Beneficiation method for fine utilization of high-sulfide type shallow copper ore and tailings thereof

A beneficiation method and vulcanization-type technology, which is applied in the mineral processing field of high-sulfurization epigenetic copper ore and its tailing fine utilization, can solve the problem of undiscovered mineral processing method for multi-purpose resource utilization, and achieve the solution of tailings pile problematic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

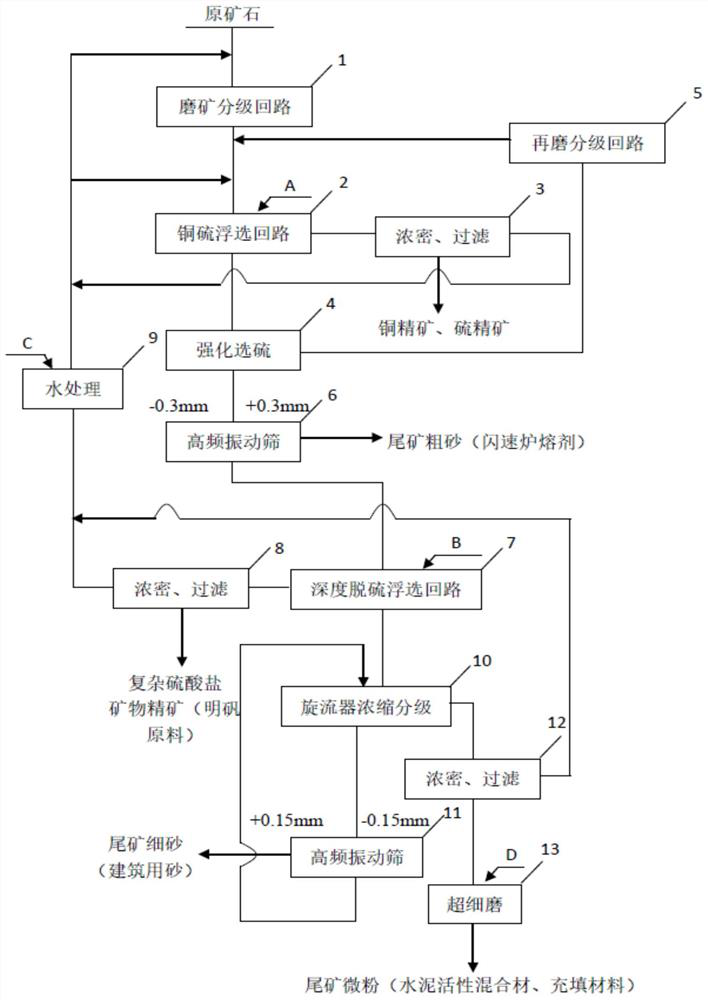

Method used

Image

Examples

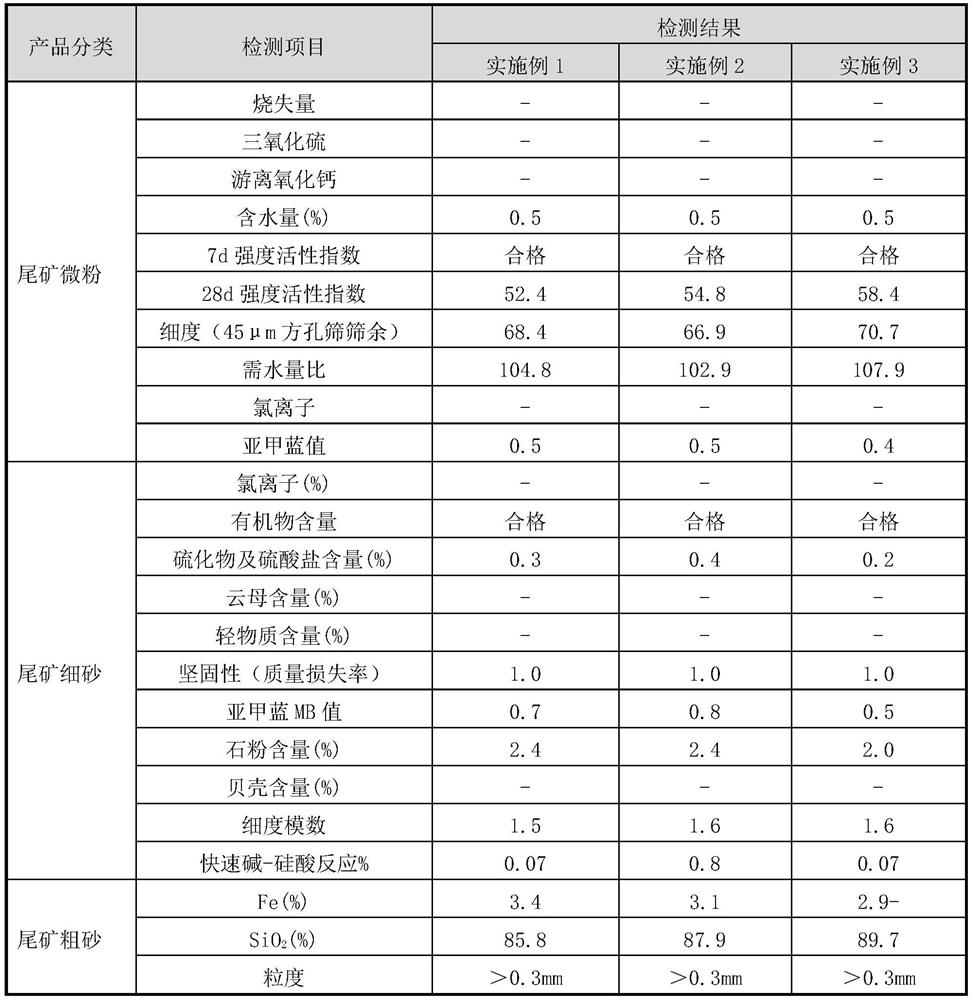

Embodiment 1

[0035] Example 1: The crushed raw ore enters the classification circuit of the mill, and the dosage of calcium oxide is added to this circuit at 1000g / t, and the classification overflow fineness is controlled at -0.074mm, accounting for 55%, and then copper and sulfur are preferentially flotation in sequence . In the copper selection circuit, the amount of water glass added is roughly 425g / t, finely selected 25g / t, and the amount of butyl xanthate + butylammonium black medicine (mixed agent prepared at a mass ratio of 1:3) is roughly 60g / t. Choose 20g / t, the amount of No. 2 oil is roughly 25g / t, sweeping 5g / t; add butyl xanthate in the sulfur selection circuit, the amount of roughing is 40g / t, sweeping 10g / t, the amount of No. 2 oil is rough 15g / t is selected, 5g / t is swept; the copper and sulfur flotation foams are thickened and filtered to obtain copper concentrate and sulfur concentrate respectively, and the overflow and filtrate are recycled. The tailings after copper-sul...

Embodiment 2

[0036] Example 2: The crushed raw ore enters the classification circuit of the mill, and the dosage of calcium oxide is added to this circuit at 1100g / t, and the classification overflow fineness is controlled at -0.074mm, which accounts for 58%, and then copper and sulfur are preferentially flotation in sequence . Add sodium hexametaphosphate to the copper selection circuit in the amount of rough selection 435g / t, fine selection 35g / t, PAC+Z-200 (mixed agent prepared at a mass ratio of 1:2) dosage of rough selection 65g / t, sweep 25g / t, MIBC dosage is 27g / t for rough selection and 7g / t for sweeping; add PAC in the sulfur selection circuit for roughing 45g / t, sweeping 15g / t, MIBC dosage for roughing 17g / t, and sweeping 7g / t ; Copper and sulfur flotation foams are thickened and filtered to obtain copper concentrate and sulfur concentrate respectively, and the overflow and filtrate are recycled. The tailings after copper-sulfur flotation are subjected to enhanced sulfur-selectio...

Embodiment 3

[0037]Example 3: The crushed raw ore enters the grading circuit of the mill, and the dosage of calcium oxide is added to this circuit at 1200g / t, and the fineness of the grading overflow product is controlled at -0.074mm, accounting for 60%, and then the copper and sulfur are preferentially floated sequentially select. In the copper selection circuit, add water glass in the amount of rough selection 450g / t, fine selection 50g / t, Y89 + butylammonium black drug (mixed agent prepared at a mass ratio of 1:1) dosage of rough selection 70g / t, sweeping 30g / t , No. 2 oil + MIBC (mixed agent prepared according to the mass ratio of 1:1) roughing 30g / t, sweeping 10g / t; adding Y89 in the sulfur selection circuit, roughing 50g / t, sweeping 20g / t , No. 2 oil + MIBC roughing 20g / t, sweeping 10g / t; copper and sulfur flotation froths are thickened and filtered to obtain copper concentrate and sulfur concentrate respectively, overflow and filtrate are recycled. The tailings after copper-sulfur ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com