Inhibitor for effectively inhibiting calcium-containing and silicon-containing minerals in barite ore

A barite and inhibitor technology, applied in solid separation, flotation and other directions, can solve the problem of difficult separation of barite ore minerals and gangue minerals, and achieve the effect of high selectivity and good inhibition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

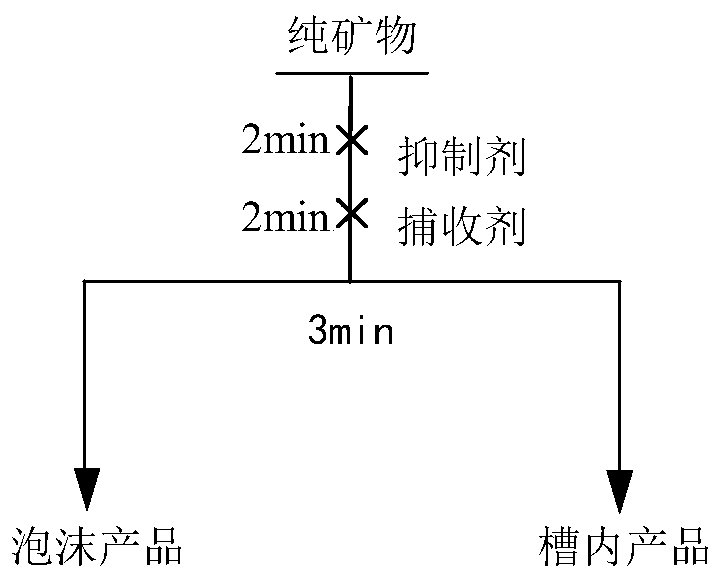

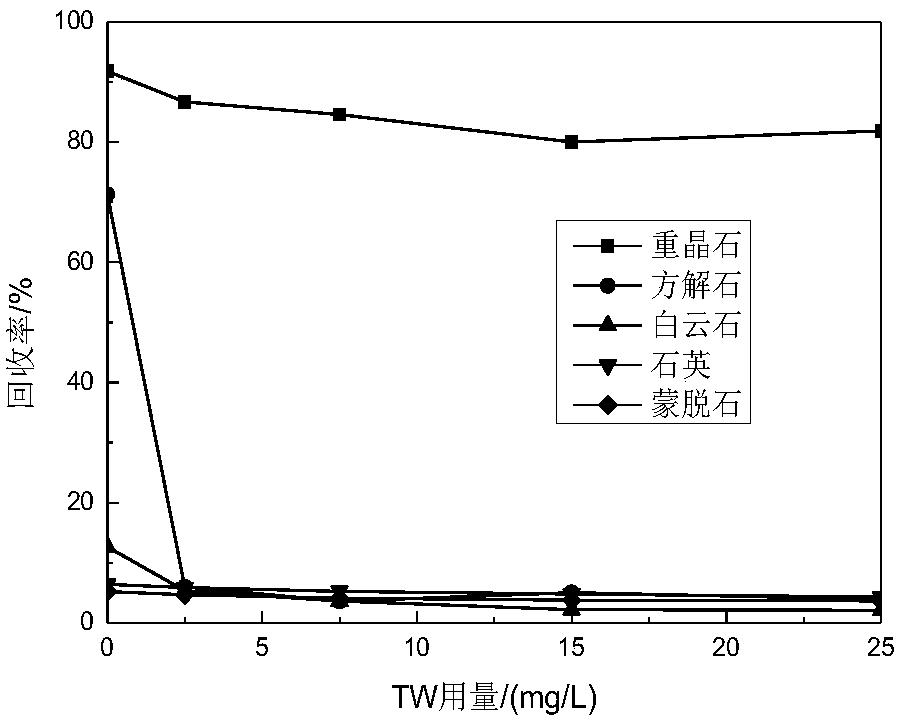

[0022] Pure minerals such as barite, calcite, and dolomite were selected and purified by hand, and then ground with an agate grinder. Pure mineral samples with a particle size of -90 μm + 38 μm were taken, washed repeatedly with distilled water, and used as experimental minerals. The mineral flotation test was carried out in a 40 mL hanging tank flotation machine. The amount of test ore sample was 2.0 g each time, stirred for 1 min, natural pH, inhibitor action for 2 min, collector action for 2 min, and flotation time for 3 min. Flotation adopts manual foam scraping, and the foam product and the product in the tank are dried and weighed separately, and the recovery rate is calculated. Under the natural pH value, when the combined collector dosage of sodium oleate+soap (2:3) is 15mg / L, and the dosage of tannic acid is 2.5mg / L, the recovery rate of calcite drops from 71.26% to 5.98%. The recovery of barite dropped only 5.11% to 86.65%, the recovery of dolomite was 5.36%, the rec...

Embodiment 2

[0024] Pure minerals such as barite, calcite, and dolomite were selected and purified by hand, and then ground with an agate grinder. Pure mineral samples with a particle size of -90 μm + 38 μm were taken, washed repeatedly with distilled water, and used as experimental minerals. The mineral flotation test was carried out in a 40 mL hanging tank flotation machine. The amount of test ore sample was 2.0 g each time, stirred for 1 min, natural pH, inhibitor action for 2 min, collector action for 2 min, and flotation time for 3 min. Flotation adopts manual foam scraping, and the foam product and the product in the tank are dried and weighed separately, and the recovery rate is calculated. Under the natural pH value, when the combined collector dosage of sodium oleate+soap (2:3) is 15mg / L, and the dosage of tannic acid is 7.5mg / L, the recovery rate of barite is 84.55%, and the recovery rate of calcite is 84.55%. 3.61%, the recovery rate of dolomite is 3.63%, the recovery rate of qu...

Embodiment 3

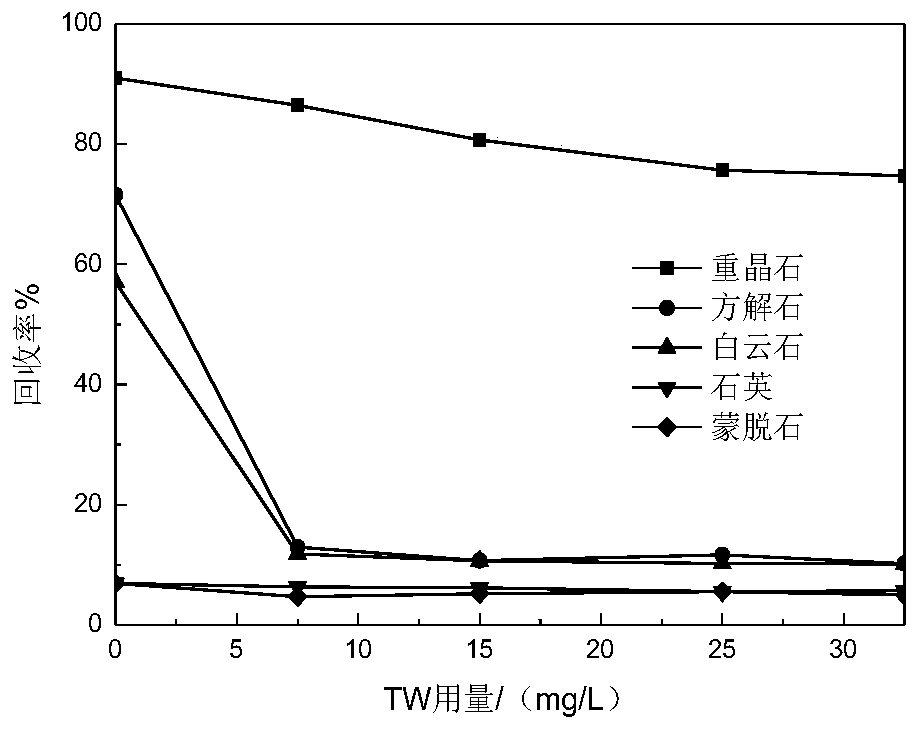

[0026] Pure minerals such as barite, calcite, and dolomite were selected and purified by hand, and then ground with an agate grinder. Pure mineral samples with a particle size of -90 μm + 38 μm were taken, washed repeatedly with distilled water, and used as experimental minerals. The mineral flotation test was carried out in a 40 mL hanging tank flotation machine. The amount of test ore sample was 2.0 g each time, stirred for 1 min, natural pH, inhibitor action for 2 min, collector action for 2 min, and flotation time for 3 min. Flotation adopts manual foam scraping, and the foam product and the product in the tank are dried and weighed separately, and the recovery rate is calculated. Under the natural pH value, when the combined collector dosage of sodium lauryl sulfate + sodium dodecylsulfonate (1:1) is 25mg / L, and the dosage of tannic acid is 7.5mg / L, the recovery rate of barite The recovery rate of calcite is 12.93%, the recovery rate of dolomite is 11.79%, the recovery ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com