Beneficiation method of lead-zinc oxide mine difficult to beneficiate

A technology of lead-zinc oxide and beneficiation method, applied in chemical instruments and methods, wet separation, solid separation and other directions, can solve the problem of no beneficiation method for lead-zinc oxide ore, etc., and achieve the improvement of resource utilization rate, sedimentation performance improvement, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

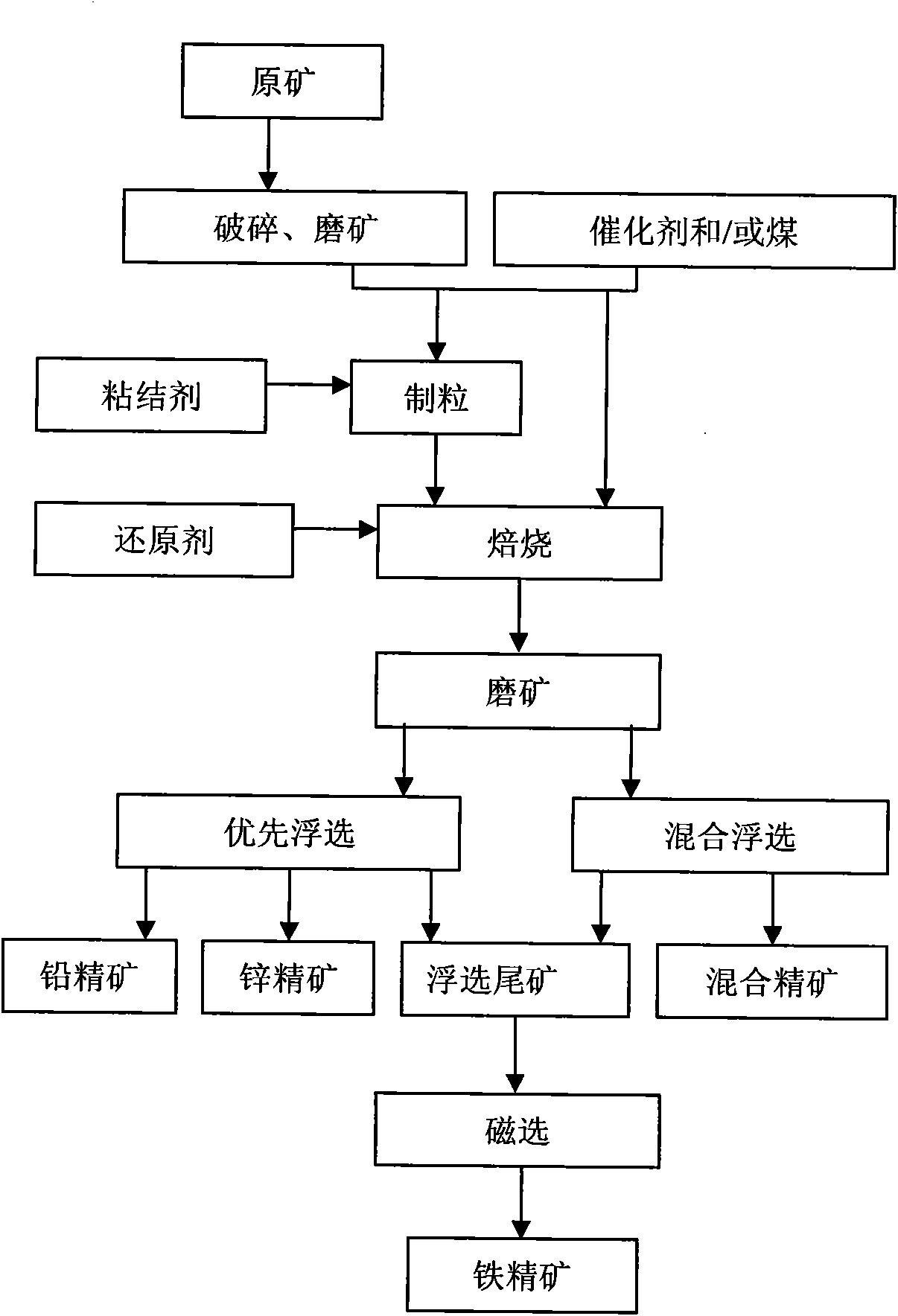

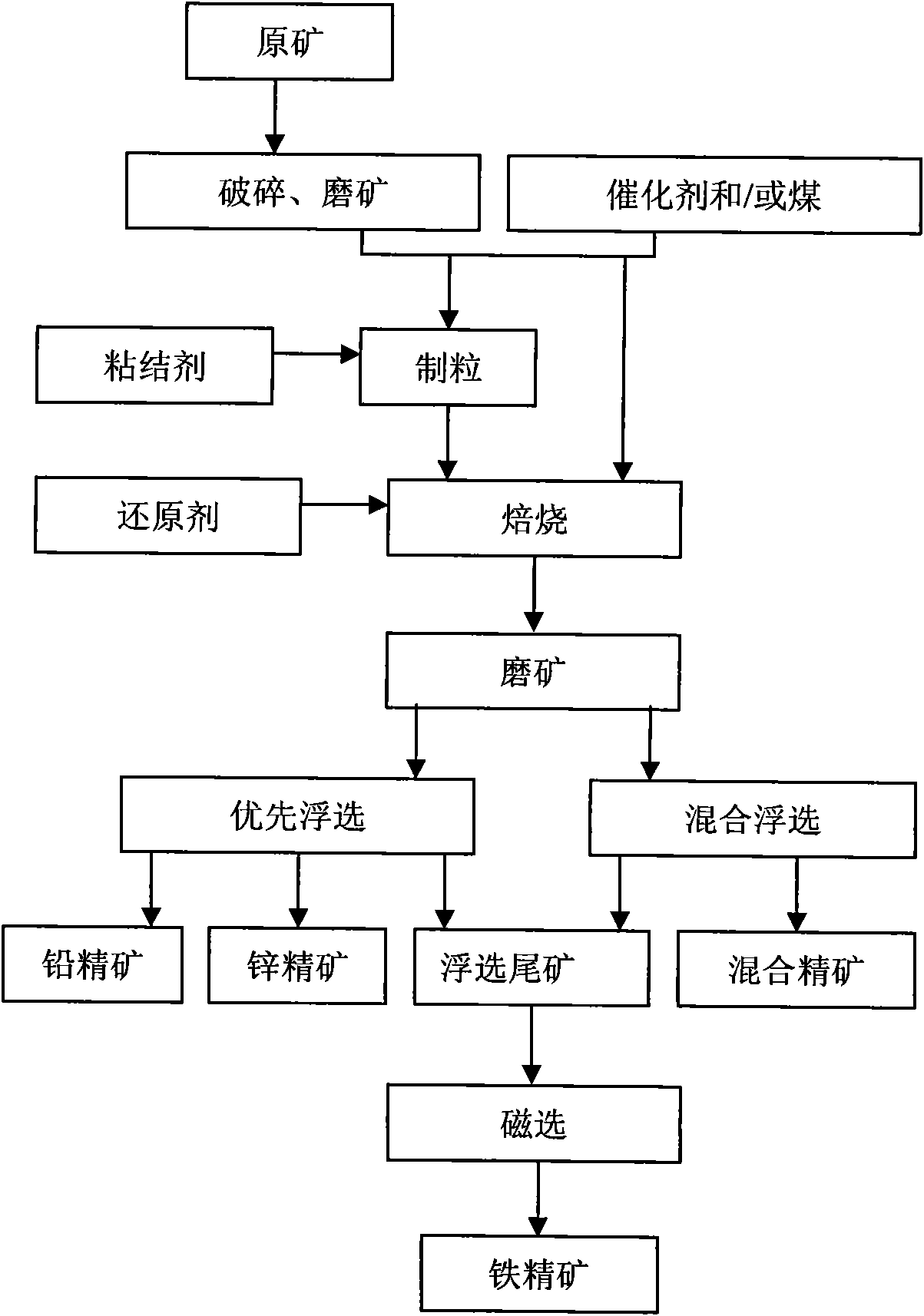

[0027] Embodiment 1: see figure 1 Non-granulation and roasting of medium raw materials-lead-zinc priority flotation scheme

[0028] The raw ore contains 1.5% lead and 6.5% zinc, crushed to -10mm, mixed with 1.0% NaCl, added 0.5% reducing agent coal in the rotary kiln and roasted at 750°C for 150 minutes, then directly water quenched, the roasting after water quenching After the ore is ground to -200 mesh 90% (basic monomers of useful minerals are dissociated), the conventional lead-zinc sulfide ore lead-zinc priority flotation process is followed: the lead flotation system obtains a grade of 30-35% through one rough, one sweep and three fine , The lead concentrate with a recovery rate of about 75%, and the zinc flotation system can obtain zinc concentrate with a grade of 40-45% and a recovery rate of 75-80% through the first roughing, second sweeping and third refining. The flotation tailings after flotation can be recovered by magnetic separation.

Embodiment 2

[0029] Example 2: see figure 1 Non-granulating roasting of medium raw materials-lead-zinc mixed flotation scheme

[0030] The raw ore contains 1.5% lead and 6.5% zinc, crushed to -3mm, adding 0.5% coal and 1.0% FeCl 3 Mix evenly, roast in a rotary kiln at 750°C for 120 minutes, and then quench directly in water. Grind the roasted ore in a rod mill to -200 mesh 90% (dissociation of the basic monomer of useful minerals) and then mix and float it with conventional lead-zinc sulfide ore. The separation process is to obtain a mixed concentrate with a grade of Pb+Zn>40% and a recovery rate of lead and zinc of about 80% through one roughing, two sweeping and three fines. The flotation tailings after flotation can be recovered by magnetic separation.

Embodiment 3

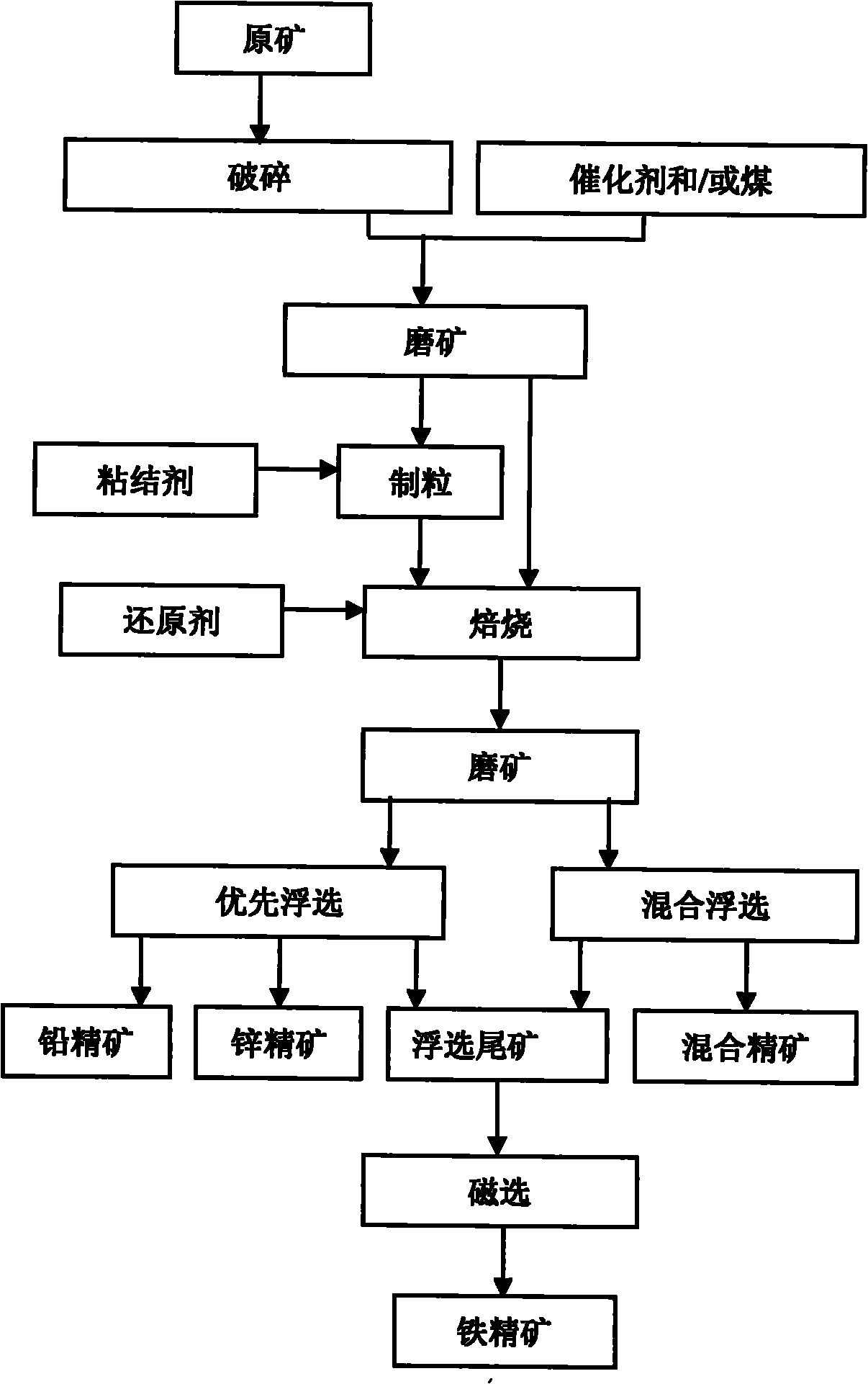

[0031] Embodiment 3: see figure 2 Medium raw material granulation roasting-lead-zinc mixed flotation scheme

[0032] The raw ore contains 1.5% lead, 6.5% zinc, crushed to -3mm, added 0.5% coal, 1.0% catalyst NaCl and 3% bentonite, mixed and pre-ground to about 40% -200 mesh, then granulated, and rotated at 750°C After kiln roasting for 90 minutes, it is directly water-quenched, and the roasted ore is ground in a rod mill to -200 mesh 90% (the basic monomer of useful minerals is dissociated). Sanjing can obtain a mixed concentrate with a grade of Pb+Zn>40% and a lead-zinc recovery rate of about 80%. For the flotation tailings after flotation, the iron concentrate can be recovered by magnetic separation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com