Heat energy recovery method for supercritical water oxidizing system

A technology of oxidation system and recovery method, which is applied in the field of energy and environment, can solve the problems of huge heat consumption, achieve the effect of reducing energy consumption, realizing heat energy balance, and realizing heat self-sufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

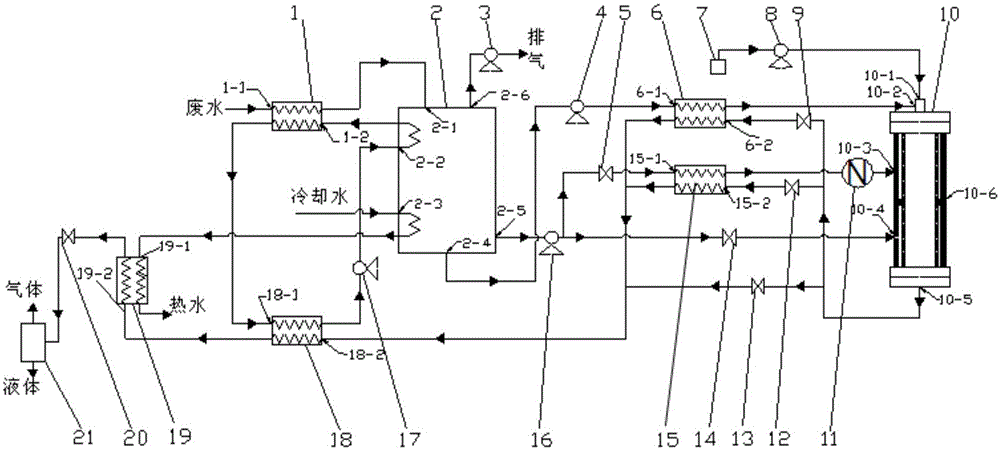

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] The heat recovery process of the primary recovery system: In the heat energy recovery system of the supercritical water oxidation system, the concentrated waste liquid generated by the low-temperature multiple-effect distiller 2 is boosted by the waste liquid booster pump 4, and enters the fourth heat exchanger from the inlet channel 6-1. After the heater 6 is initially preheated, it is injected from the top inlet channel 10-2 of the water film reactor 10; 10-1 injecting, concentrating the organic matters and oxygen in the waste liquid to carry out the supercritical water oxidation reaction in the water film reactor 10. The distilled water is boosted by the distilled water booster pump 16 and divided into upper and lower branches. The evaporated water in the upper branch is regulated by the first regulating valve 5, and enters the fifth heat exchanger 15 from the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com