Continuous high-temperature oxygen-isolated carbonization process for treatment of municipal solid waste and apparatus used therein

A technology of urban domestic garbage and urban garbage, which is applied in the field of continuous high-temperature oxygen-insulated carbonization device, to achieve the effects of saving cost, reducing gas volume, and realizing convenience and simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

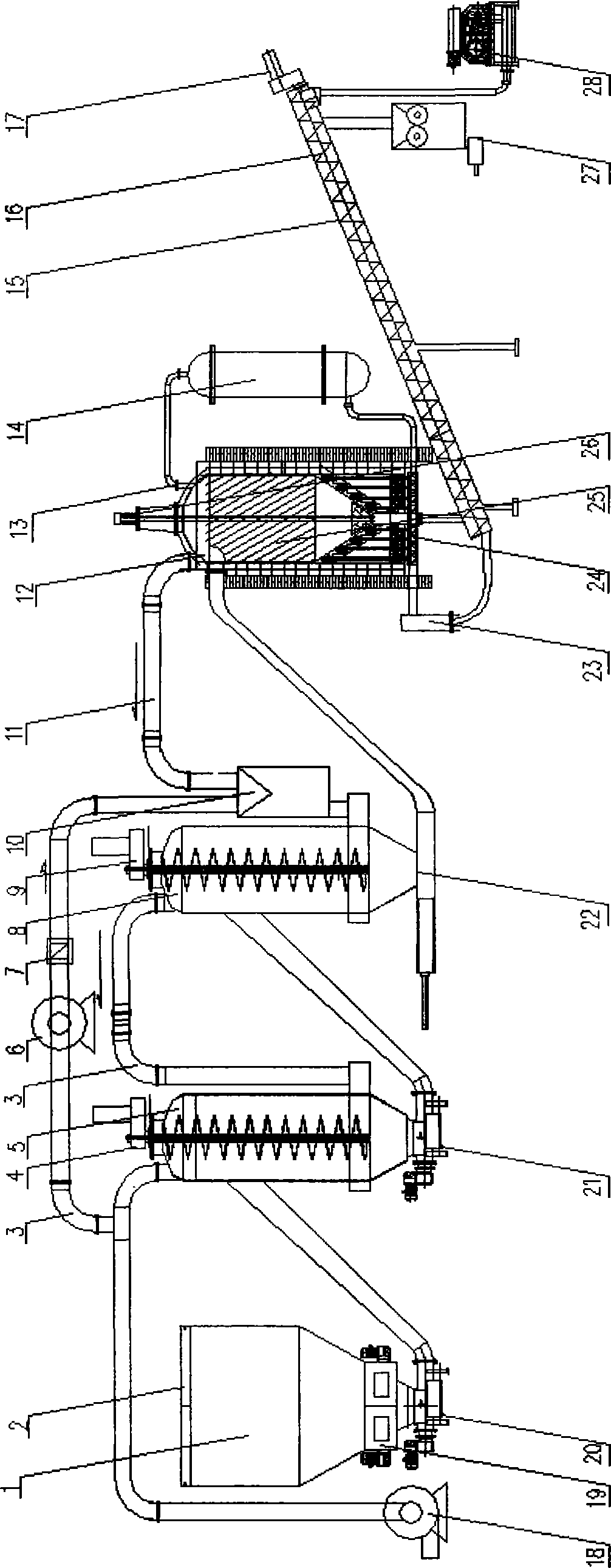

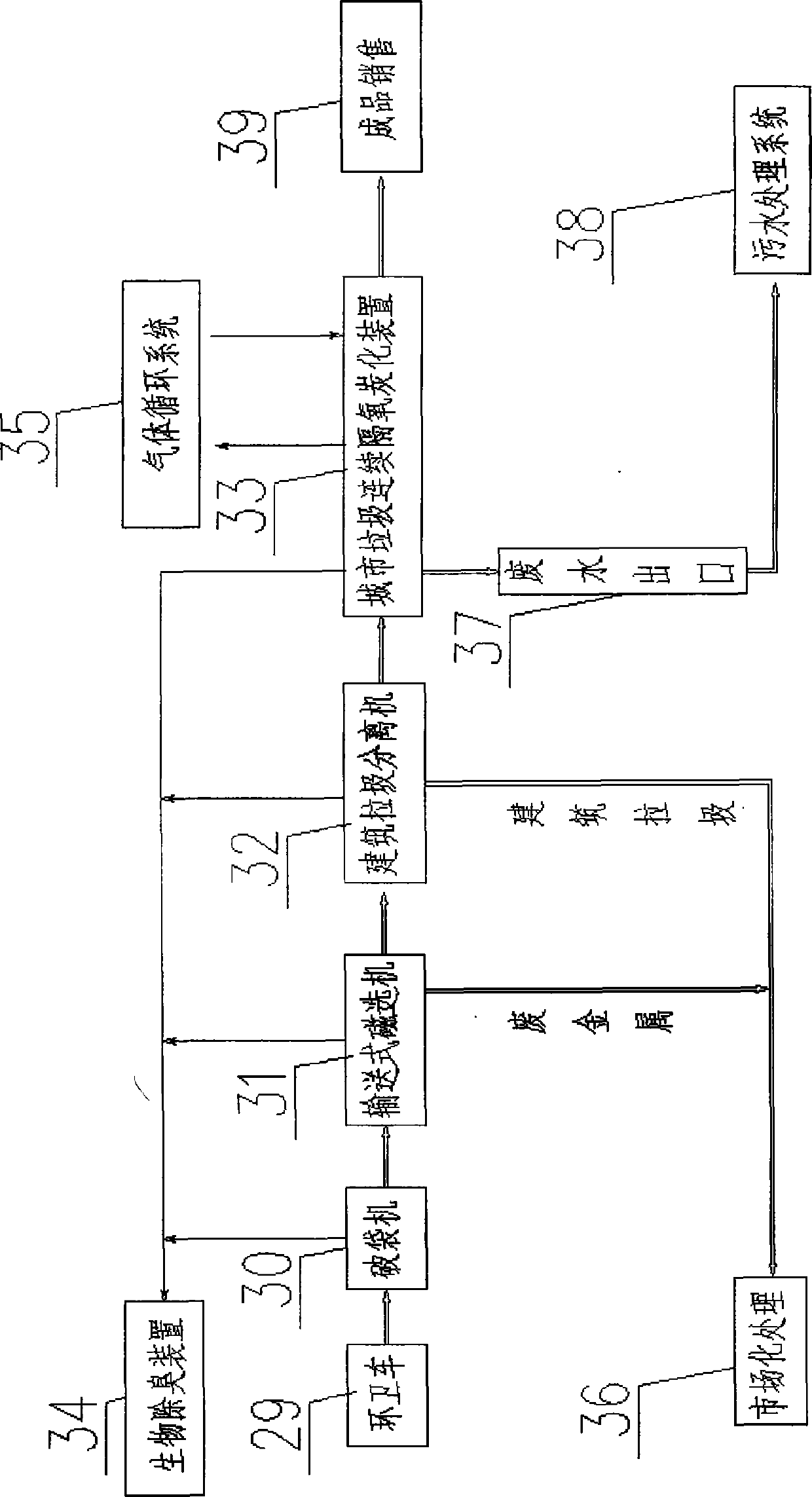

[0134] Please refer to the attached figure 1 , shown in 2, the device consists of a closed feed bin (1), a preheater (5), a drier (8), a gas mixing thermostat (10), a pyrolysis carbonization furnace (12), a material conveyor (15 ), the furnace powder wheel mill forming machine (27) constitutes. in:

[0135] The garbage carried by the sanitation vehicle (29) passes through the bag breaking machine (30), the conveying magnetic separator (31) and the construction waste separator (32) and then enters the closed type in the continuous high temperature oxygen barrier carbonization device (33) for urban waste. Silo (1).

[0136] The material input end of the closed silo (1) of garbage is connected to the construction waste separator (32), and the material output end is connected to the material input end of the preheating device (5) through a primary press feeder (20); the preheating device The material output end of (5) links to each other with the material input end of drier (8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com