A device and method for improving multi-effect concentration and evaporation capacity

A technology of evaporation capacity and multi-effect concentration, which is applied in the field of chemical equipment, can solve the problems that the concentration capacity of multi-effect concentration devices is difficult to improve, and achieve the effects of reducing complicated procedures, simple structure, and improving concentration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

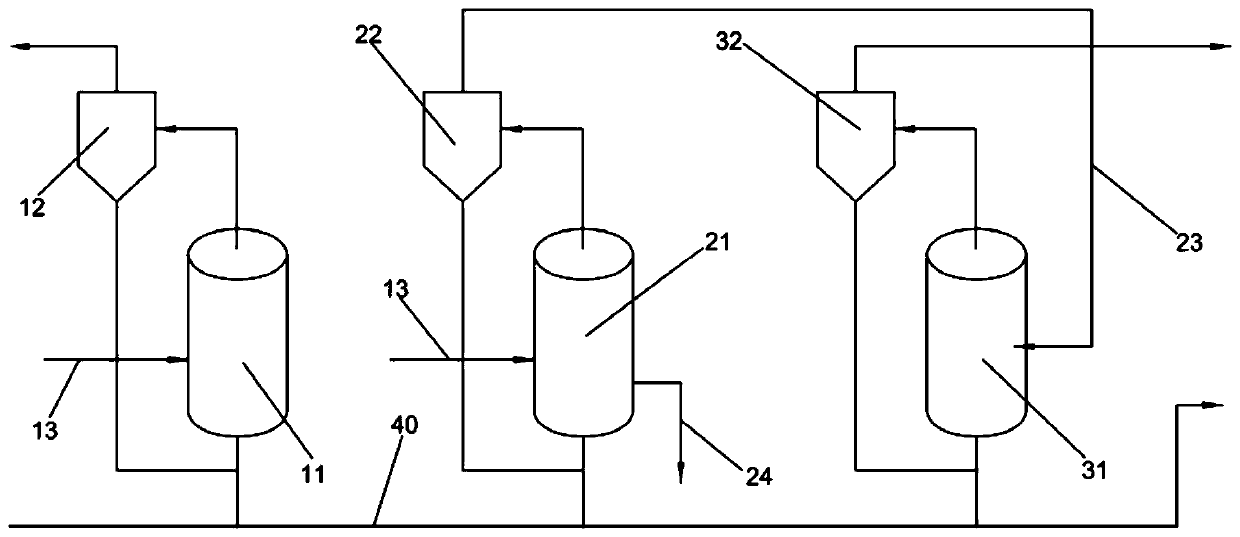

[0033] A device for improving the evaporation capacity of multi-effect concentration, such as figure 1 As shown, it includes a multi-effect heating and evaporating mechanism, and the multi-effect heating and evaporating mechanism mainly includes a first-effect heating and evaporating component, a second-effect heating and evaporating component and a three-effect evaporating component;

[0034] The one-effect heating evaporation assembly includes a first-effect heater 11 and a first-effect separation chamber 12, the second-effect heating evaporation assembly includes a second-effect heater 21 and a second-effect separation chamber 22, and the three-effect evaporation assembly includes a three-effect heating device 31 and three-effect separation chamber 32, the one-effect heater 11, the second-effect heater 21 and the three-effect heater 31 are sequentially connected in series through the downstream pipeline 40, and the one-effect separation chamber 12 is respectively connected w...

specific Embodiment approach

[0037] Specific embodiments: The multi-effect concentration device provided by the present invention mainly includes a multi-effect heating and evaporating mechanism. Taking a three-effect concentration device as an example, the multi-effect heating and evaporating mechanism includes a first-effect heating and evaporating component, a second-effect heating and evaporating component and Three-effect heating evaporation components; each set of heating evaporation components includes a heater and a separation chamber, where the main function of the heater is to heat and generate steam, and the main function of the separator is to separate gas and liquid to generate secondary steam;

[0038] Take the concentration of clear mother liquor (low-concentration liquid that needs to be concentrated) as an example. When concentrating the clear mother liquor, first put the clear mother liquor into the first-effect heater 11 from the feed tank, and send it to the first-effect heater through t...

Embodiment 2

[0043] A device for improving the multi-effect concentration and evaporation capacity. This device takes four effects as an example, and the low-concentration liquid that needs to be concentrated is the clear mother liquor;

[0044] The multi-effect concentration device provided by the present invention mainly includes a multi-effect heating and evaporating mechanism. Taking a four-effect concentration device as an example, the multi-effect heating and evaporating mechanism includes a first-effect heating and evaporating component, a second-effect heating and evaporating component, and a three-effect heating and evaporating component. Components and four-effect heating evaporator components; each set of heating evaporator components includes a heater and a separation chamber, where the main function of the heater is to heat and generate steam, and the main function of the separator is to separate gas, liquid and air to generate secondary steam;

[0045] The specific implementat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com