Method for treating stainless steel pickling wastewater and synchronously synthesizing secondary iron minerals

A technology for pickling wastewater and stainless steel, which is applied in the field of sewage treatment, can solve the problems of large amount of neutralizing sediment and large demand for neutralizing agents, and can reduce the amount of alkali, reduce the neutralization sediment, and facilitate extraction and reuse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

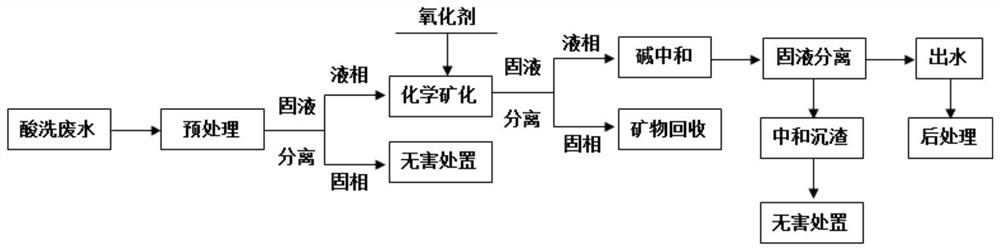

[0048] A method for treating stainless steel pickling wastewater and synchronously synthesizing secondary iron minerals, the process is as follows figure 1 As shown, the method includes the following steps:

[0049] (1) Take 83mL of stainless steel pickling wastewater with a pH of 0.04, add tap water to make up to 250mL, that is, dilute 3 times. Obtained total Fe concentration is 20.67g / L, total SO 4 2- The concentration is 81.00g / L, the total Cr concentration is 5.00g / L, the total Ni concentration is 1.93g / L, the total Mn concentration is 1.40g / L, the total Cu concentration is 0.04g / L, and the total Si concentration is 0.02g / L The liquid phase of L.

[0050] (2) Chemically mineralize the liquid phase obtained above in a shaker with a rotating speed of 180r / min and a temperature of 28°C. The reaction conditions are: add 1.1mL hydrogen peroxide every half hour, and add 6 times in total; The initial pH is 2.5; the reaction time is 24h. After mineralization, the suction filt...

Embodiment 2

[0056] A method for treating stainless steel pickling wastewater and synchronously synthesizing secondary iron minerals, the process is as follows figure 1 As shown, the method includes the following steps:

[0057] (1) Get 250ml pH=0.04 stainless steel pickling wastewater, then add 20g CaCl 2 , after stirring and reacting for 1 h, solid-liquid separation was carried out under the conditions of 6000 g and 10 min using a centrifuge. Obtain 49.11g sludge, and pretreated liquid phase;

[0058] (2) The liquid phase obtained above was chemically mineralized in a shaker with a rotating speed of 180r / min and a temperature of 28°C. The reaction conditions were: adding 20mL of hydrogen peroxide; the initial pH of the reaction was 2.5; the reaction time was 24h. After mineralization, use a centrifuge to separate the solid and liquid under the condition of 6000g and 10min to obtain liquid phase and solid phase minerals. The solid phase was washed three times with dilute sulfuric acid ...

Embodiment 3

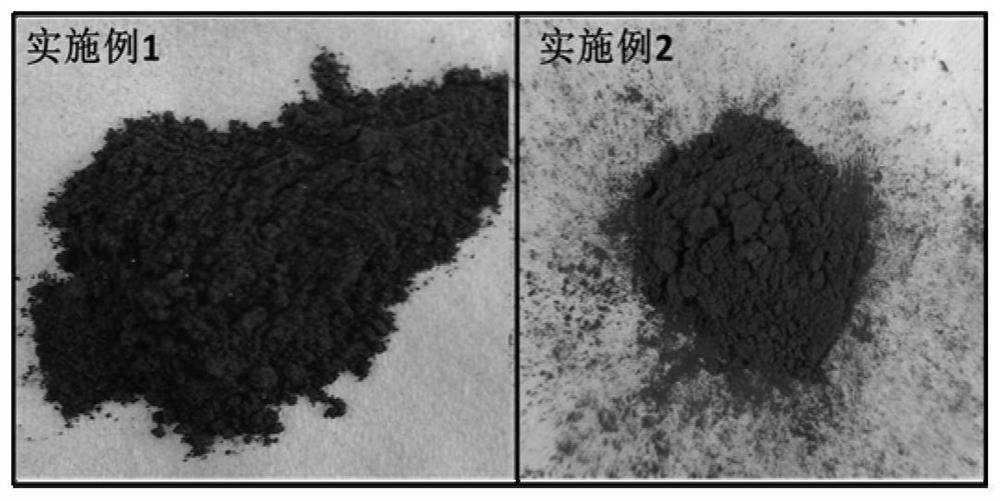

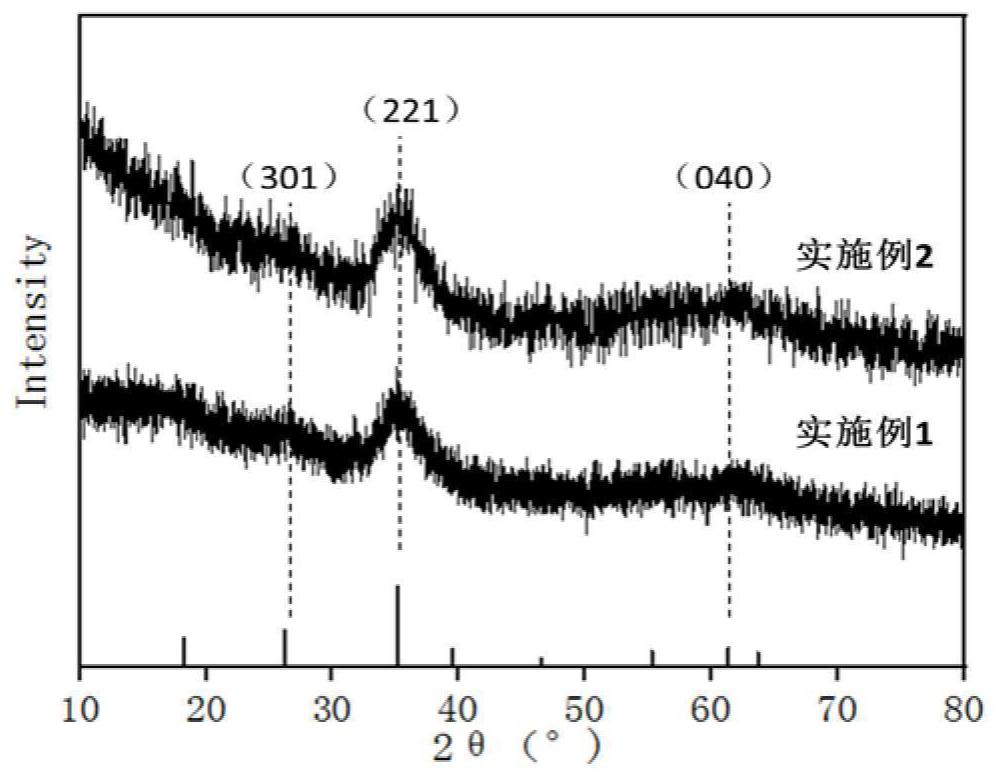

[0064] In this example, trivalent arsenic is used as the adsorption object to study the adsorption capacity of the solid-phase minerals obtained in Examples 1 and 2.

[0065] The mineral obtained in embodiment 1 is denoted as Sch 1, and the mineral obtained in embodiment 2 is denoted as Sch 2, and the trivalent arsenic adsorption capacity determination method is:

[0066] (1) Accurately weigh 0.010g Sch 1 and Sch 2 respectively, add to 10mg / L~400mg / L trivalent arsenic solution, adjust the pH value of the solution to 7.0, shake in a shaker at 25°C and 180r / min. Monitor the pH value of the solution every 0.5h and re-adjust the pH value to 7.0. After 4h, take a sample, pass through a 0.45μm filter membrane, and measure the content of trivalent arsenic.

[0067] (2) Draw the adsorption isotherms of the two minerals for trivalent arsenic. The results are shown in Table 3. According to the Langmuir formula, the maximum adsorption capacities of Sch 1 and Sch 2 for trivalent arsenic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com