Method for preparing formed coke from low-metamorphic pulverized coal, heavy oil and tar residues as raw materials

A technology for low-metamorphic pulverized coal and tar residue, applied in the field of coal chemical industry, can solve the problems of difficult rapid mixing and heating of heat carrier and pulverized coal, less storage, and affecting the stable operation of the system, so as to solve the problems of storage and pollution, expand the Using the effect of the field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

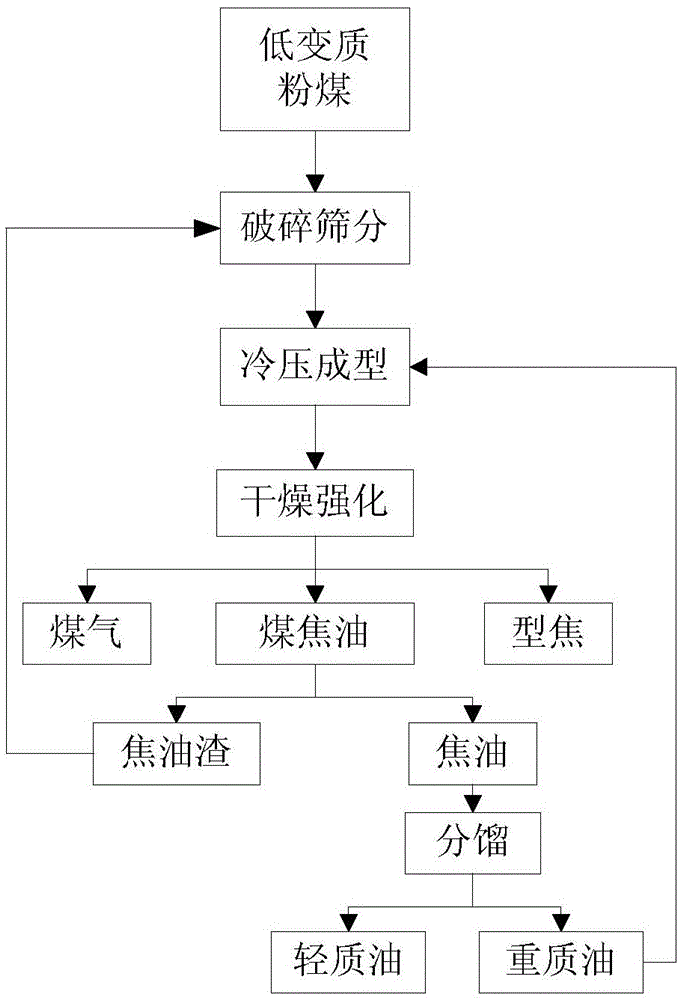

[0034] Such as figure 1 As shown, a method for preparing molded coke with low metamorphic pulverized coal, heavy oil, and tar residue as raw materials comprises the following steps:

[0035] Step 1, after the low metamorphic pulverized coal and the tar residue are pretreated by grinding and screening, the particle size of the low metamorphic pulverized coal is controlled to 80 mesh, and the particle size of the tar residue is controlled below 3 mm;

[0036] Step 2: According to weight percentage, take 70% of low metamorphic coal powder with a particle size of less than 80 mesh, 15% of heavy oil, and 15% of tar residue, and put them together into a beaker for stirring. After the materials are evenly mixed, put them into a mold , cold-pressed under a pressure of 6Mpa to obtain cylindrical briquettes (Φ30mm×20mm).

[0037] In step 3, the prepared coal briquettes are intensively treated at a low temperature of 300° C. for 40 minutes, and then taken out and cooled to room temperat...

Embodiment 2

[0040] Such as figure 1 As shown, a method for preparing molded coke with low metamorphic pulverized coal, heavy oil, and tar residue as raw materials comprises the following steps:

[0041] Step 1, after the low metamorphic pulverized coal and the tar residue are pretreated by grinding and screening, the particle size of the low metamorphic pulverized coal is controlled to 80 mesh, and the particle size of the tar residue is controlled below 3mm;

[0042] Step 2: According to weight percentage, take 65% low-deteriorated coal powder with a particle size of less than 80 mesh, 15% heavy oil, and 20% tar residue, and put them together into a beaker for stirring. After the materials are evenly mixed, put them into a mold , cold-pressed under a pressure of 6Mpa to obtain cylindrical briquettes (Φ30mm×20mm).

[0043] In step 3, the prepared briquettes are subjected to intensive treatment at a low temperature of 200° C. for 40 minutes, and then taken out and cooled to room temperature...

Embodiment 3

[0046] Such as figure 1 As shown, a method for preparing molded coke with low metamorphic pulverized coal, heavy oil, and tar residue as raw materials comprises the following steps:

[0047] Step 1, after the low metamorphic pulverized coal and the tar residue are pretreated by grinding and screening, the particle size of the low metamorphic pulverized coal is controlled to 80 mesh, and the particle size of the tar residue is controlled below 3mm;

[0048] Step 2: Take 75% of low-deteriorated coal powder with a particle size of less than 80 mesh, 10% of heavy oil, and 15% of tar residue according to weight percentage, and put them together into a beaker for stirring. After the materials are evenly mixed, put them into a mold , cold-pressed under a pressure of 6Mpa to obtain cylindrical briquettes (Φ30mm×20mm).

[0049] In step 3, the prepared coal briquettes are intensively treated at a low temperature of 300° C. for 40 minutes, and then taken out and cooled to room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com