High-hardness wear-resistant ultra-high molecular weight polyethylene product and preparation method thereof

An ultra-high molecular weight and high hardness technology, applied in the field of ultra-high molecular weight polyethylene materials, can solve the problems of high cost and unsatisfactory effect of ultra-high molecular weight polyethylene, achieve low production cost, solve the problem of comprehensive utilization of resources, and simple method Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

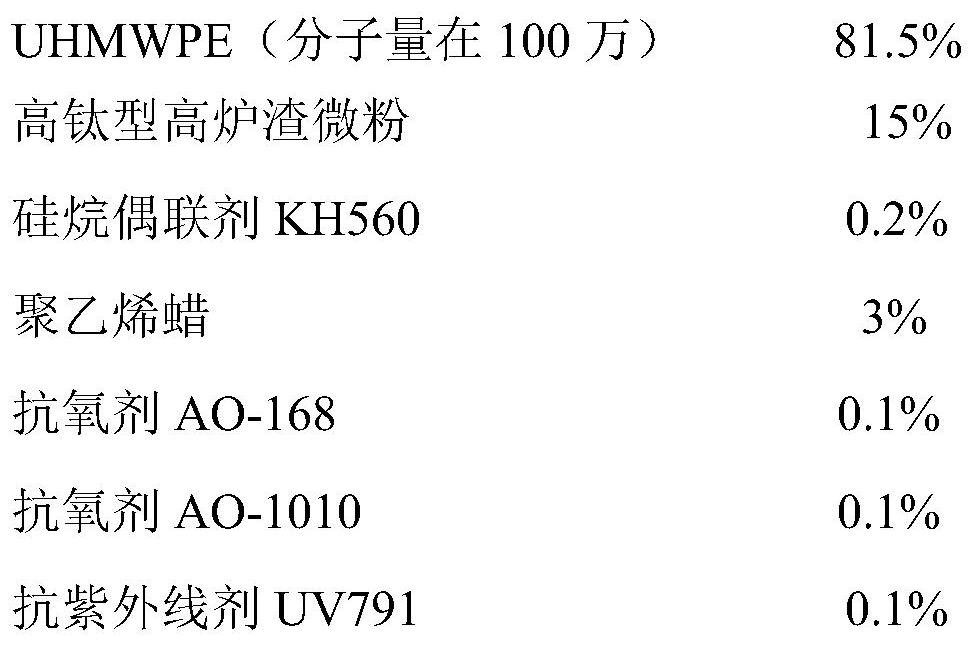

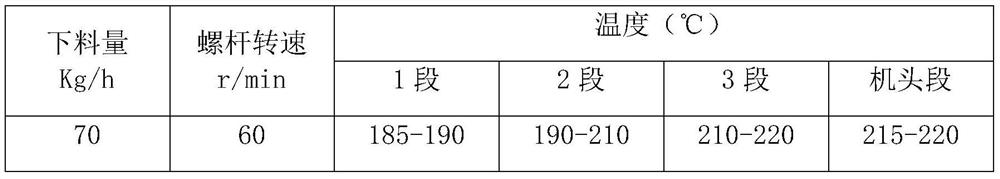

[0036] In this example, a high-hardness and wear-resistant ultra-high molecular weight polyethylene sheet is prepared. The method is to put the measured high-titanium blast furnace slag powder into a high-speed mixer and mix it at a high speed, and raise the temperature to 110 ° C for 16 minutes to dehumidify , fully remove the moisture in the micropowder, then add the metered coupling agent and mix at high speed for 10 minutes, then discharge the material and cool it for use; put the metered dispersant, antioxidant and anti-ultraviolet agent at room temperature in a high-speed mixer Mix in medium for 8 minutes, mix evenly and discharge for use; mix the mixture of high-titanium blast furnace slag powder and coupling agent, the mixture of dispersant, antioxidant and anti-ultraviolet agent, and UHMW-PE according to the following ratio and method in SJSZ Extruded by -80 type plate extruder, the extrusion molding process parameters are shown in Table 1.

[0037] The formula of the...

Embodiment 2

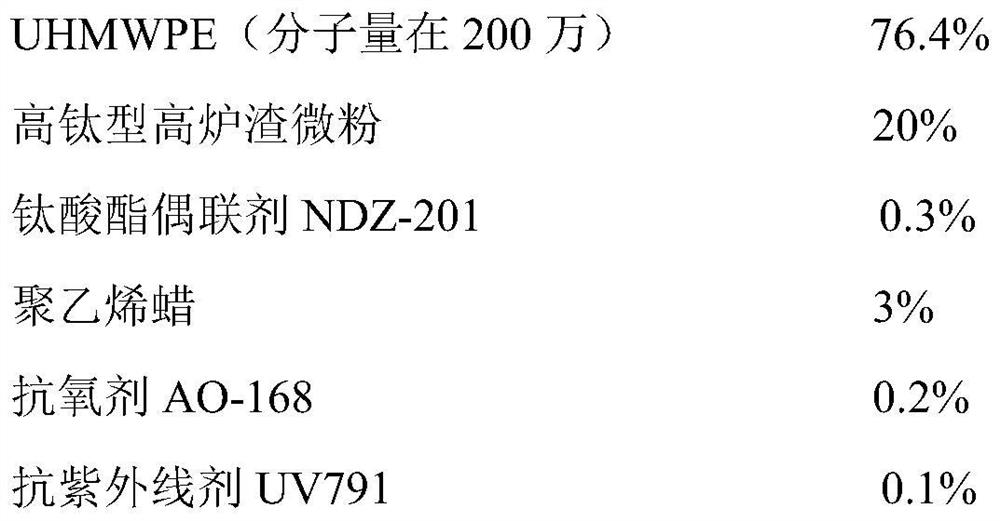

[0042]In this example, a high-hardness and wear-resistant ultra-high molecular weight polyethylene sheet is prepared. The method is to put the metered high-titanium blast furnace slag powder into a high-speed mixer for high-speed stirring and mixing, and raise the temperature to 120 ° C for 16 minutes to dehumidify. Fully remove the moisture in the micropowder, then add the measured coupling agent and mix at high speed for 10 minutes, then discharge and cool for use; put the measured dispersant, antioxidant and anti-ultraviolet agent in the high-speed mixer at room temperature Mix for 8 minutes, mix well and discharge for use; mix the mixture of high-titanium blast furnace slag powder and coupling agent, the mixture of dispersant, antioxidant and anti-ultraviolet agent, and UHMW-PE according to the following ratio and method in SJSZ- 80-type plate extruder extrusion, extrusion molding process parameters are shown in Table 2.

[0043] The formula of the high hardness and wear-r...

Embodiment 3

[0048] In this example, a high-hardness wear-resistant ultra-high molecular weight polyethylene sheet is prepared. The method is to put the measured high-titanium blast furnace slag powder into a high-speed mixer and mix it at a high speed, and raise the temperature to 130 ° C for 16 minutes to dehumidify , fully remove the moisture in the micropowder, then add the metered coupling agent and mix at high speed for 10 minutes, then discharge and cool for use; put the metered dispersant, antioxidant and anti-ultraviolet agent at room temperature in a high-speed mixer Mix in medium for 8 minutes, mix evenly and discharge for use; mix the mixture of high-titanium blast furnace slag powder and coupling agent, the mixture of dispersant, antioxidant and anti-ultraviolet agent, and UHMW-PE in the following proportions and methods in SJSZ Extruded by -80 type plate extruder, the extrusion molding process parameters are shown in Table 3.

[0049] The formula of the high hardness and wear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com