A mold for side punching of U-shaped section products

A product and section technology, applied in the field of auto parts production equipment, can solve the problems of low product hole size accuracy, inconvenient mold adjustment and product pick-and-place, low production efficiency, etc., to ensure product size accuracy and surface requirements, shorten adjustment The effect of reducing mold time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

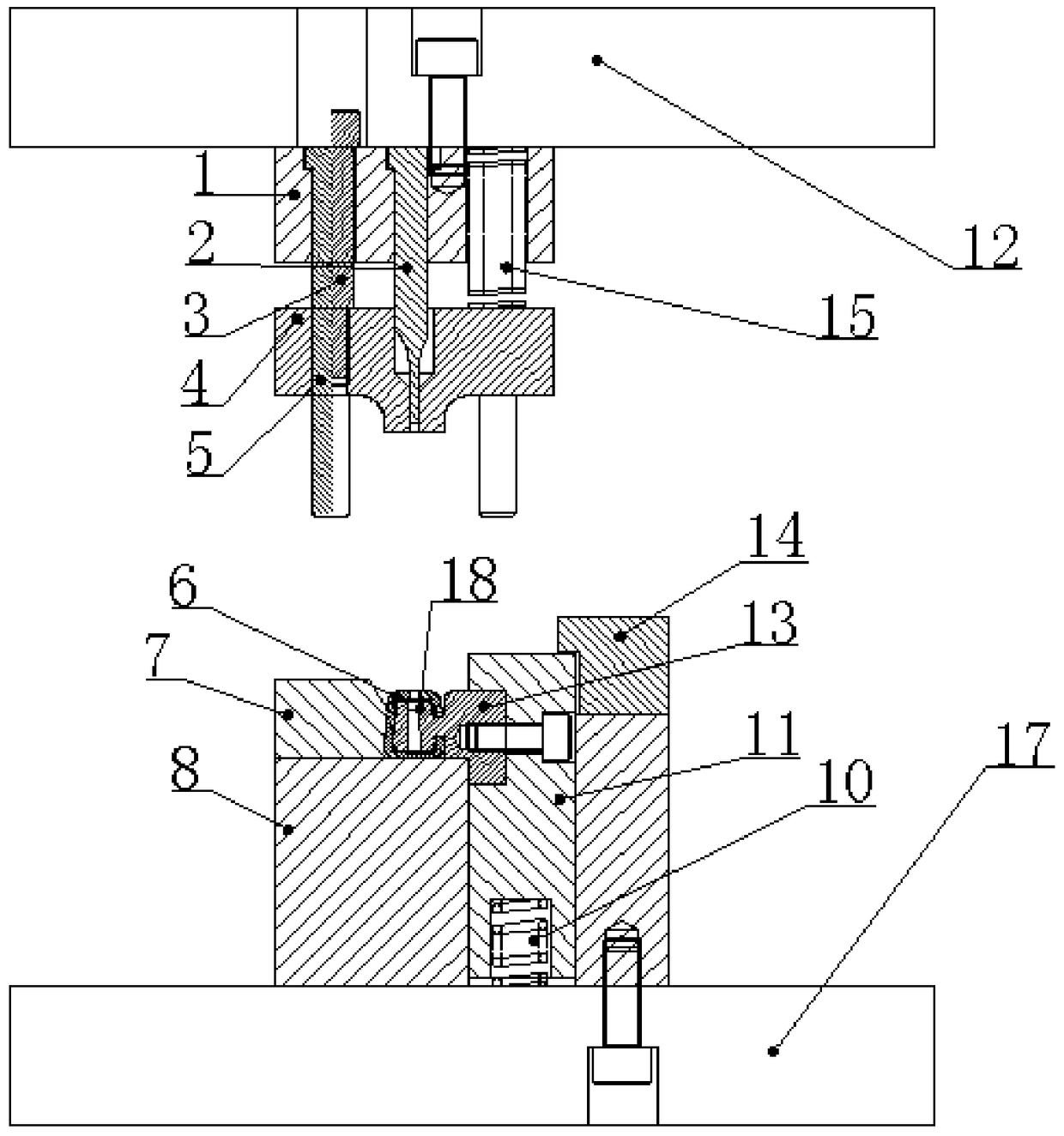

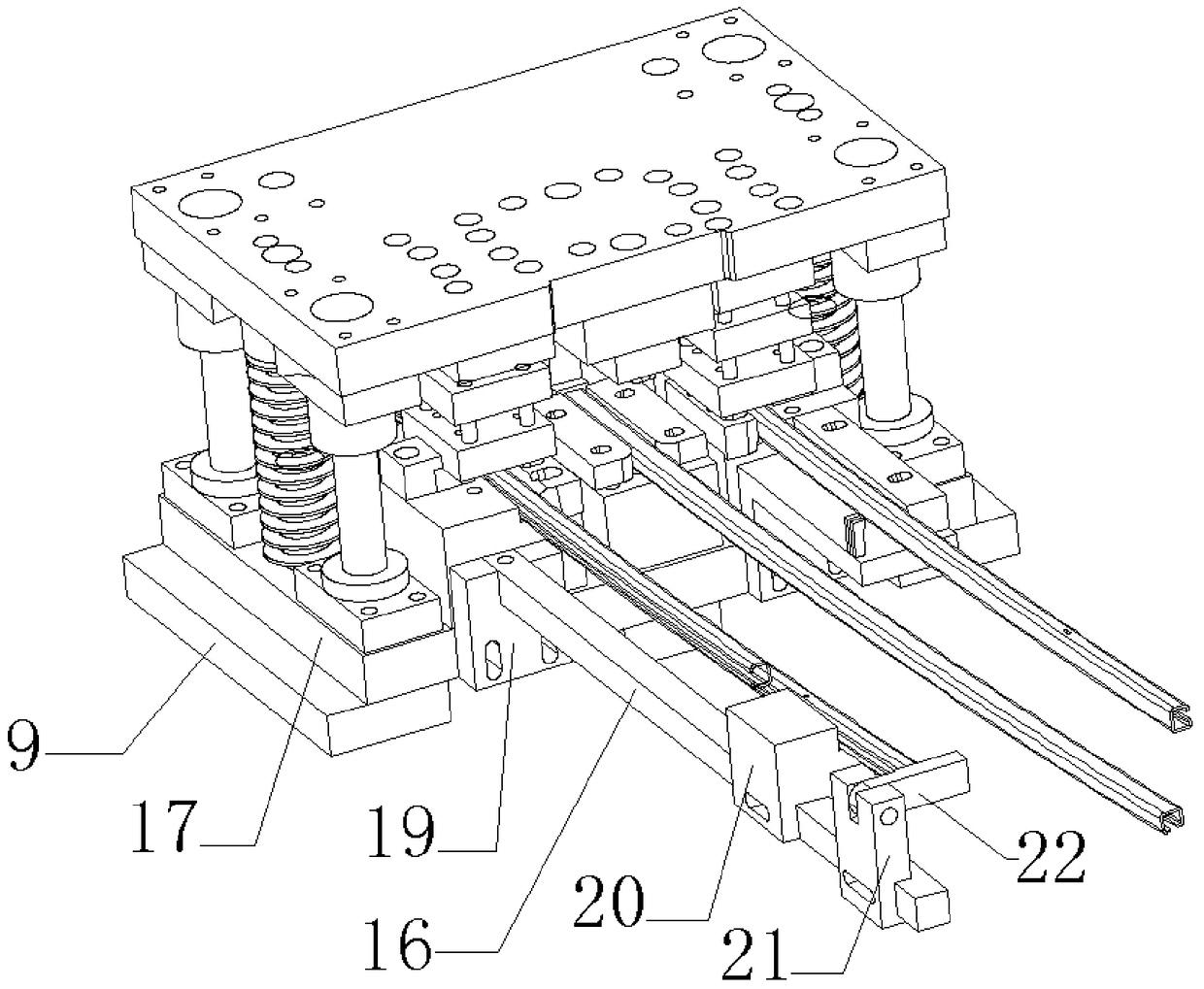

[0032] Place the mold on a 25T punch and rely on the up and down movement of the punch to achieve the up and down movement of the mold. First, the upper mold plate 12 and the fixed plate 1 are controlled to move upward by a punching machine. The discharge screw 3 slidably connected in the upper mold plate 12 drives the discharge plate 4 to move upward together. The discharge plate 4 and the die 13, the sliding block 11 and the side positioning The block 7 is separated, and the compressed round wire coil spring 10 pushes the slider 11 and the die 13 to move upward. After the upper end of the slider 11 bears against the horizontal part of the L-shaped limit block 14, it will move from the side of the die along the die 13 Insert the product 6 until the front end of the product 6 bears against the baffle 22, and then the punch controls the upper template 12 and the fixed plate 1 to move downwards. The discharge plate 4 contacts the concave die 13, and the flat wire coil spring 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com