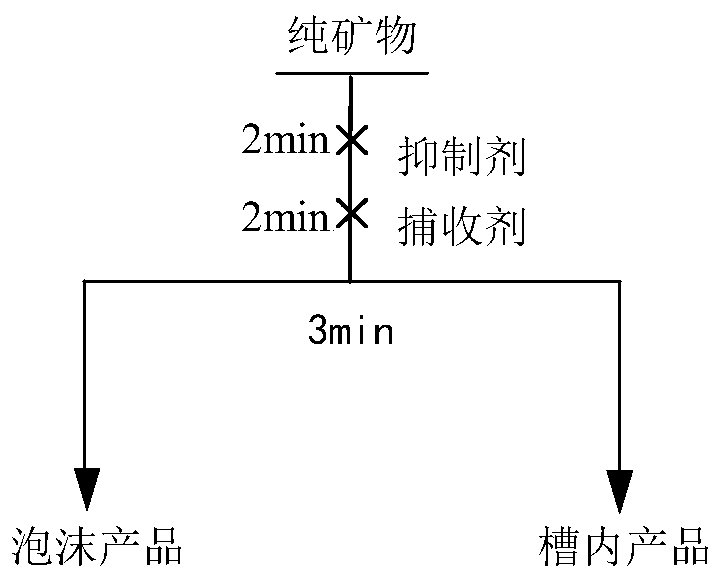

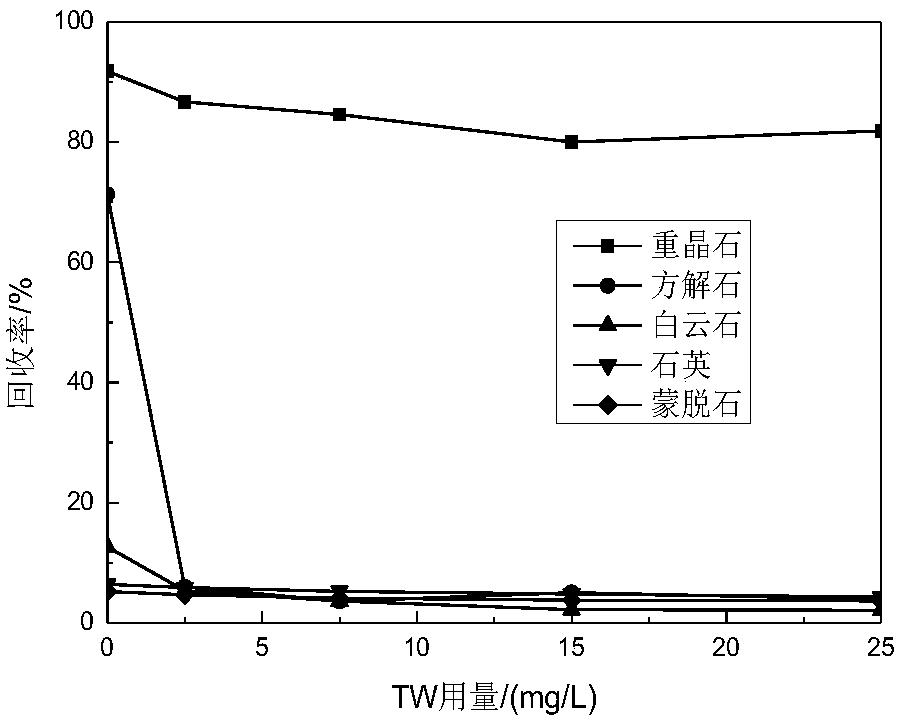

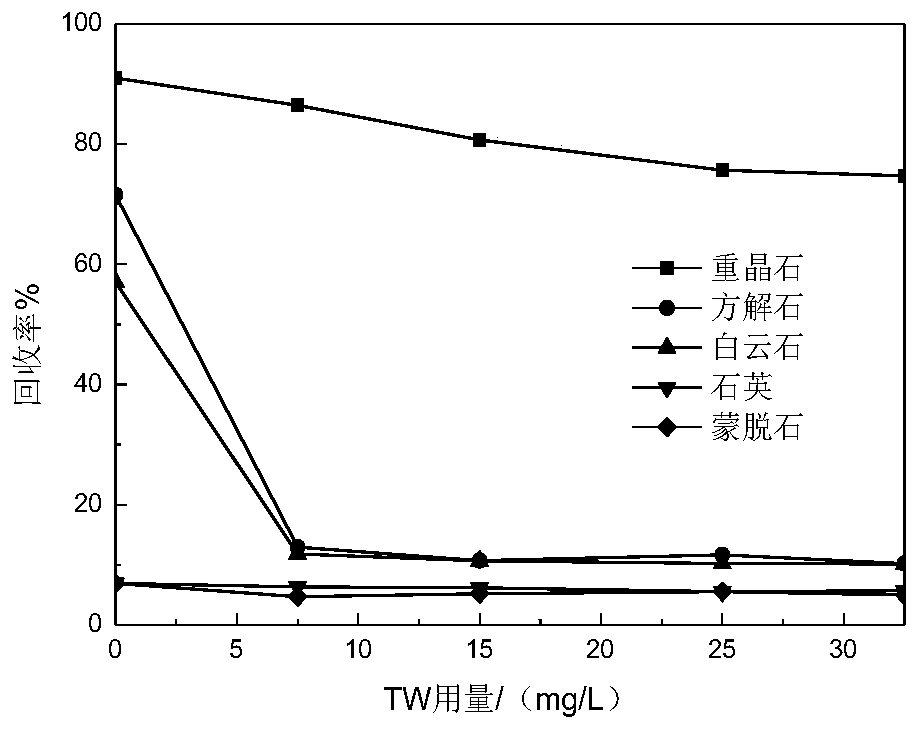

Inhibitor for effectively inhibiting calcium-containing and silicon-containing minerals in barite ore

InactiveCN110614165AImprove the mineral processing index purposeInhibition of calcium-containing silicon-containing gangue mineralsFlotationCalciteSulfate minerals

The invention discloses an inhibitor for effectively inhibiting calcium-containing and silicon-containing minerals in barite ore, and belongs to the field of sulfate mineral flotation. The inhibitor is tannic acid and is added into ore pulp during flotation. In a tannic acid solution with a certain concentration and under the condition of a natural pH value, the infrared spectrum of minerals is measured to show that most tannic acid is adsorbed on the surfaces of calcite and dolomite, and least tannic acid is adsorbed by the surface of barite, showing that the tannic acid selectively inhibitsthe calcite and dolomite which are calcium-containing minerals, so that the collection of the barite by a collecting agent is facilitated. An experiment proves that the tannic acid is used as an inhibitor in a fatty acid and alkyl sulfate collecting system; barite and gangue minerals containing calcium and silicon have a good flotation difference, so that the tannic acid can effectively inhibit the calcite and the dolomite which are calcium-containing minerals in fatty acid and alkyl sulfate collecting systems, and the inhibitor provides a basis for enriching the barite in barite-calcite-dolomite type ore.

Owner:GUIZHOU UNIV

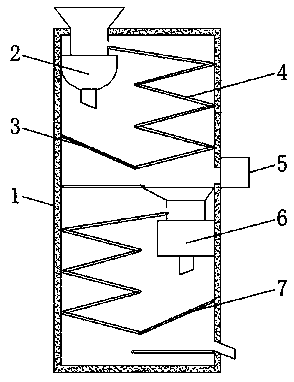

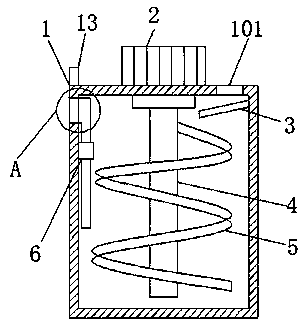

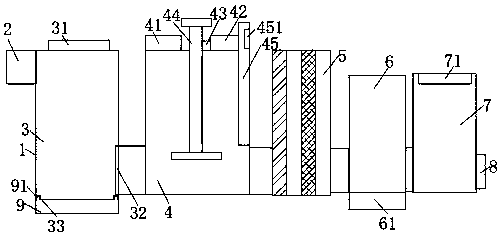

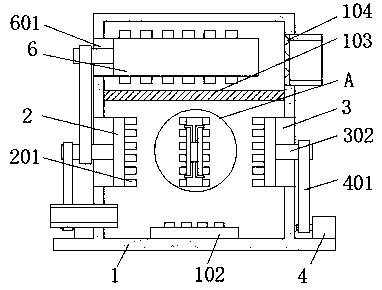

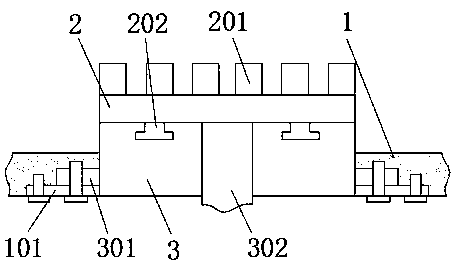

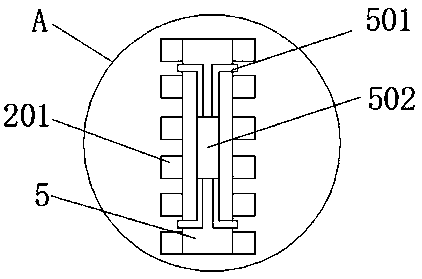

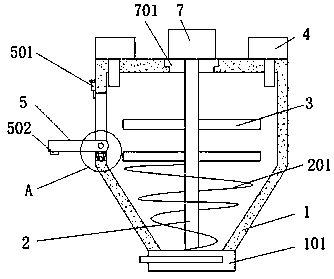

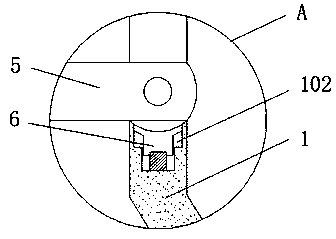

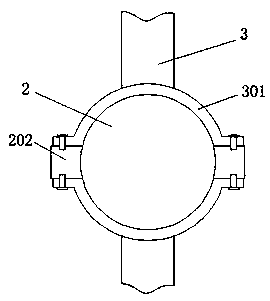

Crushing and grinding integrated device used for producing ferrous sulfate mineral substance

InactiveCN108745589AAvoid the shortcomings of poor dust removal effect and incomplete dust removalFilter thoroughlyDirt cleaningGrain treatmentsEngineeringSulfate minerals

The invention discloses a crushing and grinding integrated device used for producing the ferrous sulfate mineral substance and relates to the technical field of crushing and grinding devices. The crushing and grinding integrated device comprises a housing, wherein a crushing device is fixedly connected to one side of the upper end of the inside of the housing, a crushing screen is fixedly connected to the lower end of the crushing device, one end of the crushing screen is fixedly connected with one end of a recycle conveyor belt, a filter device is fixedly connected to the middle of one side of the housing, a ball-milling device is fixedly connected to the other side of the middle of the inside of the housing, a grinding screen is fixedly connected to the lower end of the ball-milling device, a button is fixedly connected to the upper end of one side of the filter device, the middle of one side of the button is fixedly connected with one end of a pressing column, the other end of the pressing column is movably connected with the top end of a pressing handle by a hinge pin, the bottom end of the pressing handle is fixedly connected with one end of an arc-shaped rod, and a triangularbump is fixedly connected to the other end of the arc-shaped rod. According to the crushing and grinding integrated device used for producing the ferrous sulfate mineral substance, the defect that the dedusting is not thorough when a spraying device is used can be avoided, and the dedusting capacity can be effectively enhanced.

Owner:JIANGSU XIAOCHUN NEW MATERIAL CO LTD

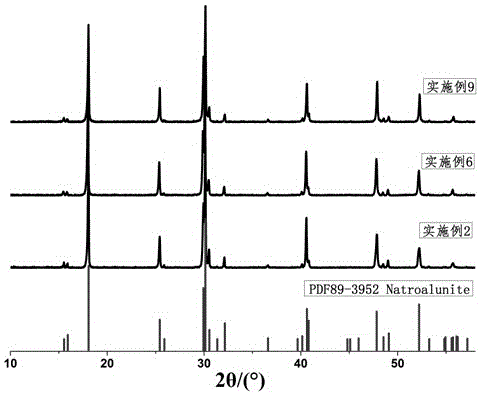

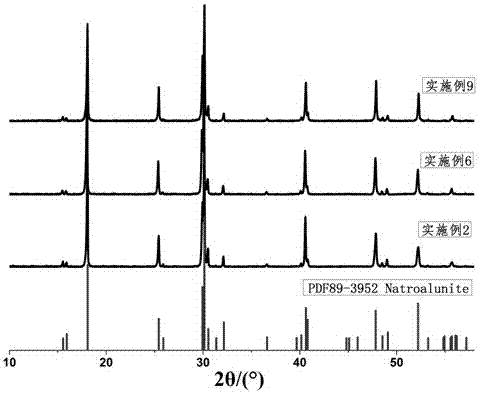

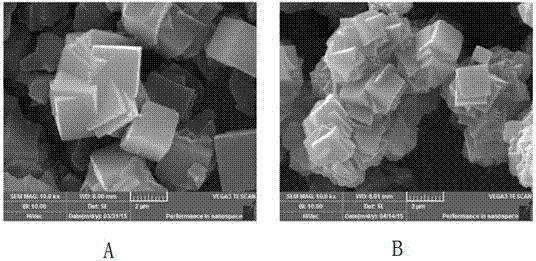

Low-temperature solid-phase method for synthesis of arsenic natroalunite

The present invention discloses a preparation method and application of a sulfate mineral containing arsenic, and particularly relates to a low-temperature solid-phase method for synthesis of an arsenic natroalunite solid solution and application thereof. The method uses aluminum sulfate or aluminum nitrate as an Al source, sodium sulfate as a Na source, arsenic, sodium arsenite or arsenic waste residue as an As source, and conducts a solid phase reaction at 100-220 DEG C for 2.5-72 h, so as to synthesize the arsenic natroalunite solid solution with high crystallinity and good stability. The method is mainly used in the transformation of solid phase soluble arsenic substances into poorly soluble arsenic natroalunite solid solution, solves the disadvantages of required high pressure, high requirements on the reactor, huge energy consumption and high economic cost in the conventional hydrothermal synthesis of arsenic natroalunite, as well as environmental pollution caused by poor stability of conventional arsenic compound. Compared to prior art, the obtained arsenic natroalunite solid solution has advantages of good long-term stability, safe and reliable storage, low economical cost, and reaction conditions close to the industrialization.

Owner:KUNMING UNIV OF SCI & TECH

Microbial granular fertilizer and preparation method thereof

InactiveCN109134069AEasy to movePromote growthOrganic fertilisersSolid/semi-solid fertilisersAgricultural sciencePotassium

The invention relates to the field of fertilizers, in particular to a microbial granular fertilizer and a preparation method thereof. The microbial granular fertilizer comprises, by weight, 3-8 partsof microbial flora powder, 7-15 parts of soluble potassium salt and / or sulfate minerals and 3-5 parts of coagulators. The microbial granular fertilizer can rapidly build microbial profitable strains and improve crop yield.

Owner:陕西赛恩农业科技股份有限公司

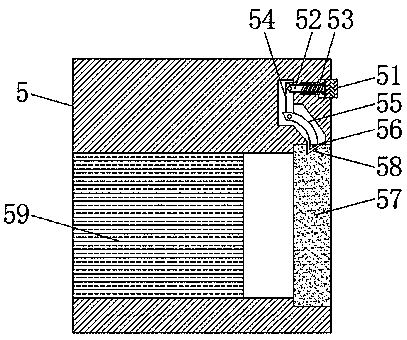

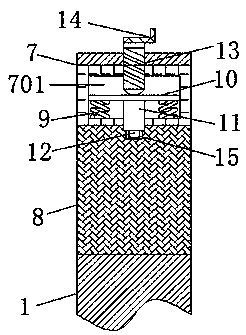

Powder exhaust apparatus for producing ferrous sulfate mineral substances

InactiveCN108654245AEasy to installEasy to disassembleDispersed particle filtrationAir pumpSulfate minerals

The invention discloses a powder exhaust apparatus for producing ferrous sulfate mineral substances, which relates to the technical field of the production of ferrous sulfate mineral substances. The powder exhaust apparatus comprises a box body, wherein the top end of one side of an inner cavity of the box body is provided with a guide plate, the upper part of the other side of the inner cavity ofthe box body is provided with an air pumping device, the top end of one side wall of the box body is provided with a socket groove, a filter plate is arranged in the socket groove in a plugging manner, the top end of the socket groove is provided with an operating cavity, the operating cavity comprises a reset spring, a buffering plate, a connecting column, a clamping block, a threaded rod, a cranking bar and a clamping groove. According to the powder exhaust apparatus for producing the ferrous sulfate mineral substances, the top end of the socket groove is provided with the operating cavity,and the reset spring, the buffering plate, the connecting column, the clamping block, the threaded rod, the cranking bar and the clamping groove are cooperated to achieve an effect for facilitating the installation and disassembling of the filtering plate, and the problem that the filtering plate of the existing powder exhaust apparatus for producing the ferrous sulfate mineral substances is inconvenient to install and disassemble can be solved.

Owner:JIANGSU XIAOCHUN NEW MATERIAL CO LTD

A kind of separation method of high sulfate iron ore

The invention discloses a separation method of high-sulfate iron ore. The method includes the following steps: firstly, performing primary ore grinding-classification on the high-sulfate iron ore, anddischarging primary classification overflow products, wherein the ore grinding particle size is controlled at -0.076mm 50%-55%; performing flotation on the primary classification overflow products, selecting sulfides, and obtaining a sulfur concentrate with a TS grade being greater than or equal to 40.0%; carrying out primary low-intensity magnetic separation on floating sulfur tailings to obtaina primary low-intensity magnetic separation iron concentrate, carrying out secondary ore grinding-classification on the primary low-intensity magnetic separation iron concentrate, and carrying out secondary low-intensity magnetic separation on secondary classification overflow products to obtain a secondary low-intensity magnetic separation iron concentrate; performing high-frequency fine screening-elutriation magnetic separation-pulsating magnetic separation and scavenging combined process on the secondary magnetic separation iron concentrate to obtain a magnetite concentrate, and removing sulfur from the sulfates to enter tailings. The scheme of the invention can effectively remove sulfur from the sulfates in the iron ore, can realize efficient separation of magnet minerals and sulfateminerals, realizes sulfur reduction of the iron concentrate, and also ensures the recovery rate of magnetic iron.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD

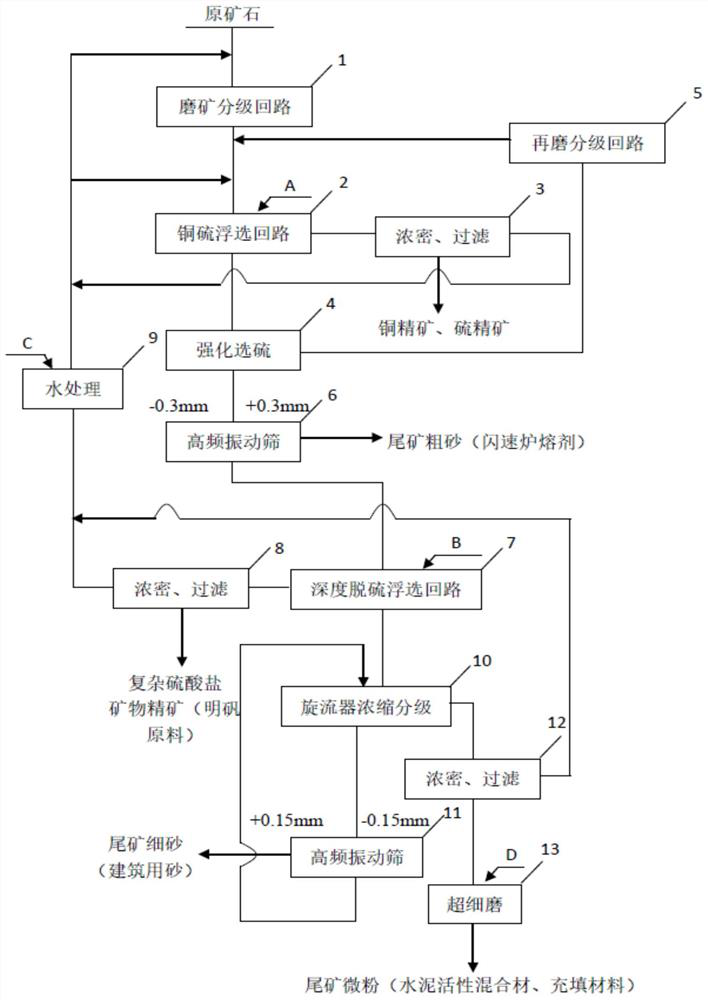

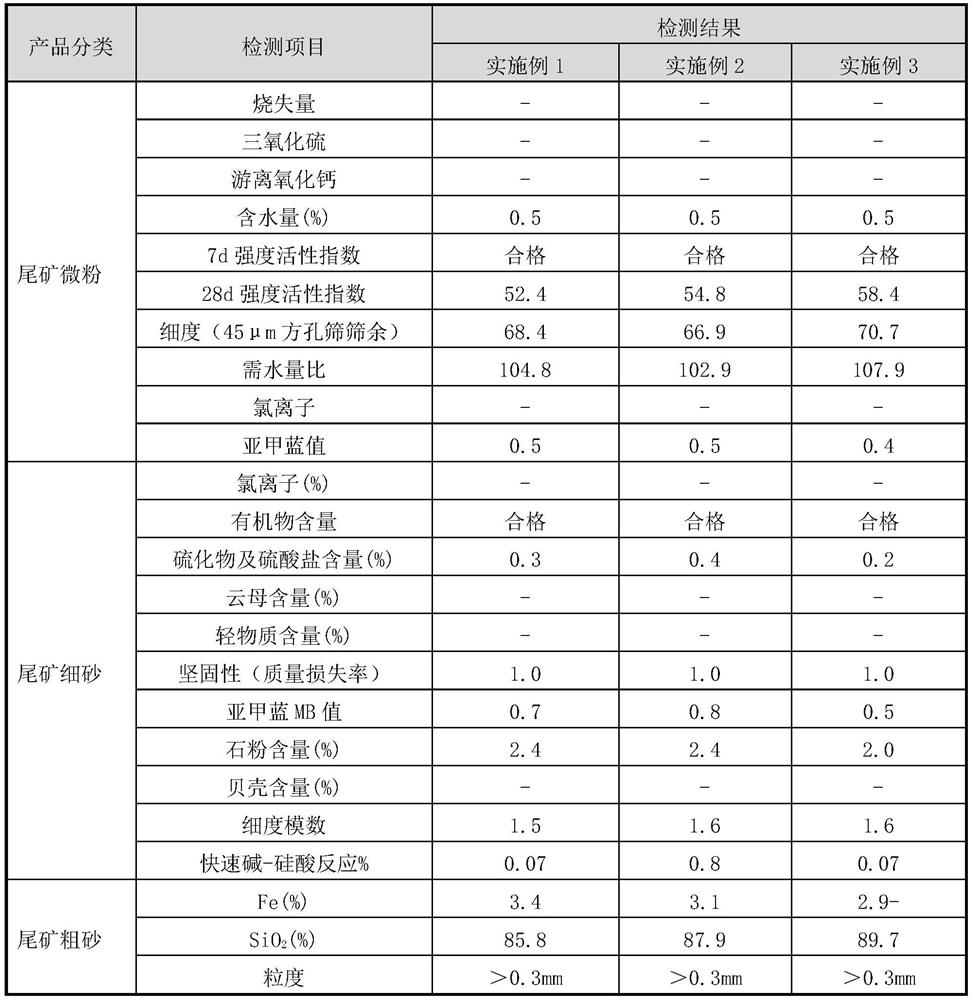

Beneficiation method for fine utilization of high-sulfide type shallow copper ore and tailings thereof

ActiveCN113926586AEfficient use ofSolve storage problemsSolid separationProcess efficiency improvementEngineeringSulfide

The invention relates to a beneficiation method for fine utilization of high-sulfide type shallow copper ore and tailings thereof. The beneficiation method comprises the following steps of analyzing chemical components, mineral composition, dissemination granularity and granularity composition characteristics of the high-sulfide type shallow low-grade copper ore; and adopting a technical route of stage grinding separation, separation of copper-sulfur minerals and complex sulfate minerals, multilayer grading of gangue minerals, superfine grinding and wastewater full-flow recycling, and a product route of copper concentrate, sulfur concentrate, alunite concentrate, coarse sand, fine sand and micro powder. The beneficiation method has the advantages that copper and sulfur elements can be completely recycled, no tailings are generated, zero wastewater discharge is realized, gangue minerals are comprehensively utilized according to different chemical components and particle size characteristics, the problem of tailing stockpiling is solved from the source, and huge economic benefits are created; and the method is suitable for copper tailing treatment and application.

Owner:ZIJIN MINING GROUP

Soil pollution prevention treatment device for industrial production of ferrous sulfate mineral substance

InactiveCN108483754AReduce pollutionAvoid pollutionWater treatment compoundsTreatment involving filtrationLiquid wasteFiltration

The invention discloses a soil pollution prevention treatment device for industrial production of a ferrous sulfate mineral substance and relates to the technical field of soil pollution prevention. The device comprises a treatment device body, wherein the treatment device body comprises a liquid inlet, a recovery tank, a neutralization tank, a filtration tank, a sediment tank, a dilution tank anda liquid discharge pipe; one end of the liquid inlet is fixedly connected with the upper side of one end of the recovery tank; the lower side of the other end of the recovery tank is fixedly connected with the lower side of one end of the neutralization tank. According to the soil pollution prevention treatment device for the industrial production of the ferrous sulfate mineral substance, on onehand, the recovery tank can recycle waste liquid for treatment; on the other hand, a collecting tank can be dismounted to facilitate recovery of a separated substance in the waste liquid; a neutralization chamber can neutralize the waste liquid to reduce the pollution of the waste liquid after discharge to soil; in addition, the dilution tank can dilute the treated waste liquid before the discharge to prevent the soil pollution.

Owner:SUQIAN MODERN CHEM

A high-value comprehensive utilization method of lithium slag

ActiveCN108147658BRealize high-value utilizationAchieve full utilizationSolid waste managementSlagSlurry

Owner:TIANQI XINLONG CO LTD

Ultrafine solid waste-based grouting material and preparation method thereof

ActiveCN112500056BImprove stabilityImprove thixotropySolid waste managementInorganic saltsEnvironmental engineering

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Geopolymer-based artificial defense stone prepared from all waste and its preparation method

The invention discloses a geopolymer-based artificial defense stone prepared from all wastes and a preparation method thereof, comprising the following raw materials in parts by weight: 288-412 parts of waste silicon-aluminum materials; 85-150 parts of alkali-containing waste ; 29-75 parts of waste sulfate minerals; 1501-1860 parts of recycled aggregate; 216-241 parts of reclaimed water; 0-2 parts of waste fiber; 0-5 parts of agricultural waste. The process of the invention is simple, the prepared artificial stone has no appearance defects, has the advantages of high volume density, high strength (above 34MPa), good weathering resistance, frost resistance and abrasion resistance, and is easy to cast during use. Convenience, good integrity, strong stability, anti-freezing and thawing, anti-weathering, high-speed sand-containing water flow resistance, not easy to get lost under high-speed water flow, it is an ideal substitute for natural stone defense stone.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

Method and application of low-temperature solid-phase synthesis of sodium arsenic alunite solid solution

The invention discloses a method for preparing arsenic-containing sulfate minerals and its application, in particular to a method for low-temperature solid-phase synthesis of sodium arsenic alunite solid solution and its application in the treatment of arsenic-containing waste residue. The method uses aluminum sulfate Or aluminum nitrate is the Al source, sodium sulfate is the Na source, sodium arsenate, sodium arsenite or arsenic-containing waste residue is the As source, and the crystallinity is high and the stability Good sodium arsenite solid solution; this method is mainly used to transform the easily soluble arsenic substance in the solid phase into insoluble sodium arsenite solid solution, so as to solve the high pressure conditions and reaction conditions required for the traditional hydrothermal synthesis of arsenite. The disadvantages of the kettle are high requirements, high energy consumption, high economic cost, and environmental pollution caused by the poor stability of traditional arsenic compounds; compared with traditional technologies, the obtained arsenic sodium alumite solid solution has good long-term stability, safe and reliable storage, and low economic cost , The reaction conditions are close to industrialization.

Owner:KUNMING UNIV OF SCI & TECH

A kind of cement clinker and production method thereof

The invention relates to a production method of cement clinker. The production method is characterized by comprising the steps that yellow phosphorus slag and / or alkaline slag and limestone, shale and sandy loess are mixed, and ground into raw material by a raw material preparation system. The production method of the cement clinker comprises the following steps of recycling the yellow phosphorus slag and / or the alkaline slag, quickly reacting sulfur and alkaline compounds enriched by a rotary kiln system and a preheater system, and balancing the sulfur and alkaline ratio, so that the SO2 (sulfur dioxide) gas is effectively cured, the refractory sulfate mineral is generated, the standard discharge is realized, the solid-phase reaction degree in the rotary kiln is improved, the particle forming of the clinker in calcining is denser, and the quality of the clinker is more stable. The production method of the cement clinker has the advantages that by compounding the industrial solid wastes to prepare the raw material, the high-investment equipment is not used, the standard discharge is realized, the burnability of the cement raw material is improved, and the energy consumption of the clinker is decreased; the yellow phosphorus slag and the alkaline slag are industrial waste slag, the pollution by industrial waste slag is eliminated by the desulfurizing of the waste slag in the cement kiln, and the effect of changing wastes into valuables is realized.

Owner:华润水泥(合浦)有限公司

Airflow vortex powder refining machine used for producing ferrous sulfate mineral substance

InactiveCN108745590AEasy accessAchieve the effect of vortex powderGrain treatmentsElectric machinerySulfate minerals

The invention discloses an airflow vortex powder refining machine used for producing the ferrous sulfate mineral substance and relates to the technical field of ferrous sulfate mineral substance producing and processing. The airflow vortex powder refining machine comprises a housing, wherein rotary table fixing seats are fixedly connected to the middles of the two sides of the housing, rotation shafts are fixedly connected to the centers of the rotary table fixing seats, a motor is movably connected to one end of one rotation shaft through a belt, powder rotary tables are fixedly connected tothe other ends of the rotation shafts, a blowing device is fixedly connected to the middle of the bottom end of the housing, and a toothed plate is fixedly connected to the middle of the cavity of thehousing. According to the airflow vortex powder refining machine used for producing the ferrous sulfate mineral substance, powder processing can be performed to the mineral substance by arranging thepowder rotary table and a powder knife, the airflow can be released in a processing area by arranging a jet head and a jet device, when the powder rotary table rotates, the airflow is guided into a vortex shape, a vortex powder effect is realized, and the mineral substance can be processed repeatedly between the powder rotary table and the toothed plate by arranging a filter screen.

Owner:SUQIAN MODERN CHEM

Treating material for polluted water, method for production thereof and use thereof

InactiveCN100355668CPhysical/chemical process catalystsSilicon compoundsSilicic acidHazardous substance

A treating material for treating a polluted water containing, as a hazardous substance, arsenic, lead, cadmium, antimony, uranium, phosphorus, fluorine or the like, which comprises an oxygen-containing iron compound carried on a material containing a silicic acid based fiber or a silicate based fiber; a method for producing the treating material which comprises contacting and reacting a silicate based fiber, such as rock wool, with an iron-containing acidic water; and a method for treating the polluted water witch comprises contacting the treating material with the polluted water. The treating material has a fine structure wherein the above oxygen-containing iron compound is attached in a sheath form on the surface of a fiber reduced in an alkali component and increased in a silicic acid component as compared to, for example, rock wool. The oxygen-containing iron compounds include schwertmannite, ferrihydrite, akaganeite, amorphous hydrous iron oxide and fired ferric sulfate.

Owner:NIPPON STEEL CHEMICAL CO LTD

Ferrous sulfate mineral substance discharge powder treatment equipment for industrial production

InactiveCN108750711ASmooth dischargeImprove opening and closing effectLoading/unloadingSpiral bladeSulfate minerals

The invention discloses ferrous sulfate mineral substance discharge powder treatment equipment for industrial production and relates to the technical field of mineral substance production and processing. The equipment comprises a shell. The bottom of the shell is fixedly connected with a discharge valve. The middle portion of the top end of the shell is fixedly connected with a rotary shaft fixingseat. The middle portion of the rotary shaft fixing seat is movably connected with a rotary shaft. The top end of the rotary shaft is movably connected with a motor. Stirring rods are fixedly connected to the circumference of the middle portion of the rotary shaft. A spiral blade is fixedly connected to the circumference of the lower end of the rotary shaft. A feed door is movably connected to one side of the shell. According to the ferrous sulfate mineral substance discharge powder treatment equipment for industrial production, on one hand, through arrangement of arc-shaped plates and fixedblocks, the stirring rods can be firmly fixed to the rotary shaft; on the other hand, the equipment can be dismantled conveniently, and the rotary shaft fixing seat is fixed through bolts, clamping parts and clamping grooves; through second grooves and springs, the rotary shaft fixing seat can be taken down conveniently, and the convenient disassembling and assembling effect is achieved.

Owner:JIANGSU XIAOCHUN NEW MATERIAL CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com