Purification system and purification method for asphalt smoke

A technology for asphalt flue gas and purification system, which is applied in chemical instruments and methods, separation methods, gas treatment and other directions to avoid secondary pollution, improve purification effect and purification efficiency, and achieve the effect of sufficient desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

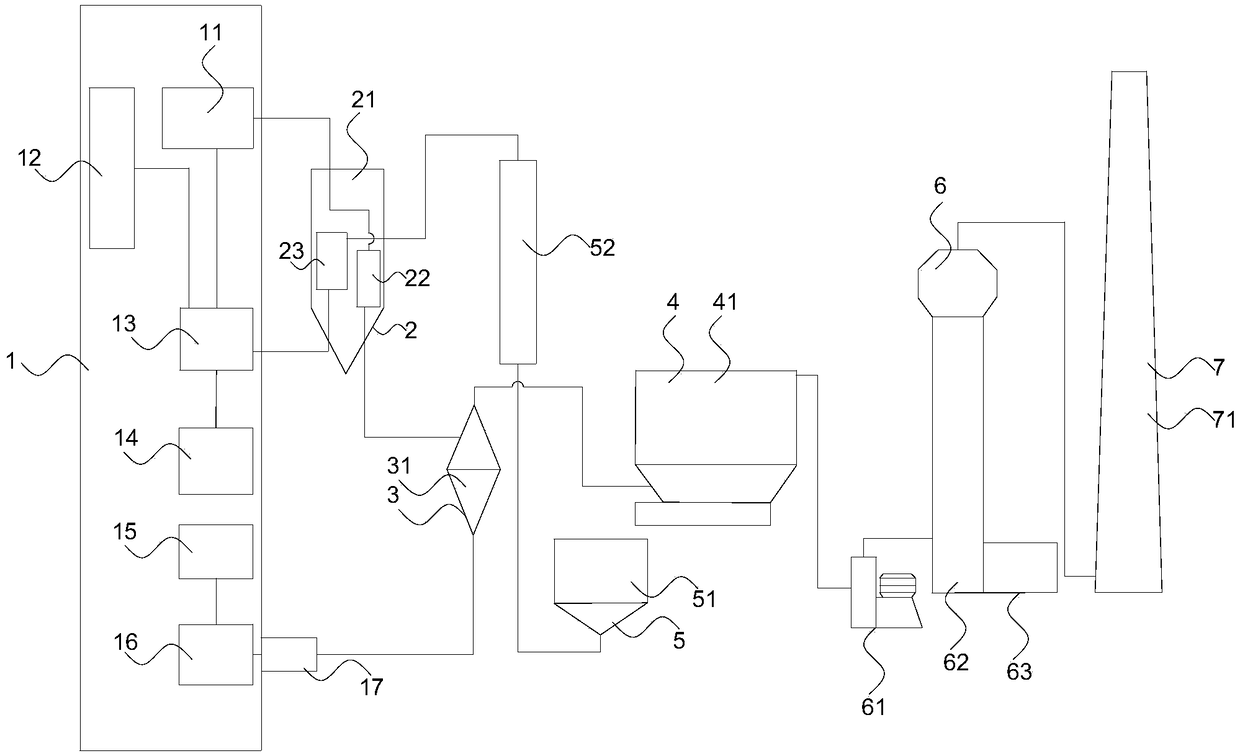

[0054] Such as figure 1 Shown, a bitumen flue gas purification system, comprising:

[0055] In production system 1, raw petroleum coke is calcined to obtain calcined coke powder, and part of the calcined coke powder is output to storage device 2; in production system 1, after kneading calcined coke powder and pitch to form a mold base, the The mold base is roasted at high temperature, and then the mold base is cooled to make a finished product; the production system 1 will generate asphalt fume when the mold base is roasted and cooled at high temperature, and the asphalt fume will be collected into the main flue 17;

[0056] Material storage device 2, use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com