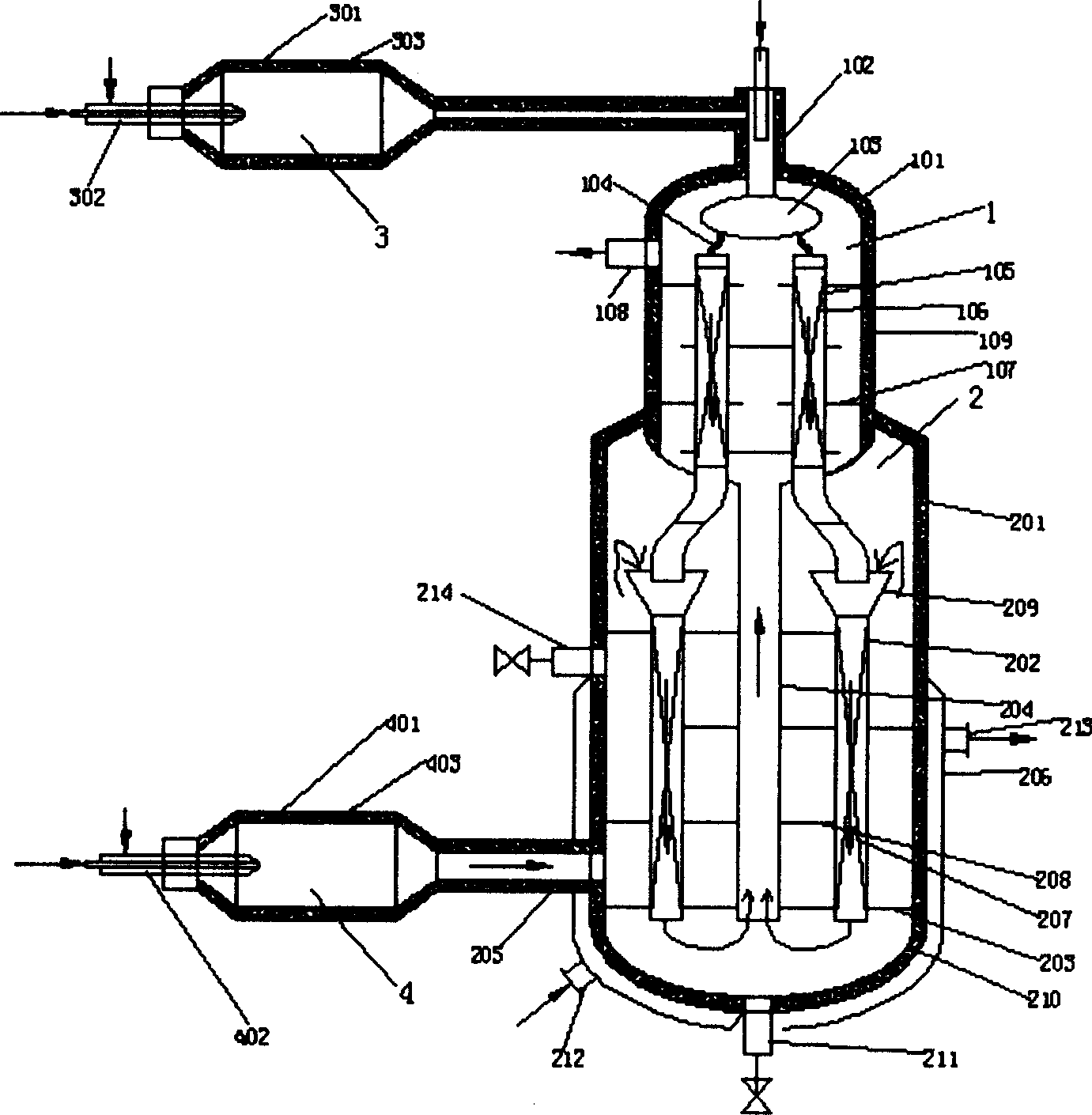

Hydrocarbon-converting synthetic gas producing apparatus and method

A hydrocarbon conversion and synthesis gas technology, which is applied in chemical instruments and methods, inorganic chemistry, chemical industry, etc., can solve the problems of high requirements for reaction device design and materials, high reaction temperature, and increased catalyst costs, so as to reduce energy consumption Consumption, uniform radial distribution, and the effect of reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] The mixture of 50kmol / h fuel methane desulfurized and preheated to 450-500°C, 90kmol / h oxygen and 360kmol / h water vapor preheated to 450-500°C respectively passes through the combustion nozzle of the upper external burner A combustion reaction takes place in the burner. The combustion reactants are mixed with 360 kmol / h desulfurized raw material methane through the mixer of the upper reformer, and then enter the raw gas collector, where the temperature of the mixed gas reaches 900-1000°C, and then are evenly distributed to the reformer through pigtail pipes. Catalytic conversion reaction of hydrocarbons takes place in the reaction tube.

[0057] The mixture of 100kmol / h fuel methane desulfurized and preheated to 450-500°C, 180kmol / h oxygen and 500kmol / h water vapor preheated to 450-500°C respectively passes through the combustion nozzle of the lower external burner The combustion reaction occurs in the burner, and then enters the bottom of the lower reformer through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com