Anaerobic-autotrophic nitrogen removal-ozone oxidation coupling landfill leachate whole flow process zero emission processing process

A technology of landfill leachate and ozone oxidation, which is applied in anaerobic digestion treatment, oxidized water/sewage treatment, aerobic and anaerobic process treatment, etc. It can solve the problems of difficult disposal of concentrated liquid and high disposal cost, and achieve stable system operation. , the effect of improving the removal rate and reducing the consumption of ozone dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

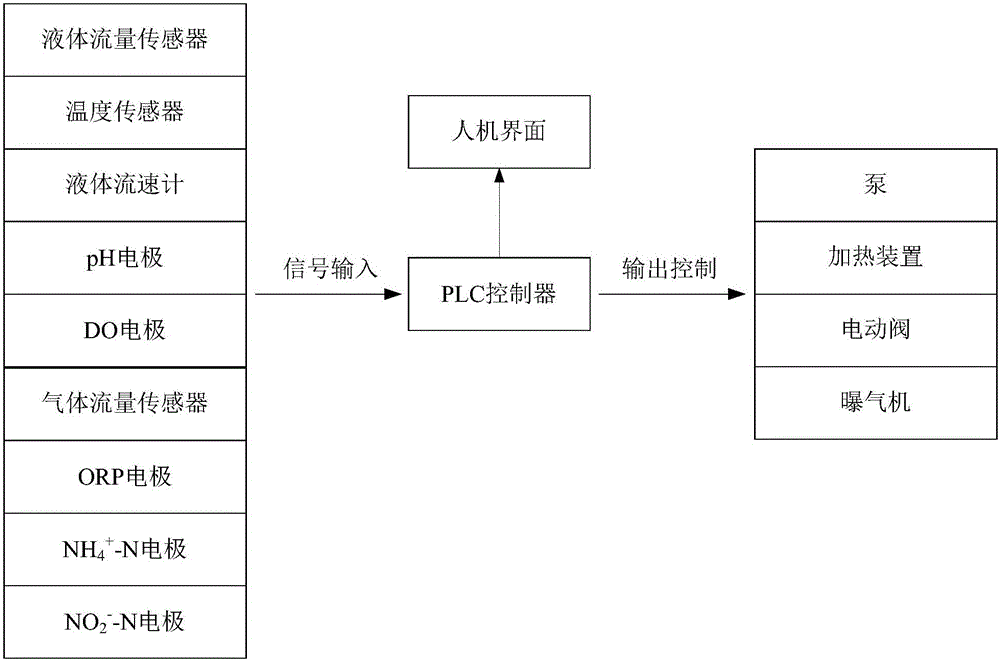

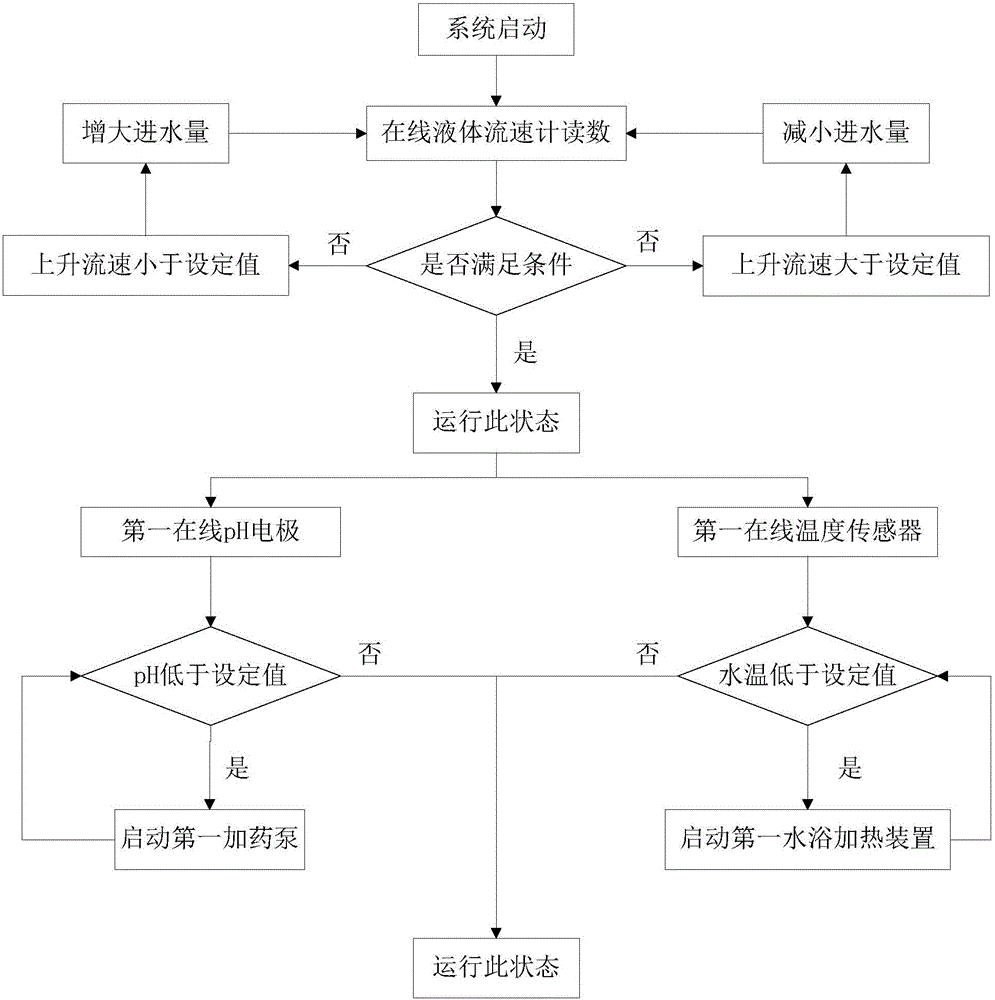

[0045] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

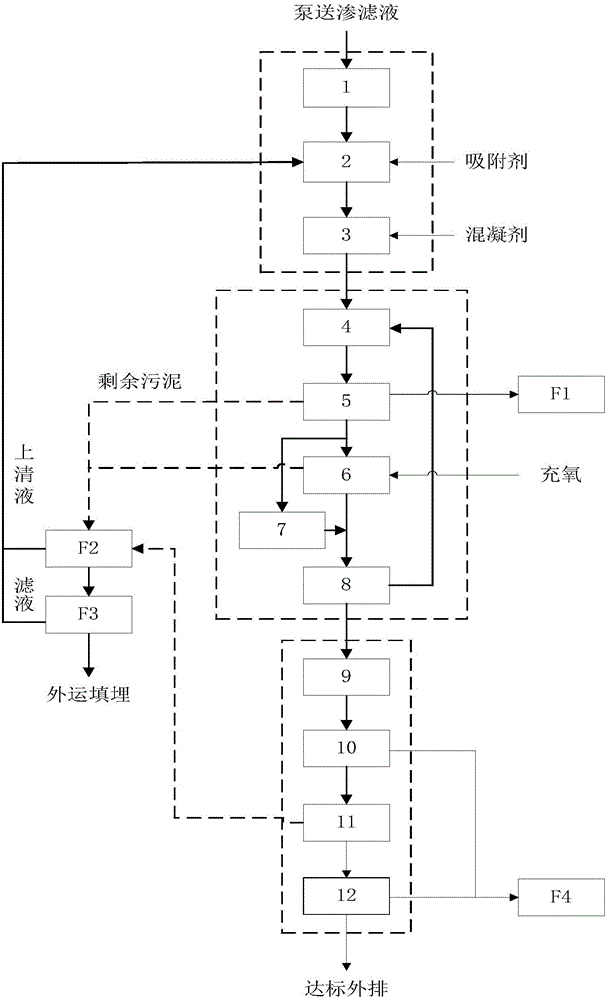

[0046] The invention provides a combined process for landfill leachate treatment (see Figure 1 to Figure 5 ), including the following specific steps:

[0047] 1) Adsorption coagulation pretreatment:

[0048] The landfill leachate first enters the adjustment tank 1 to adjust the water quality and balance the water volume, and then enters the adsorption tank 2. Add a certain amount of adsorbent (fly ash and other cheap adsorbents) into the adsorption tank, turn on the stirring equipment, and adjust it to a reasonable speed. Carry out adsorption treatment, after the reaction is complete, stop stirring, leave standstill, the effluent of the adsorption tank enters in the coagulation tank 3, and in the coagulation tank 3, add a certain amount of coagulant (high polymerization coagulant such as polyferric sulfate) ) and coagulant PAM, adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com