Method for recycling surplus sludge hydrothermal carbonization solution

A technology of hydrothermal carbonization and excess sludge, applied in chemical instruments and methods, water/sludge/sewage treatment, pyrolysis treatment of sludge, etc., can solve the problems of low resource utilization efficiency of the liquid phase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

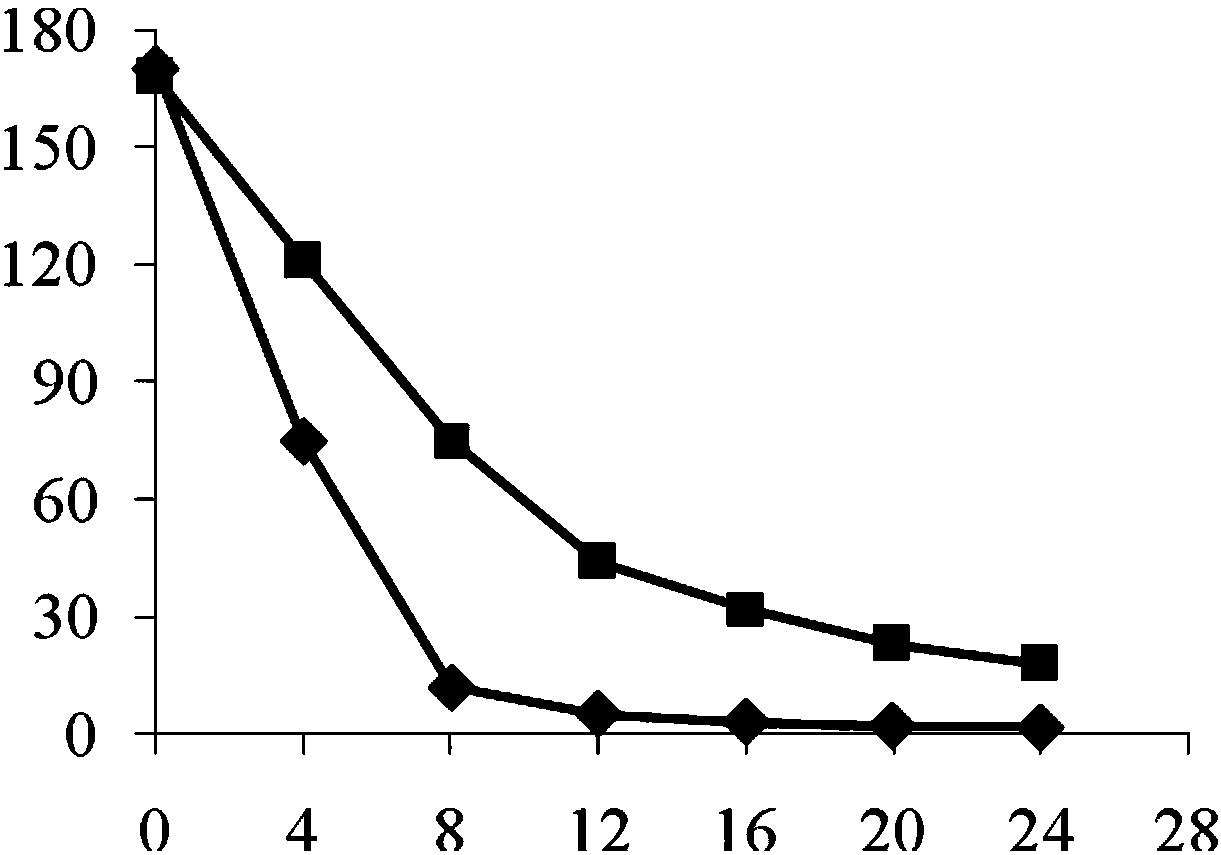

Image

Examples

Embodiment 1

[0023] (1) Hydrothermal carbonization of excess sludge

[0024] Take the remaining sludge from the urban sewage treatment plant, adjust the concentration of the remaining sludge to 100g / L, control the temperature of the hydrothermal carbonization reactor to 240°C, and the reaction time to 3h to obtain the hydrothermal carbonization product of the sludge; After the thermal carbonization product undergoes solid-liquid separation, the hydrothermal charcoal is recovered, and the liquid phase is collected as the water phase of the next hydrothermal carbonization cycle; the liquid phase after 10 hydrothermal carbonization cycles is the hydrothermal carbonization liquid;

[0025] (2) Struvite method to recover nitrogen and phosphorus in hydrothermal carbonization liquid

[0026] Mg in the hydrothermal carbonization liquid that adjustment step (1) obtains 2+ , NH 4 + 、PO 4 3- The molar ratio is 1:1:1, the pH value is controlled at 9, and the reaction time is 30 minutes. After sol...

Embodiment 2

[0030] (1) Hydrothermal carbonization of excess sludge

[0031] Take the remaining sludge from the urban sewage treatment plant, adjust the concentration of the remaining sludge to 100g / L, control the temperature of the hydrothermal carbonization reactor to 260°C, and the reaction time to 2h to obtain the hydrothermal carbonization product of the sludge; After the thermal carbonization product undergoes solid-liquid separation, the hydrothermal charcoal is recovered, and the liquid phase is collected as the water phase of the next hydrothermal carbonization cycle; the liquid phase after 8 hydrothermal carbonization cycles is the hydrothermal carbonization liquid;

[0032] (2) Struvite method to recover nitrogen and phosphorus in hydrothermal carbonization liquid

[0033] Mg in the hydrothermal carbonization liquid that adjustment step (1) obtains 2+ , NH 4 + 、PO 4 3- The molar ratio is 1:1:1, the pH value is controlled at 9.5, and the reaction time is 30 minutes. After so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com