Fracturing proppant for shale gas development and preparation method thereof

A fracturing proppant and shale gas technology, which is applied in the fields of mining fluid, chemical instruments and methods, applications, etc., can solve the problems of high fragmentation rate, high acid solubility, weak compression resistance, etc., and achieve short preparation process and smooth finish Good, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

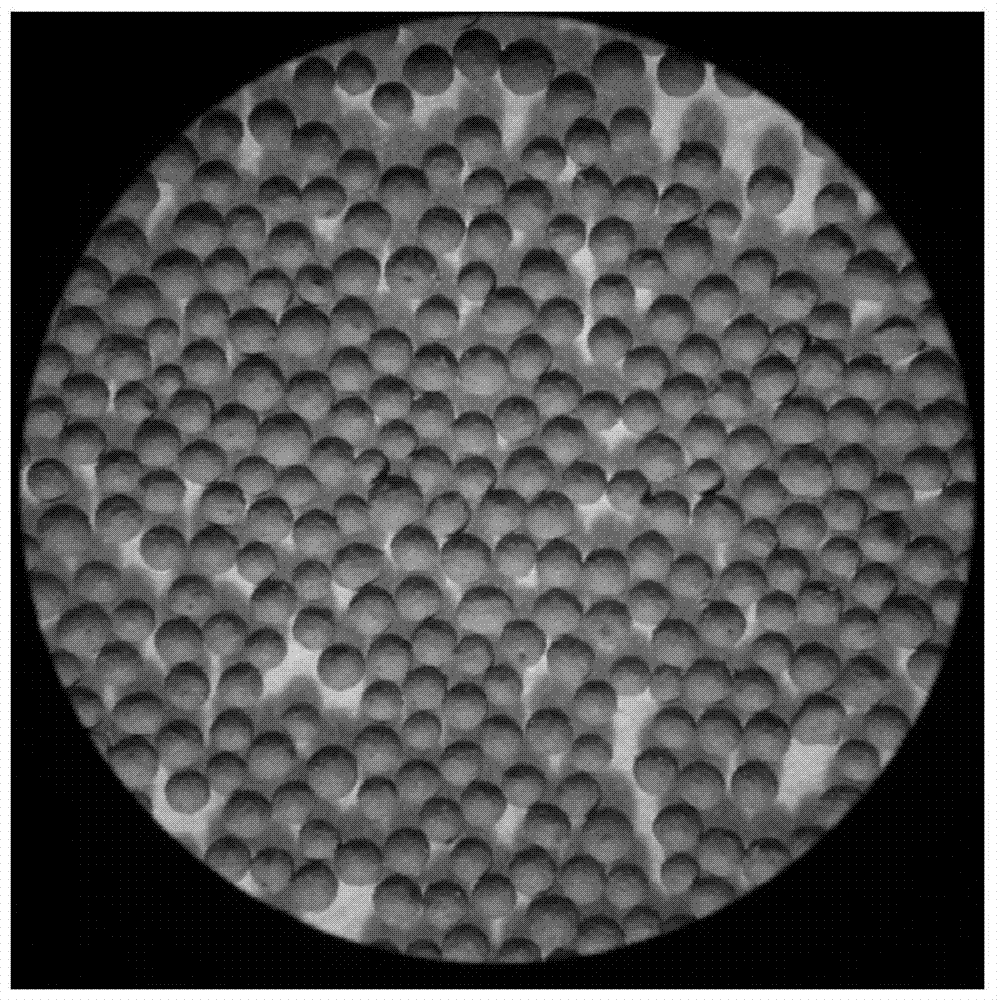

Image

Examples

Embodiment 1

[0031] In this example, the fracturing proppant is used for shale gas development, and the raw materials are composed of the following components in mass percentage: 49% of low-grade bauxite, 48% of shale, 2% of barium carbonate, and 1% of boric acid.

[0032] In this embodiment, the preparation method of fracturing proppant for shale gas development includes the following steps:

[0033] (1) The low-grade bauxite and shale are crushed to less than 7mm through the experimental jaw crusher (jaw crusher), and then added to the Φ500mm ball mill for 6 hours, until the fineness of the powder reaches 400 mesh sieve respectively The remaining ≤ 5%;

[0034](2) In terms of mass percentage, prepare mixed powder according to 49% of low-grade bauxite, 48% of shale, 2% of barium carbonate, and 1% of boric acid, and first weigh 1.5kg of mixed powder and add it to the granulator , add 230g of water, adjust the drum speed to 500r / min, and the rotor speed to 3500r / min, add dry mixed powder i...

Embodiment 2

[0039] In this embodiment, the fracturing proppant is used for shale gas development, and the raw materials are composed of the following components in mass percentage: 46% of low-grade bauxite, 51% of shale, 1% of barium carbonate, and 2% of boric acid.

[0040] In this embodiment, the preparation method of fracturing proppant for shale gas development includes the following steps:

[0041] (1) respectively crush the low-grade bauxite and shale to less than 7mm by jaw crusher, and then add Φ500mm ball mill to grind them for 6 hours, until the fineness of the powder reaches 400 mesh sieve ≤ 5% respectively;

[0042] (2) In terms of mass percentage, prepare mixed powder according to 46% of low-grade bauxite, 51% of shale, 1% of barium carbonate, and 2% of boric acid, and first weigh 1.5kg of mixed powder and add it to the granulator , add 230g of water, adjust the drum speed to 500r / min, and the rotor speed to 3500r / min, add dry mixed powder in 4 times, add 100g each time, poli...

Embodiment 3

[0046] In this example, fracturing proppant is used for shale gas development, and the raw materials are composed of the following components in mass percentage: 47% of low-grade bauxite, 50% of shale, 2% of barium carbonate, and 1% of boric acid.

[0047] Among them, the low-grade bauxite adopts the low-grade bauxite around Gongyi, Henan, and its Al 2 o 3 The content is 50-60%, SiO 2 The content is 15-30%, and the aluminum-silicon ratio is relatively low. The shale adopts siliceous shale around Gongyi, Henan, and its Al 2 o 3 The content is 15-25%, SiO 2 The content is 35-50%, Fe 2 o 3 The content is 2-5%, the Platts hardness coefficient is 1.5-3.5, and the plasticity index is 5-20.

[0048] In this embodiment, the preparation method of fracturing proppant for shale gas development includes the following steps:

[0049] (1) respectively crush the low-grade bauxite and shale to less than 7mm by jaw crusher, and then add Φ500mm ball mill to grind them for 6 hours, until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com