Full-phase high-valued recycling method for lithium slag

A high-value, lithium slag technology, used in solid waste removal, sustainable waste treatment, solid waste management, etc., can solve problems such as rising spodumene prices, recycling and treatment of lithium slag single application, and restricting application development. , to achieve the effect of increasing added value, no waste gas, no solid waste discharge, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

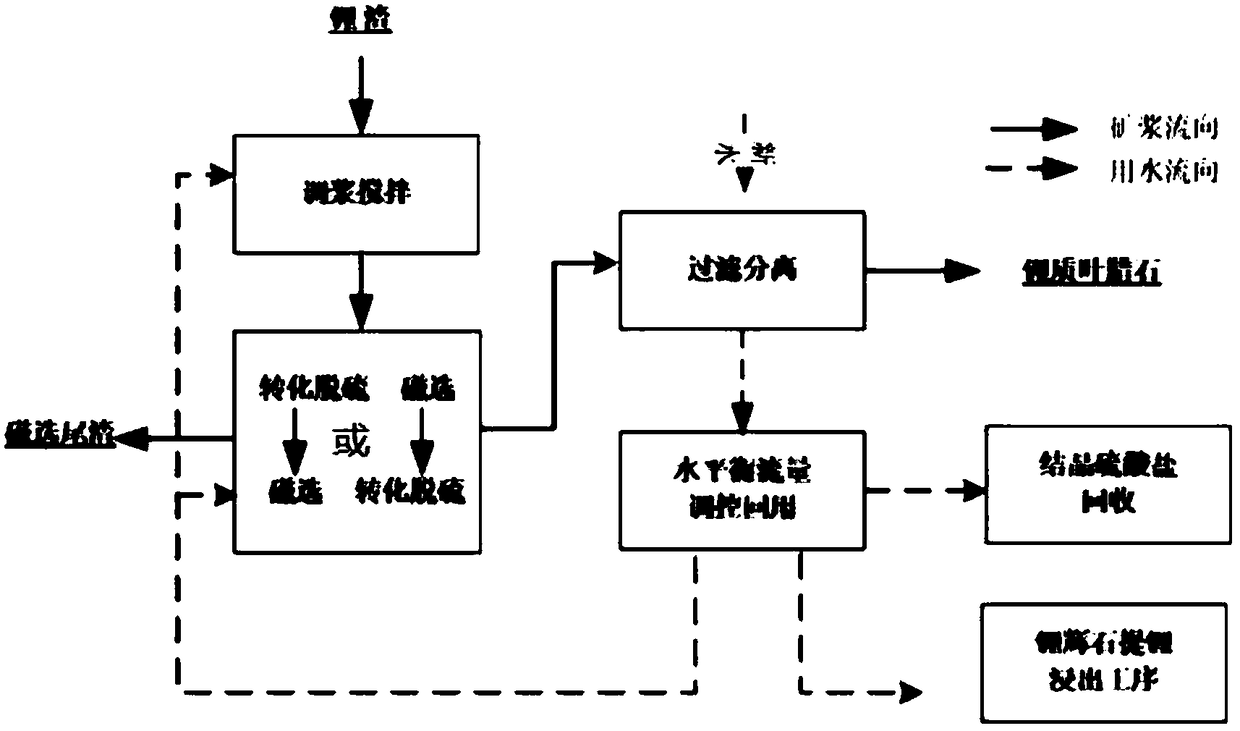

Method used

Image

Examples

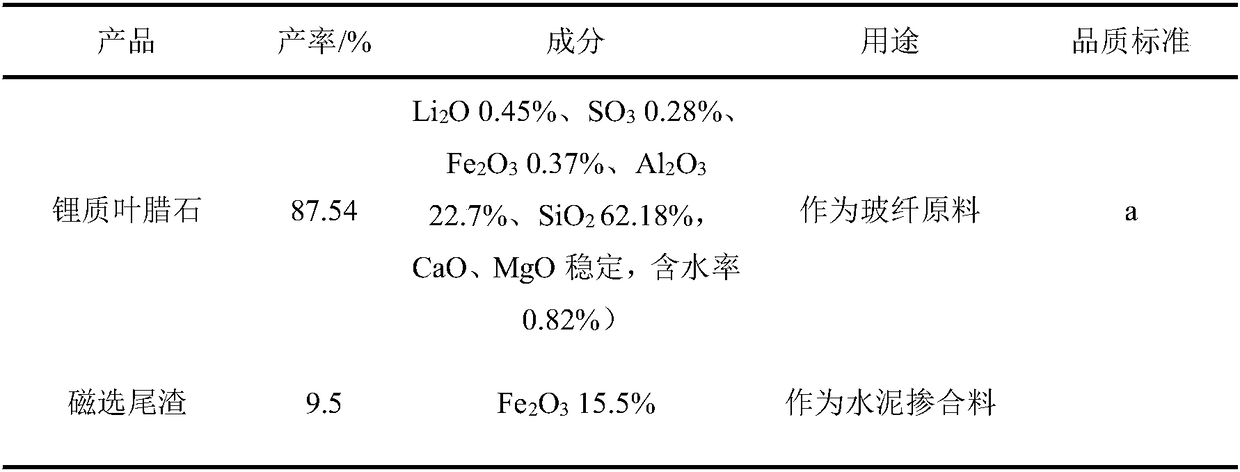

Embodiment 1

[0069] For a spodumene lithium extraction enterprise in Sichuan, the lithium slag (Li 2 O 0.3%, SO 3 6.58%, Fe 2 o 3 1.8%, SiO 2 62%, Al 2 o 3 21%), add water to adjust slurry, pulp concentration 40%, and add dispersant sodium silicate 1000 g / t lithium slag; add sodium carbonate (87.5kg / t lithium slag) to ore pulp for desulfurization reaction, control pH9.2, The pulp is leached at room temperature for 100 minutes; the desulfurized slurry enters the wet strong magnetic separator, and the strong magnetic separation adopts a rough and sweep process. The rough separation controls the magnetic field strength to 1.2T, and the sweeping control magnetic field strength is 1.5T to obtain the magnetic separation slurry and magnetic separation tailings; after magnetic separation, the obtained magnetic separation slurry is concentrated, filtered and dried to obtain a lithium pyrophyllite product for glass fiber. The filtrate obtained by filtering is used for the desulfurization react...

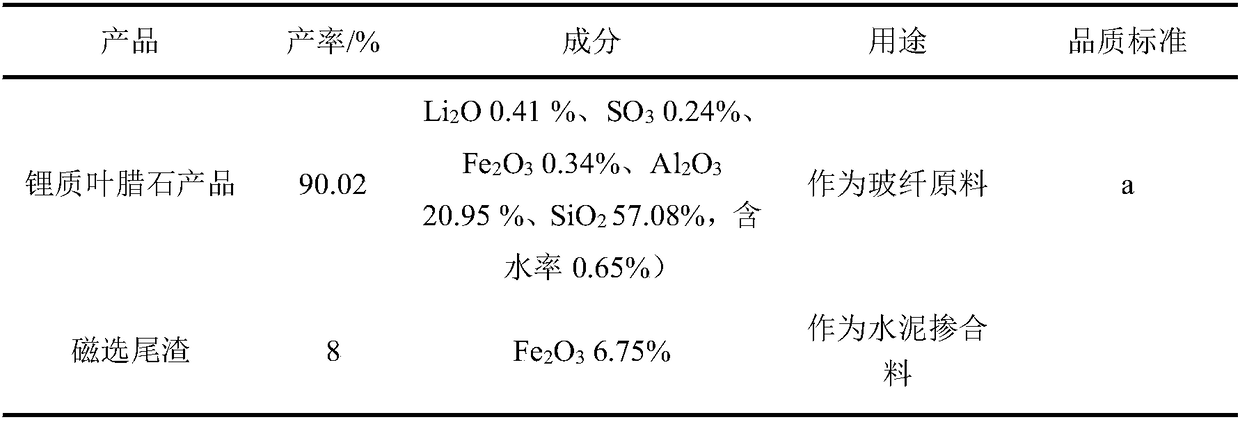

Embodiment 2

[0076] For a spodumene lithium extraction enterprise in Sichuan, the lithium slag (Li 2 O 0.5%, SO 3 11.05%, Fe 2 o 3 0.85%, SiO 2 55%, Al 2 o 3 21%), add water to adjust the pulp, the concentration of the pulp is 50%, and add 1500 g / t lithium slag as a dispersant sodium silicate; the pulp enters the wet strong magnetic separator. The magnetic field strength is 1.3T, and the sweeping control magnetic field strength is 1.5T to obtain magnetic separation slurry and magnetic separation tailings; add sodium carbonate (148kg / t lithium slag) to the magnetic separation slurry for reaction, control pH 10.5, and adjust the slurry at room temperature Leach for 90 minutes; then concentrate, filter and dry the obtained desulfurization slurry to obtain lithium pyrophyllite for glass fiber. The filtrate of filtering gained is regulated and controlled 68% (v / v) filtrate and be used for wet magnetic separation by water balance flow rate; Regulate and control 12% (v / v) filtrate and be us...

Embodiment 3

[0083] Lithium slag (Li 2 O 0.27%, SO 3 1.92%, Fe 2 o 3 1.13%, SiO 2 67%, Al 2 o 3 23%), add water through the mortar pump and pour into the mixing tank, control the concentration of the pulp to 30%, and add 1000 g / t lithium slag as a dispersant sodium silicate; add sodium carbonate (27kg / t lithium slag) to the pulp for desulfurization reaction , control pH 11.2, leaching for 60 minutes at room temperature; desulfurization slurry enters wet strong magnetic separator, strong magnetic separation adopts a rough and sweep process, the rough separation control magnetic field strength is 1.5T, and the sweep control magnetic field strength is 1.8T , to obtain magnetic separation slurry and magnetic separation tailings; after magnetic separation, the obtained magnetic separation slurry is concentrated, filtered and dried to obtain a lithium pyrophyllite product for glass fiber. The filtrate obtained by filtering is regulated by water balance flow rate, and 10% (v / v) of the filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com