Bubbling and spraying combined humidifier and fuel cell humidifying system using same

A humidification system and humidifier technology, applied in the field of humidity control of fuel cells and fuel cells, can solve the problems of slow change response, large energy consumption, small humidity range, etc. The effect of running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

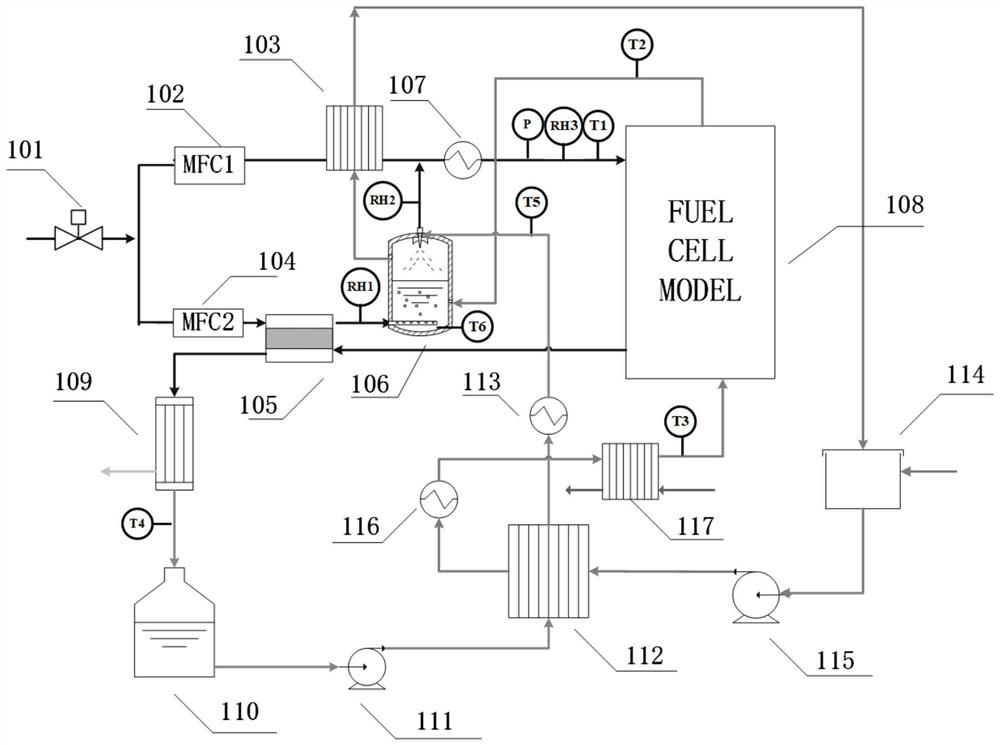

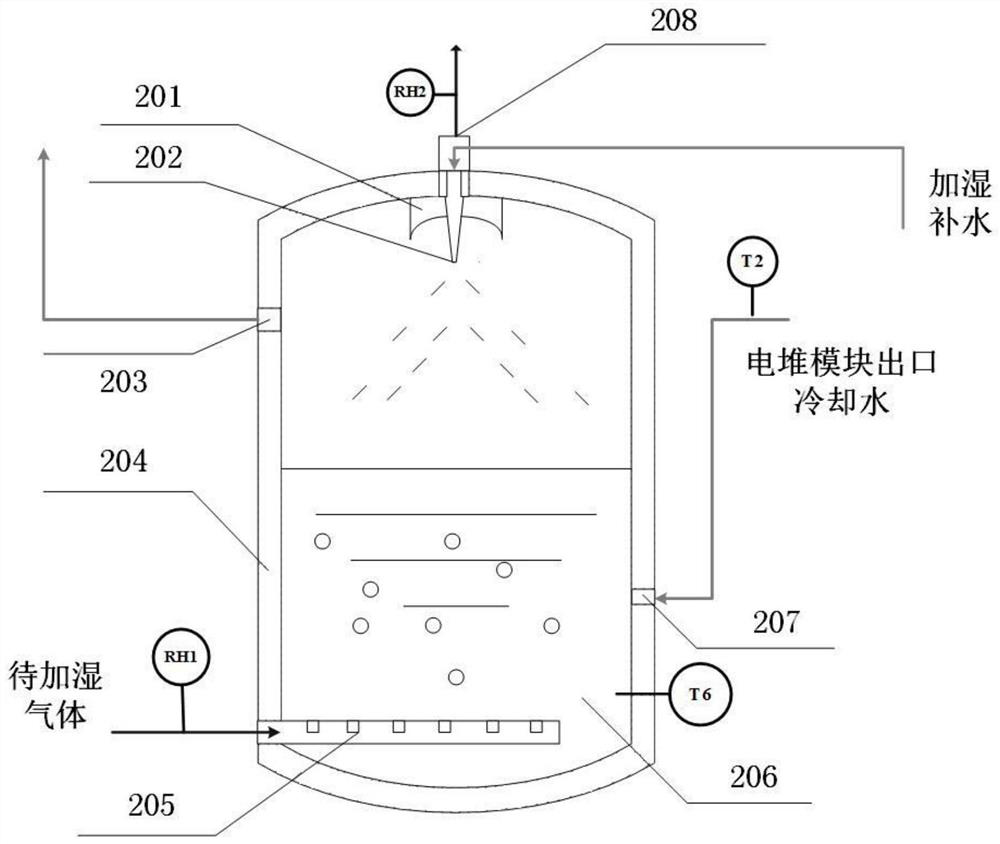

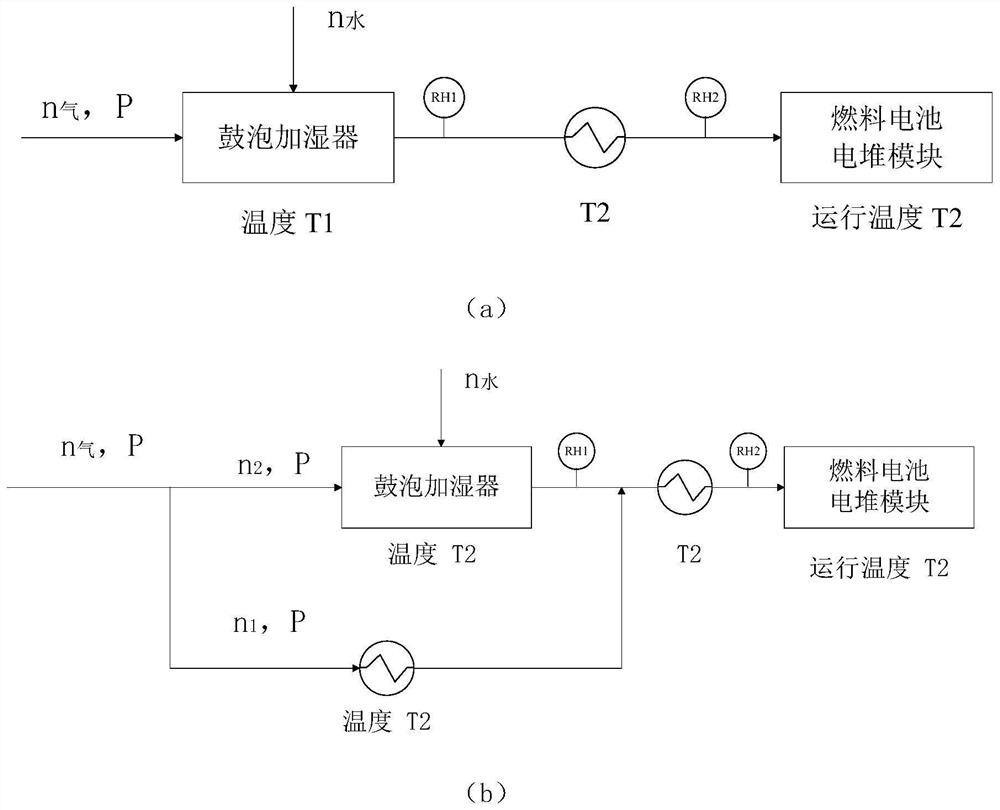

[0037] Such as figure 1 As shown, the system includes: a fuel cell stack module 108, a dry and wet gas distribution system, a combined gas humidification system, a condensate replenishment system and a stack module cooling system.

[0038] The fuel cell stack module 108 is a power conversion device. During the operation of the battery, the water content of the membrane largely determines the conductivity, power generation efficiency and life of the fuel cell. Therefore, in order to ensure the high-performance output of the module under different loads , the humidity of the reaction gas should be precisely controlled through the humidification system before entering the stack module, and the battery will generate a lot of heat during the power generation process. In order to maintain sufficient hydration of the membrane, the fuel cell should work at an appropriate temperature , so the excess heat of the system should be discharged in time through the cooling system.

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com