Pressure relief system for pilot oil of oscillating cylinder hydraulic control valve

A technology of pilot oil and hydraulic control valve, applied in the field of hydraulic pressure, can solve problems such as pressure relief lag and affecting pumping efficiency, and achieve the effects of sufficient supply, difficult problems, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

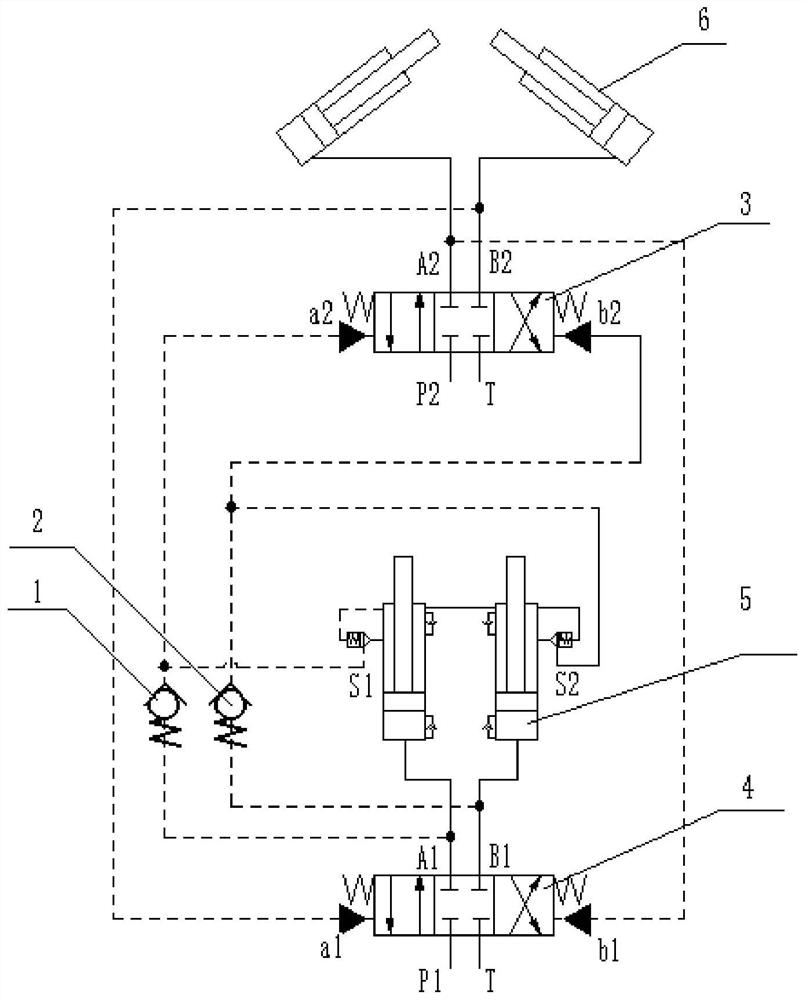

[0013] A pressure relief system for the pilot oil of a swing cylinder hydraulic control valve, which includes two swing cylinders 6, a swing cylinder hydraulic valve 3, two pumping cylinders 5 and a pumping cylinder hydraulic valve 4, two pumping cylinder hydraulic valves The oil outlets A1 and B1 are respectively connected with the oil inlets of the two pumping cylinders, and the oil returns of the two swing cylinders are respectively connected with the two oil return ports a1 and b1 of the hydraulic valves of the pumping cylinders through the oil return pipelines. The signal ports S1 and S2 of the pumping cylinder communicate with the two pilot oil ports a2 and b2 of the hydraulic valve of the swing cylinder respectively. A one-way valve 1, the inlet of the first one-way valve is connected to the pilot oil port a2 of the swing cylinder hydraulic valve and the signal port S1 of the pumping cylinder at the same time, the outlet is connected to the oil outlet A1 of the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com