Double-circulation desulfurization device and desulfurization process

A desulfurization device and desulfurization process technology, applied in calcium/strontium/barium sulfate, gas treatment, membrane technology, etc., can solve problems such as poor quality, pipeline blockage, scaling, etc., to improve conversion rate and quality, and reduce blockage The effect of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

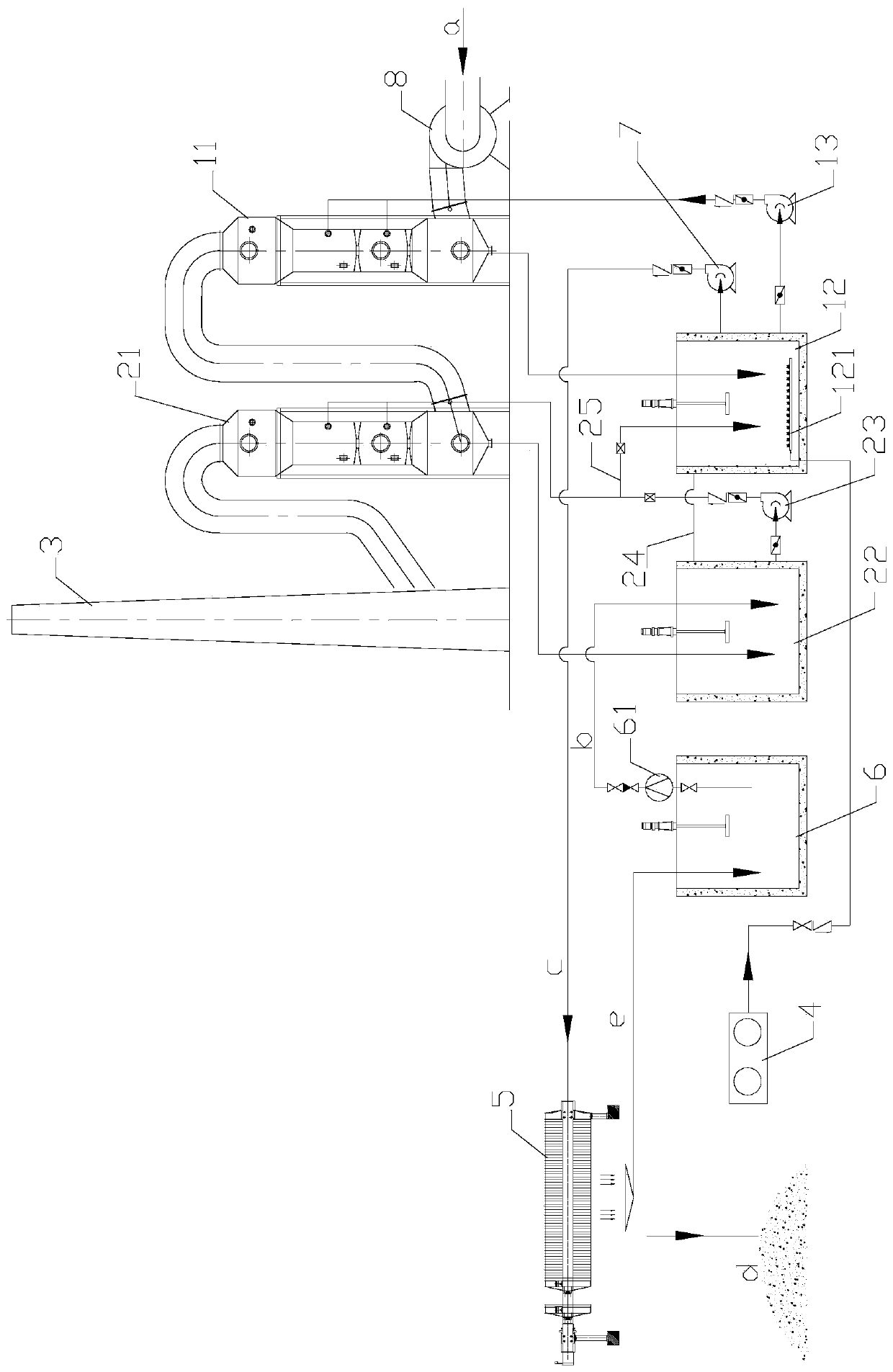

[0030] Such as figure 1 As shown, a double-cycle desulfurization device according to the present invention can be divided into four modules, namely a flue gas module, a desulfurization liquid circulation module, a gypsum treatment module and a pulping module. The flue gas module includes an induced draft fan 8, a primary desulfurization tower 11, a secondary desulfurization tower 21, a chimney 3, a first smoke pipe, a second smoke pipe and a third smoke pipe. One end of the first smoke pipe is connected to the outlet of the induced draft fan 8 , and the other end is connected to the air inlet of the primary desulfurization tower 11 . One end of the second smoke pipe is connected to the gas outlet of the primary desulfurization tower 11 , and the other end is connected to the gas inlet of the secondary desulfurization tower 21 . One end of the third smoke pipe is connected to the gas outlet of the secondary desulfurization tower 21 , and the other end is connected to the chimn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com