Fully glazed ceramic chip and preparation method thereof

A technology of full-polishing glaze and ceramic pieces, applied in the field of architectural ceramics, can solve the problems of no improvement in glaze texture, brightness, flatness, pinholes, etc., to improve the glaze effect and aesthetic value, texture layered, textured rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

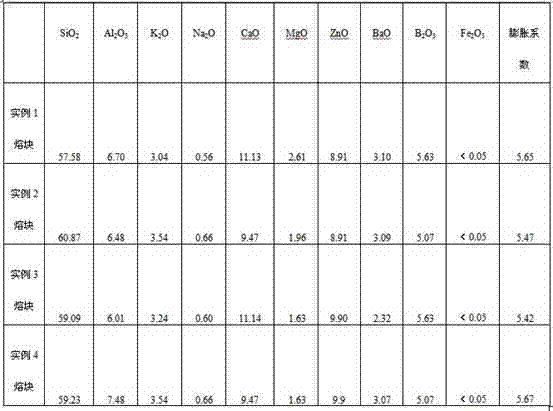

Embodiment 1

[0022] Weigh 30kg of potassium feldspar, 15kg of calcite, 5kg of calcined talc, 6kg of zinc oxide, 4kg of barium carbonate, 10kg of boric acid, 2kg of alumina, and 28kg of quartz. After mixing evenly, melt in an electric furnace at 1530°C for 2 hours to form a melt. , quenched, crushed, and dried to obtain a fully glazed frit.

[0023] Weigh 64kg of glaze frit for ceramic tiles, 5kg of air-knife soil, 0.3kg of sodium tripolyphosphate, 0.1kg of sodium carboxymethylcellulose, and 31kg of water. After mixing evenly, ball mill until 100g of slurry is passed through a 325 mesh sieve The sieved residue is 0.1~0.2%, and the specific gravity is adjusted to 1.82 to obtain a full glaze glaze slurry for porcelain tiles.

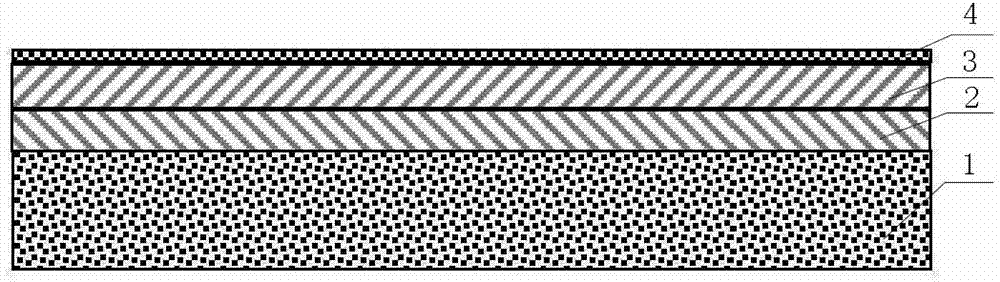

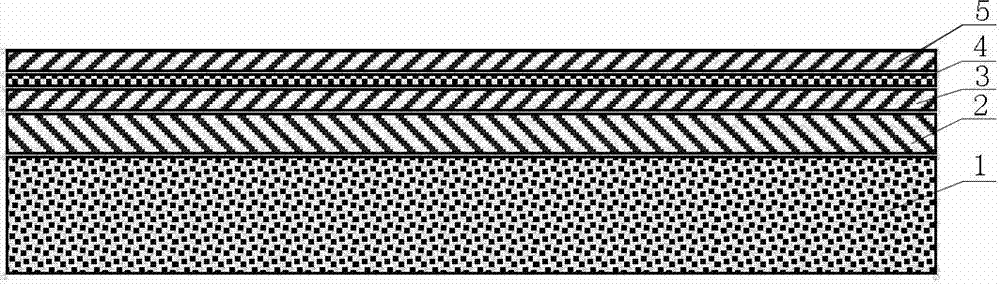

[0024] Taking a tile of 300mm×600mm as an example, pour 100g of bottom glaze, top glaze, pattern glaze, and full glaze glaze slurry on the body layer 1 to form bottom glaze layer 2, top glaze layer 3, and pattern glaze layer. 4 and the full glaze layer 5, the thicknes...

Embodiment 2

[0026] Weigh 32 kg of potassium feldspar, 16 kg of calcite, 6 kg of calcined talc, 7 kg of zinc oxide, 3 kg of barium carbonate, 6 kg of boric acid, 1 kg of alumina, and 29 kg of quartz. Melting at high temperature for 2.5 hours to form a melt, quenching, crushing, and drying to obtain a fully glazed frit.

[0027] Weigh 71 kg of glaze frit for ceramic tiles, 0.3 kg of sodium tripolyphosphate, 0.1 kg of sodium carboxymethyl cellulose, and 29 kg of water. After mixing evenly, ball mill until 100 g of slurry is passed through a 325-mesh sieve. 0.1~0.2%, and adjust the specific gravity to 1.84 to get full glaze glaze slurry.

[0028] Taking a tile of 300mm×600mm as an example, pour 100g of bottom glaze, top glaze, pattern glaze, and full glaze glaze slurry on the body layer 1 to form bottom glaze layer 2, top glaze layer 3, and pattern glaze layer. 4 and the full glaze layer 5, the thickness of the full glaze layer 5 is 0.15mm. Enter the kiln for sintering at 1120°C, take it...

Embodiment 3

[0030] Weigh 33 kg of potassium feldspar, 15 kg of calcite, 5 kg of calcined talc, 8 kg of zinc oxide, 3 kg of barium carbonate, 7 kg of boric acid, 1 kg of alumina, and 28 kg of quartz. Melting at high temperature for 3 hours to form a melt, quenching, crushing, and drying to obtain a fully glazed frit.

[0031] 65 kg of full glaze frit for ceramic tiles, 3 kg of air knife soil, 0.3 kg of sodium tripolyphosphate, 0.1 kg of sodium carboxymethyl cellulose, and 32 kg of water, weighed, mixed evenly, and ball milled until 100 g of slurry was passed through 325 The remainder of the mesh sieve is 0.1~0.2%, and the specific gravity is adjusted to 1.83 to obtain the full glaze glaze slurry.

[0032] Taking a tile of 300mm×600mm as an example, pour 100g of bottom glaze, top glaze, pattern glaze, and full glaze glaze slurry on the body layer 1 to form bottom glaze layer 2, top glaze layer 3, and pattern glaze layer. 4 and the full glaze layer 5, the thickness of the full glaze layer 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com